My Grizzly G0619 mill

- my1987toyota

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

16 Jan 2023 13:02 - 16 Jan 2023 13:05 #262121

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

I am having them re-cut. The company I work for paid for them because they were sent in with another job to be cut at the

same time. Kind of like a bonus. just with materials instead of money. They use a different program that puts out DXF files

I am the only one who uses Fusion 360 ( not sure for how much longer though ). and Yes the new cut files will have other info

attached to make sure they are the correct size.

same time. Kind of like a bonus. just with materials instead of money. They use a different program that puts out DXF files

I am the only one who uses Fusion 360 ( not sure for how much longer though ). and Yes the new cut files will have other info

attached to make sure they are the correct size.

Last edit: 16 Jan 2023 13:05 by my1987toyota.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

16 Jan 2023 23:49 #262194

by andypugh

Replied by andypugh on topic My Grizzly G0619 mill

Are they, by any chance, exactly 2.54x the size they should be?

ie, a DXF in cm has been interpreted in inches?

ie, a DXF in cm has been interpreted in inches?

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11679

- Thank you received: 3937

16 Jan 2023 23:57 #262196

by rodw

Replied by rodw on topic My Grizzly G0619 mill

The issue with DXF is that they are dimensionless so the scale of the units needs to be set when its opened in CAM/Nesting sftware.

Andy's suggestion sounds plausible.

F360 DXF's have proven reliable for me if created via the method I shared earlier.(provided they are scaled correctly when opened )I have cut many nested with Sheetcam without issue. I do remember almost getting caught with a provided DXF in inches becoming 25.4x larger than it should have been because I blindly accepted the default scale of mm.

)I have cut many nested with Sheetcam without issue. I do remember almost getting caught with a provided DXF in inches becoming 25.4x larger than it should have been because I blindly accepted the default scale of mm.

Andy's suggestion sounds plausible.

F360 DXF's have proven reliable for me if created via the method I shared earlier.(provided they are scaled correctly when opened

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

18 Jan 2023 18:23 - 18 Jan 2023 18:26 #262359

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

yesAre they, by any chance, exactly 2.54x the size they should be?

ie, a DXF in cm has been interpreted in inches?

Last edit: 18 Jan 2023 18:26 by my1987toyota.

