Probe Basic Lathe Status

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

10 Sep 2021 21:42 #220173

by anfänger

Replied by anfänger on topic Probe Basic Lathe Status

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

11 Sep 2021 03:50 #220189

by spumco

I'm not a 'lathe' expert, but having run my Fanuc live-tool XZC turret lathe for a year or so now I thought might add something about lathe tools...

In some cases, you can have multiple tools on a single turret station. This is more common on larger, newer lathes but its not that rare to set up a couple tools on a single holder for other lathes. Imagine having a tool holder (VDI, BMT, Capto, HSK, etc.) with a spot drill, tap drill, and tap all on the same block. Makes for very quick cycle times - much like a gang tool lathe - as well as freeing up an otherwise used turret station.

Controls are different, but on my somewhat elderly Fanuc 21TB there are 12 tool stations. However, there are 16 'slots' on the tool data page. Slots #13-#16 are used (by me) to offset a tool or have multiple tools in the turret station.

Example 1: T0101 calls turret slot #1, offset #1. If I have an end mill (or multifunction tool) and want to drill with it I want the tool center to be at X0. If I want to use the tool as a boring tool, then the control point is now the cutting corner/edge and I need to offset the tool 1/2 the diameter. In that case I would program T0113, with slot #13 being the first 'unused' offset in the table. The control point is now based on the different offset.

You could, of course, hand code all of this with a single offset, but for a CAM program it's simple. F360 permits posting tools with an offset different from the turret station for that reason.

Example 2: Similar situation as above, where you have a single tool holder with a drill and tap next to each other. T0101 is the drill, and T0113 (or whatever open offset slot you chose) is the tap. The program drills, then a "tool change" applies the new offset and the tap operation is done.

Obiously, it's not just an X offset, but Z offset as well. And Y-axis lathes are even more likely to have multiple tools in a single block.

How this multi-tool or single-tool, multi-offset is used dependent on the lathe control, but the above is how it works on my Fanuc. Regarding LCNC generally, and Probe Basic Lathe specifically, there may an opportunity to account for the above use cases. I find it cumbersome to remember which offset to use for different tools (or control points) in the turret, and like just about everything on a turret lathe can be a 'pucker moment' when you are proving out a program. Did I use the right offset?

Having a lathe tool table function like a mill ATC table with tool numbers connected to turret positions would require a change in thought process for 'lathe people' used to gang-tool or older controls (like mine). And post processors would have to change, of course, but I think having a single tool number which represents all the data - turret position, X/Y/Z offset, nose radius, wear, tip orientation, description - might be helpful in the long run.

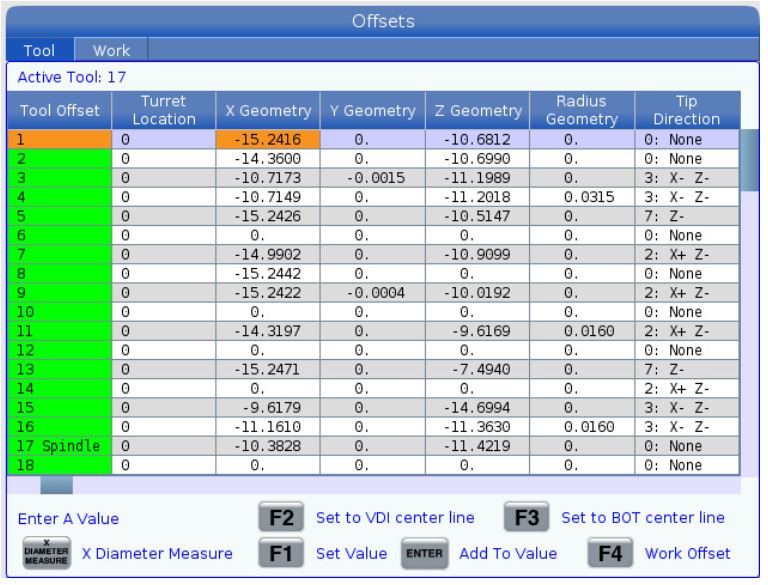

I'll end with a screenshot of the Haas lathe tool table. No description field, but you just call "T1" and all the data for that tool is applied. No remembering different offsets for each station.

