QTDragon spindle raise issues

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

29 Aug 2024 14:30 #308936

by gardenweazel

Replied by gardenweazel on topic QTDragon spindle raise issues

Attachments:

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7291

- Thank you received: 2128

01 Sep 2024 03:03 #309125

by cmorley

Replied by cmorley on topic QTDragon spindle raise issues

I'm sorry for taking so long each time - distracted lately.

Maybe you could compress your configuration folder so I can look at everything?

Because you have custom ui and handler files makes things hard to know what is what.

Maybe you could compress your configuration folder so I can look at everything?

Because you have custom ui and handler files makes things hard to know what is what.

The following user(s) said Thank You: gardenweazel

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

01 Sep 2024 19:04 #309167

by gardenweazel

Replied by gardenweazel on topic QTDragon spindle raise issues

Attachments:

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

04 Sep 2024 19:47 #309377

by gardenweazel

Replied by gardenweazel on topic QTDragon spindle raise issues

Any suggestions for my setup?

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7291

- Thank you received: 2128

06 Sep 2024 22:15 #309530

by cmorley

Replied by cmorley on topic QTDragon spindle raise issues

So I added your custom files to my sim:

I see two external pins:

696 bit IN FALSE qtdragon.external-pause

696 bit IN FALSE qtdragon.external-pause-2

I can't see what is different in qtdragon_hd.ui or qtdragon_hd_handler.py in your qtvcp/screens/qtdragon_hd folder. They see to be the same as the most current.

If that is true then I don't think you need the pause_pin.py file anymore.

We need to get to one version of external pausing.

So can you confirm my understanding - the qtdragon_hd.ui and qtdragon_hd_handler.py are are just copies of the most current?

I see two external pins:

696 bit IN FALSE qtdragon.external-pause

696 bit IN FALSE qtdragon.external-pause-2

I can't see what is different in qtdragon_hd.ui or qtdragon_hd_handler.py in your qtvcp/screens/qtdragon_hd folder. They see to be the same as the most current.

If that is true then I don't think you need the pause_pin.py file anymore.

We need to get to one version of external pausing.

So can you confirm my understanding - the qtdragon_hd.ui and qtdragon_hd_handler.py are are just copies of the most current?

The following user(s) said Thank You: gardenweazel

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

18 Sep 2024 19:45 #310411

by gardenweazel

Replied by gardenweazel on topic QTDragon spindle raise issues

Sorry it's taken a while to get back to you.

"So can you confirm my understanding - the qtdragon_hd.ui and qtdragon_hd_handler.py are are just copies of the most current?"

This is confirmed and correct. I put those files there as I may make changes to them for myself.

I ran a file yesterday that had a 2 tool changes, one at the beginning(as expected) of the file and one later on.

Here's what I did in order:

1. from the MDI menu: G54 X0 Y0

Results were as suspected.

2. Lowered Z Axis to top of stock and zero'ed Z

All good so far.

3. started running the file. The first tool change was successful and so was the touch-off on the tool height sensor.

All good here.

4. All of the cutting/paths was precisely as commanded.

All good.

5. At the very end of the first job, and BEFORE the tool was changed. The spindle raised up and was stopped but, NOT at the

tool change position. The RESUME button on the screen was blinking. Not good.

So I changed the tool just in case I didn't get the actual tool change prompt.

6. Once I clicked RESUME the spindle raised to the top as expected and then moved to the tool-change position. The spindle was still stopped at this point. I received the tool change prompt as expected and clicked OK to indicate that I had changed to the tool.

All good here.

7. The spindle moved to the tool setter sensor, descended and touched off the sensor as expected.

All good here

8. From here the spindle moved BACK to the tool change location and began running.

All good here but I don't understand why it's returned to the ACTUAL tool change location and then switch on verses just turning on at a safe level above the sensor and them move to the next path?

9. And finally the spindle moved to the correct path and began "air-cutting" just above(10-20mm) the correct path.

Not good here.

This leads me to believe that something in my subroutines didn't work properly.

I am attaching these two subs.

