Probe Basic Lathe Status

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

12 Sep 2021 12:16 #220297

by anfänger

Replied by anfänger on topic Probe Basic Lathe Status

sometimes its the simple problem.

don't ta to make the gcode look nice. Using Tabs was a problem. second problem is a , . issue which I am fixing right now

don't ta to make the gcode look nice. Using Tabs was a problem. second problem is a , . issue which I am fixing right now

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

12 Sep 2021 14:31 #220316

by anfänger

Replied by anfänger on topic Probe Basic Lathe Status

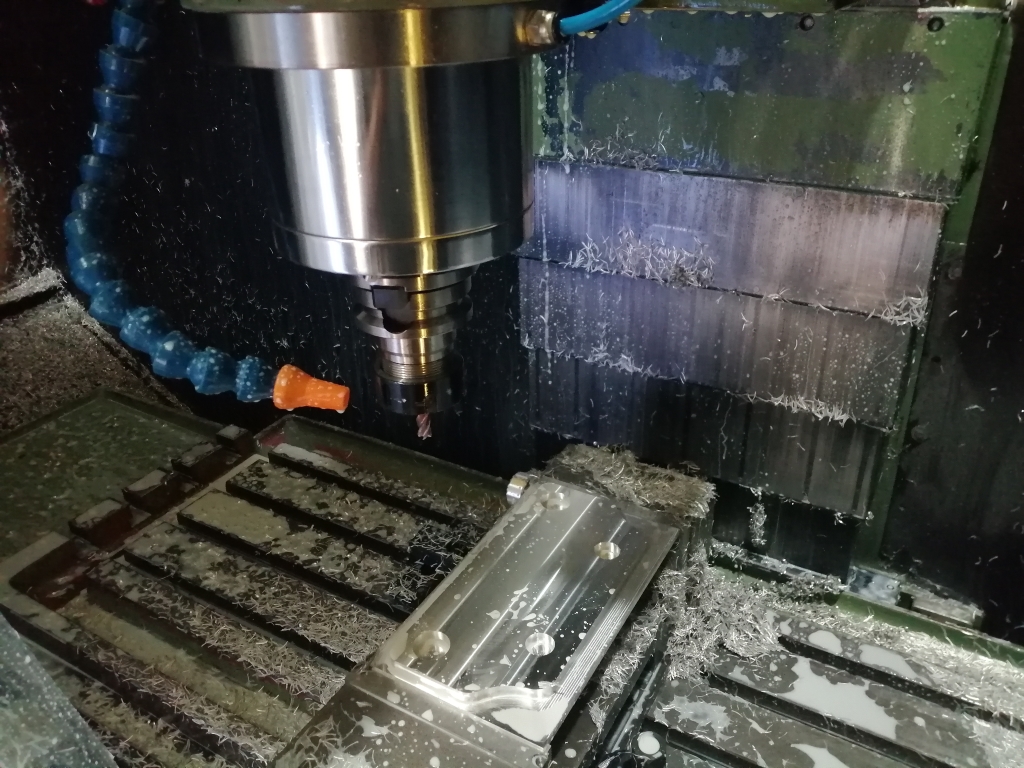

First ones are running…

Dry test:

Mishap:

And actually cutting:

Thanks all of you for your help.

The scripts are easy to share. How can I share the changes to the ui easily?

Cheers Patrick

Dry test:

Mishap:

And actually cutting:

Thanks all of you for your help.

The scripts are easy to share. How can I share the changes to the ui easily?

Cheers Patrick

The following user(s) said Thank You: tommylight, Lcvette, harindugamlath

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

12 Sep 2021 17:02 #220341

by robertspark

Replied by robertspark on topic Probe Basic Lathe Status

interested to see how you have done this or integrated it

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1556

- Thank you received: 730

13 Sep 2021 00:59 #220386

by Lcvette

Replied by Lcvette on topic Probe Basic Lathe Status

Patrick, that looks fantastic!

You can submit a pull request and i can merge into probe basic master! Thank you very much for such an excellent contribution! I can't wait to merge and check it out firsthand in sim!

Thanks again!

Chris

You can submit a pull request and i can merge into probe basic master! Thank you very much for such an excellent contribution! I can't wait to merge and check it out firsthand in sim!

Thanks again!

Chris

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

13 Sep 2021 05:19 #220395

by anfänger

Replied by anfänger on topic Probe Basic Lathe Status

I’ve hardly done anything, the scripts and images are done by Andy and alkabal, I just added the gui. Since I changed a lot in the ui let me checkout a new master and see if I can merge it.

