- Configuring LinuxCNC

- Advanced Configuration

- Using a servo as a spindle and positional axis - keep getting vague errors

Using a servo as a spindle and positional axis - keep getting vague errors

- ffffrf

- Offline

- Senior Member

-

Less

More

- Posts: 51

- Thank you received: 2

03 Apr 2025 00:56 #325564

by ffffrf

Using a servo as a spindle and positional axis - keep getting vague errors was created by ffffrf

Hello,

I have a little lathe that was originally using a bldc motor. I wanted to change it out with a servo motor and use it both in positional mode, but also with turning. I went through the basic configurations in pncconf using my mesa 7i96s and got it to work as a turning machine with a stepgen spindle.

I read about the possibility of using mux2 to switch between the two modes but I am stuck getting strange errors like command 176, etc. I cant figure out how to debug or what I need to change in my INI and HAL (I have two hal files I am using). I am wondering if someone could look over my files and see if I am missing something obvious? I keep staring at it and am getting nowhere...

I config'd it as an XZ lathe with stepgen spindle originally. I have to HAL files I use: C+turning and the mux HAL

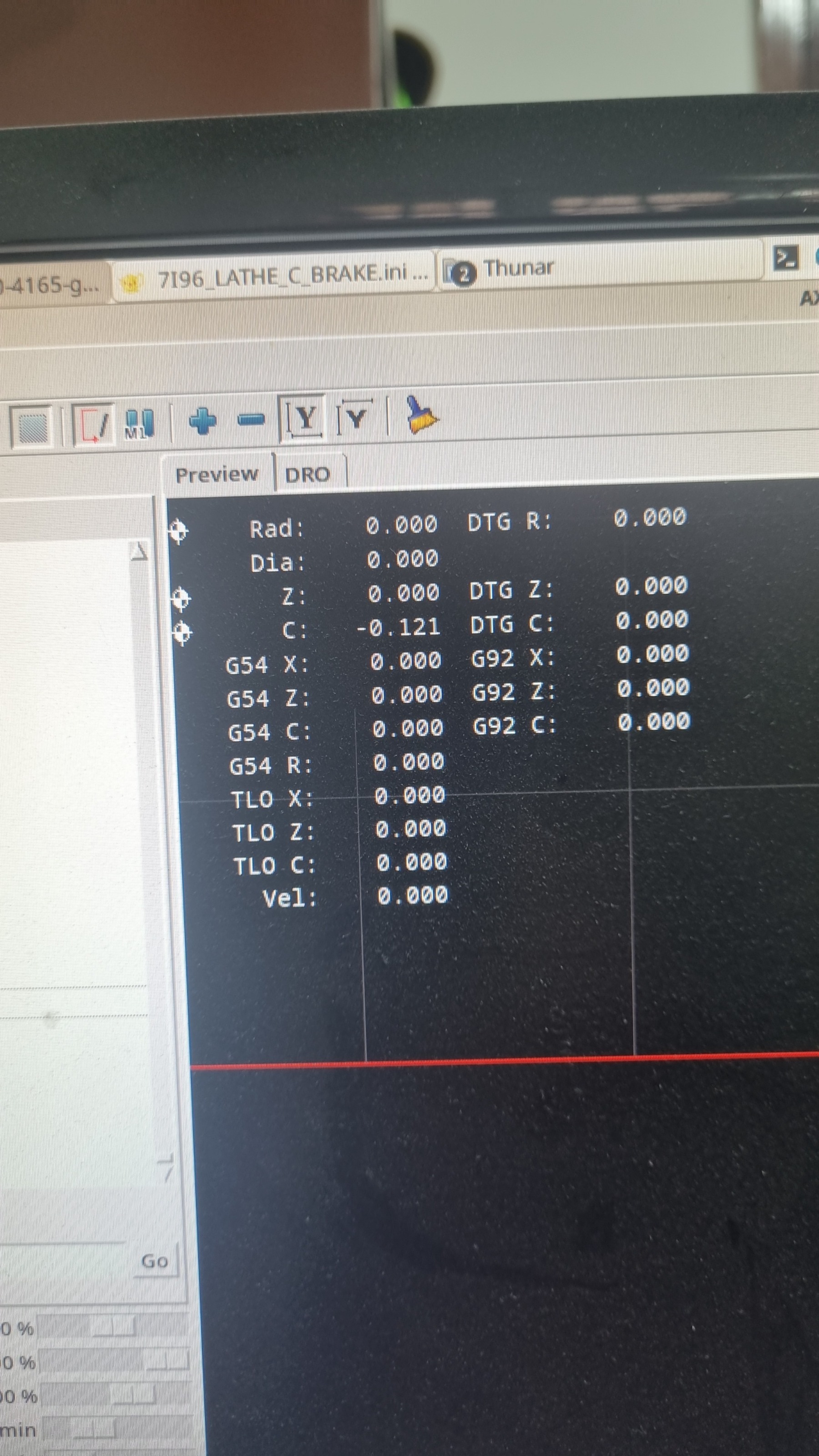

My current issue is as follows: The program compiles and opens. I then home axis, which causes my X and Z axis to home. I can now move those freely. However, when I go to try and move the C axis, I get "error on joint 2" and on terminal it just gives all sorts of "command" errors that I cant seem to debug further. Has anyone experienced this?

Main HAL:

Auxillary HAL

INI FILE

I have a little lathe that was originally using a bldc motor. I wanted to change it out with a servo motor and use it both in positional mode, but also with turning. I went through the basic configurations in pncconf using my mesa 7i96s and got it to work as a turning machine with a stepgen spindle.

I read about the possibility of using mux2 to switch between the two modes but I am stuck getting strange errors like command 176, etc. I cant figure out how to debug or what I need to change in my INI and HAL (I have two hal files I am using). I am wondering if someone could look over my files and see if I am missing something obvious? I keep staring at it and am getting nowhere...

