Setting Servo Max Acceleration

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

27 Jan 2021 22:43 - 27 Jan 2021 22:49 #196837

by Michael

These both look interesting but does it limit it over the entire velocity command or can it be tailored to just the initial acceleration? And what sort of values would I be looking at?

Replied by Michael on topic Setting Servo Max Acceleration

You might be able to dial the current back by limiting the PID.

There are a number of parameters that could help.

pid.N.maxoutput float in

Output limit. The absolute value of the output will not be permitted to exceed maxoutput, unless maxoutput is zero. When the output is limited, the error integrator will hold instead of integrating, to prevent windup and overshoot.

pid.N.maxerror float in

Limit on the internal error variable used for P, I, and D. Can be used to prevent high Pgain values from generating large outputs under conditions when the error is large (for example, when the command makes a step change). Not normally needed, but can be useful when tuning non-linear systems.

These both look interesting but does it limit it over the entire velocity command or can it be tailored to just the initial acceleration? And what sort of values would I be looking at?

Last edit: 27 Jan 2021 22:49 by Michael.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17611

- Thank you received: 5149

27 Jan 2021 23:02 #196844

by PCW

Replied by PCW on topic Setting Servo Max Acceleration

if you bound the maxerror, that will limit the correction but not the

main velocity command (which is not an error but rather a feed

forward term determined by FF1)

You could do a rough check of the analog output delay by

looping back an analog output to one of the analog inputs on the field I/O

main velocity command (which is not an error but rather a feed

forward term determined by FF1)

You could do a rough check of the analog output delay by

looping back an analog output to one of the analog inputs on the field I/O

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

28 Jan 2021 15:08 #196946

by Mike_Eitel

Replied by Mike_Eitel on topic Setting Servo Max Acceleration

Hi Michael

If you really want to know the physical possibilities of your hw this is not to difficult.

Use two (new) in dependant switches and position them in the middle of your axes in safe distance to both ends. Write a bit of hal that just inverts he direction of your axle movement. In a way that the axis moves between those two positions. But do not forget the needed breaking distance. Start slow and test. Than augment your analog value till you reach fasted oscillation. That's the max of your system

AND HAVE YOUR HAND OVER E-STOP. ALWAYS!!!

If you really want to know the physical possibilities of your hw this is not to difficult.

Use two (new) in dependant switches and position them in the middle of your axes in safe distance to both ends. Write a bit of hal that just inverts he direction of your axle movement. In a way that the axis moves between those two positions. But do not forget the needed breaking distance. Start slow and test. Than augment your analog value till you reach fasted oscillation. That's the max of your system

AND HAVE YOUR HAND OVER E-STOP. ALWAYS!!!

