Retrofitting a 1986 Maho 400E

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19741

- Thank you received: 4579

15 Dec 2017 17:13 #103138

by andypugh

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

TE have a bad picture on their page:

www.te.com/usa-en/product-925370-6.html

But if you look at the CAD files it has the locking clips.

www.te.com/usa-en/product-925370-6.html

But if you look at the CAD files it has the locking clips.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1522

- Thank you received: 560

15 Dec 2017 19:34 - 15 Dec 2017 19:45 #103143

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks Andy. I can get them through Conrad with cheap postage. If I cant track down the shielded 5x2 twisted pair cable, I might use CAT5E for the signal wires, 5V and 0V, and just run a separate wire for the 12V.

Mark

Mark

Last edit: 15 Dec 2017 19:45 by RotarySMP.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19741

- Thank you received: 4579

17 Dec 2017 02:23 #103180

by andypugh

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

I think Conrad are linked to Rapid? They sell lots of nice cables by the metre.

www.rapidonline.com/drag-chain-cable?ra_source=tier-left-list

www.rapidonline.com/drag-chain-cable?ra_source=tier-left-list

Please Log in or Create an account to join the conversation.

- yahiyaoui

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

17 Dec 2017 22:23 #103256

by yahiyaoui

Replied by yahiyaoui on topic Retrofitting a 1986 Maho MH400E

Hello everyone,

I am new here, I have a lathe cnc maho GR400 C, when I press the start button to start the hydraulic, an error is displayed on the screen (E07) which means from the manual (missing signal Bb1).

I hope you can help me.

thank you in advance.

I am new here, I have a lathe cnc maho GR400 C, when I press the start button to start the hydraulic, an error is displayed on the screen (E07) which means from the manual (missing signal Bb1).

I hope you can help me.

thank you in advance.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1522

- Thank you received: 560

18 Dec 2017 15:51 #103292

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hello yahiyaoui,

For a MAHO /Graziano lathe with a Phillips controller, please open a separate thread. And post lots of photos to it. Cool machine.

If the driver electronic unit is an Indramat 3TRM2, then Bb1 to Bb2 are on connector L4, which is the LH most connector of the Indramat. It is the output of the internal voltage monitoring system. This is the switch which the Indramat closes to say that it is ready. It opens if the internal +15V reference voltage deviates more than -0.5V low. You should also have a low votage warning LED on the Indramat.

If you PM me your email address I can send you the PDF of the Indrmat 3TRM2 manual.

Mark

For a MAHO /Graziano lathe with a Phillips controller, please open a separate thread. And post lots of photos to it. Cool machine.

If the driver electronic unit is an Indramat 3TRM2, then Bb1 to Bb2 are on connector L4, which is the LH most connector of the Indramat. It is the output of the internal voltage monitoring system. This is the switch which the Indramat closes to say that it is ready. It opens if the internal +15V reference voltage deviates more than -0.5V low. You should also have a low votage warning LED on the Indramat.

If you PM me your email address I can send you the PDF of the Indrmat 3TRM2 manual.

Mark

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1522

- Thank you received: 560

18 Dec 2017 16:13 #103294

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks Andy, I had been looking on the conrad website for Data cable, but looks like I needed to look for drag chain cable.

...

Nope, they don't have shielded, twisted pair, 10 [or 12] x 2 x [anything between 0.14mm² to 0.34mm²] . Also on Rapid, nothing beyond 8 wires in twisted pair. Since Heidenhain did their single cable in twisted pair plus double shielding, which is less likely to cause noise on encoder signals:

1/ Single ended, twisted pair on the power wires, double shielded.

2/ Differential, twisted pair on the data lines, and on the 5V/0V line, the 12V running extra.

3/ Differential, no twisted pairs, but all data and power lines together in a shielded cable?

I tried the Z Axis encoder on the known working EXE yesterday. No signal at all at LinuxCNC. The Indramat and Motor were very well behaved, performing a slow jog until the following error limit was reached. My next trouble shooting step will be pulling ht covers to see if the Glass scale encoder is actually fitted.

Mark

...