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

21 Jan 2023 20:39 #262607

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

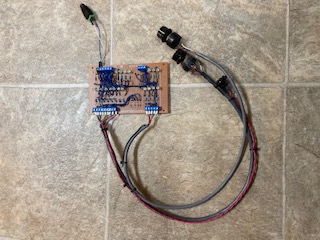

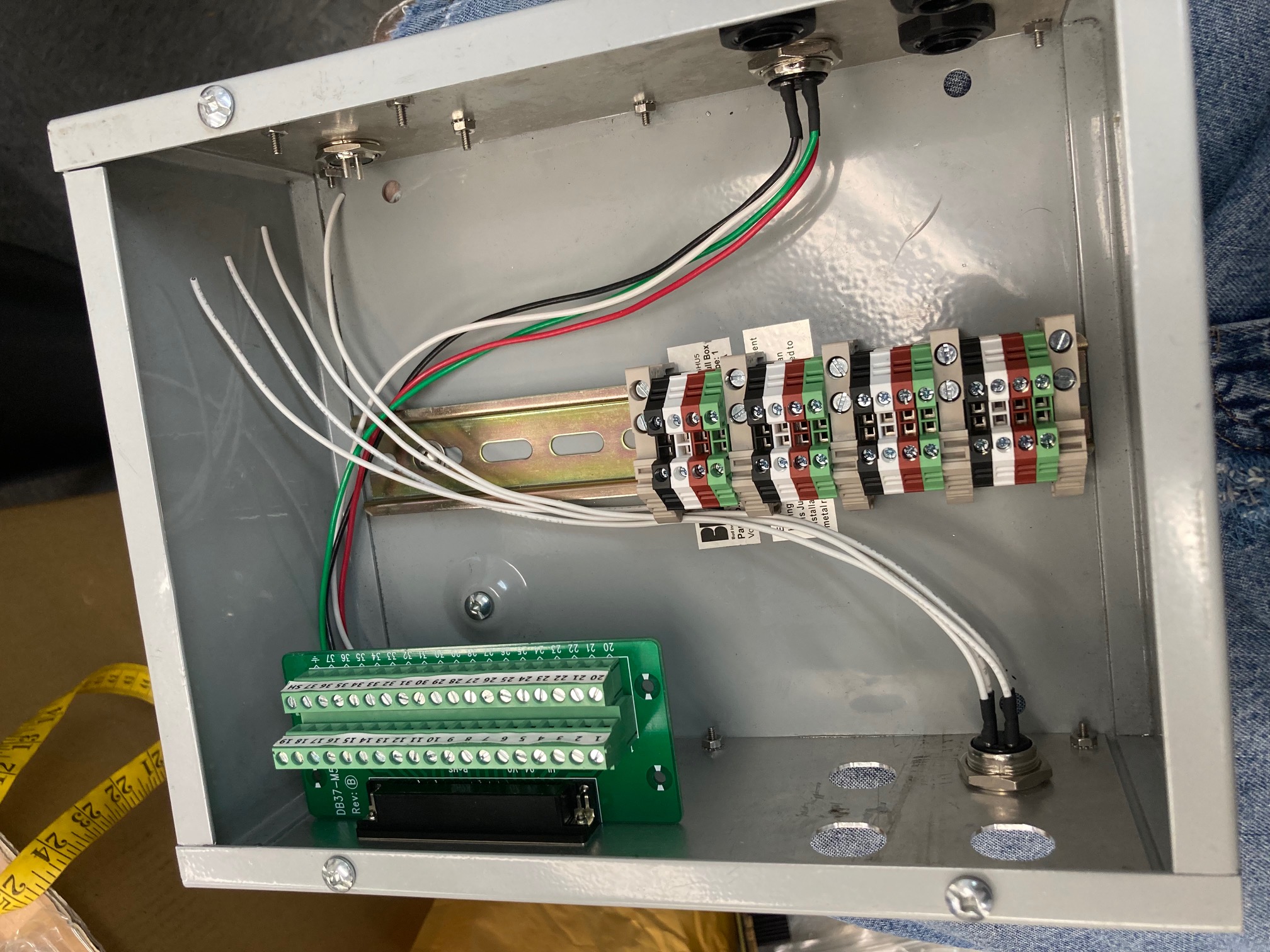

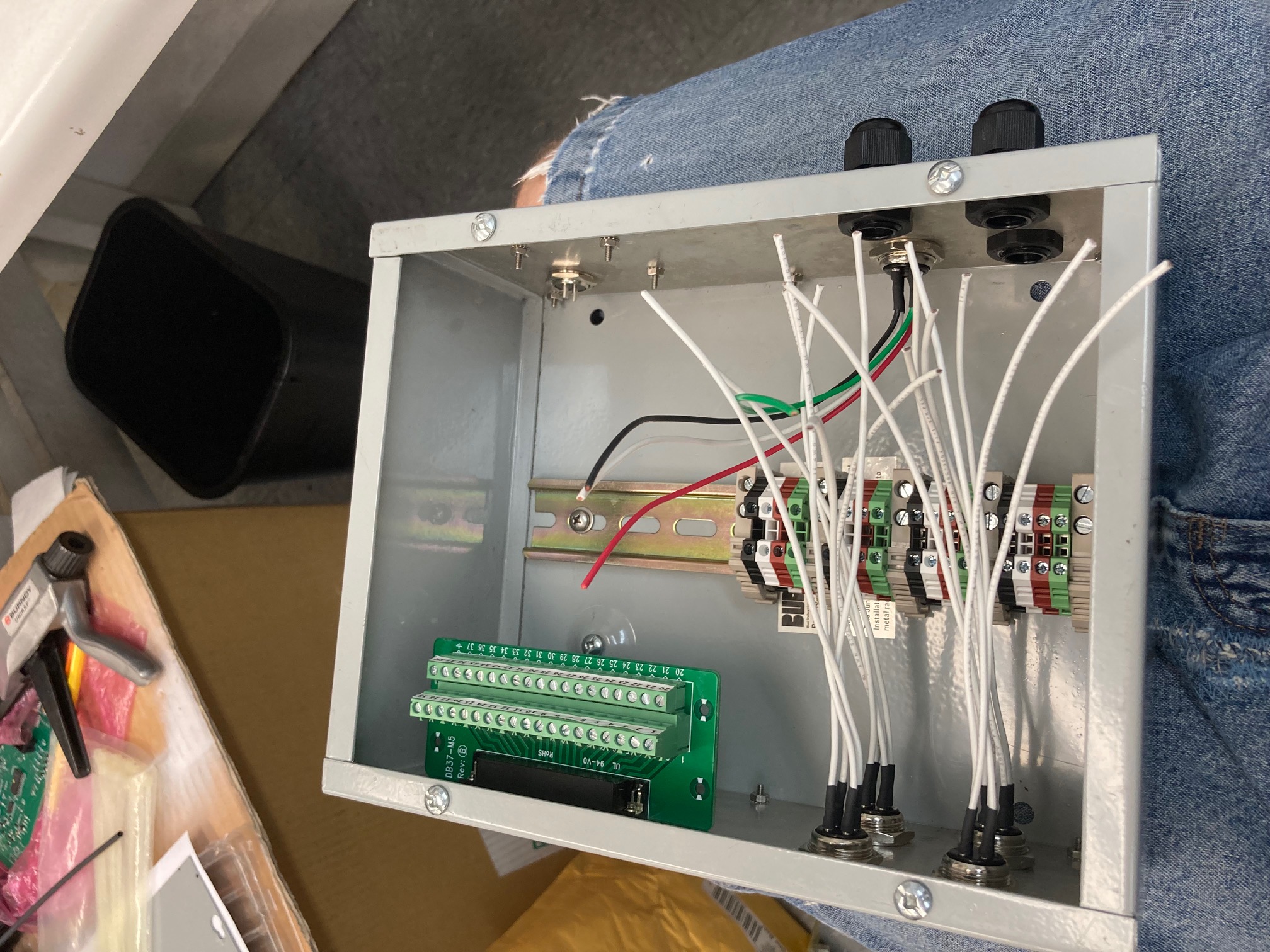

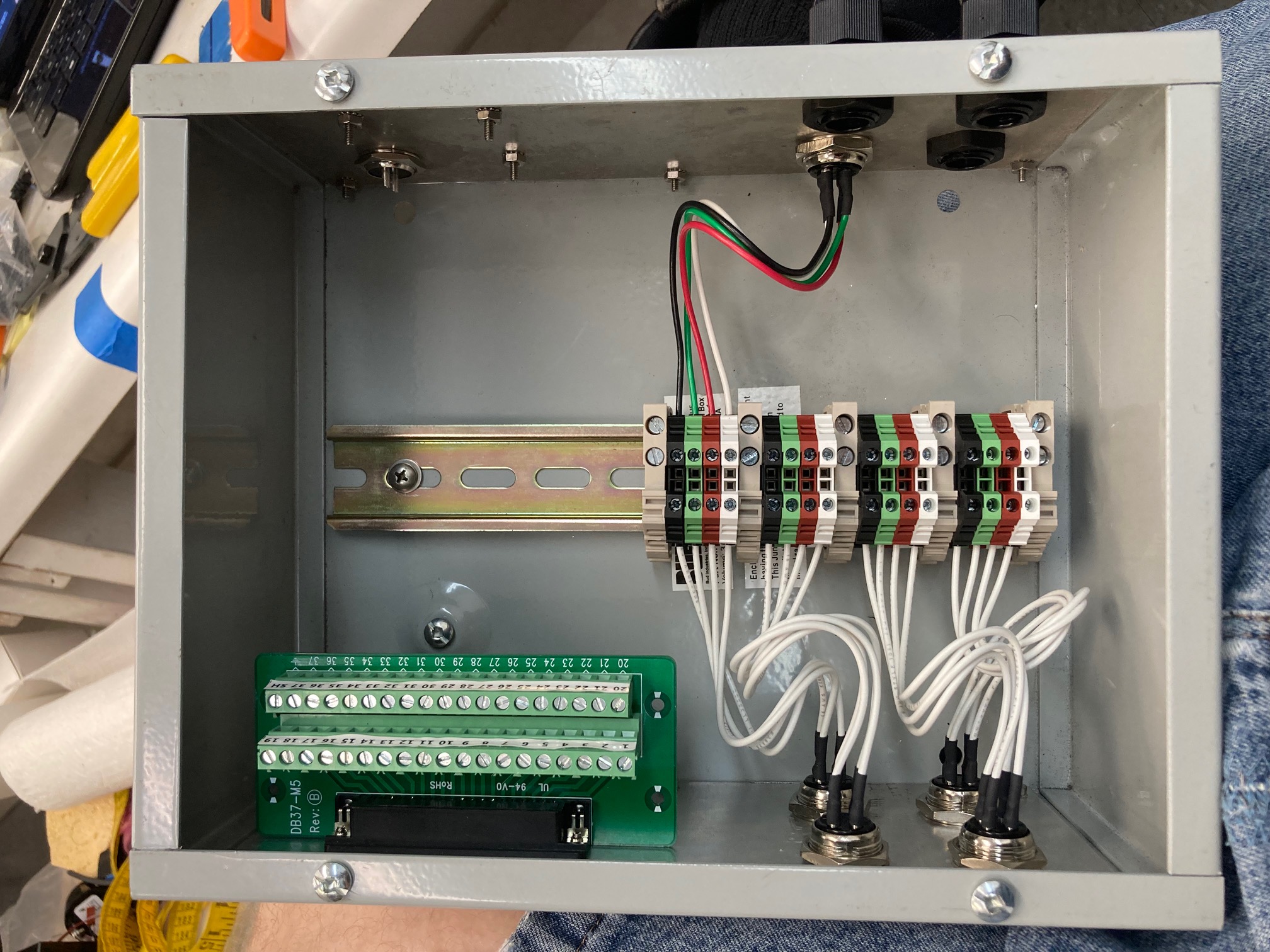

So I have spent part of this week working on a diode matrix for my MPG panel. Since I will be using MUX

I could have actually used more but for now that doesn't seem necessary. After Building my prototype

I will need to design my actual card. If everything goes well the new board should be at least half of the

prototype's size.

the Selector switch will connecting to one of 9 selections

1= OFF

2= X

3= Y

4= Z

5= 4th

6= Feed Override

7= Spindle Override

8= Jog Override

9= Step Mode

The 4 position Increment selector

1= 0.0001" or 4th 1.0 degree

2= 0.001" or 4th 0.1 of a degree

3= 0.01 or 4th 0.01 of a degree

4= Continuous Jog

This is what the prototype looks like

I could have actually used more but for now that doesn't seem necessary. After Building my prototype

I will need to design my actual card. If everything goes well the new board should be at least half of the

prototype's size.

the Selector switch will connecting to one of 9 selections

1= OFF

2= X

3= Y

4= Z

5= 4th

6= Feed Override

7= Spindle Override

8= Jog Override

9= Step Mode

The 4 position Increment selector

1= 0.0001" or 4th 1.0 degree

2= 0.001" or 4th 0.1 of a degree

3= 0.01 or 4th 0.01 of a degree

4= Continuous Jog

This is what the prototype looks like

Attachments:

