EtherCAT plasma torch voltage reader

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11695

- Thank you received: 3947

22 Feb 2025 19:30 #322296

by rodw

Replied by rodw on topic EtherCAT plasma torch voltage reader

EDIT: with modern plasma machines without HF start, its not necessary for a seperate grounding stake

Please Log in or Create an account to join the conversation.

- Hakan

- Online

- Platinum Member

-

Less

More

- Posts: 1182

- Thank you received: 414

22 Feb 2025 20:12 #322300

by Hakan

Replied by Hakan on topic EtherCAT plasma torch voltage reader

It makes sense to have it that way. However, in my Herocut 55i plasma cutter, the work lead or ground clamp is not automatically connected to mains ground.

And that also means that the plasma electrode is at -100 Volts or so. So when connecting it you have to be a little careful and not just assume that the electrode is the positive one because it is not. In this case. My machine has the polarity of the pins in the torch voltage connector well documented and is just a matter of following.

About ohmic sensing, that was my assumption too. A glimmer of hope was born when RDA mentioned it though.

And that also means that the plasma electrode is at -100 Volts or so. So when connecting it you have to be a little careful and not just assume that the electrode is the positive one because it is not. In this case. My machine has the polarity of the pins in the torch voltage connector well documented and is just a matter of following.

About ohmic sensing, that was my assumption too. A glimmer of hope was born when RDA mentioned it though.

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 43

22 Feb 2025 20:34 #322304

by RDA

Replied by RDA on topic EtherCAT plasma torch voltage reader

Yes plasma cutting is electrode negative so your will be positive.

The work is typically connected to mains ground at some point. Your normal industrial plasma will have a ground rod or some other way to ground the table. All grounds connect to this star ground. The plasma's themselves have the work tied to ground directly or through a resistor, if I remember correctly hyperhtem has a 100k resistor between PE and work, thermal dynamics and kjellberg have a direct connection. So you should assume these are at the same potential.

Sorry I did not check the sampling rate of the ADS1115, I just looked if the "same" chip came as 16-bit. Typically you dont need 1ms sample rate, higher rates would let you do digital filtering and some pretty fancy electrode wear estimation but this goes out of the scope of a typical height controller. I would not sped too much in this stuff on hobby stuff as its quite irrelevant. Sorry I bit of derailed the whole thing with the 16-bit, prob best to forget it for now.

The 2V you see while actually input should be 0, can also be noise from wires etc. Would not worry about it too much.

I don't know what you mean with the polarity thing. I made a sensing circuit for a friend a while back. Its just an opto with some protection, it feeds the ohmic 12V and triggers when it touches work. Its been used with a high def HF plasma.

The work is typically connected to mains ground at some point. Your normal industrial plasma will have a ground rod or some other way to ground the table. All grounds connect to this star ground. The plasma's themselves have the work tied to ground directly or through a resistor, if I remember correctly hyperhtem has a 100k resistor between PE and work, thermal dynamics and kjellberg have a direct connection. So you should assume these are at the same potential.

Sorry I did not check the sampling rate of the ADS1115, I just looked if the "same" chip came as 16-bit. Typically you dont need 1ms sample rate, higher rates would let you do digital filtering and some pretty fancy electrode wear estimation but this goes out of the scope of a typical height controller. I would not sped too much in this stuff on hobby stuff as its quite irrelevant. Sorry I bit of derailed the whole thing with the 16-bit, prob best to forget it for now.

The 2V you see while actually input should be 0, can also be noise from wires etc. Would not worry about it too much.

I don't know what you mean with the polarity thing. I made a sensing circuit for a friend a while back. Its just an opto with some protection, it feeds the ohmic 12V and triggers when it touches work. Its been used with a high def HF plasma.

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 43

22 Feb 2025 20:40 #322307

by RDA

Replied by RDA on topic EtherCAT plasma torch voltage reader

This is not true, you can do tip sensing as well. Take a look at example thermal dynamics A-series manual, they provide tip sensing :Finally, ohmic sensing will only work if the torch tip is shielded. You can't do it if the tip is exposed.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Hakan

- Online

- Platinum Member

-

Less

More

- Posts: 1182

- Thank you received: 414

23 Feb 2025 00:57 - 23 Feb 2025 00:58 #322330

by Hakan

Replied by Hakan on topic EtherCAT plasma torch voltage reader

Had to go out and check a few things on the plasma cutter. Both electrode and work lead are disconnected from PE. At lest when switched on and not cutting. And electrode comes in as arc- and work lead as arc+. Consistent with DCEN. And work lead should be connected to ground as you both say. So the work lead/ground potential can be considered still, while the negative arc voltage will fluctuate. 0 to around -100V.. And I just realised that wasn't so good. There are ground and ground planes on THTIC connected to the negative input which will vary in potential after how the negative arc voltage fluctuates. How can this have worked? Obviously it did. But there should be a negative op amp amplifier instead. I'll test that tomorrow, I can modify one of the boards.

