Retrofitting a 1986 Maho MH400E

- cgroth

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 9

07 Nov 2019 06:10 #149805

by cgroth

Replied by cgroth on topic Retrofitting a 1986 Maho MH400E

Hi there,

I finally got a place for my MH 300 C and have it running still using the 432/9. Unfortunatly the conversion sill suffers from a lack of spare time.

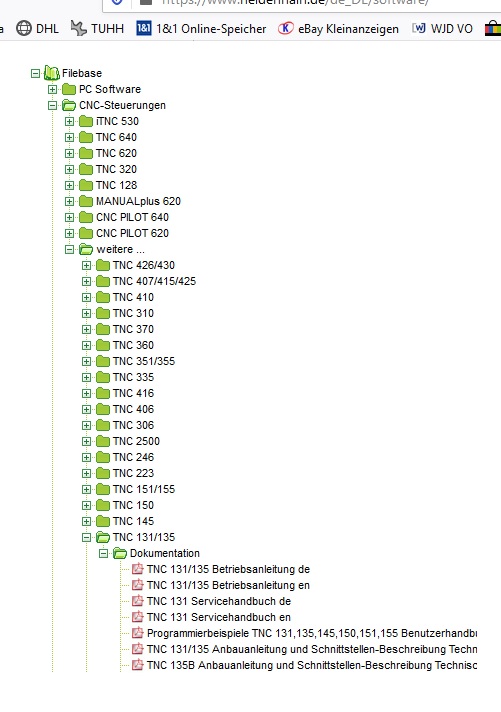

You should definitely have a look on this website:

www.heidenhain.de/de_DE/software/

Information on the TNC135 is more or less complete, also in english:

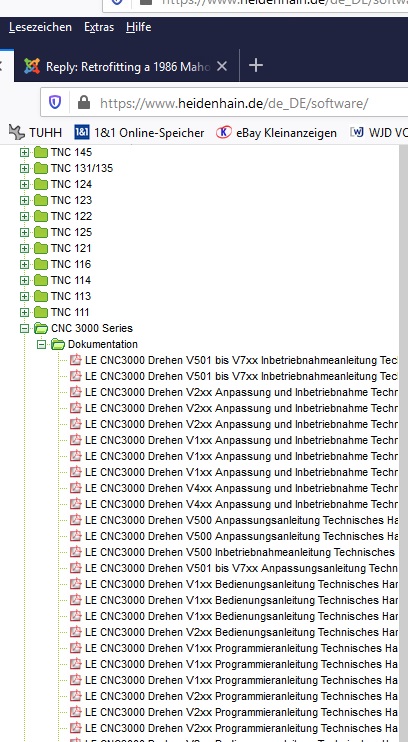

And for those of you fiddeling around with the Philips you have to know that this system was sold as CNC 3000:

V1XX to V4XX will fit to most of the 432/9, V5XX to V600 to 432/10 running a 80286 processor and V7XX for the 80386.

Good luck!

I finally got a place for my MH 300 C and have it running still using the 432/9. Unfortunatly the conversion sill suffers from a lack of spare time.

You should definitely have a look on this website:

www.heidenhain.de/de_DE/software/

Information on the TNC135 is more or less complete, also in english:

And for those of you fiddeling around with the Philips you have to know that this system was sold as CNC 3000:

V1XX to V4XX will fit to most of the 432/9, V5XX to V600 to 432/10 running a 80286 processor and V7XX for the 80386.

Good luck!

Attachments:

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

07 Nov 2019 06:56 #149808

by db1981

Replied by db1981 on topic Retrofitting a 1986 Maho MH400E

Hi brad,

Post a Photo from the tnc After power up, please .

Db

Post a Photo from the tnc After power up, please .

Db

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

07 Nov 2019 07:21 #149812

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I speak german, so if you have any questions on it, ask away.

The following user(s) said Thank You: chris mcm

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

07 Nov 2019 08:10 #149814

by db1981

Replied by db1981 on topic Retrofitting a 1986 Maho MH400E

Hi Brad,

i am native german.....

please do the following checks:

-post photo from the TNC and Screen after power up

-post photo from the S5 after power up and after switching on estop with the bridged TNC contact

-Does the hydraulic Pump and the Bed Lube pump start, after switching e stop?

-check the 24V beetween 140/141 Page 8252, better with oszilloscop to see if all Diodes are ok.