I config'd it as an XZ lathe with stepgen spindle originally. I have to HAL files I use: C+turning and the mux HAL

My current issue is as follows: The program compiles and opens. I then home axis, which causes my X and Z axis to home. I can now move those freely. However, when I go to try and move the C axis, I get "error on joint 2" and on terminal it just gives all sorts of "command" errors that I cant seem to debug further. Has anyone experienced this?

Main HAL:

# Generated by PNCconf at Wed Apr 2 16:24:00 2025

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_eth board_ip="10.10.10.10" config="num_encoders=1 num_pwmgens=1 num_stepgens=5 sserial_port_0=0xxxxxxx"

setp hm2_7i96s.0.pwmgen.pwm_frequency 20000

setp hm2_7i96s.0.pwmgen.pdm_frequency 6000000

setp hm2_7i96s.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.z,pid.s,pid.c

loadrt near

addf hm2_7i96s.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf pid.c.do-pid-calcs servo-thread

addf near.0 servo-thread

addf hm2_7i96s.0.write servo-thread

setp hm2_7i96s.0.dpll.01.timer-us -50

setp hm2_7i96s.0.stepgen.timer-number 1

# external output signals

# --- X-ENABLE ---

net x-enable => hm2_7i96s.0.ssr.00.out-00

# --- Z-ENABLE ---

net z-enable => hm2_7i96s.0.ssr.00.out-01

# external input signals

# --- MIN-HOME-X ---

net min-home-x <= hm2_7i96s.0.inm.00.input-00-not

# --- MAX-HOME-Z ---

net max-home-z <= hm2_7i96s.0.inm.00.input-01-not

# --- ESTOP-EXT ---

net estop-ext <= hm2_7i96s.0.inm.00.input-02

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp hm2_7i96s.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i96s.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i96s.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i96s.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i96s.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i96s.0.stepgen.00.step_type 0

setp hm2_7i96s.0.stepgen.00.control-type 1

setp hm2_7i96s.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_7i96s.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

setp hm2_7i96s.0.stepgen.00.step.invert_output true

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => hm2_7i96s.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i96s.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_7i96s.0.stepgen.00.enable

