EtherCAT plasma torch voltage reader

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1233

- Thank you received: 435

20 Feb 2025 21:39 #322113

by Hakan

EtherCAT plasma torch voltage reader was created by Hakan

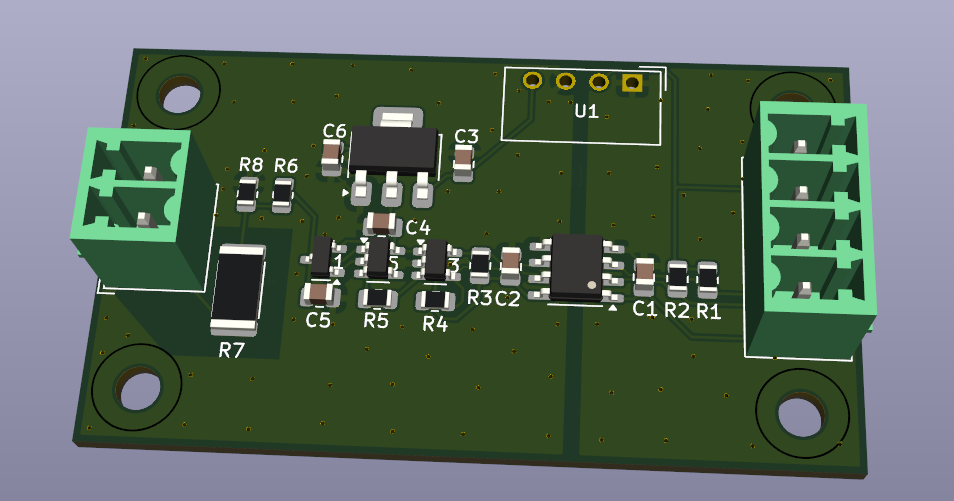

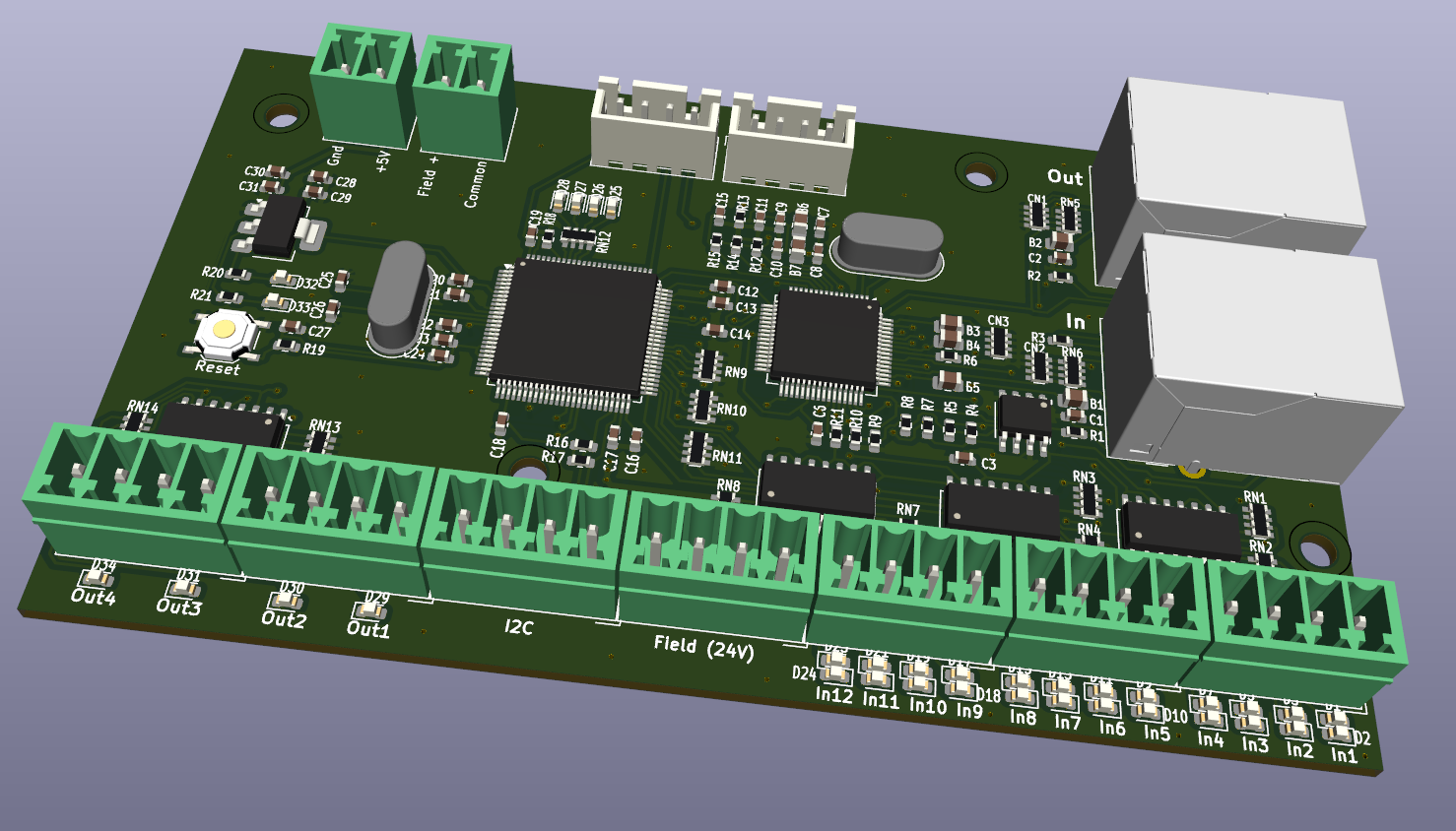

I just uploaded the description and design of the EaserCAT 7000 board and the two plasma torch voltage readers THTIC and THTIC2 on github.

github.com/MetalMusings/MyOwnEtherCATDev...ith-thtic-and-thtic2

Reads the plasma voltage, feeds it to my EaserCAT-7000 card over I2C and makes it available either as raw data read from the ADC or scaled to calibrated plasma torch voltage.

I have used it for maybe an hour of cutting (feed time) and it just works. Very happy with it.

There are two versions, for a bit blurry reasons, but always good with options I guess.

The ADC card is small 55x32 mm.

github.com/MetalMusings/MyOwnEtherCATDev...ith-thtic-and-thtic2

Reads the plasma voltage, feeds it to my EaserCAT-7000 card over I2C and makes it available either as raw data read from the ADC or scaled to calibrated plasma torch voltage.

I have used it for maybe an hour of cutting (feed time) and it just works. Very happy with it.

There are two versions, for a bit blurry reasons, but always good with options I guess.

The ADC card is small 55x32 mm.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3968

21 Feb 2025 02:36 #322155

by rodw

Replied by rodw on topic EtherCAT plasma torch voltage reader

Very cool! If you wanted another plasma challenge, how about an ethercat plasma board powered by 24v PoE so you can mount a board that does the ArcOK input, Torch on relay and the torch voltage right at the plasma cutter itself. Add a PoE injector in your control panel amd its all self contained.

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1233

- Thank you received: 435

21 Feb 2025 07:14 #322175

by Hakan

Replied by Hakan on topic EtherCAT plasma torch voltage reader

It can be done pretty easily with external components.

Feed 24V using the unused leads in the CAT cable, and a step-down unit from 24V to 5V and there you have it.