With this control you are able to drive the axis manual, without an speed command from the tnc. look at page 8264 (connection control input Indramat).

9 XYZ ist the first input driven by manual control

10 XYZ ist the second input driven by the TNC, on the right side you see the axis enable section.

You wrote you can drive in one direction, check the following:

-is +15V and -15V ok? (L6, 12,11,14)

-Relais 7k2 and 7k3 are for the direction, do booth of them switching if you press an plus or minus button for an axis?

-check the voltages the wrote down on the sheet

-On Input L1 9 X has to be an +Voltage for moving and an -V for the opposite direction.

-check the inputs from the TNC L1,2,3 10, they have to be ~0V

i am native german.....

please do the following checks:

-post photo from the TNC and Screen after power up

-post photo from the S5 after power up and after switching on estop with the bridged TNC contact

-Does the hydraulic Pump and the Bed Lube pump start, after switching e stop?

-check the 24V beetween 140/141 Page 8252, better with oszilloscop to see if all Diodes are ok.

With this control you are able to drive the axis manual, without an speed command from the tnc. look at page 8264 (connection control input Indramat).

9 XYZ ist the first input driven by manual control

10 XYZ ist the second input driven by the TNC, on the right side you see the axis enable section.

You wrote you can drive in one direction, check the following:

-is +15V and -15V ok? (L6, 12,11,14)

-Relais 7k2 and 7k3 are for the direction, do booth of them switching if you press an plus or minus button for an axis?

-check the voltages the wrote down on the sheet

-On Input L1 9 X has to be an +Voltage for moving and an -V for the opposite direction.

-check the inputs from the TNC L1,2,3 10, they have to be ~0V

The following user(s) said Thank You: J Green, chris mcm

Please Log in or Create an account to join the conversation.

- chris mcm

- Offline

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 1

07 Nov 2019 08:26 #149815

by chris mcm

Replied by chris mcm on topic Retrofitting a 1986 Maho MH400E

Hello db 1981

It is Friday tomorrow in New Zealand. We will carry out your checks as soon as Brad is available. Thank you for your help.

Cheers

Chris

It is Friday tomorrow in New Zealand. We will carry out your checks as soon as Brad is available. Thank you for your help.

Cheers

Chris

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

08 Nov 2019 07:00 #149906

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Chris, that is a tasty DSG 13x you hid behind the MAHO.

Mark

Mark

Please Log in or Create an account to join the conversation.

- chris mcm

- Offline

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 1

08 Nov 2019 10:14 #149909

by chris mcm

Replied by chris mcm on topic Retrofitting a 1986 Maho MH400E

Yes, I bought the D.S.G 13" x 30 since the Maho. I swore I was not going to buy any more machine tools. The D.S.G was with a machinery dealer but likely had been rescued from a scrap yard.

The machine had been greased and nothing moved. A week of dirty work, replaced a few bronze bushings and I have a really nice tight D.S.G with hardened bed ways. These days if a machine is not metric it is obsolete. American decimal measure is no bother to me.

I wish the Maho was as easy for me to fix.

Thanks for your interest. Cheers

Chris

The machine had been greased and nothing moved. A week of dirty work, replaced a few bronze bushings and I have a really nice tight D.S.G with hardened bed ways. These days if a machine is not metric it is obsolete. American decimal measure is no bother to me.

I wish the Maho was as easy for me to fix.

Thanks for your interest. Cheers

Chris

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

08 Nov 2019 12:49 #149912

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Photos, or it didn't happen  . My Dad served his time at MoW in Dundin and always raved about DSG lathes. I have never used one.

. My Dad served his time at MoW in Dundin and always raved about DSG lathes. I have never used one.

Did you and Brad make any progress on the troubleshooting steps detailed by db?

Mark

Did you and Brad make any progress on the troubleshooting steps detailed by db?

Mark

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

08 Nov 2019 12:58 #149913

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Chris---

Mark commentated on the D.S.G. lathe ,which is impressive. but I spied the launch engine. Looks as if you haven't been sitting around playing cards all day. What is the stern to bow length of the boat that engine is to power and what size will the boiler be?

Given any thought to a Heidenhan firing control of the boiler?