When I am done I’ll come back and ask how I can do that pull request

When I am done I’ll come back and ask how I can do that pull request

The following user(s) said Thank You: Clive S, Lcvette, harindugamlath

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

13 Sep 2021 20:59 #220504

by robertspark

Replied by robertspark on topic Probe Basic Lathe Status

I know the scripts and images but I'm curious to know how you passed the variables to the parameters.... I presume that there is a python script that runs when you press a button to load the script.

Please Log in or Create an account to join the conversation.

- harindugamlath

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 18

14 Sep 2021 15:22 #220609

by harindugamlath

Replied by harindugamlath on topic Probe Basic Lathe Status

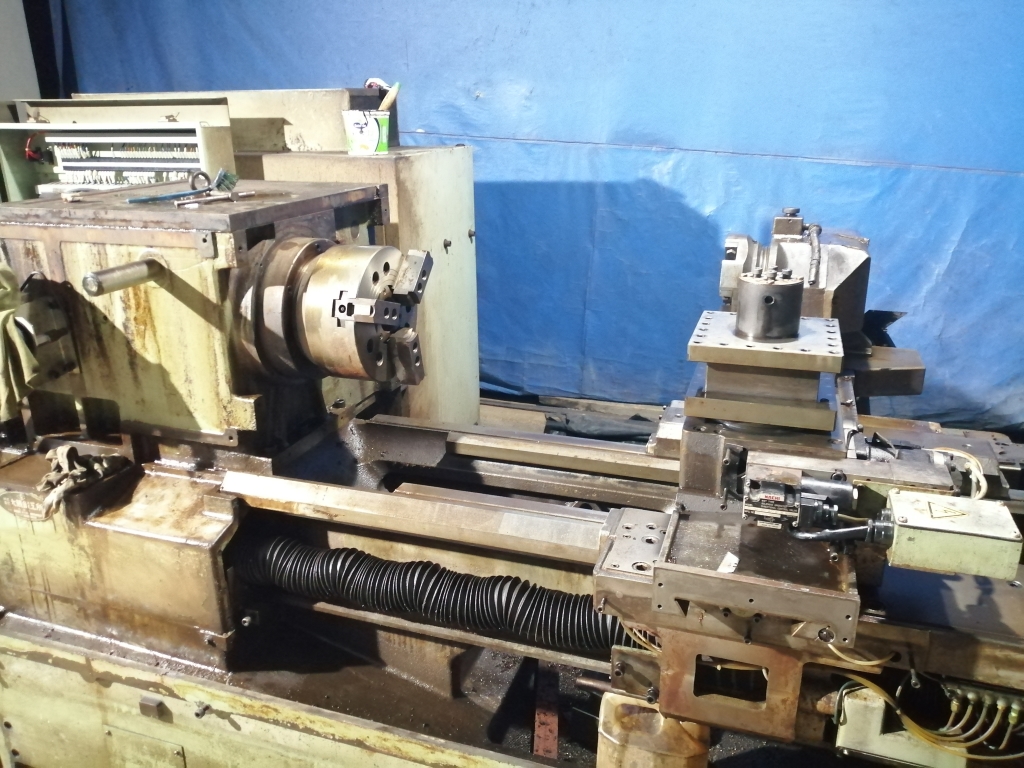

PatrickAwesome work! Saw your video on youtube and I'm now working on my lathe.I will definitely give a hand on Pb development.Super awesome to see probe basic getting more people.this is my old lathe. Taking things apart and cleaning at the moment. Okuma LS-30N dual turret. I guess I'll be making a new tool turret image for this.

Attachments:

Please Log in or Create an account to join the conversation.