Nope, they don't have shielded, twisted pair, 10 [or 12] x 2 x [anything between 0.14mm² to 0.34mm²] . Also on Rapid, nothing beyond 8 wires in twisted pair. Since Heidenhain did their single cable in twisted pair plus double shielding, which is less likely to cause noise on encoder signals:

1/ Single ended, twisted pair on the power wires, double shielded.

2/ Differential, twisted pair on the data lines, and on the 5V/0V line, the 12V running extra.

3/ Differential, no twisted pairs, but all data and power lines together in a shielded cable?

I tried the Z Axis encoder on the known working EXE yesterday. No signal at all at LinuxCNC. The Indramat and Motor were very well behaved, performing a slow jog until the following error limit was reached. My next trouble shooting step will be pulling ht covers to see if the Glass scale encoder is actually fitted.

Mark

Please Log in or Create an account to join the conversation.

- cgroth

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 9

18 Dec 2017 21:03 #103310

by cgroth

Replied by cgroth on topic Retrofitting a 1986 Maho MH400E

Marc,

I am sorry but job and children keep from doing anything to the machines at the moment, so I am waiting for the Christmas break. What do you want the cables for? Heidenhain used 3x2x0,14mm² + 2x0,5 mm² for the "normal" sinusoidal scales. You can use Helukabel Toplex 22800 or Lapp Kabel ÖLFLEX SERVO 720 CY 0036168. Unfortunatley they are not available in shorter lengths. www.voelkner.de/products/604051/LappKabe...au-0036168-50-m.html If you are interested, I could check for shorter delivery times, order a coil and sell you what you need.

Christian

I am sorry but job and children keep from doing anything to the machines at the moment, so I am waiting for the Christmas break. What do you want the cables for? Heidenhain used 3x2x0,14mm² + 2x0,5 mm² for the "normal" sinusoidal scales. You can use Helukabel Toplex 22800 or Lapp Kabel ÖLFLEX SERVO 720 CY 0036168. Unfortunatley they are not available in shorter lengths. www.voelkner.de/products/604051/LappKabe...au-0036168-50-m.html If you are interested, I could check for shorter delivery times, order a coil and sell you what you need.

Christian

Please Log in or Create an account to join the conversation.

- giz

-

- Offline

- Premium Member

-

Less

More

- Posts: 126

- Thank you received: 11

19 Dec 2017 04:46 #103331

by giz

Replied by giz on topic Retrofitting a 1986 Maho MH400E

Excellent thread with a wealth of information. Thanks for updating!