I looked at that hypertherm torch, not in depth or anything. The copper tip is exposed but there can be some arrangement where the tip is somewhat isolated from the start parts and work lead. My cutter has the bare tip connected to the work lead and there is zero difference in voltage when the tip comes in contact with the steel sheet.

I looked at that hypertherm torch, not in depth or anything. The copper tip is exposed but there can be some arrangement where the tip is somewhat isolated from the start parts and work lead. My cutter has the bare tip connected to the work lead and there is zero difference in voltage when the tip comes in contact with the steel sheet.

Last edit: 23 Feb 2025 00:58 by Hakan.

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 43

23 Feb 2025 16:47 #322378

by RDA

Replied by RDA on topic EtherCAT plasma torch voltage reader

Sorry but I might misunderstand something.

Where did you measure to work to PE? Like Rod said earlier, typically you have a common star ground where all the devices are grounded. This is to avoid things like grounding motors through bearings., again like Rod mentioned. If you have this kind of setup, then everything ground to the star and if you have example a non isolated metal frame AC/DC converter then the PE connects to the electrical cabinet frame, where you have a ground wire to star so the moment you connect the work lead, you have a path between PE and work. Of course you dont want random things like this, example grounding everything through a PC power supply, this is why you plan your ground wires so that everything gets grounded "good".

It would be quite unusual, not really sure if unusual is the correct word, to have the table completely separated from PE. At least you should not design the equipment to work only in this scenario if you have even a small chance to use it outside the current project.

So about the tip, hypertherm has a nice video about HF ignition HF Ignition , blow back would be the same just without the HF, its the moving start mechanism that creates the spark. So Rod made a small mistake in the start sequence, there is a separate current path from the tip back to the plasma (see the hypertherm video). You do not want to have the tip at work potential (see below).

Having the tip connected to work would sound really strange, you would want to avoid that at all cost. If the tip is in the same potential as work, its almost guaranteed to double arc, meaning you cut the tip instead of the material. Current will try to find the shortest path to travel, now look at the orifice of the tip and imagine the plasma arc going through it, then compare that to your cut height. If the tip would be at work potential its very likely that the arc would start to cut to the tip instead of the plate.

I assume what you refer as tip is not a tip/nozzle?

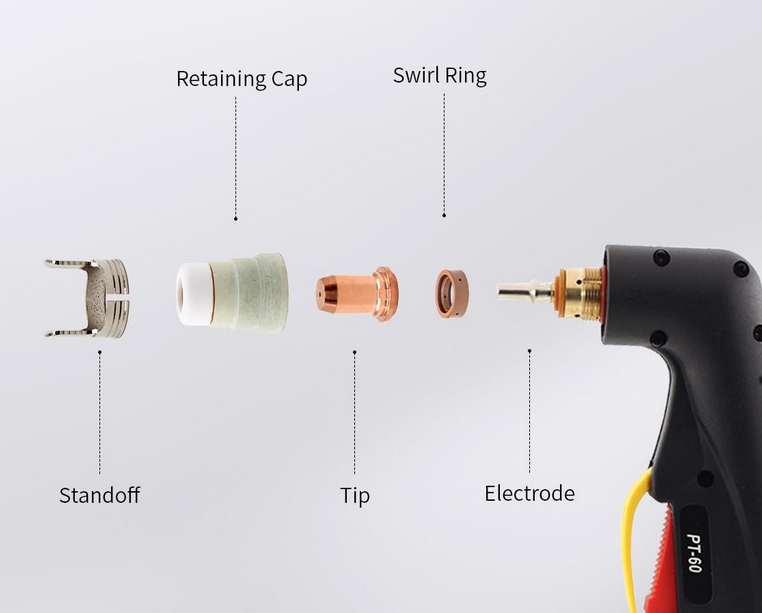

I found a random picture from some herocut manual that shows the tip/nozzle inside so its not exposed, the exposed part being shield cup. Is this your setup? Can you send a photo or something?

Where did you measure to work to PE? Like Rod said earlier, typically you have a common star ground where all the devices are grounded. This is to avoid things like grounding motors through bearings., again like Rod mentioned. If you have this kind of setup, then everything ground to the star and if you have example a non isolated metal frame AC/DC converter then the PE connects to the electrical cabinet frame, where you have a ground wire to star so the moment you connect the work lead, you have a path between PE and work. Of course you dont want random things like this, example grounding everything through a PC power supply, this is why you plan your ground wires so that everything gets grounded "good".

It would be quite unusual, not really sure if unusual is the correct word, to have the table completely separated from PE. At least you should not design the equipment to work only in this scenario if you have even a small chance to use it outside the current project.

So about the tip, hypertherm has a nice video about HF ignition HF Ignition , blow back would be the same just without the HF, its the moving start mechanism that creates the spark. So Rod made a small mistake in the start sequence, there is a separate current path from the tip back to the plasma (see the hypertherm video). You do not want to have the tip at work potential (see below).