Just food for thought...

-Ralph

Replied by spumco on topic Probe Basic Lathe Status

LinuxCNC total beginner here, but I've been following the Probe Basic development for a while - frankly this screenset is what convinced me to (try) and switch over to LCNC. Thank you for all the effort, by the way. I'll preface this by stating that I can't find a screenshot of Probe Basic lathe tool table, and my LCNC computer is down while I rebuild my mill - can't even run a sim at the moment.I considered making a turret graphic for PB Lathe, but because of the nature of how that worked i felt it may be unnecessary.. typically for lathe the tools are always 1,2,3,4,5,6,7,8,9,etc regardless of which tool is being used unlike mill where pocket 1 may contain tool 397 or whatever number. with lathe the tool number is the turret position number. so it would seem to not make as much sense as there will only always be 12 tools for a 12 tool turret and their tool numbers will always be 1-12. does that make sense?

I'm not a 'lathe' expert, but having run my Fanuc live-tool XZC turret lathe for a year or so now I thought might add something about lathe tools...

In some cases, you can have multiple tools on a single turret station. This is more common on larger, newer lathes but its not that rare to set up a couple tools on a single holder for other lathes. Imagine having a tool holder (VDI, BMT, Capto, HSK, etc.) with a spot drill, tap drill, and tap all on the same block. Makes for very quick cycle times - much like a gang tool lathe - as well as freeing up an otherwise used turret station.

Controls are different, but on my somewhat elderly Fanuc 21TB there are 12 tool stations. However, there are 16 'slots' on the tool data page. Slots #13-#16 are used (by me) to offset a tool or have multiple tools in the turret station.

Example 1: T0101 calls turret slot #1, offset #1. If I have an end mill (or multifunction tool) and want to drill with it I want the tool center to be at X0. If I want to use the tool as a boring tool, then the control point is now the cutting corner/edge and I need to offset the tool 1/2 the diameter. In that case I would program T0113, with slot #13 being the first 'unused' offset in the table. The control point is now based on the different offset.

You could, of course, hand code all of this with a single offset, but for a CAM program it's simple. F360 permits posting tools with an offset different from the turret station for that reason.

Example 2: Similar situation as above, where you have a single tool holder with a drill and tap next to each other. T0101 is the drill, and T0113 (or whatever open offset slot you chose) is the tap. The program drills, then a "tool change" applies the new offset and the tap operation is done.

Obiously, it's not just an X offset, but Z offset as well. And Y-axis lathes are even more likely to have multiple tools in a single block.

How this multi-tool or single-tool, multi-offset is used dependent on the lathe control, but the above is how it works on my Fanuc. Regarding LCNC generally, and Probe Basic Lathe specifically, there may an opportunity to account for the above use cases. I find it cumbersome to remember which offset to use for different tools (or control points) in the turret, and like just about everything on a turret lathe can be a 'pucker moment' when you are proving out a program. Did I use the right offset?

Having a lathe tool table function like a mill ATC table with tool numbers connected to turret positions would require a change in thought process for 'lathe people' used to gang-tool or older controls (like mine). And post processors would have to change, of course, but I think having a single tool number which represents all the data - turret position, X/Y/Z offset, nose radius, wear, tip orientation, description - might be helpful in the long run.

I'll end with a screenshot of the Haas lathe tool table. No description field, but you just call "T1" and all the data for that tool is applied. No remembering different offsets for each station.

Just food for thought...

-Ralph

Attachments:

The following user(s) said Thank You: harindugamlath

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Away

- Moderator

-

Less

More

- Posts: 1582

- Thank you received: 741

11 Sep 2021 04:09 #220192

by Lcvette

Replied by Lcvette on topic Probe Basic Lathe Status

Correct, i also have 21T with multi center tool slot tool blocks. They are all still called by a turret position number which is my reasoning. In other words, T1 will always be turret position 1. You can have multiple offsets for that turret position, but it's still going to be the same turret position.

With mill, you can have carousel pocket, unique to number, unique tool offset. This made it nice to have a graphic showing what tools were currently loaded in the carousel. For help in knowing what to to call to change our etc..i just don't see that being mytv of an issue with lathe.