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17611

- Thank you received: 5149

28 Jan 2021 17:30 #196974

by PCW

Replied by PCW on topic Setting Servo Max Acceleration

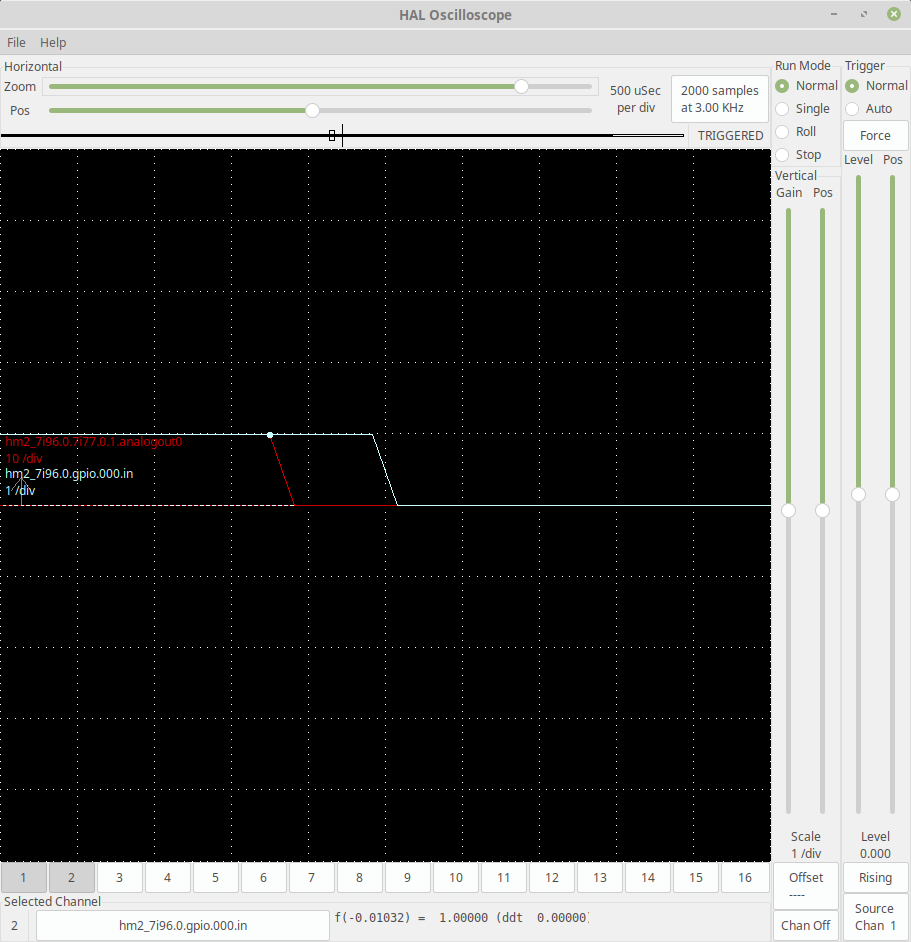

Here is a halscope plot of a 7I77 analog output driving a isolated input

(10V analog out driving input with ~5V threshold):

Note that about 1/2 of the total roughly 666 usec delay

is the 1 servo period pipeline delay (333 usec in this case)

due to the analog write being done at the end of one servo

thread invocation and the GPIO read being done at the

beginning of the next servo thread invocation.

This shows that the delay from LinuxCNC write to

analog output is in the region of 333 usec.

The one servo-thread period pipeline delay

is compensated in the PID via the

"pid.N.error-previous-target" bit being set true.

(10V analog out driving input with ~5V threshold):

Note that about 1/2 of the total roughly 666 usec delay

is the 1 servo period pipeline delay (333 usec in this case)

due to the analog write being done at the end of one servo

thread invocation and the GPIO read being done at the

beginning of the next servo thread invocation.

This shows that the delay from LinuxCNC write to

analog output is in the region of 333 usec.

The one servo-thread period pipeline delay

is compensated in the PID via the

"pid.N.error-previous-target" bit being set true.

Attachments:

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

09 Feb 2021 17:41 #198169

by Michael

Replied by Michael on topic Setting Servo Max Acceleration

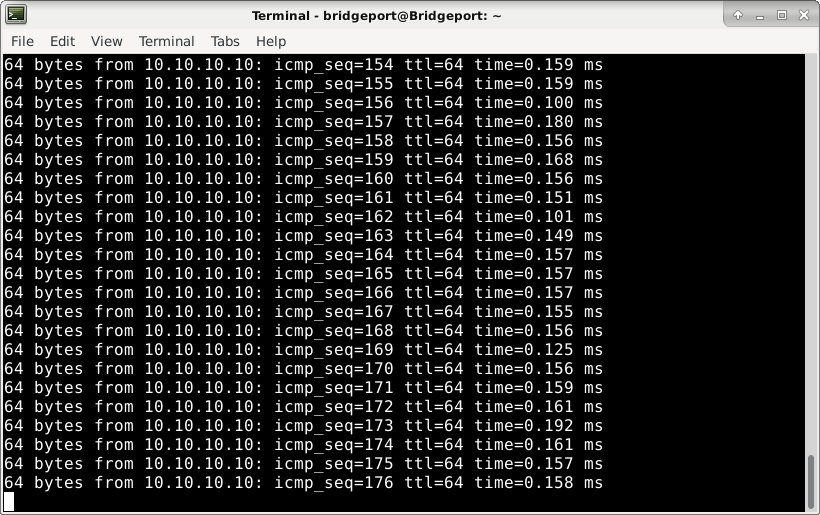

Before I ditch using these servos in analog mode altogether I wanted to check these ping times are accurate. The very first ping was .310ms and then there are a couple intermittent ones that approach .200ms but for the most part are around .150ms. Any thoughts on these times or ways to improve them if we can?

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17611

- Thank you received: 5149

09 Feb 2021 18:19 - 09 Feb 2021 18:22 #198173

by PCW

Replied by PCW on topic Setting Servo Max Acceleration

The first ping will tend to be longer because the ARP cache data will have expired

and a ARP transaction will be needed before the first ICMP echo request (ping) can proceed.

(the driver disables ARP while running)

As long as the servo thread can run without violating real time constraints the actual timing

is not terribly important, as sampling events (such as reading the encoders or stepgens

position) that affect motion can be re-timed by the DPLL

and a ARP transaction will be needed before the first ICMP echo request (ping) can proceed.

(the driver disables ARP while running)

As long as the servo thread can run without violating real time constraints the actual timing

is not terribly important, as sampling events (such as reading the encoders or stepgens

position) that affect motion can be re-timed by the DPLL

Last edit: 09 Feb 2021 18:22 by PCW.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

09 Feb 2021 18:30 #198175

by Michael

Replied by Michael on topic Setting Servo Max Acceleration

I did try and play with the DPLL and encoder timing in a few different ways and only managed to make things worse. This included the encoder sample frequency filter between true and false, none of which shortened the delay time.

Short of a "real oscilloscope" reading on the drives analog input and encoder output, the manufacturer won't acknowledge that the drive response is the issue. I don't have an oscilloscope.

Short of a "real oscilloscope" reading on the drives analog input and encoder output, the manufacturer won't acknowledge that the drive response is the issue. I don't have an oscilloscope.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17611

- Thank you received: 5149

09 Feb 2021 18:48 #198177

by PCW

Replied by PCW on topic Setting Servo Max Acceleration

The DPLL does not shorten the delay time, it just reduces the uncertainly in the sampling time.

Note that my plot shows ~666 usec delay from commanded analog out to detected read data

and as I explained, because of the:

1. Read (encoders)

2. Process data

3 Write (Analog)

4. Wait until next servo thread invocation (step 1)

ordering of operations, about 1/2 of this 666 usec delay is inherent in LinuxCNCs

read. process, write operational sequence. So our hardware /LinuxCNC/Host Ethernet

overhead is only responsible for at most a few 100 usec of delay. The rest is in the drive.

Note that my plot shows ~666 usec delay from commanded analog out to detected read data

and as I explained, because of the:

1. Read (encoders)

2. Process data

3 Write (Analog)

4. Wait until next servo thread invocation (step 1)

ordering of operations, about 1/2 of this 666 usec delay is inherent in LinuxCNCs

read. process, write operational sequence. So our hardware /LinuxCNC/Host Ethernet

overhead is only responsible for at most a few 100 usec of delay. The rest is in the drive.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

09 Feb 2021 18:55 #198180

by Michael

Replied by Michael on topic Setting Servo Max Acceleration

Oh I agree with you and have no doubts that Linuxcnc is solid. Thank you for all the help.

Just getting the drive manufacturer to accept the halscope as fact was surprisingly impossible. I will be running them in position mode until I can afford better servos/drives.

Just getting the drive manufacturer to accept the halscope as fact was surprisingly impossible. I will be running them in position mode until I can afford better servos/drives.

Please Log in or Create an account to join the conversation.

Time to create page: 0.156 seconds