At the prototype stage this simple cable will work. And 24V stepdown converter (board needs 5V) is dirt cheap.

BTW the photo-diode opens so good that I don't need a torch-on relay, but can be had if needed.

Feed 24V using the unused leads in the CAT cable, and a step-down unit from 24V to 5V and there you have it.

At the prototype stage this simple cable will work. And 24V stepdown converter (board needs 5V) is dirt cheap.

BTW the photo-diode opens so good that I don't need a torch-on relay, but can be had if needed.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3968

21 Feb 2025 11:34 #322195

by rodw

Replied by rodw on topic EtherCAT plasma torch voltage reader

Perfect! Not sure what plasma cutter you have but if it was say hypertherm, a surface mount circular connector that just pushes into the socket on the machine and you would have a nice complete self mounting package. I used the 7i76e spindle relay for torch on so there is nothing wrong with your photo diode. You just need to add a pull down resistor on the arcOK as discussed in the qtplasmac docs.

Of course if you had a XPR hi def its Ethercat anyway!

Of course if you had a XPR hi def its Ethercat anyway!

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1233

- Thank you received: 435

21 Feb 2025 12:35 #322199

by Hakan

Replied by Hakan on topic EtherCAT plasma torch voltage reader

The idea to power it from 24V stuck, I am going to do it that way. Will get rid of a 5V power supply in the cabinet.

The voltage reader can fit in a connector, that would be possible, but not the EtherCAT components. They need say 100x60 mm as it is today.

Two-sided and dense packing, no still not inside a connector.

I will try that idea to put the EtherCAT function on the plasma cutter. It doesn't make sense for me since it is a matter of 0.5 meter, but why not?

Could be a question of how long the ethernet cable can safely be versus how long the I2C cable can be.

That power injector/ejector is here on Monday.

I have a Herocut 55i, it is all very small scale, hobby and prototypes for my enjoyment.