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1522

- Thank you received: 560

23 Dec 2017 21:11 - 23 Dec 2017 21:13 #103498

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

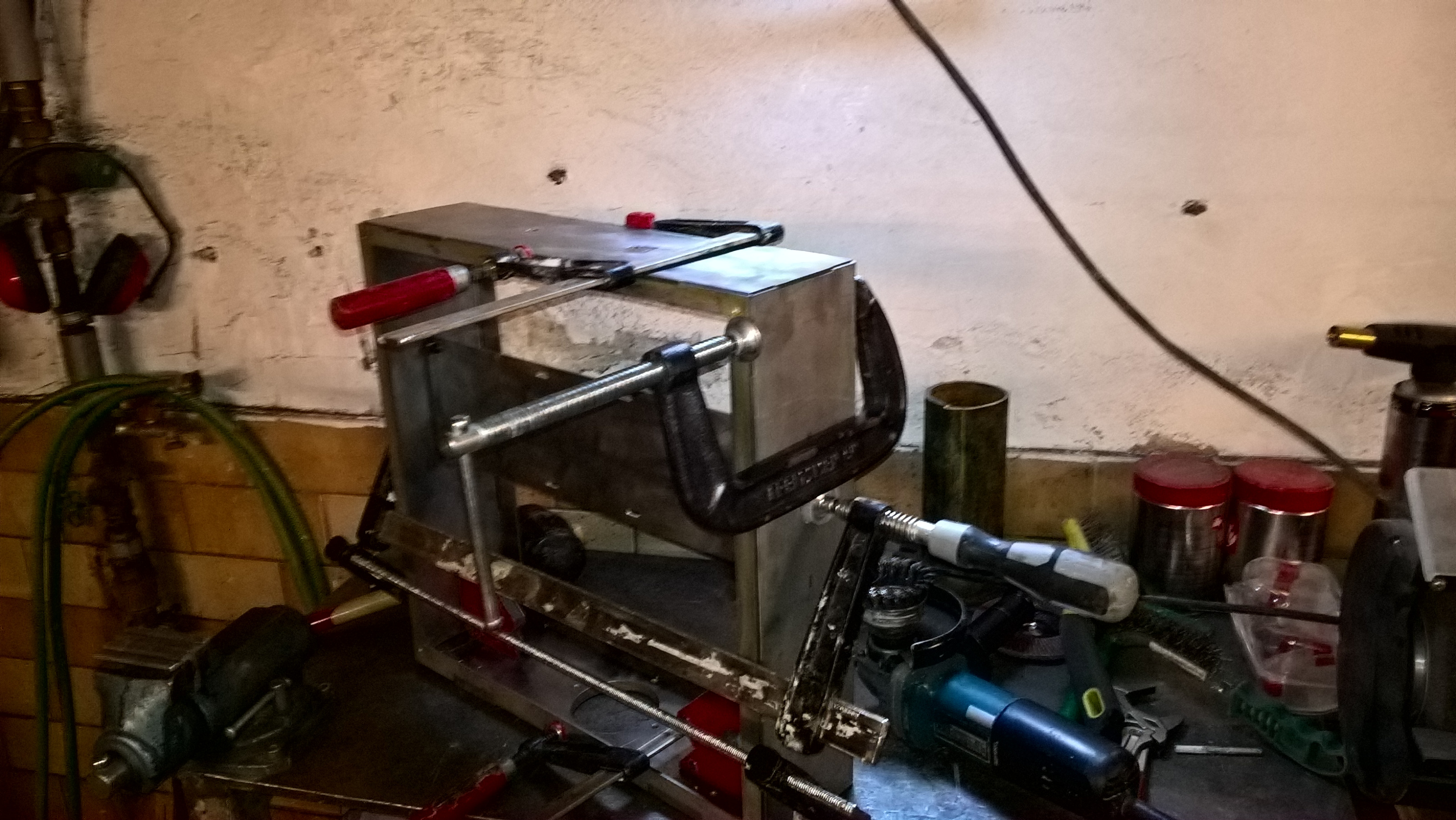

I've been a little too busy with other things lately, so the MAHO hasn't had much attention. My friend dropped off the lasered parts he kindly arranged last weekend,

so today I spent the day working on the new control panel.

I used HCl to removed the mill scale. First I've done that, and it works really well. Way easier than trying to grind it off.

Whoever came up with the idea of self fixturing laser weldment was a genius. I took quite a while to model the sheets in CAD and get them all interlocking properly. When I first put them together with too many clamps, I couldn't get them to fit, but the secret was fewer clamps, and they just snapped together.

After I tacked it together...

... it was time to check that the monitor mounting was correct.

I am not much of a welder, so there is going to be a fair bit of grinding to get those edges looking nice for painting.

Mark

so today I spent the day working on the new control panel.

I used HCl to removed the mill scale. First I've done that, and it works really well. Way easier than trying to grind it off.

Whoever came up with the idea of self fixturing laser weldment was a genius. I took quite a while to model the sheets in CAD and get them all interlocking properly. When I first put them together with too many clamps, I couldn't get them to fit, but the secret was fewer clamps, and they just snapped together.

After I tacked it together...

... it was time to check that the monitor mounting was correct.

I am not much of a welder, so there is going to be a fair bit of grinding to get those edges looking nice for painting.

Mark

Last edit: 23 Dec 2017 21:13 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1522

- Thank you received: 560

26 Dec 2017 13:21 #103643

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Merry Xmas everyone.