I'm not against it, i just don't see how it's useful. I'm not above saying i could be wrong, wouldn't be the first time..lol.

With mill, you can have carousel pocket, unique to number, unique tool offset. This made it nice to have a graphic showing what tools were currently loaded in the carousel. For help in knowing what to to call to change our etc..i just don't see that being mytv of an issue with lathe.

I'm not against it, i just don't see how it's useful. I'm not above saying i could be wrong, wouldn't be the first time..lol.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

11 Sep 2021 05:18 #220193

by spumco

Replied by spumco on topic Probe Basic Lathe Status

I'm frequently wrong, and this could certainly be one of those times.

Yes, we're in agreement - turret slot #1 is always tool #1... on an older control.

My thought was to get away from the (old) Fanuc model - which I can't stand. It just seem so ripe for disaster.

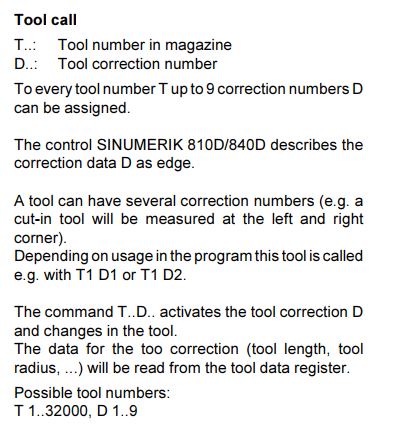

Consider the Siemens 840D tool table. There are tool numbers availble for each slot, but there are also "D" numbers. These are separate offsets associated with each turret position. You can have up to 9 D-numbers for each slot, and there's no need to remember "did I assign offset #13 to the #1 tool secondary position, or #14?" No random offset number needed to shift a turret position.

So a 3-tool gang block would be:

T1D1(spot drill)

T1D2(drill)

T1D3(tap)

It's different than the Haas setup (one number for all data), and I think I like it better.

BTW, what's your 21 control on? Mine's on an older Emco 325-II.

Siemens tool table function:

Yes, we're in agreement - turret slot #1 is always tool #1... on an older control.

My thought was to get away from the (old) Fanuc model - which I can't stand. It just seem so ripe for disaster.

Consider the Siemens 840D tool table. There are tool numbers availble for each slot, but there are also "D" numbers. These are separate offsets associated with each turret position. You can have up to 9 D-numbers for each slot, and there's no need to remember "did I assign offset #13 to the #1 tool secondary position, or #14?" No random offset number needed to shift a turret position.

So a 3-tool gang block would be:

T1D1(spot drill)

T1D2(drill)

T1D3(tap)

It's different than the Haas setup (one number for all data), and I think I like it better.

BTW, what's your 21 control on? Mine's on an older Emco 325-II.

Siemens tool table function:

Attachments:

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Away

- Moderator

-

Less

More

- Posts: 1582

- Thank you received: 741

11 Sep 2021 05:36 #220194

by Lcvette

Replied by Lcvette on topic Probe Basic Lathe Status

Hardinge Cobra 42...

whatever lcnc had is what probe basic works with, so not sure if it can do what your saying and if not, the gui can't add that functionality as is just accessing lcnc.

whatever lcnc had is what probe basic works with, so not sure if it can do what your saying and if not, the gui can't add that functionality as is just accessing lcnc.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

11 Sep 2021 05:42 #220195

by spumco

Replied by spumco on topic Probe Basic Lathe Status

See? We've very quickly reached my ignorance threshold on Lcnc. I've never run an lathe under Lcnc, so I don't know what's possible and what's a pipe dream.

Thanks for the discussion, and I'll be revisiting PB Lathe when I pick up an old HSL or DV-59 to turn in to a gang tool monster.

-R

Thanks for the discussion, and I'll be revisiting PB Lathe when I pick up an old HSL or DV-59 to turn in to a gang tool monster.