Also adding the file that I was using. Note that for readability sake, I've truncated

quite a bit of the file size noted by

CUT, CUT, CUT

lines.

"So can you confirm my understanding - the qtdragon_hd.ui and qtdragon_hd_handler.py are are just copies of the most current?"

This is confirmed and correct. I put those files there as I may make changes to them for myself.

I ran a file yesterday that had a 2 tool changes, one at the beginning(as expected) of the file and one later on.

Here's what I did in order:

1. from the MDI menu: G54 X0 Y0

Results were as suspected.

2. Lowered Z Axis to top of stock and zero'ed Z

All good so far.

3. started running the file. The first tool change was successful and so was the touch-off on the tool height sensor.

All good here.

4. All of the cutting/paths was precisely as commanded.

All good.

5. At the very end of the first job, and BEFORE the tool was changed. The spindle raised up and was stopped but, NOT at the

tool change position. The RESUME button on the screen was blinking. Not good.

So I changed the tool just in case I didn't get the actual tool change prompt.

6. Once I clicked RESUME the spindle raised to the top as expected and then moved to the tool-change position. The spindle was still stopped at this point. I received the tool change prompt as expected and clicked OK to indicate that I had changed to the tool.

All good here.

7. The spindle moved to the tool setter sensor, descended and touched off the sensor as expected.

All good here

8. From here the spindle moved BACK to the tool change location and began running.

All good here but I don't understand why it's returned to the ACTUAL tool change location and then switch on verses just turning on at a safe level above the sensor and them move to the next path?

9. And finally the spindle moved to the correct path and began "air-cutting" just above(10-20mm) the correct path.

Not good here.

This leads me to believe that something in my subroutines didn't work properly.

I am attaching these two subs.

Also adding the file that I was using. Note that for readability sake, I've truncated

quite a bit of the file size noted by

CUT, CUT, CUT

lines.

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

22 Sep 2024 18:14 #310615

by gardenweazel

Replied by gardenweazel on topic QTDragon spindle raise issues

One other note that I just noticed is that the spindle does not inhibit when paused. It does however, slow-down but, never completely.

I have my spindle set to operate between 5000 and 24000 RPM. Could that be the reason?

I have my spindle set to operate between 5000 and 24000 RPM. Could that be the reason?

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7291

- Thank you received: 2128

24 Sep 2024 02:10 #310681

by cmorley

Replied by cmorley on topic QTDragon spindle raise issues

I bet the M0 in your toolchange NGC is being caught in the handler code.

I never considered an M0 in remap code.

Spindle inhibit works by setting the spindle speed to zero, but the spindle is still on.

If your spindle won't honour 0 spindle speed then that is probably why it doesn't stop.

Maybe linuxcnc should turn the spindle off rather then set the speed 0 when spindle-inhibit is true. (The spindle on/off behavior has changed since inhibit was added. setting speed to zero used to turn the spindle off. )

I never considered an M0 in remap code.

Spindle inhibit works by setting the spindle speed to zero, but the spindle is still on.

If your spindle won't honour 0 spindle speed then that is probably why it doesn't stop.

Maybe linuxcnc should turn the spindle off rather then set the speed 0 when spindle-inhibit is true. (The spindle on/off behavior has changed since inhibit was added. setting speed to zero used to turn the spindle off. )

The following user(s) said Thank You: gardenweazel

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

24 Sep 2024 17:28 #310723

by gardenweazel

Replied by gardenweazel on topic QTDragon spindle raise issues

I need to look at my GS20 VFD docs. I believe there was a parameter that I may have set to prevent to only allow the Spindle to run between 5k and 24k. So we can probably not waste unnecessary cycles on the spindle not stopping.

