Retrofitting a 1986 Maho MH400E

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

07 Oct 2017 17:32 - 07 Oct 2017 17:34 #100054

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

I am planning to put this on the cabin, and mounting it to the side.

www.google.gr/search?q=Fazn+Firefly+II+M...imgrc=FkhBsjGU3J278M:

www.google.gr/search?q=Fazn+Firefly+II+M...imgrc=FkhBsjGU3J278M:

Last edit: 07 Oct 2017 17:34 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1571

- Thank you received: 580

07 Oct 2017 19:31 - 07 Oct 2017 20:34 #100057

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

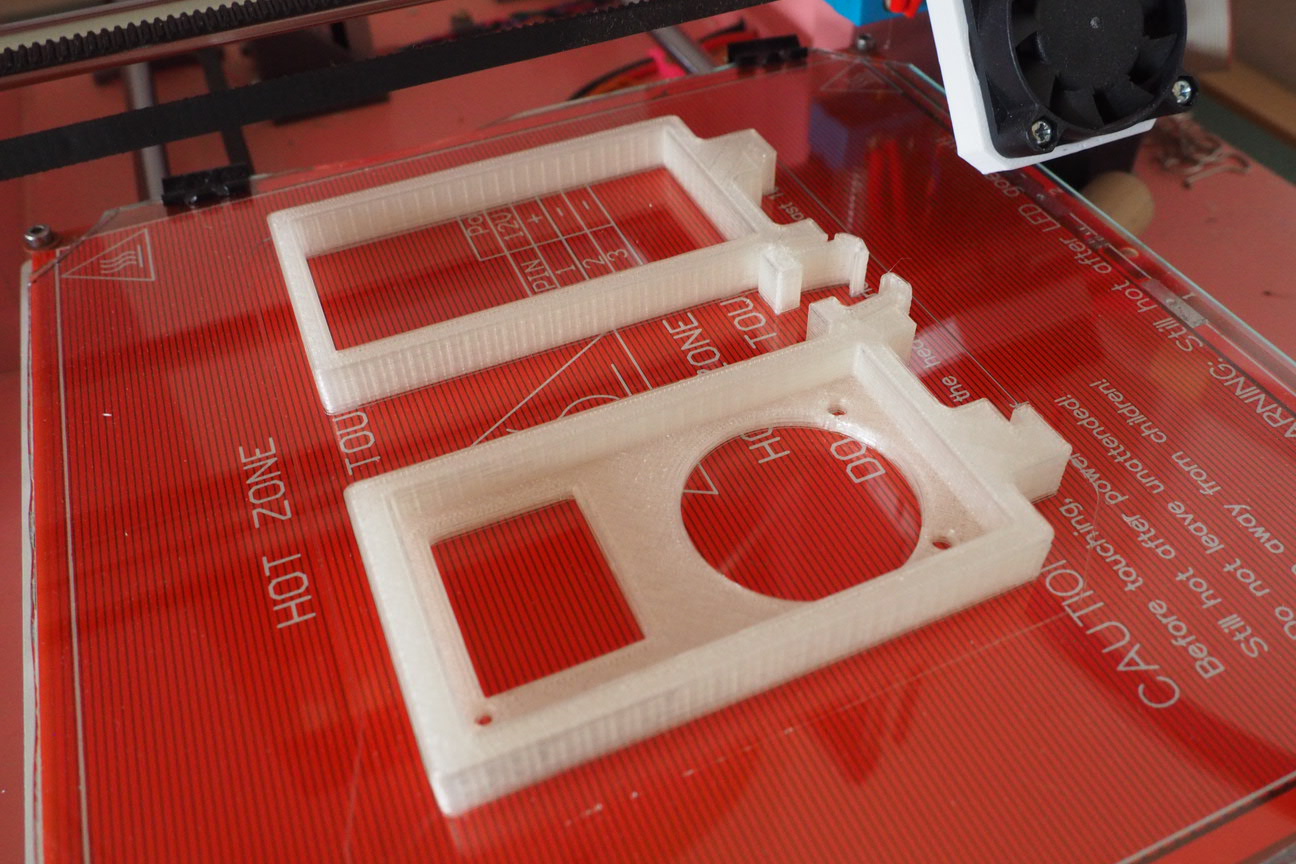

The 3D printer is a development of the Mendel90 which a friend of mine designed. I only finished making it in summer, so I don't have much experience with it yet, but it is really handy for making smallish plastic parts like those DIN rail adaptors. If you need any brackets /adapters etc made for your control cabinet, just send me a .STL file, and I can try to print it.

If you have the resolvers closing the velocity loop with the indramat, and glass scales closing the position loop back to LinuxCNC, what do you want to add motor encoders for?

I was also going to put my PC in the cabinet it its case, but it was a really small Micro.ITX form case, and the MESA 5i25 was too tall for the case, so I chopped it up, and attached the tray to my back plane.

Mark

If you have the resolvers closing the velocity loop with the indramat, and glass scales closing the position loop back to LinuxCNC, what do you want to add motor encoders for?

I was also going to put my PC in the cabinet it its case, but it was a really small Micro.ITX form case, and the MESA 5i25 was too tall for the case, so I chopped it up, and attached the tray to my back plane.

Mark

Last edit: 07 Oct 2017 20:34 by RotarySMP.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

08 Oct 2017 02:53 #100068

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