I don't feel qualified to give you-all advice . But maybe some of my thoughts

db1981 @ others mentioned checking the fluid level of both pumps (lube an hydraulic) . The reason being is a low level can effect a lock out in the start up sequence. Also I think the hydraulic pump has a pressure switch for min/max pressure. Don't remember if lubrication pump has a pressure switch but easy to check. My thought is to make up several low amperage light bulb sets and wire them across the contacts Think it is a 24 volt DC supplied on a MH600E but you need to verify what your C 700 is. To me, fumbling with volt meter test leads on a timing out circuit and trying to see the meter action has gotten old long ago . Use low amperage bulbs such that they indicate -not emulate the switch contact action . Something like several 12 volt auto instrument panel bulbs in series having very long wire leads that can be seen while working at the control panel .

db1981 noted the checking of various power supply voltages an looking for ripple to qualify functioning of diodes an filter capacitors

If a scope is not available some idea can be obtained by measuring the A.C. voltage level in the D.C. circuit. High A.C.value = high ripple = diode and or filter capacitor problem.

You stated the back up battery has been replaced. I have found that in today's world ,new replacement stuff may not have the quality that used to be. Not very hard to check the new battery ,might also check it's charging supply.at the battery terminals with some load.

I always try to make copies of the electrical schematics . That means greasy fingers- coffee/tea spills -pencil marks -etc don't cause a train wreck ( hull breach - loss of boiler feed water) due to the documentation being trashed.

It might help db1981 and others if you could note the extent of your documentation. Like schematics of your machine - schematics of the Heidenhain control - schematics of the Siemens PLC and if any service manuals.

Hope you and Brad find a quick solution.

Bob

Mark commentated on the D.S.G. lathe ,which is impressive. but I spied the launch engine. Looks as if you haven't been sitting around playing cards all day. What is the stern to bow length of the boat that engine is to power and what size will the boiler be?

Given any thought to a Heidenhan firing control of the boiler?

I don't feel qualified to give you-all advice . But maybe some of my thoughts

db1981 @ others mentioned checking the fluid level of both pumps (lube an hydraulic) . The reason being is a low level can effect a lock out in the start up sequence. Also I think the hydraulic pump has a pressure switch for min/max pressure. Don't remember if lubrication pump has a pressure switch but easy to check. My thought is to make up several low amperage light bulb sets and wire them across the contacts Think it is a 24 volt DC supplied on a MH600E but you need to verify what your C 700 is. To me, fumbling with volt meter test leads on a timing out circuit and trying to see the meter action has gotten old long ago . Use low amperage bulbs such that they indicate -not emulate the switch contact action . Something like several 12 volt auto instrument panel bulbs in series having very long wire leads that can be seen while working at the control panel .

db1981 noted the checking of various power supply voltages an looking for ripple to qualify functioning of diodes an filter capacitors

If a scope is not available some idea can be obtained by measuring the A.C. voltage level in the D.C. circuit. High A.C.value = high ripple = diode and or filter capacitor problem.

You stated the back up battery has been replaced. I have found that in today's world ,new replacement stuff may not have the quality that used to be. Not very hard to check the new battery ,might also check it's charging supply.at the battery terminals with some load.

I always try to make copies of the electrical schematics . That means greasy fingers- coffee/tea spills -pencil marks -etc don't cause a train wreck ( hull breach - loss of boiler feed water) due to the documentation being trashed.

It might help db1981 and others if you could note the extent of your documentation. Like schematics of your machine - schematics of the Heidenhain control - schematics of the Siemens PLC and if any service manuals.

Hope you and Brad find a quick solution.

Bob

Please Log in or Create an account to join the conversation.

- chris mcm

- Offline

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 1

08 Nov 2019 20:37 #149936

by chris mcm

Replied by chris mcm on topic Retrofitting a 1986 Maho MH400E

Thanks Bob. Unfortunately, I have to wait for Brad who is a busy manager of an Electrical & Automation Company. I can do some of the testing my self. And yes I do have copies of the Electrical Schematics. I may post them on this site. They may be useful to others.

Regarding my other machines and my long time Steam Launch Project. I don't want to change subject on this Forum. Any one interested. see waitematawoodys.com/?s=mcmullen+steam+launch&submit=Search

Thanks

Regarding my other machines and my long time Steam Launch Project. I don't want to change subject on this Forum. Any one interested. see waitematawoodys.com/?s=mcmullen+steam+launch&submit=Search

Thanks

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.291 seconds