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

16 Apr 2023 18:35 - 16 Apr 2023 18:39 #269228

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

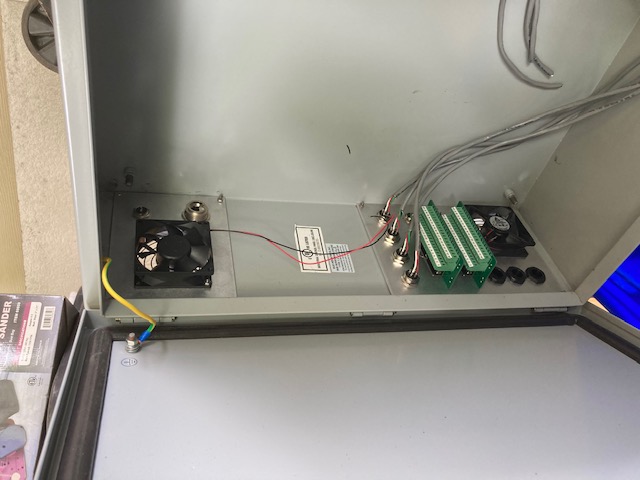

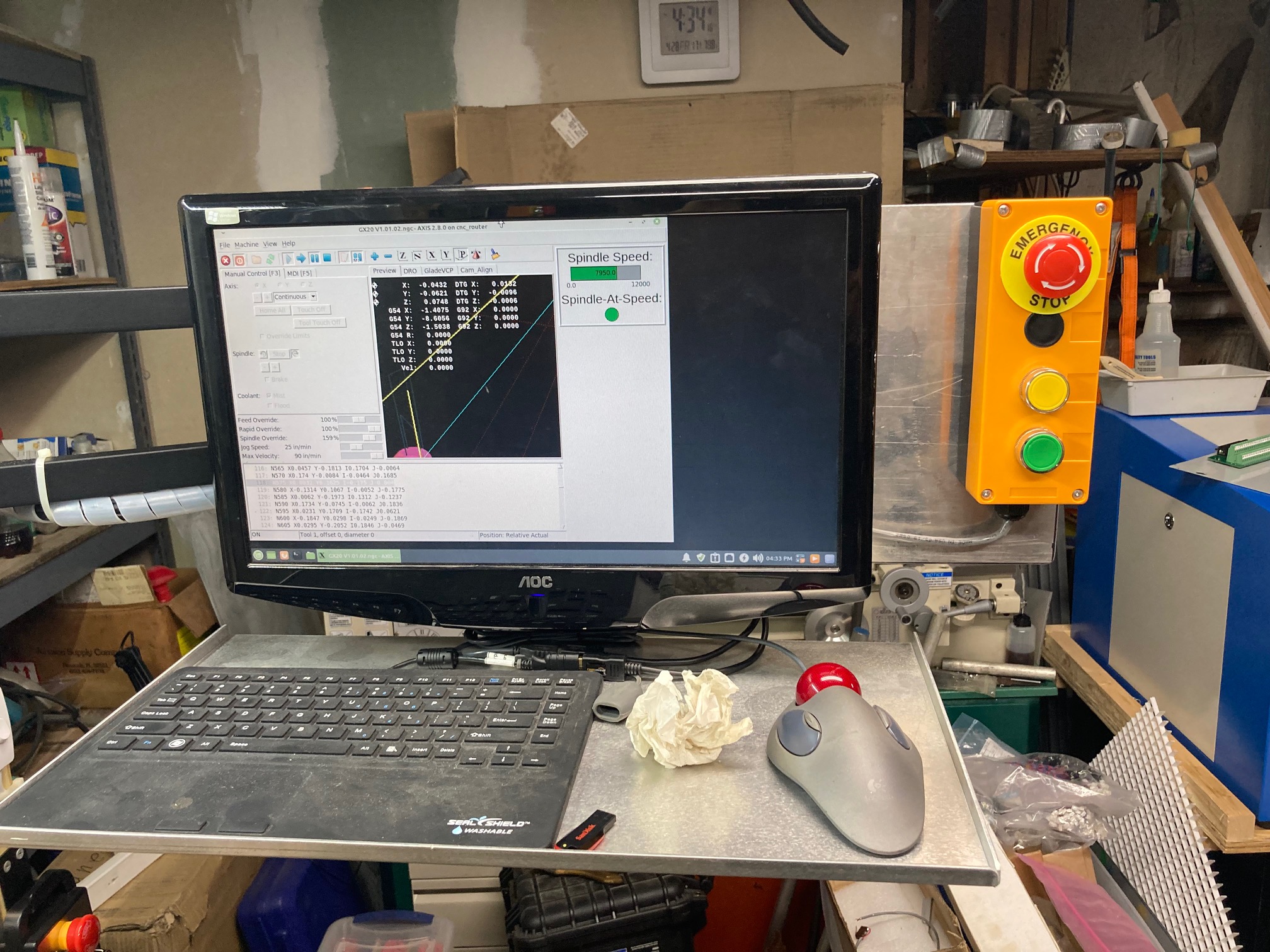

Attachments:

Last edit: 16 Apr 2023 18:39 by my1987toyota.

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

16 Apr 2023 18:37 - 16 Apr 2023 18:38 #269229

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

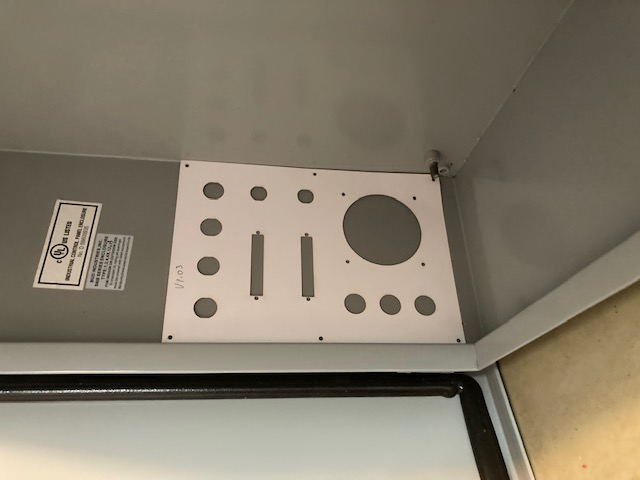

Attachments:

