Genserkins failure with custom robot

- Wireline

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 67

- Thank you received: 9

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21271

- Thank you received: 7262

Please Log in or Create an account to join the conversation.

- chimeno

- Offline

- Elite Member

-

- Posts: 295

- Thank you received: 125

very good!!

regards

Chimeno

Please Log in or Create an account to join the conversation.

- Wireline

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 67

- Thank you received: 9

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19797

- Thank you received: 4606

Please Log in or Create an account to join the conversation.

- thang

- Offline

- Elite Member

-

- Posts: 196

- Thank you received: 11

ERR kI - compute_jinv (joints: 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000), (iterations=0)

That shows up whenever you run a MDI command or auto mode. you can see it if u run linuxcnc from terminal.

Please Log in or Create an account to join the conversation.

- Wireline

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 67

- Thank you received: 9

hey did you fix error:

ERR kI - compute_jinv (joints: 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000), (iterations=0)

That shows up whenever you run a MDI command or auto mode. you can see it if u run linuxcnc from terminal.

Hi Thang

No I have not been able to eliminate the error, but the gcode seems to run fine and the homing problem seems to have been resolved.

Please Log in or Create an account to join the conversation.

- Wireline

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 67

- Thank you received: 9

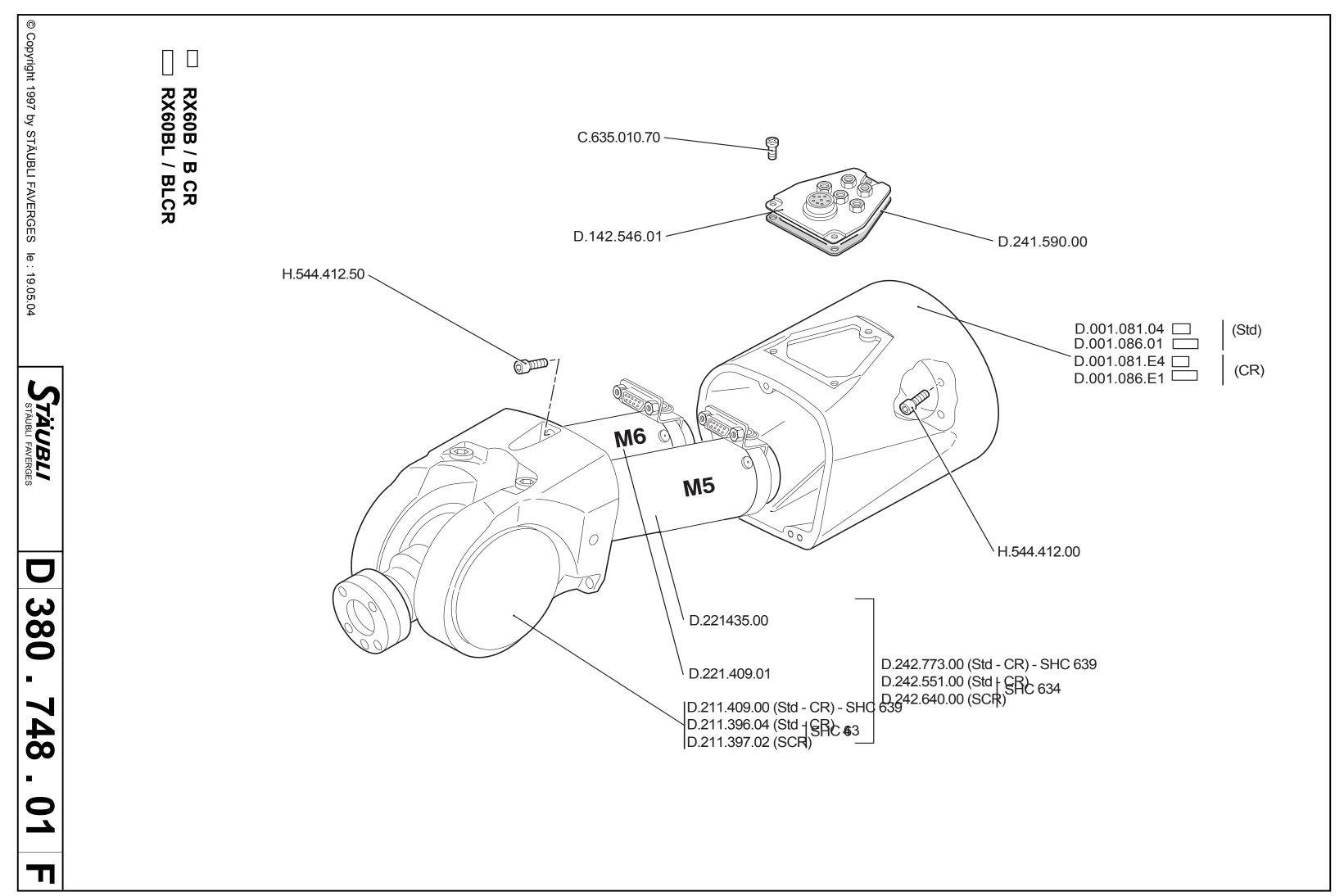

Does that Staubli have the end-effector that needs two motors to work in combination?

Hi Andy,

Good question, I am not sure. Its the RX60BL that used to be at the London Hackspace, I heard mention that you had contact with some of their members

Is this likely to cause a problem with the kinematics?

EDIT:

This is an exploded section of the arm. The end effector as far as I know is pneumatically operated, e.g. for a gripper. There are two motors each controlling joints 5 and 6.

Please Log in or Create an account to join the conversation.

- Wireline

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 67

- Thank you received: 9

Thought I would let you know that now the robot is in a realtime build, the error has disappeared. I don't know why this would be but there are other posts on the internet where people found a realtime build eliminated the problem.

Cheers

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2348

Nice work!!

It is good to see this very impressive gif animation.

For future development I issue a custom robot screen design, separate of the axis screen.

This would bring so much more user interface possebilities, and it is simple after one year of study !!

Try also external offsets and adaptive speed. For robot's it's really fun. If you have distance sensor on the gripper, you can let the robot move with external offset's from his program path and go back to it. Just like table tennis. Really amazing to see this. With laser you can use the external offsets to follow the welding path. Valk Welding does this with panasonic robot's. I worked over there years ago.

Is it possible to make a short tutorial how to make a vismach working model and how to load it into linuxcnc?

Maybe a few links, wich 3d file format to import, etc. The important issue's.

This can save other's much time.

I like to try a plasma gantry model in vismach. But i have also a seperate external rotary axis. Is it possible to make this in vismach?

Please Log in or Create an account to join the conversation.