# ---setup home / limit switch signals---

net min-home-x => joint.0.home-sw-in

net min-home-x => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Z JOINT 1

#*******************

setp pid.z.Pgain [JOINT_1]P

setp pid.z.Igain [JOINT_1]I

setp pid.z.Dgain [JOINT_1]D

setp pid.z.bias [JOINT_1]BIAS

setp pid.z.FF0 [JOINT_1]FF0

setp pid.z.FF1 [JOINT_1]FF1

setp pid.z.FF2 [JOINT_1]FF2

setp pid.z.deadband [JOINT_1]DEADBAND

setp pid.z.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp hm2_7i96s.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_7i96s.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_7i96s.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_7i96s.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_7i96s.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_7i96s.0.stepgen.01.step_type 0

setp hm2_7i96s.0.stepgen.01.control-type 1

setp hm2_7i96s.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_7i96s.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

setp hm2_7i96s.0.stepgen.01.step.invert_output true

# ---closedloop stepper signals---

net z-pos-cmd <= joint.1.motor-pos-cmd

net z-vel-cmd <= joint.1.vel-cmd

net z-output => hm2_7i96s.0.stepgen.01.velocity-cmd

net z-pos-fb <= hm2_7i96s.0.stepgen.01.position-fb

net z-pos-fb => joint.1.motor-pos-fb

net z-enable <= joint.1.amp-enable-out

net z-enable => hm2_7i96s.0.stepgen.01.enable

# ---setup home / limit switch signals---

net max-home-z => joint.1.home-sw-in

net z-neg-limit => joint.1.neg-lim-sw-in

net max-home-z => joint.1.pos-lim-sw-in

#*******************

# AXIS C JOINT 2

#*******************

setp pid.c.Pgain [JOINT_2]P

setp pid.c.Igain [JOINT_2]I

setp pid.c.Dgain [JOINT_2]D

setp pid.c.bias [JOINT_2]BIAS

setp pid.c.FF0 [JOINT_2]FF0

setp pid.c.FF1 [JOINT_2]FF1

setp pid.c.FF2 [JOINT_2]FF2

setp pid.c.deadband [JOINT_2]DEADBAND

setp pid.c.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.c.error-previous-target true

setp pid.c.maxerror 0.012700

net c-index-enable => pid.c.index-enable

net c-axis-pos-cmd => pid.c.command

net c-pos-fb => pid.c.feedback

net c-output <= pid.c.output

# ---closedloop stepper setup---

net c-vel-cmd <= joint.2.vel-cmd

net c-output => hm2_7i96s.0.stepgen.04.velocity-cmd

net c-pos-fb <= hm2_7i96s.0.stepgen.04.position-fb

net c-pos-fb => joint.2.motor-pos-fb

net c-enable <= joint.2.amp-enable-out

net spindle-enable => pid.c.enable

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.s.maxerror 0.012700

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# Step Gen signals/setup

setp hm2_7i96s.0.stepgen.04.dirsetup [SPINDLE_0]DIRSETUP

setp hm2_7i96s.0.stepgen.04.dirhold [SPINDLE_0]DIRHOLD

setp hm2_7i96s.0.stepgen.04.steplen [SPINDLE_0]STEPLEN

setp hm2_7i96s.0.stepgen.04.stepspace [SPINDLE_0]STEPSPACE

setp hm2_7i96s.0.stepgen.04.position-scale [SPINDLE_0]STEP_SCALE

setp hm2_7i96s.0.stepgen.04.step_type 0

setp hm2_7i96s.0.stepgen.04.control-type 1

setp hm2_7i96s.0.stepgen.04.maxaccel [SPINDLE_0]STEPGEN_MAXACCEL

setp hm2_7i96s.0.stepgen.04.maxvel [SPINDLE_0]STEPGEN_MAXVEL

setp hm2_7i96s.0.stepgen.04.step.invert_output true

#net machine-is-on => hm2_7i96s.0.stepgen.04.enable

#net spindle-vel-cmd-rps => hm2_7i96s.0.stepgen.04.velocity-cmd

# ---Encoder feedback signals/setup---

setp hm2_7i96s.0.encoder.00.counter-mode 0

setp hm2_7i96s.0.encoder.00.filter 1

setp hm2_7i96s.0.encoder.00.index-invert 0

setp hm2_7i96s.0.encoder.00.index-mask 0

setp hm2_7i96s.0.encoder.00.index-mask-invert 0

setp hm2_7i96s.0.encoder.00.scale [SPINDLE_0]ENCODER_SCALE

net spindle-revs <= hm2_7i96s.0.encoder.00.position

net spindle-vel-fb-rps <= hm2_7i96s.0.encoder.00.velocity

net spindle-vel-fb-rpm <= hm2_7i96s.0.encoder.00.velocity-rpm

net spindle-index-enable <=> hm2_7i96s.0.encoder.00.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