I get voltage, arc-ok and can control torch-on. Power level, air pressure isn't, well require more work than I want to spend right now.

Must also say I am very happy with QtPlasmaC, works really nice.

The voltage reader can fit in a connector, that would be possible, but not the EtherCAT components. They need say 100x60 mm as it is today.

Two-sided and dense packing, no still not inside a connector.

I will try that idea to put the EtherCAT function on the plasma cutter. It doesn't make sense for me since it is a matter of 0.5 meter, but why not?

Could be a question of how long the ethernet cable can safely be versus how long the I2C cable can be.

That power injector/ejector is here on Monday.

I have a Herocut 55i, it is all very small scale, hobby and prototypes for my enjoyment.

I get voltage, arc-ok and can control torch-on. Power level, air pressure isn't, well require more work than I want to spend right now.

Must also say I am very happy with QtPlasmaC, works really nice.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3968

21 Feb 2025 22:44 #322242

by rodw

Replied by rodw on topic EtherCAT plasma torch voltage reader

I wasn't thinking of putting it the connector shell but having a surface mount connector if they exist that plugs straight in like a raspberry pi hat.

The amphenol connector used by Hypertherm and Thermal Dynamics, I think comes with surface mount options....

Glad you like my idea, Pretty cool one I thought!

The amphenol connector used by Hypertherm and Thermal Dynamics, I think comes with surface mount options....

Glad you like my idea, Pretty cool one I thought!

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1233

- Thank you received: 435

22 Feb 2025 07:46 #322254

by Hakan

Replied by Hakan on topic EtherCAT plasma torch voltage reader

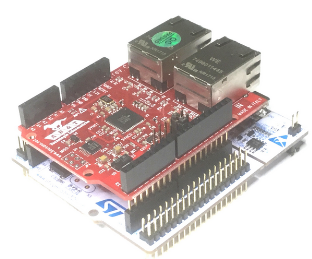

I see, a bit like EasyCAT kind but for the voltage reader.

I am more into putting the torch voltage reader components onto the EaserCAT board.

Now when I have looked at it I am not so worried about the voltage levels and that.

One just need to take some precautions.

And if I understand right, most new plasma cutters gives out scaled down voltage

so it is more to handle the floating voltage, and this circuitry does that.

I am more into putting the torch voltage reader components onto the EaserCAT board.

Now when I have looked at it I am not so worried about the voltage levels and that.

One just need to take some precautions.

And if I understand right, most new plasma cutters gives out scaled down voltage

so it is more to handle the floating voltage, and this circuitry does that.

Attachments:

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 43

22 Feb 2025 10:32 #322265

by RDA

Replied by RDA on topic EtherCAT plasma torch voltage reader

Looks good. I dont think you have issues with the voltage levels. In another thread I said I would scope out the work to electrode voltage to show what those voltages are, but unfortunately I have not had the chance, maybe next week.

When you use the divided arc voltage, you could put this design in to your easercat pcb, as in you dont need it to be separate.

If you find a decent 16-bit one example ADS1114IDGST then it might be worth the money. The 16-bit one gives you more opportunities if you want to make some additional features in the future, its quite a bit more expensive I know.

For the OP-amp if you find something with more tolerance in the input, that would make it safer but may not be worth it.

If you can give me an email address where you can be reached, I can share you an ohmic sensing schematic if you want to try it out and then share to the community.

When you use the divided arc voltage, you could put this design in to your easercat pcb, as in you dont need it to be separate.

If you find a decent 16-bit one example ADS1114IDGST then it might be worth the money. The 16-bit one gives you more opportunities if you want to make some additional features in the future, its quite a bit more expensive I know.

For the OP-amp if you find something with more tolerance in the input, that would make it safer but may not be worth it.

If you can give me an email address where you can be reached, I can share you an ohmic sensing schematic if you want to try it out and then share to the community.

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1233

- Thank you received: 435

22 Feb 2025 12:05 - 22 Feb 2025 12:11 #322269

by Hakan

Replied by Hakan on topic EtherCAT plasma torch voltage reader

From what I have seen during the tests the torch voltage is below 200V. During start and piercing it easily goes up to 180V but not above that.

It cuts around 100V. Thin material in the 80s-90s, thick in the 110s.

The arc is also DCEN, DC electrode negative, I have been told. The work piece ground is not connected to mains ground.

200V isn't uncommon to have on a PCB, mains 230V AC is common here. My understanding is that with enough isolation distance it is fine. And the whole ADC side is isolated.