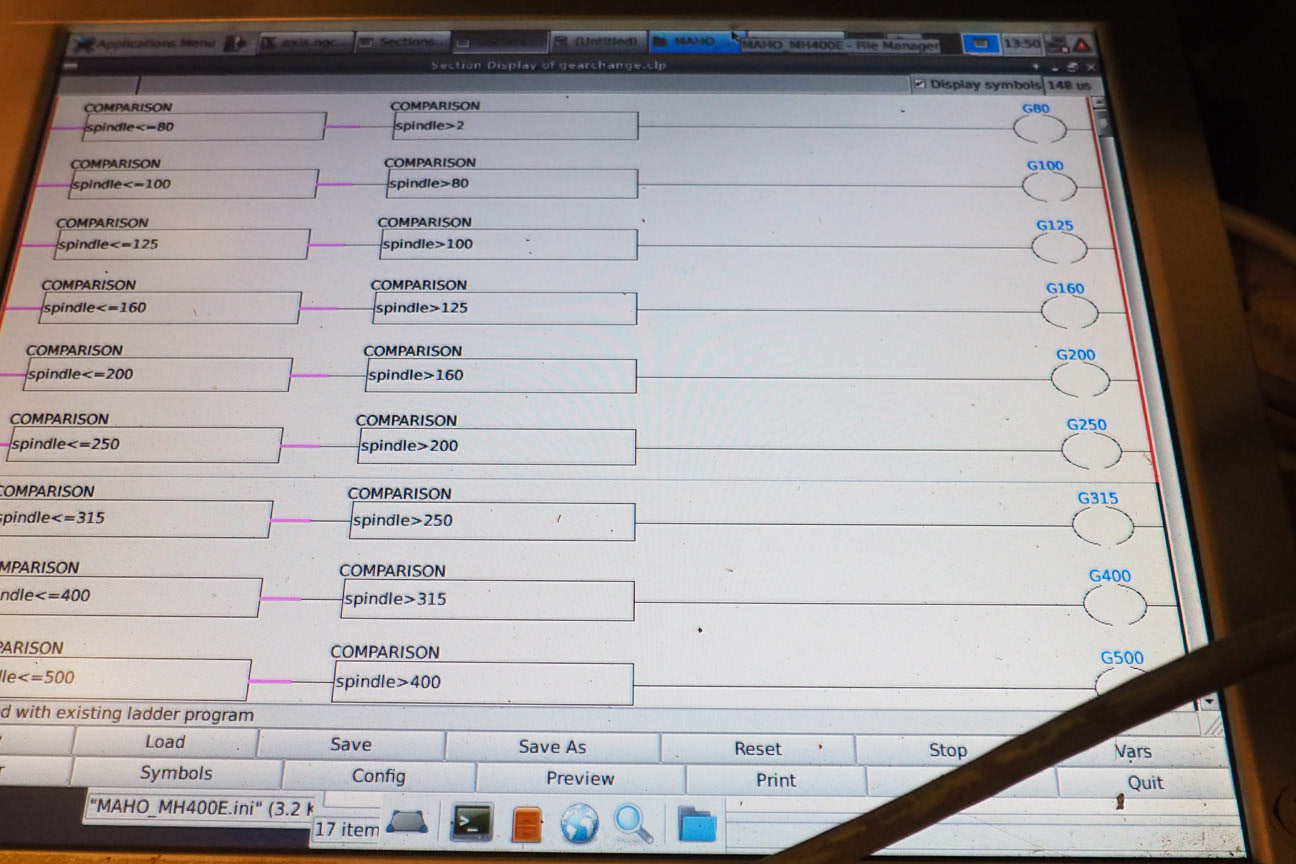

John, sorry it has taken me till today to follow your advice and make a new PNCConf config and then paste in the files you sent me. Like that the Classic ladder files for the gearbox are editable.

Did you make progress on calling the ladder functions when an S word is called? I have started looking at reassigning M (S) codes.

What is the trick for pulling MAHO ball screw pulleys? I read on a german forum that there is a trick, but it didn't say what that is.

I confirmed that the Y axis is moving ~130mm on a 100 mm command.

The new control panel housing is progressing. A lot of grinding, and some more welding to fix slag inclusions, more grinding and I couldnt resist mocking it up again.

It undercoated now, to stop it rusting, then I'll bog it to hide the divets from grinding and other eyesores.