net spindle-vel-cmd-rps => near.0.in1

net spindle-vel-fb-rps => near.0.in2

net spindle-at-speed <= near.0.out

setp near.0.scale 1.000000

setp near.0.difference 3.333333

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.1.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---Use external manual tool change dialog---

loadusr -W hal_manualtoolchange

net tool-change-request => hal_manualtoolchange.change

net tool-change-confirmed <= hal_manualtoolchange.changed

net tool-number => hal_manualtoolchange.number

# ---ignore tool prepare requests---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-preparedAuxillary HAL

# Include your custom HAL commands here

# This file will not be overwritten when you run PNCconf again

loadrt mux2 count=1

addf mux2.0 servo-thread

# Mux inputs

net c-axis-pos-cmd joint.2.motor-pos-cmd => mux2.0.in0

net spindle-vel-cmd-rpm => mux2.0.in1

net spindle-enable => mux2.0.sel

net spindle-enable => hm2_7i96s.0.stepgen.04.enable

# Mux output to stepgen.04

net mux-out mux2.0.out => hm2_7i96s.0.stepgen.04.position-cmd

# Feedback and enable

net c-pos-fb <= hm2_7i96s.0.stepgen.04.position-fb

net c-pos-fb => joint.2.motor-pos-fbINI FILE

# Generated by PNCconf at Wed Apr 2 16:24:00 2025

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = Turn+C_lathe

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = axis

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/maksym/linuxcnc/nc_files

PYVCP = pyvcp-panel.xml

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

LATHE = 1

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 13.333333

MAX_LINEAR_VELOCITY = 41.666667

MIN_LINEAR_VELOCITY = 0.500000

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyz

CYCLE_TIME = 100

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

RS274NGC_STARTUP_CODE = G21 G40 G90 G94 G97 G64 P0.025

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1000000

[HMOT]

# **** This is for info only ****

CARD0=hm2_7i96s.0

[HAL]

HALUI = halui

HALFILE = Turn+C_lathe.hal

HALFILE = c_axis_mux.hal

HALFILE = custom.hal

POSTGUI_HALFILE = custom_postgui.hal

SHUTDOWN = shutdown.hal

[HALUI]

[KINS]

JOINTS = 3

KINEMATICS = trivkins coordinates=XZC

[TRAJ]

COORDINATES = XZC

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 4.17

MAX_LINEAR_VELOCITY = 41.67

NO_FORCE_HOMING = 1

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#******************************************

[AXIS_X]

MAX_VELOCITY = 41.666666666666664

MAX_ACCELERATION = 500.0

MIN_LIMIT = -0.0

MAX_LIMIT = 100.0

[JOINT_0]

TYPE = LINEAR

HOME = 20.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 41.666666666666664

MAX_ACCELERATION = 500.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 52.08

STEPGEN_MAXACCEL = 625.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 10000

STEPSPACE = 10000

STEP_SCALE = -800.0

MIN_LIMIT = -0.0

MAX_LIMIT = 100.0

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = -13.333333

HOME_LATCH_VEL = -0.500000

HOME_FINAL_VEL = 5.000000

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = 2

#******************************************

#******************************************

[AXIS_Z]

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

MIN_LIMIT = -432.0

MAX_LIMIT = 0.0

[JOINT_1]

TYPE = LINEAR

HOME = -20.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 31.25

STEPGEN_MAXACCEL = 937.50

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 10000

STEPSPACE = 10000

STEP_SCALE = 800.0

MIN_LIMIT = -432.0

MAX_LIMIT = 0.0

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = -13.333333

HOME_LATCH_VEL = -0.500000

HOME_FINAL_VEL = 5.000000

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = 1

#******************************************

#******************************************

[AXIS_C]

MAX_VELOCITY = 360

MAX_ACCELERATION = 720

MIN_LIMIT = -999999

MAX_LIMIT = 999999

ANGULAR = 1

[JOINT_2]

TYPE = ANGULAR

HOME = 0

FERROR = 5

MIN_FERROR = 1.0

MAX_VELOCITY = 360

MAX_ACCELERATION = 720

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 400

STEPGEN_MAXACCEL = 800

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 27.77778

HOME_SEQUENCE = 0

[SPINDLE_0]

MAX_VELOCITY = 3.3333333333333335

MAX_ACCELERATION = 300.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 4.17

STEPGEN_MAXACCEL = 375.00

P = 0.0

I = 0.0

D = 0.0

FF0 = 1.0

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 2000.0

ENCODER_SCALE = 8000.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = -1000.0Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17628

- Thank you received: 5157

03 Apr 2025 04:47 #325584

by PCW

Replied by PCW on topic Using a servo as a spindle and positional axis - keep getting vague errors

its fairly complex...