I think an ADS1115 can be used just as well, ebay aliX amazon are full of them at super low cost. To go with the 11-bit version meant that I get 3.3 kHz sample time. The ADS1115 is only 860 Hz max. That was the main factor. For the ADS1xxx ADCs one need to put them in continuous conversion mode or the time to get a value is terrible, several milliseconds. In continuous mode its 150 microseconds. I know now how to read the ADS1014 which is actually two channels A0 A1, and I think it would be possible to use the ADS1115 with 15-bit resolution in continuous mode reading one differential channel (between A0 and A1). How important is updating exactly every 1 ms with a new value? It can't be that important, there is a bit of noise in the voltage and to read the same value every 7th time can't be that bad, can it? Anyway, that was the decision point and I choose 11-bit resolution, one differential channel and 3.3 kHz updating rate. The footprint is the same for those ADS1xxx so one can easily solder in another one, and reprogram. It is actually only something like 10 lines of code for the ADC.

The BAT54S is there to protect the input of the op-amp. Don't know much about that, it is something I found. The lmv321 was also not actively chosen but was known to work. I do see non-linearity at the very bottom of the range, so it isn't fully rail-to-rail. They aren't as I understood it, and it isn't important, it isn't working close to the rail voltages. But it means the display says 2V when it is 0V, but it should be linear above say 5V (in the 0-200V range).

Do you have an ohmic sensing solution when the plasma nozzle is the same polarity as the work piece?

I can see no change in voltage when the torch touches the work piece. I was hoping for that, but no.

I am very interested to include that.

It cuts around 100V. Thin material in the 80s-90s, thick in the 110s.

The arc is also DCEN, DC electrode negative, I have been told. The work piece ground is not connected to mains ground.

200V isn't uncommon to have on a PCB, mains 230V AC is common here. My understanding is that with enough isolation distance it is fine. And the whole ADC side is isolated.

I think an ADS1115 can be used just as well, ebay aliX amazon are full of them at super low cost. To go with the 11-bit version meant that I get 3.3 kHz sample time. The ADS1115 is only 860 Hz max. That was the main factor. For the ADS1xxx ADCs one need to put them in continuous conversion mode or the time to get a value is terrible, several milliseconds. In continuous mode its 150 microseconds. I know now how to read the ADS1014 which is actually two channels A0 A1, and I think it would be possible to use the ADS1115 with 15-bit resolution in continuous mode reading one differential channel (between A0 and A1). How important is updating exactly every 1 ms with a new value? It can't be that important, there is a bit of noise in the voltage and to read the same value every 7th time can't be that bad, can it? Anyway, that was the decision point and I choose 11-bit resolution, one differential channel and 3.3 kHz updating rate. The footprint is the same for those ADS1xxx so one can easily solder in another one, and reprogram. It is actually only something like 10 lines of code for the ADC.

The BAT54S is there to protect the input of the op-amp. Don't know much about that, it is something I found. The lmv321 was also not actively chosen but was known to work. I do see non-linearity at the very bottom of the range, so it isn't fully rail-to-rail. They aren't as I understood it, and it isn't important, it isn't working close to the rail voltages. But it means the display says 2V when it is 0V, but it should be linear above say 5V (in the 0-200V range).

Do you have an ohmic sensing solution when the plasma nozzle is the same polarity as the work piece?

I can see no change in voltage when the torch touches the work piece. I was hoping for that, but no.

I am very interested to include that.

Last edit: 22 Feb 2025 12:11 by Hakan.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3968

22 Feb 2025 19:28 #322294

by rodw

Replied by rodw on topic EtherCAT plasma torch voltage reader

Best practice per the Hypertherm docs is to have a star ground point on your machine.

www.hypertherm.com/Download?fileId=HYP103900&zip=False

Most plasma machines have a grounding point. It and the work lead should be connected to this star ground.

Also there shouldd be a seperate groound wire for every motor that leads back to the star ground. The purpose of this is to provide a path for EMI that is not going through all of your linear carriage bearings which adds to noise and damage.

Finally, ohmic sensing will only work if the torch tip is shielded. You can't do it if the tip is exposed. This is because the electrode is shorted in the torch internally to the work piece until the arc is initiated at which time it blows back by air to clear the short.

Who said plasma was easy?

www.hypertherm.com/Download?fileId=HYP103900&zip=False

Most plasma machines have a grounding point. It and the work lead should be connected to this star ground.

Also there shouldd be a seperate groound wire for every motor that leads back to the star ground. The purpose of this is to provide a path for EMI that is not going through all of your linear carriage bearings which adds to noise and damage.

Finally, ohmic sensing will only work if the torch tip is shielded. You can't do it if the tip is exposed. This is because the electrode is shorted in the torch internally to the work piece until the arc is initiated at which time it blows back by air to clear the short.

Who said plasma was easy?

Please Log in or Create an account to join the conversation.

Time to create page: 0.164 seconds