Having the tip connected to work would sound really strange, you would want to avoid that at all cost. If the tip is in the same potential as work, its almost guaranteed to double arc, meaning you cut the tip instead of the material. Current will try to find the shortest path to travel, now look at the orifice of the tip and imagine the plasma arc going through it, then compare that to your cut height. If the tip would be at work potential its very likely that the arc would start to cut to the tip instead of the plate.

I assume what you refer as tip is not a tip/nozzle?

I found a random picture from some herocut manual that shows the tip/nozzle inside so its not exposed, the exposed part being shield cup. Is this your setup? Can you send a photo or something?

Please Log in or Create an account to join the conversation.

- Hakan

- Online

- Platinum Member

-

Less

More

- Posts: 1182

- Thank you received: 414

23 Feb 2025 19:28 #322389

by Hakan

Replied by Hakan on topic EtherCAT plasma torch voltage reader

I have a plasma cutter, I attach the ground/work lead to the steel sheet and cut. Simple as that, and everything follows from that. That PE isn't connected to the ground clamp is what I measure.

The Herocut uses a IPT60 or IPTM60 which is the straight one I have on the plasma table. Blowback start.

The electrode and the tip are normally shortened, separated when cutting. Copper tip is electrically connected to the work piece.

The Herocut uses a IPT60 or IPTM60 which is the straight one I have on the plasma table. Blowback start.

The electrode and the tip are normally shortened, separated when cutting. Copper tip is electrically connected to the work piece.

Attachments:

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

Less

More

- Posts: 157

- Thank you received: 43

23 Feb 2025 22:11 #322415

by RDA

Replied by RDA on topic EtherCAT plasma torch voltage reader

First my apologies to Rodw saying he was wrong about the tip being connected to work. I had no idea someone made plasma's this way. I guess when you want to squeeze out every dollar you would do this. As the tip is tied to work then obviously the tip sensing would not work, just like Rodw said.

I did not take a look at your schematic, probably should of, but yes you would normally have negative feedback and the positive grounded.

I did not take a look at your schematic, probably should of, but yes you would normally have negative feedback and the positive grounded.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7252

23 Feb 2025 23:35 #322416

by tommylight

Replied by tommylight on topic EtherCAT plasma torch voltage reader

Some things do not add up here, but most of the discussion is OK in general, so i did not reply till now.

As for the "Copper tip is electrically connected to the work piece", most probably you are both right, as that would have to be connected to something (even work) for it to be able to strike an arc, but also most probably it will have to be disconnected as soon as the cutting current is engaged, otherwise it would just eat through the tip that is copper and would be a puddle in under 1 second, as RDA said it will take the path of least resistance.

All this is perfectly explained in HyperTherm documentation for blow back start plasma sources, service manuals, if you can find them as they showed those behind a paywall lately.

Sorry, but i do not recall the exact procedure and inner workings, it's been 8 years since i read that.

-

As forUnusual = yes for sure, but possible as almost all my machines have a separate cutting table that is not grounded as there is no need for it since the electronics and the surrounding machine frame are all grounded properly, so despite that table acting as a huge antenna, no issues with interference at all. And some are grounded through the plasma source clamp, hence avoiding ground loops.

But, and this is a big but:

Ground everything, properly, in star formation, avoid at all cost "ground loops", use good shielded cable, that will get rid of 90% of issues, and ground the cutting table if the plasma source has no connection between PE and clamp.

As for the "Copper tip is electrically connected to the work piece", most probably you are both right, as that would have to be connected to something (even work) for it to be able to strike an arc, but also most probably it will have to be disconnected as soon as the cutting current is engaged, otherwise it would just eat through the tip that is copper and would be a puddle in under 1 second, as RDA said it will take the path of least resistance.

All this is perfectly explained in HyperTherm documentation for blow back start plasma sources, service manuals, if you can find them as they showed those behind a paywall lately.

Sorry, but i do not recall the exact procedure and inner workings, it's been 8 years since i read that.

-

As for

It would be quite unusual, not really sure if unusual is the correct word, to have the table completely separated from PE.But, and this is a big but:

Ground everything, properly, in star formation, avoid at all cost "ground loops", use good shielded cable, that will get rid of 90% of issues, and ground the cutting table if the plasma source has no connection between PE and clamp.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

24 Feb 2025 06:03 #322453

by phillc54

Replied by phillc54 on topic EtherCAT plasma torch voltage reader

It is possible to do ohmic sensing from the tip. At least it is on a Hypertherm 30XP using relay ohmic, I imagine it would work the same with a THCAD. I have been doing this for a few years now without any issues. The only mod to my torch from memory was to insert a diode, the inspiration was from

here

and

here

.

Please Log in or Create an account to join the conversation.

Time to create page: 0.136 seconds