You might take a look at this, using the orient component.

forum.linuxcnc.org/10-advanced-configura...is-from-inside-gcode

You might take a look at this, using the orient component.

forum.linuxcnc.org/10-advanced-configura...is-from-inside-gcode

Please Log in or Create an account to join the conversation.

- ffffrf

- Offline

- Senior Member

-

Less

More

- Posts: 51

- Thank you received: 2

03 Apr 2025 05:45 #325585

by ffffrf

Replied by ffffrf on topic Using a servo as a spindle and positional axis - keep getting vague errors

sadly so yes, although i cannot help but think there must be a simpler way to do this with mux, just somehow switch between position and velocity modes depending on an input

Please Log in or Create an account to join the conversation.

- COFHAL

- Offline

- Platinum Member

-

Less

More

- Posts: 421

- Thank you received: 56

03 Apr 2025 07:20 - 03 Apr 2025 07:31 #325591

by COFHAL

Replied by COFHAL on topic Using a servo as a spindle and positional axis - keep getting vague errors

Attachments:

Last edit: 03 Apr 2025 07:31 by COFHAL.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4649

- Thank you received: 2068

03 Apr 2025 09:21 #325598

by Aciera

Replied by Aciera on topic Using a servo as a spindle and positional axis - keep getting vague errors

This config might also be of interest:

forum.linuxcnc.org/38-general-linuxcnc-q...blem?start=20#324276

forum.linuxcnc.org/38-general-linuxcnc-q...blem?start=20#324276

Please Log in or Create an account to join the conversation.

- ffffrf

- Offline

- Senior Member

-

Less

More

- Posts: 51

- Thank you received: 2

03 Apr 2025 14:22 #325616

by ffffrf

Replied by ffffrf on topic Using a servo as a spindle and positional axis - keep getting vague errors

cheapo 1kw servo motor

motor model A2M-80SV03230

driver S2SVD20

It works well and was generally easy to get running, atleast without the whole switching between c axis and turning

motor model A2M-80SV03230

driver S2SVD20

It works well and was generally easy to get running, atleast without the whole switching between c axis and turning

Please Log in or Create an account to join the conversation.

- ffffrf

- Offline

- Senior Member

-

Less

More

- Posts: 51

- Thank you received: 2

03 Apr 2025 14:23 #325617

by ffffrf

Replied by ffffrf on topic Using a servo as a spindle and positional axis - keep getting vague errors

thank you I will take a look at that

Please Log in or Create an account to join the conversation.

- COFHAL

- Offline

- Platinum Member

-

Less

More

- Posts: 421

- Thank you received: 56

03 Apr 2025 18:50 #325636

by COFHAL

Replied by COFHAL on topic Using a servo as a spindle and positional axis - keep getting vague errors

This setup works for me. My servo is a LICHUAN, so you need to install the caxis.comp and gn_userkins.comp components, create a remaps folder, and save the two ngc files there.

Attachments:

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- COFHAL

- Offline

- Platinum Member

-

Less

More

- Posts: 421

- Thank you received: 56

03 Apr 2025 19:06 #325638

by COFHAL

Replied by COFHAL on topic Using a servo as a spindle and positional axis - keep getting vague errors

Do you have the servo driver manual?

Please Log in or Create an account to join the conversation.

- ffffrf

- Offline

- Senior Member

-

Less

More

- Posts: 51

- Thank you received: 2

04 Apr 2025 02:53 #325651

by ffffrf

Replied by ffffrf on topic Using a servo as a spindle and positional axis - keep getting vague errors

Hey - yes I do have the servo manual, however, it is not letting me attach it to the email as it says the attachment size exceeds the result.... Is there any other way I can send it? I would also love to ask you a couple more question on your setup if possible to learn more about how you went about making it incase I need to modify things. Do you have a discord account or something?

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- Using a servo as a spindle and positional axis - keep getting vague errors

Time to create page: 0.248 seconds