Last edit: 16 Apr 2023 18:38 by my1987toyota.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

30 Apr 2023 09:10 #270297

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

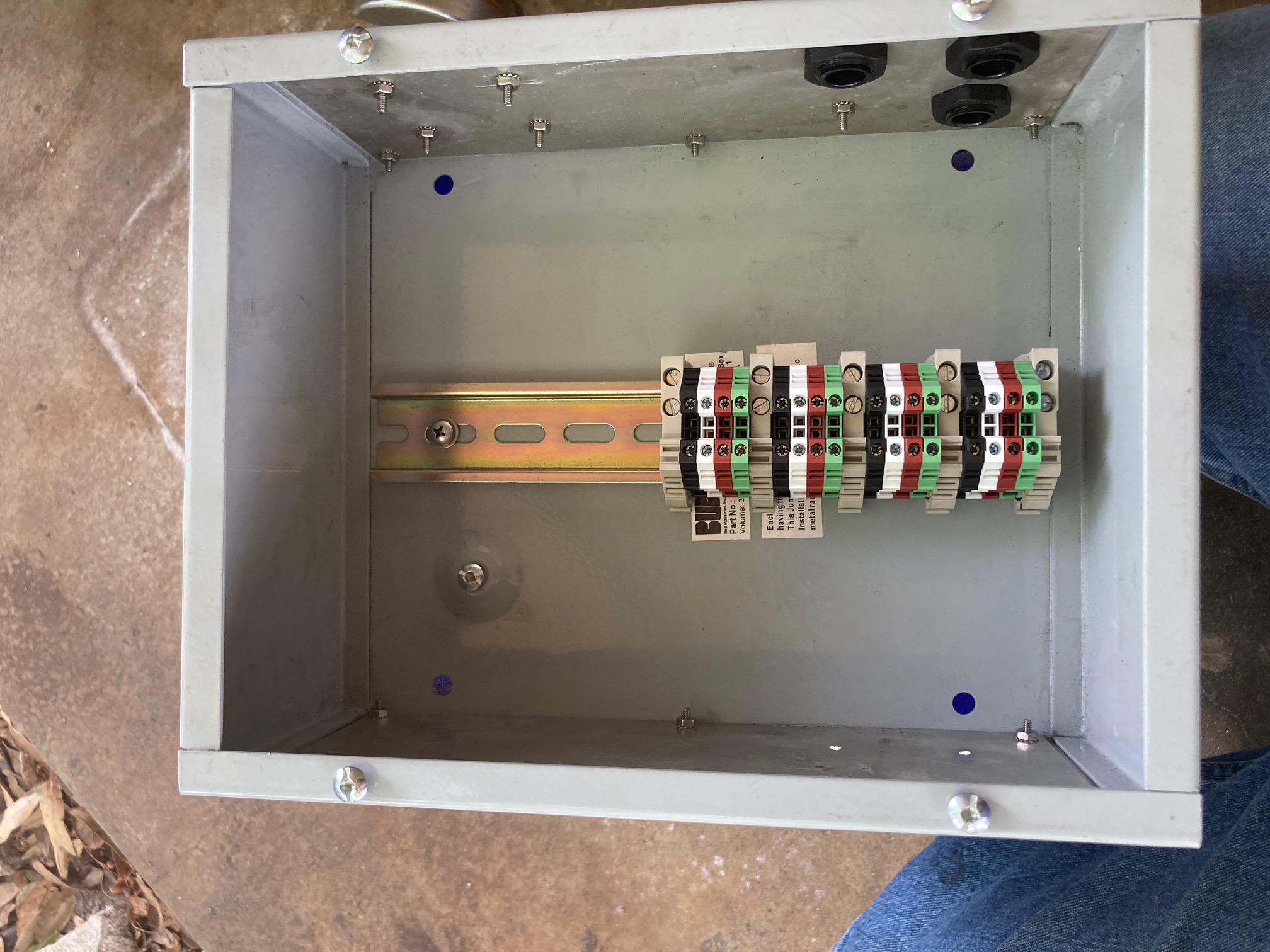

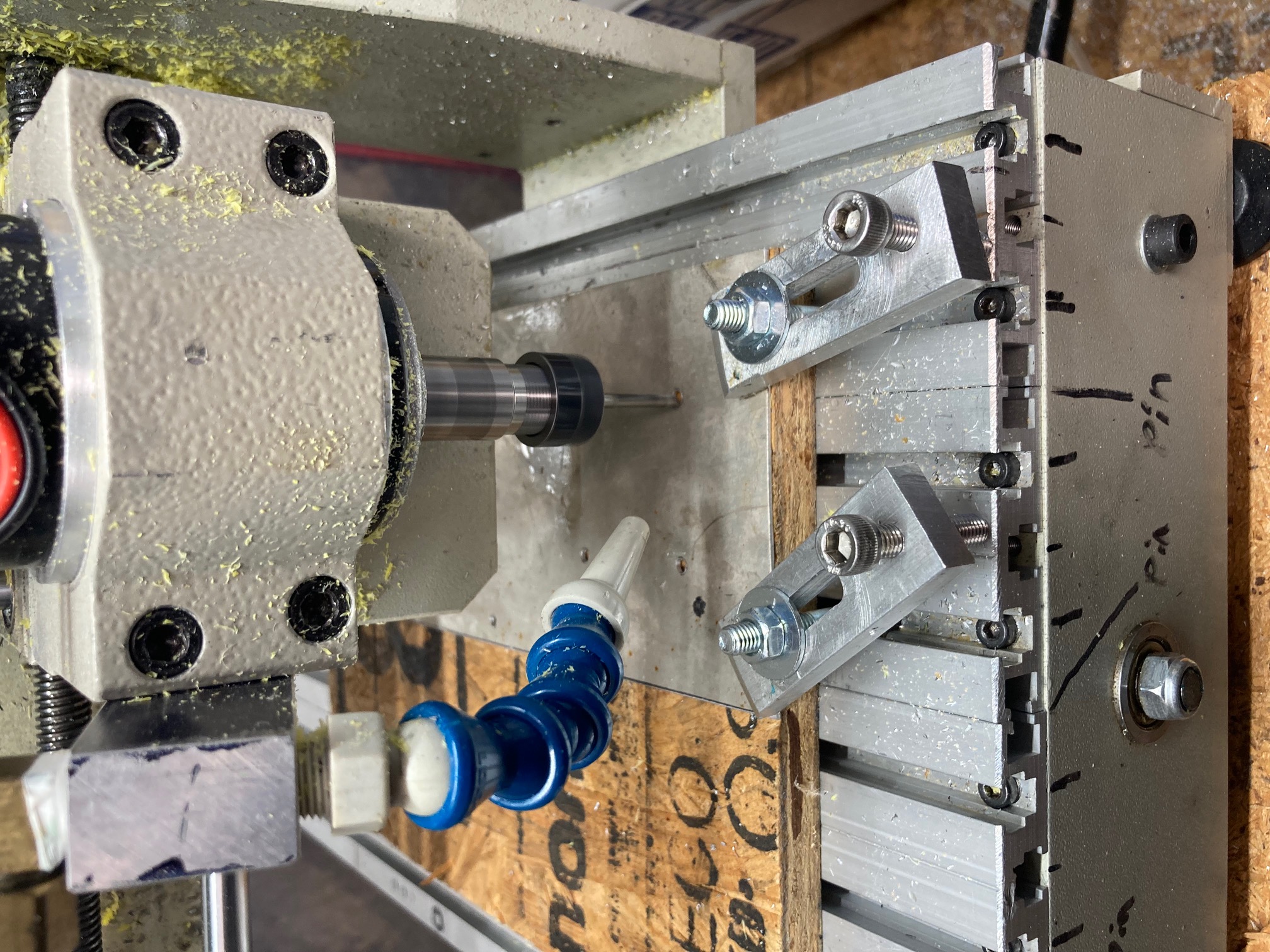

Attachments:

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

30 Apr 2023 09:17 #270298

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

30 Apr 2023 17:18 #270317

by my1987toyota

Replied by my1987toyota on topic My Grizzly G0619 mill

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.546 seconds