- harindugamlath

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 18

14 Sep 2021 15:45 #220618

by harindugamlath

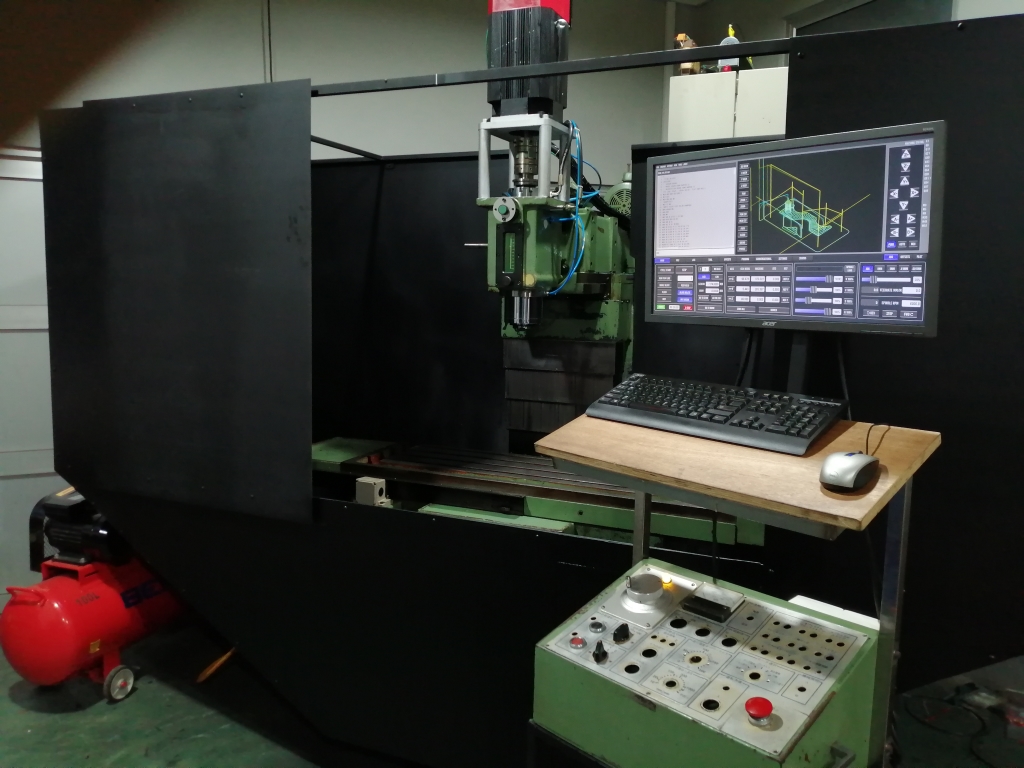

Thanks everyone for posting. really appreciate it

Here's my Mill running PB. Anotheold Okuma. Like you said it was PB that made me jump on linuxcnc. Let's keep the good work.

Mill Looks totally different now. I've also added axis load meters(not properly connected yet, but functional)

Replied by harindugamlath on topic Probe Basic Lathe Status

I Second this. I too keep a tool table for all of my tooling for the mill with PB in a similar fashion. And hope to do the same with the lathe. If you have a quick change holder its really nice. I'll dig deep into this when i get a PC soon for the lathe.

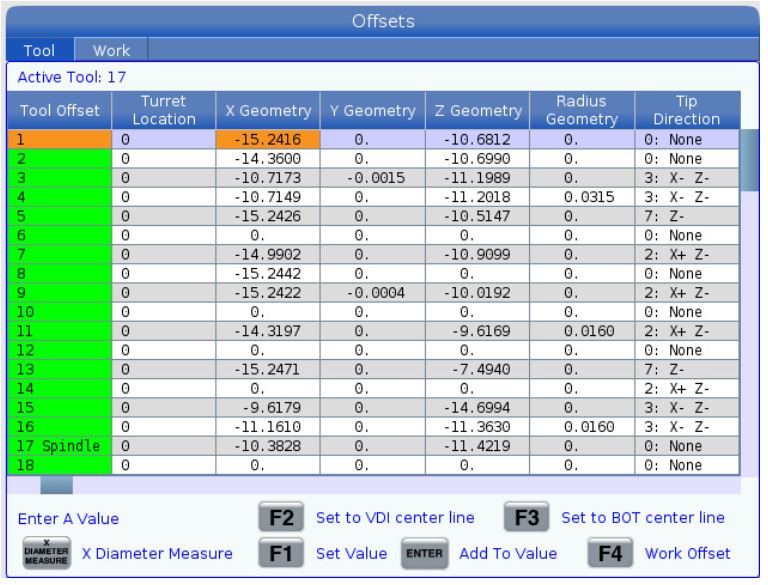

I considered making a turret graphic for PB Lathe, but because of the nature of how that worked i felt it may be unnecessary.. typically for lathe the tools are always 1,2,3,4,5,6,7,8,9,etc regardless of which tool is being used unlike mill where pocket 1 may contain tool 397 or whatever number. with lathe the tool number is the turret position number. so it would seem to not make as much sense as there will only always be 12 tools for a 12 tool turret and their tool numbers will always be 1-12. does that make sense?