With the encoders on the motor it will be much easier to tune the PID loop, mostly due to zero backlash. With the scales you get ultimate accuracy, but it is much more difficult to tune. The maho engineers had the knowledge and skills to properly tune a system with scales, but I am no were near their level.

It is possible that I am overthinking this, but I feel more comfortable with this approach.

It is possible that I am overthinking this, but I feel more comfortable with this approach.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1571

- Thank you received: 580

08 Oct 2017 07:38 - 08 Oct 2017 10:04 #100069

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks for explaining that decision, John. So will the glass scale info be fed back LinuxCNC at all?

It looks like the VGA and USB cables from the PC out to the monitor and control panel will be about 5m long. I took a quick look at the MAHO cable conduit, and it might be a challenge to get a VGA cable down it. I need to remove the existing Phillips control panel and have a closer look.

Mark

It looks like the VGA and USB cables from the PC out to the monitor and control panel will be about 5m long. I took a quick look at the MAHO cable conduit, and it might be a challenge to get a VGA cable down it. I need to remove the existing Phillips control panel and have a closer look.

Mark

Last edit: 08 Oct 2017 10:04 by RotarySMP.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

08 Oct 2017 08:32 - 08 Oct 2017 08:40 #100070

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Hi, for now I am not going to feed the scales to LinuxCnc. In the future I may tray dual loop

John

There is vga to Ethernet adapters, if the vga is not fit insight the cable pipe.

www.aliexpress.com/item/Hot-Selling-New-...earch0301.4.8.oR4aH0

John

There is vga to Ethernet adapters, if the vga is not fit insight the cable pipe.

www.aliexpress.com/item/Hot-Selling-New-...earch0301.4.8.oR4aH0

Last edit: 08 Oct 2017 08:40 by drimaropoylos.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1571

- Thank you received: 580

08 Oct 2017 10:14 - 08 Oct 2017 10:18 #100075

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Last edit: 08 Oct 2017 10:18 by RotarySMP.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