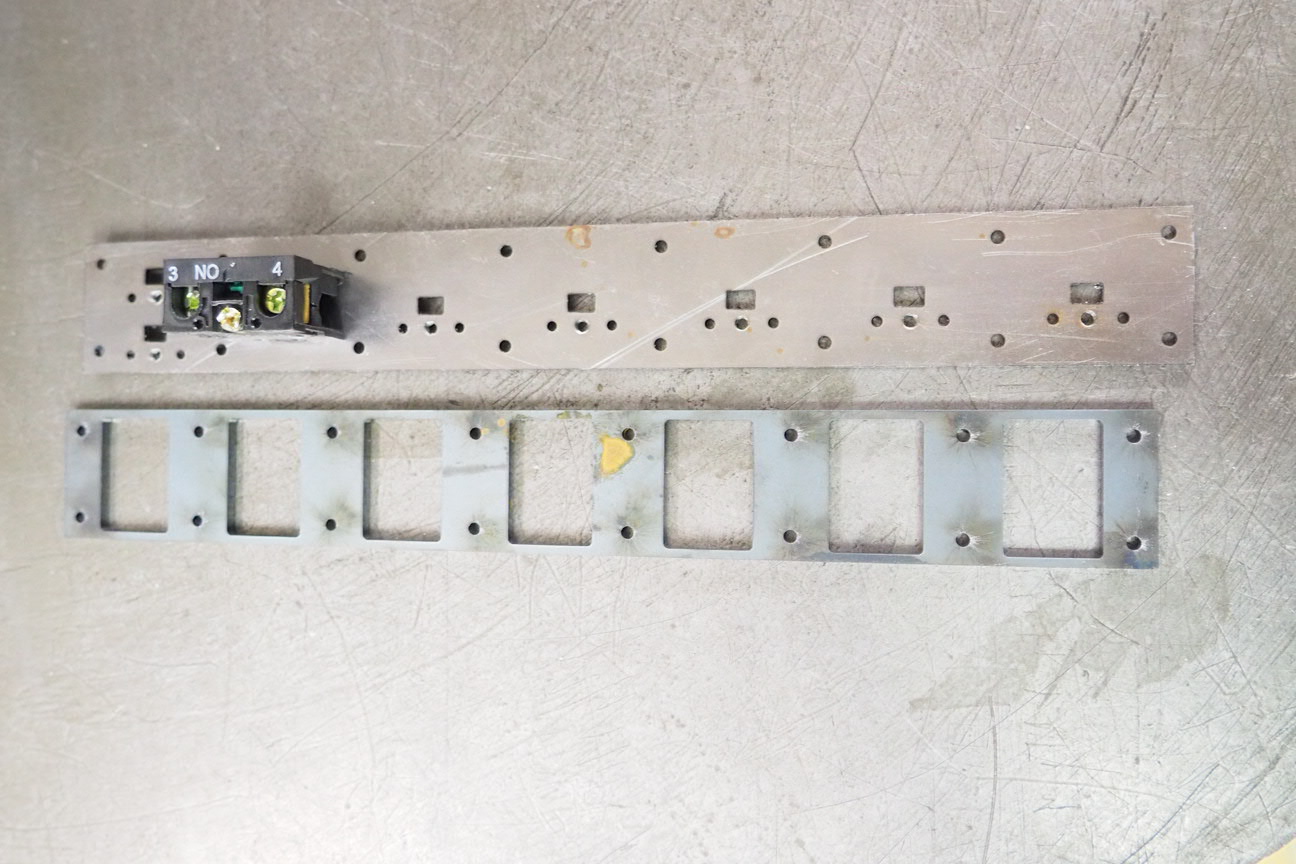

To mount the buttons and associated switches, some fiddly bits were also lasered.

Mark

John, sorry it has taken me till today to follow your advice and make a new PNCConf config and then paste in the files you sent me. Like that the Classic ladder files for the gearbox are editable.

Did you make progress on calling the ladder functions when an S word is called? I have started looking at reassigning M (S) codes.

What is the trick for pulling MAHO ball screw pulleys? I read on a german forum that there is a trick, but it didn't say what that is.

I confirmed that the Y axis is moving ~130mm on a 100 mm command.

The new control panel housing is progressing. A lot of grinding, and some more welding to fix slag inclusions, more grinding and I couldnt resist mocking it up again.

It undercoated now, to stop it rusting, then I'll bog it to hide the divets from grinding and other eyesores.

To mount the buttons and associated switches, some fiddly bits were also lasered.

Mark

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.324 seconds