LinuxCNC total beginner here, but I've been following the Probe Basic development for a while - frankly this screenset is what convinced me to (try) and switch over to LCNC. Thank you for all the effort, by the way. I'll preface this by stating that I can't find a screenshot of Probe Basic lathe tool table, and my LCNC computer is down while I rebuild my mill - can't even run a sim at the moment.

I'm not a 'lathe' expert, but having run my Fanuc live-tool XZC turret lathe for a year or so now I thought might add something about lathe tools...

In some cases, you can have multiple tools on a single turret station. This is more common on larger, newer lathes but its not that rare to set up a couple tools on a single holder for other lathes. Imagine having a tool holder (VDI, BMT, Capto, HSK, etc.) with a spot drill, tap drill, and tap all on the same block. Makes for very quick cycle times - much like a gang tool lathe - as well as freeing up an otherwise used turret station.

Controls are different, but on my somewhat elderly Fanuc 21TB there are 12 tool stations. However, there are 16 'slots' on the tool data page. Slots #13-#16 are used (by me) to offset a tool or have multiple tools in the turret station.

Example 1: T0101 calls turret slot #1, offset #1. If I have an end mill (or multifunction tool) and want to drill with it I want the tool center to be at X0. If I want to use the tool as a boring tool, then the control point is now the cutting corner/edge and I need to offset the tool 1/2 the diameter. In that case I would program T0113, with slot #13 being the first 'unused' offset in the table. The control point is now based on the different offset.

You could, of course, hand code all of this with a single offset, but for a CAM program it's simple. F360 permits posting tools with an offset different from the turret station for that reason.

Example 2: Similar situation as above, where you have a single tool holder with a drill and tap next to each other. T0101 is the drill, and T0113 (or whatever open offset slot you chose) is the tap. The program drills, then a "tool change" applies the new offset and the tap operation is done.

Obiously, it's not just an X offset, but Z offset as well. And Y-axis lathes are even more likely to have multiple tools in a single block.

How this multi-tool or single-tool, multi-offset is used dependent on the lathe control, but the above is how it works on my Fanuc. Regarding LCNC generally, and Probe Basic Lathe specifically, there may an opportunity to account for the above use cases. I find it cumbersome to remember which offset to use for different tools (or control points) in the turret, and like just about everything on a turret lathe can be a 'pucker moment' when you are proving out a program. Did I use the right offset?

Having a lathe tool table function like a mill ATC table with tool numbers connected to turret positions would require a change in thought process for 'lathe people' used to gang-tool or older controls (like mine). And post processors would have to change, of course, but I think having a single tool number which represents all the data - turret position, X/Y/Z offset, nose radius, wear, tip orientation, description - might be helpful in the long run.

I'll end with a screenshot of the Haas lathe tool table. No description field, but you just call "T1" and all the data for that tool is applied. No remembering different offsets for each station.

Just food for thought...

-Ralph

Thanks everyone for posting. really appreciate it

Here's my Mill running PB. Anotheold Okuma. Like you said it was PB that made me jump on linuxcnc. Let's keep the good work.

Mill Looks totally different now. I've also added axis load meters(not properly connected yet, but functional)

Attachments:

The following user(s) said Thank You: Lcvette

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

15 Sep 2021 09:12 #220684

by anfänger

Replied by anfänger on topic Probe Basic Lathe Status

Nice machine,

I made some progress, I have changed the drilling to drilling an boring. So you can bore with a drill, if you like.

And the rigid tapping. I hope I can check those the next days.

BUT they are simple cycles, they are not generating executable gcode, so it can’t be saved. For me this is enough. If I need something more fancy I will opt for cad/cam.

I made some progress, I have changed the drilling to drilling an boring. So you can bore with a drill, if you like.

And the rigid tapping. I hope I can check those the next days.

BUT they are simple cycles, they are not generating executable gcode, so it can’t be saved. For me this is enough. If I need something more fancy I will opt for cad/cam.

The following user(s) said Thank You: harindugamlath

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21260

- Thank you received: 7255

15 Sep 2021 10:15 #220690

by tommylight

Replied by tommylight on topic Probe Basic Lathe Status

In Axis GUI, file>save gcode as, so whatever you have opened it can be saved.

Don't know about other GUI's, i think QtPlasmaC also does that.

Don't know about other GUI's, i think QtPlasmaC also does that.

The following user(s) said Thank You: harindugamlath

Please Log in or Create an account to join the conversation.

Moderators: KCJ, Lcvette

Time to create page: 0.278 seconds