electronic tool setter, tool touch off process

- swalts

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 4

18 Jan 2021 13:33 #195783

by swalts

electronic tool setter, tool touch off process was created by swalts

Thank you for reading this.

I am looking for the tool touch off process for QtPyVCP / ProbeBasic.

I have an electronic tool setter. I do not use an automatic tool changer. I have R8 collet system.

I use the probe routine for finding work piece offsets. No problems there.

The problem comes when i touch off the tool to the tool height sensor.

Current process:

load tool #

button press to "touch off current tool".

The result is the tool is driving down into the material.

I have read that I need to touch off the nose of the spindle to the height sensor, but there is no place to store that information (that i am aware of).

Can anyone tell me their tool touch off process that uses an electronic tool setter? Any information on the subject would be very helpful.

Thank you for your time.

Respectfully.

I am looking for the tool touch off process for QtPyVCP / ProbeBasic.

I have an electronic tool setter. I do not use an automatic tool changer. I have R8 collet system.

I use the probe routine for finding work piece offsets. No problems there.

The problem comes when i touch off the tool to the tool height sensor.

Current process:

load tool #

button press to "touch off current tool".

The result is the tool is driving down into the material.

I have read that I need to touch off the nose of the spindle to the height sensor, but there is no place to store that information (that i am aware of).

Can anyone tell me their tool touch off process that uses an electronic tool setter? Any information on the subject would be very helpful.

Thank you for your time.

Respectfully.

The following user(s) said Thank You: Lcvette

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1577

- Thank you received: 740

18 Jan 2021 13:38 #195785

by Lcvette

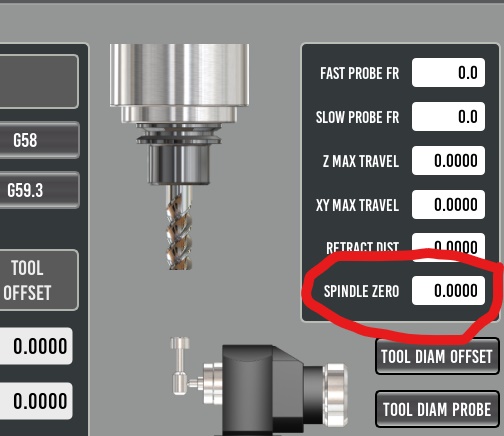

the spindle nose height is stored on the tool touch off page.

Replied by Lcvette on topic electronic tool setter, tool touch off process

Thank you for reading this.

I am looking for the tool touch off process for QtPyVCP / ProbeBasic.

I have an electronic tool setter. I do not use an automatic tool changer. I have R8 collet system.

I use the probe routine for finding work piece offsets. No problems there.

The problem comes when i touch off the tool to the tool height sensor.

Current process:

load tool #

button press to "touch off current tool".

The result is the tool is driving down into the material.

I have read that I need to touch off the nose of the spindle to the height sensor, but there is no place to store that information (that i am aware of).

Can anyone tell me their tool touch off process that uses an electronic tool setter? Any information on the subject would be very helpful.

Thank you for your time.

Respectfully.

the spindle nose height is stored on the tool touch off page.

Please Log in or Create an account to join the conversation.

- swalts

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 4

18 Jan 2021 13:42 #195786

by swalts

Replied by swalts on topic electronic tool setter, tool touch off process

great!

What tool number to call it? I tried calling it tool zero. but that does not get stored in the table.

What tool number to call it? I tried calling it tool zero. but that does not get stored in the table.

Please Log in or Create an account to join the conversation.

- swalts

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 4

18 Jan 2021 13:44 #195788

by swalts

Replied by swalts on topic electronic tool setter, tool touch off process

Also would you share your touch off process?

Thanks for helping me out.

Thanks for helping me out.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1577

- Thank you received: 740

18 Jan 2021 13:47 #195789

by Lcvette

Spindle Zero is where the spindle nose height is recorded in machine coordinates, the subroutine uses this measurement to track all of the tool lengths against the recorded spindle touch off height.

Replied by Lcvette on topic electronic tool setter, tool touch off process

great!

What tool number to call it? I tried calling it tool zero. but that does not get stored in the table.

Spindle Zero is where the spindle nose height is recorded in machine coordinates, the subroutine uses this measurement to track all of the tool lengths against the recorded spindle touch off height.

Attachments:

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1577

- Thank you received: 740

18 Jan 2021 13:50 #195790

by Lcvette

Replied by Lcvette on topic electronic tool setter, tool touch off process

all of these boxes must be filled in for touch off to have its user inputs defined and function properly

Please Log in or Create an account to join the conversation.

- swalts

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 4

18 Jan 2021 13:54 - 18 Jan 2021 13:56 #195791

by swalts

Replied by swalts on topic electronic tool setter, tool touch off process

oh Dang!

Will this populate automatically when the sensor triggers?

Will the process look like this.

1. Load tool zero

2. touch off tool (spindle nose)

3. spindle zero (circled above) is now populated

Thanks for the picture. making the jump from Mach to Linuxcnc has been a humbling adventure.

I really appreciate all the help.

Will this populate automatically when the sensor triggers?

Will the process look like this.

1. Load tool zero

2. touch off tool (spindle nose)

3. spindle zero (circled above) is now populated

Thanks for the picture. making the jump from Mach to Linuxcnc has been a humbling adventure.

I really appreciate all the help.

Last edit: 18 Jan 2021 13:56 by swalts.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1577

- Thank you received: 740

18 Jan 2021 14:04 #195792

by Lcvette

Replied by Lcvette on topic electronic tool setter, tool touch off process

no, you need to manually enter the spindle zero, record the number as positive, ie if the dro reads -12.375" record spindle zero height as 12.375. then it should work as intended!

Please Log in or Create an account to join the conversation.

- swalts

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 4

18 Jan 2021 14:08 #195793

by swalts

Replied by swalts on topic electronic tool setter, tool touch off process

this may be an elementary question, but.

How will i know when the tool setter has tripped? It has no external indicator on it. If i use hal show, then i will not be able to move the axis.

Not sure what i am missing.

How will i know when the tool setter has tripped? It has no external indicator on it. If i use hal show, then i will not be able to move the axis.

Not sure what i am missing.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1577

- Thank you received: 740

18 Jan 2021 14:11 #195794

by Lcvette

Replied by Lcvette on topic electronic tool setter, tool touch off process

you can use the probing process for z, it records a probed point. just change the probe number in the probe setting to your spindle nose tool number and probe z and record the value that the probe event gives you.

Please Log in or Create an account to join the conversation.

Moderators: KCJ, Lcvette

Time to create page: 0.277 seconds