Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

09 Oct 2017 12:16 - 09 Oct 2017 15:09 #100118

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Last edit: 09 Oct 2017 15:09 by RotarySMP.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

09 Oct 2017 17:58 #100120

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

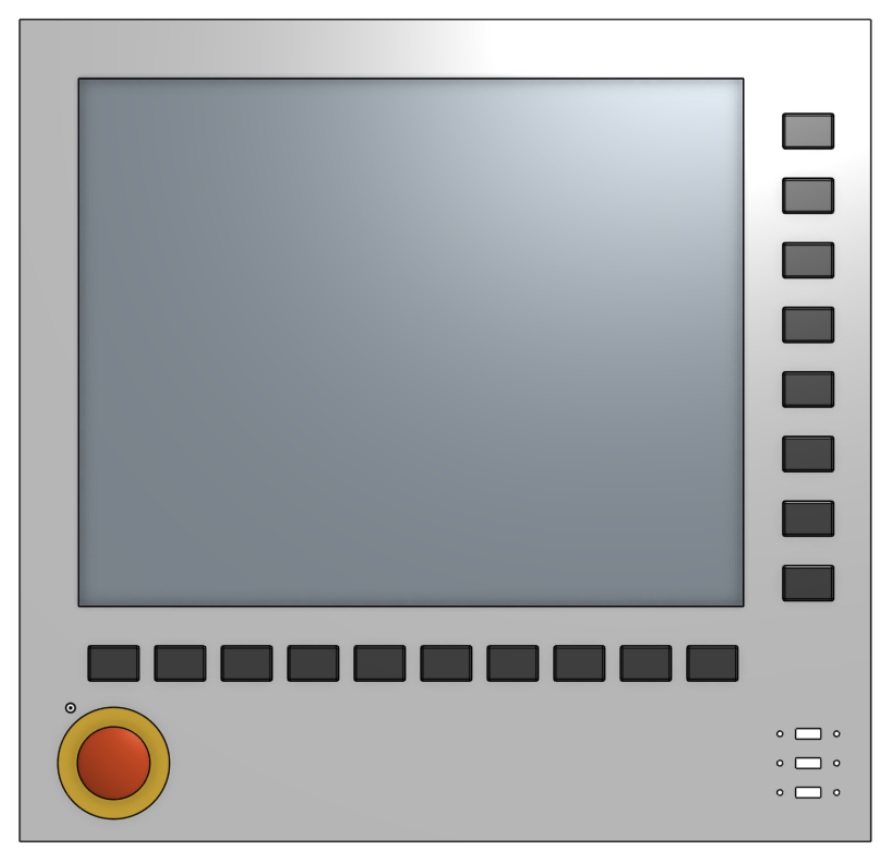

Cool, nice and simple. The 3 futures down right are usb?

John

John

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

09 Oct 2017 18:10 #100121

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

The sexiest diy controller.

www.cnczone.com/forums/news-announcement...20-cnc-software.html

www.cnczone.com/forums/news-announcement...20-cnc-software.html

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

09 Oct 2017 19:16 - 09 Oct 2017 19:18 #100124

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Yes three USB ports. My thinking was one for the USB stick to transfer files. One for the USB keyboard which I will use for setting up, but hopefully not need for machining, and one for the wireless data for those time when I need to connect to the internet, such as doing updates. I figured when doing an update, I'll need the keyboard, and possibly have a reason to us a USB memory stick as well.

I have ordered a Logilink UA14 powered USB hub, which will go under the control panel. At 5m cable length this will be at the extreme of range for the USB standard, and powered hubs are supposed to help. The fourth port on that hub will be for the touch screen interface.

Abel cheated, as he used a Heidenhain keyboard panel. I dont like the idea of a touch pad mounted vertically. I can't see that being comfortable to use. The Gmoccapy touch screen interface sure simplifies the interface. I thought about doing buttons for cycle start, coolant etc, but cycle start/pause etc end up on a soft key anyway.

I might still add an encoder for feedoverride.

A follow on project will be a pendant.

Mark

I have ordered a Logilink UA14 powered USB hub, which will go under the control panel. At 5m cable length this will be at the extreme of range for the USB standard, and powered hubs are supposed to help. The fourth port on that hub will be for the touch screen interface.

Abel cheated, as he used a Heidenhain keyboard panel. I dont like the idea of a touch pad mounted vertically. I can't see that being comfortable to use. The Gmoccapy touch screen interface sure simplifies the interface. I thought about doing buttons for cycle start, coolant etc, but cycle start/pause etc end up on a soft key anyway.

I might still add an encoder for feedoverride.

A follow on project will be a pendant.

Mark

Last edit: 09 Oct 2017 19:18 by RotarySMP.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

10 Oct 2017 03:19 - 10 Oct 2017 04:37 #100132

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Last edit: 10 Oct 2017 04:37 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

10 Oct 2017 03:31 #100133

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

A company with Water jet cutter or laser cut can make the panel frame and holes for the buttons, but I can’t find elegant buttons with slim mounting. Except button used on elevators, but they are very expensive. Any suggestions.

John

John

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

10 Oct 2017 06:23 - 10 Oct 2017 06:48 #100135

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

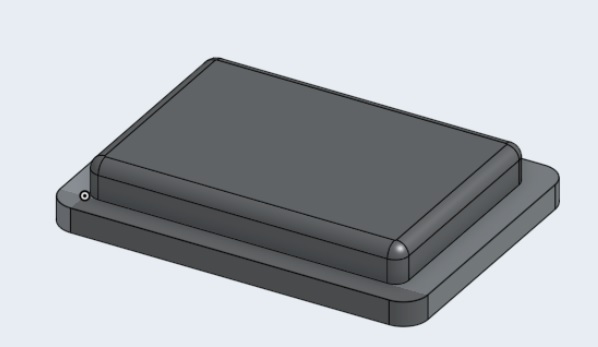

I am planning to 3D print the buttons, and have them act on print mount tactile switches. Haven't finished the design yet, as I need the switches to measure.