-R

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

11 Sep 2021 08:21 - 11 Sep 2021 12:03 #220202

by anfänger

Replied by anfänger on topic Probe Basic Lathe Status

Last edit: 11 Sep 2021 12:03 by anfänger.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Away

- Moderator

-

Less

More

- Posts: 1582

- Thank you received: 741

11 Sep 2021 12:35 #220218

by Lcvette

Replied by Lcvette on topic Probe Basic Lathe Status

Yes, you must compile , I think it is (qcompile .) But this should be on the tutorial pages somewhere

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

11 Sep 2021 15:55 #220227

by robertspark

Replied by robertspark on topic Probe Basic Lathe Status

don't forget the "." dot..... I thought it was a bit of crud / dust on my screen until I realised those dots are important....

Step #6

kcjengr.github.io/probe_basic/dev_install.html

Step #6

kcjengr.github.io/probe_basic/dev_install.html

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

11 Sep 2021 16:39 #220233

by anfänger

Replied by anfänger on topic Probe Basic Lathe Status

i know, i am really bad at documenting and its a while since i wrote my own scrits.

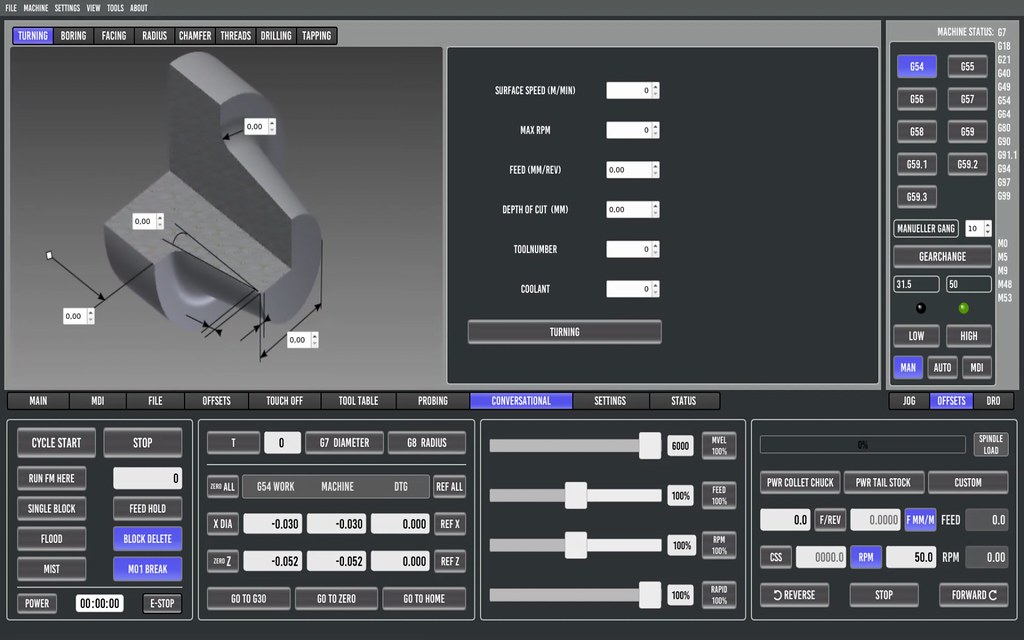

how do i access the vales of the widgets. I know it can be done I've done it on my mill, but its running right now.

I tried:

#<turning_ss> = #1

#<turning_maxrpm> = #2

#<turning_feed> = #3

#<turning_doc> = #4

#<turning_tool> = #5

#<turning_coolant> = #6

#<turning_radius> = #7

#<turning_angle> = #8

#<turning_x> = #9

#<turning_z> = #10

M108 P#<turning_ss> Q#<turning_maxrpm>

but it doesn't work turning_ss is the object name

how do i access the vales of the widgets. I know it can be done I've done it on my mill, but its running right now.

I tried:

#<turning_ss> = #1

#<turning_maxrpm> = #2

#<turning_feed> = #3

#<turning_doc> = #4

#<turning_tool> = #5

#<turning_coolant> = #6

#<turning_radius> = #7

#<turning_angle> = #8

#<turning_x> = #9

#<turning_z> = #10

M108 P#<turning_ss> Q#<turning_maxrpm>

but it doesn't work turning_ss is the object name

Please Log in or Create an account to join the conversation.

Moderators: KCJ, Lcvette

Time to create page: 0.169 seconds