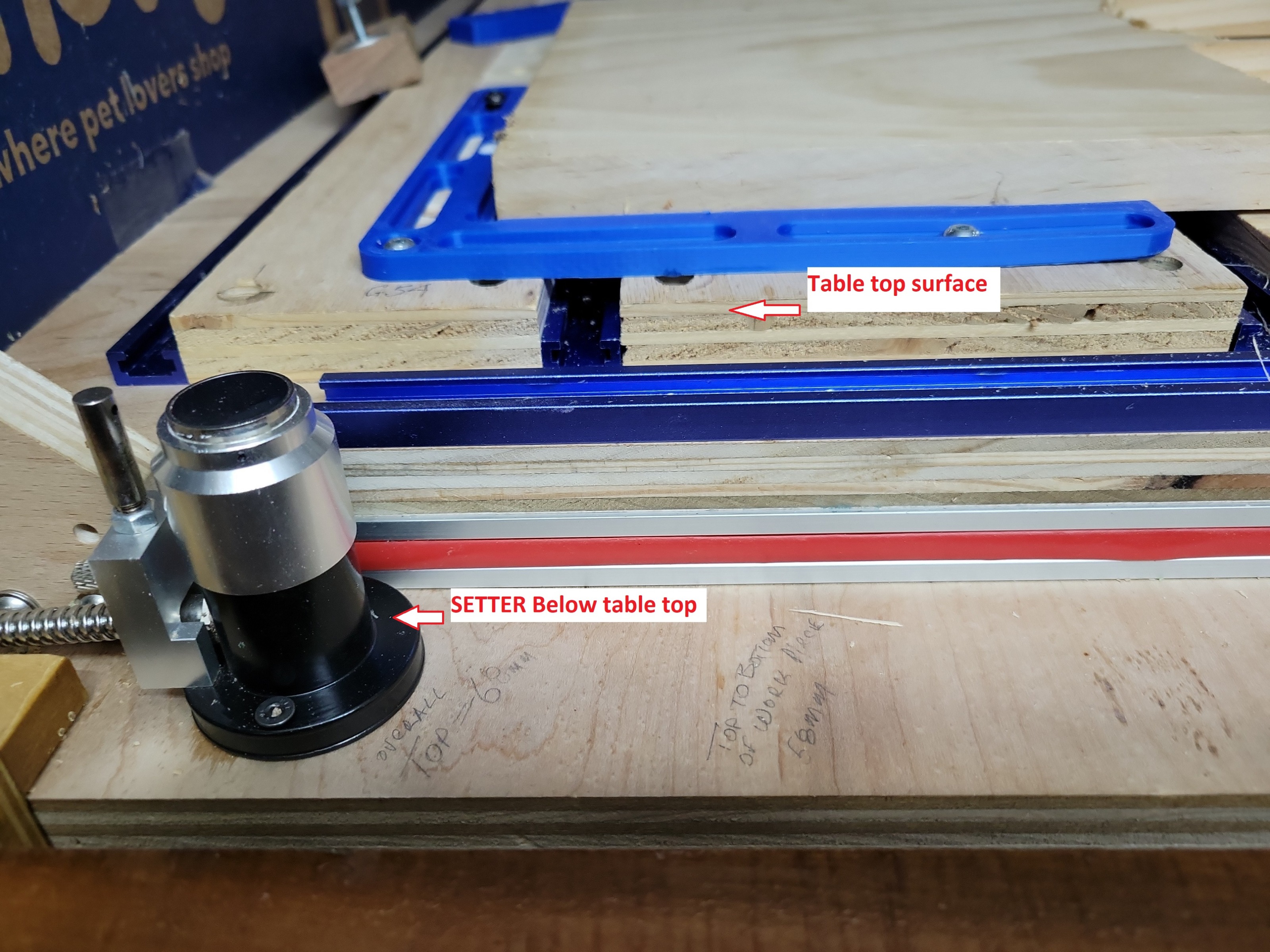

What I am concerned about is the tool length measurement. I am attaching an image which shows my rig.

Note that the setter BASE is BELOW the table top but, the setter TOP is ABOVE the table top by some 10mm.

In the QTDragon setup I have entered 10 for the height which I believe is correct?

How do I setup so that tool measurements are consistent?

What I am concerned about is the tool length measurement. I am attaching an image which shows my rig.

Note that the setter BASE is BELOW the table top but, the setter TOP is ABOVE the table top by some 10mm.

In the QTDragon setup I have entered 10 for the height which I believe is correct?

How do I setup so that tool measurements are consistent?

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 0.220 seconds