I could see the potential to then mill a set of metal buttons once the machine is up and running.

www.ebay.at/itm/20-Yellow-TASTSCHALTER-1...p2060353.m1438.l2649

I have a friend in Bratislava who can get parts lasered very inexpensively. I have have used their service a couple of times on mild steel parts, and was very stisfied. The front panel will be lasered in 2mm stainless. I haven't drawn the support structure yet, but need to get it done, as he want to order some parts this week.

I just realised I put one too many buttons down the side. Gmoccapy lower RH button is a bottom button, not side. You dont need two soft keys for the same location.

I also thought about integrating an industrial keyboard, but unless you will do a lot of conversational programming, I didn't see much need, due to the touch screen interface. I have been using one of these Logitech K400 USB wireless keyboards, and it works perfectly with linux.

www.logitech.com/en-us/product/wireless-touch-keyboard-k400r

This will get plenty of use during the initial set up and testing phase, but hopefully be unneeded once the conversion is complete. They cost next to nothing, so I don't really care if it needs replacing.

Mark

I could see the potential to then mill a set of metal buttons once the machine is up and running.

www.ebay.at/itm/20-Yellow-TASTSCHALTER-1...p2060353.m1438.l2649

I have a friend in Bratislava who can get parts lasered very inexpensively. I have have used their service a couple of times on mild steel parts, and was very stisfied. The front panel will be lasered in 2mm stainless. I haven't drawn the support structure yet, but need to get it done, as he want to order some parts this week.

I just realised I put one too many buttons down the side. Gmoccapy lower RH button is a bottom button, not side. You dont need two soft keys for the same location.

I also thought about integrating an industrial keyboard, but unless you will do a lot of conversational programming, I didn't see much need, due to the touch screen interface. I have been using one of these Logitech K400 USB wireless keyboards, and it works perfectly with linux.

www.logitech.com/en-us/product/wireless-touch-keyboard-k400r

This will get plenty of use during the initial set up and testing phase, but hopefully be unneeded once the conversion is complete. They cost next to nothing, so I don't really care if it needs replacing.

Mark

Last edit: 10 Oct 2017 06:48 by RotarySMP.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

10 Oct 2017 10:18 - 10 Oct 2017 10:24 #100138

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Last edit: 10 Oct 2017 10:24 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

10 Oct 2017 15:02 #100146

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

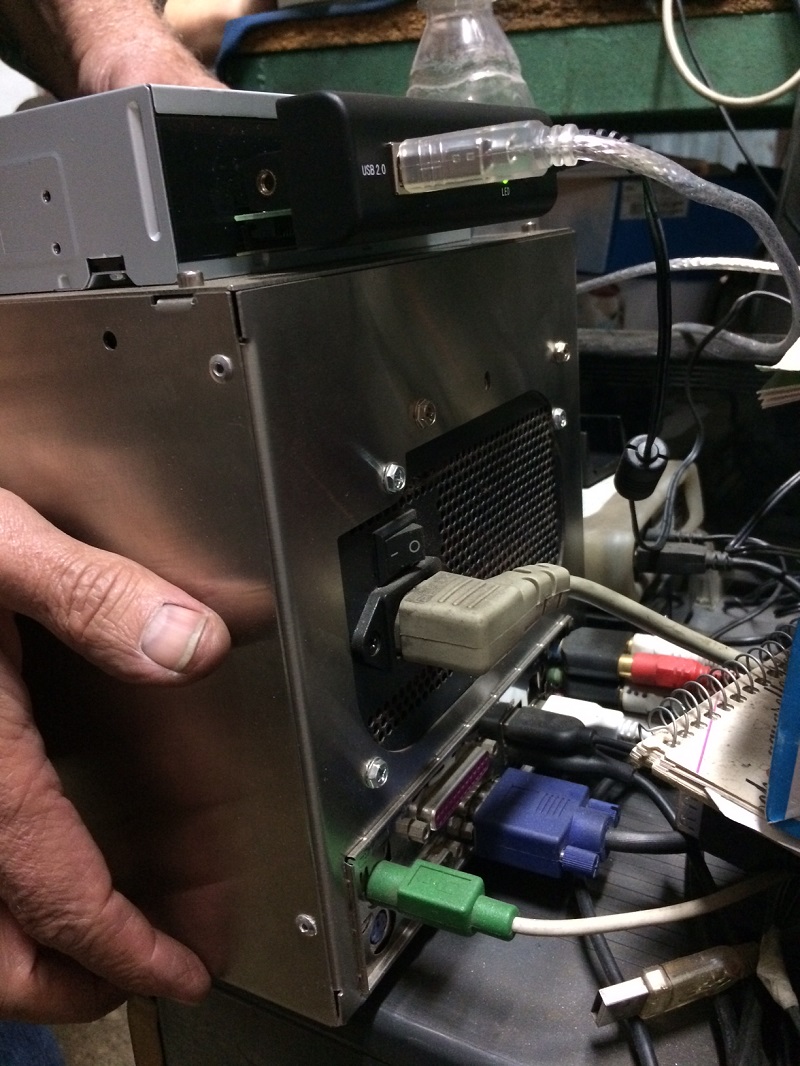

Nice workmanship there John.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

10 Oct 2017 16:01 - 10 Oct 2017 16:01 #100152

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

It is not mine, it is a friend of mine. He is designer in a cnc company www.vetasa.gr/en/

Last edit: 10 Oct 2017 16:01 by drimaropoylos.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.275 seconds