08 Oct 2017 17:40 #100087

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

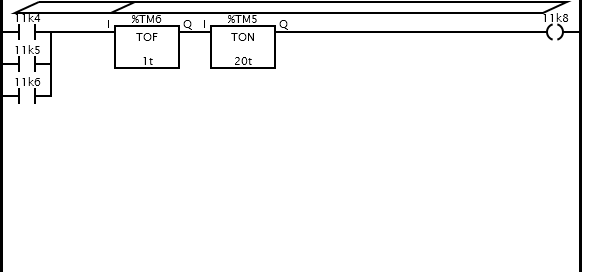

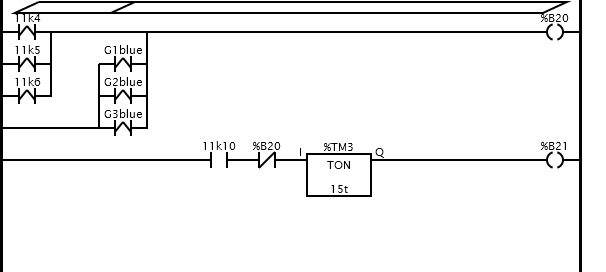

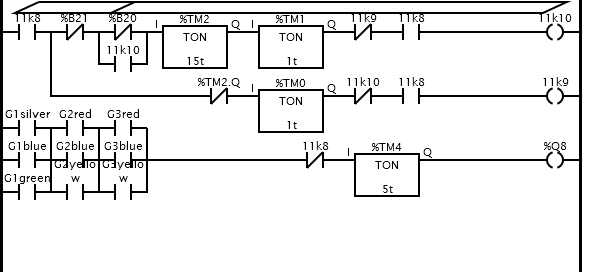

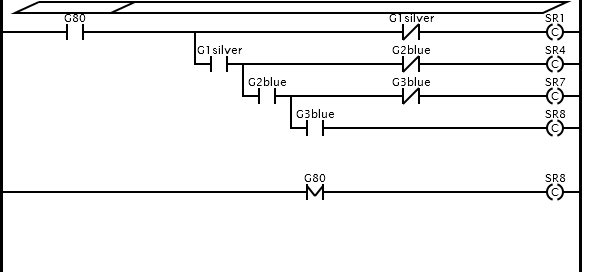

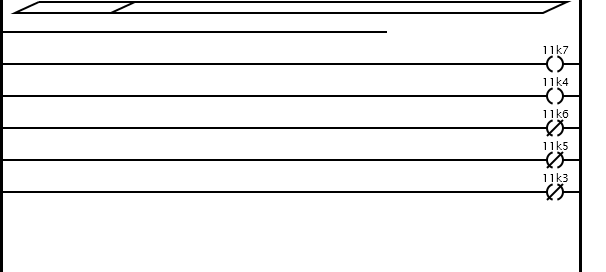

Hi, this is what I have done so far. I have included the ladder file and the pins (inputs and outputs) are configured for the 7i84 (in custom.hal file). I can’t test it because I don’t have 7i84. I haven’t assigned any input or output on the 7i77. You have to place the files in configuration folder and then you run pncconf and modify the MH400E . The ladder logic and custom.hal are safe from changes from pncconf wizard. Connect 5volt and 24 volt to mesa cards (7i77,7i84) and run the file from “application menu-CNC-LinuxCnc-MH400E”. to check the logic start from the axis menu “file-ladder”. When you start the spindle and choose a speed the ladder starts to enable the outputs on the 7i84. Don’t connect any hardware of the machine yet.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

08 Oct 2017 17:46 - 08 Oct 2017 18:10 #100089

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

In my machine the gearbox is upside down compared to yours, so we have to check that the cams rotate to the direction that supposed to.

Last edit: 08 Oct 2017 18:10 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

08 Oct 2017 18:29 #100091

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

In MH400E.hal if you put a # in front of “sets spindle-at-speed true” than the ladder can control this item and pause the feed in all axis wen a change in speed is commanded. If this solution is not desirable than I will experiment with spindle-enable out command from LinuxCnc, using it to disable any gear change while the spindle is on. And enable the gear change when we stop the spindle. But the problem then is that when we stop the spindle the commanded speed is 0 and the ladder won’t know what speed to command.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

09 Oct 2017 08:12 - 09 Oct 2017 08:15 #100114

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Last edit: 09 Oct 2017 08:15 by drimaropoylos.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.557 seconds