Retrofitting a 1986 Maho MH400E

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

26 Dec 2017 17:29 - 26 Dec 2017 17:30 #103688

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Merry Christmas to all. Hi Marc, glad that the configuration works.

On the pulley assembly the component between the pulley and the shaft it expands with the pressure of the flange and act like a safety clutch. When there is no pressure from the flange (with the six screws) it should come off by hand easily. In my case the flange was not tight enough and the clutch was rubbing on the shaft and the tiny mark from friction on the shaft was the reason the pulley was difficult to remove. I haven’t worked on the configuration after post it.

Nice work on the control panel.

John

On the pulley assembly the component between the pulley and the shaft it expands with the pressure of the flange and act like a safety clutch. When there is no pressure from the flange (with the six screws) it should come off by hand easily. In my case the flange was not tight enough and the clutch was rubbing on the shaft and the tiny mark from friction on the shaft was the reason the pulley was difficult to remove. I haven’t worked on the configuration after post it.

Nice work on the control panel.

John

Last edit: 26 Dec 2017 17:30 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1571

- Thank you received: 580

28 Dec 2017 16:55 - 28 Dec 2017 16:55 #103797

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks John, at present, there is currently nothing implemented to call the gearchange.clp is there?

I was looking at remapping S, as the Linuxcnc G code remapping widget uses Python, which I have a little bit of experience with. If I understand correctly, then the setspeed_prolog and setspeed_epilog could be used to call and wrap your ladder logic.

Here is my block diagram for that plan. Any comments and suggestions are appreciated.

I started bogging the defects on the housing, but didn't use enough hardener, and it's cold in the basement, so I put it by the furnance in the hope that is goes hard.

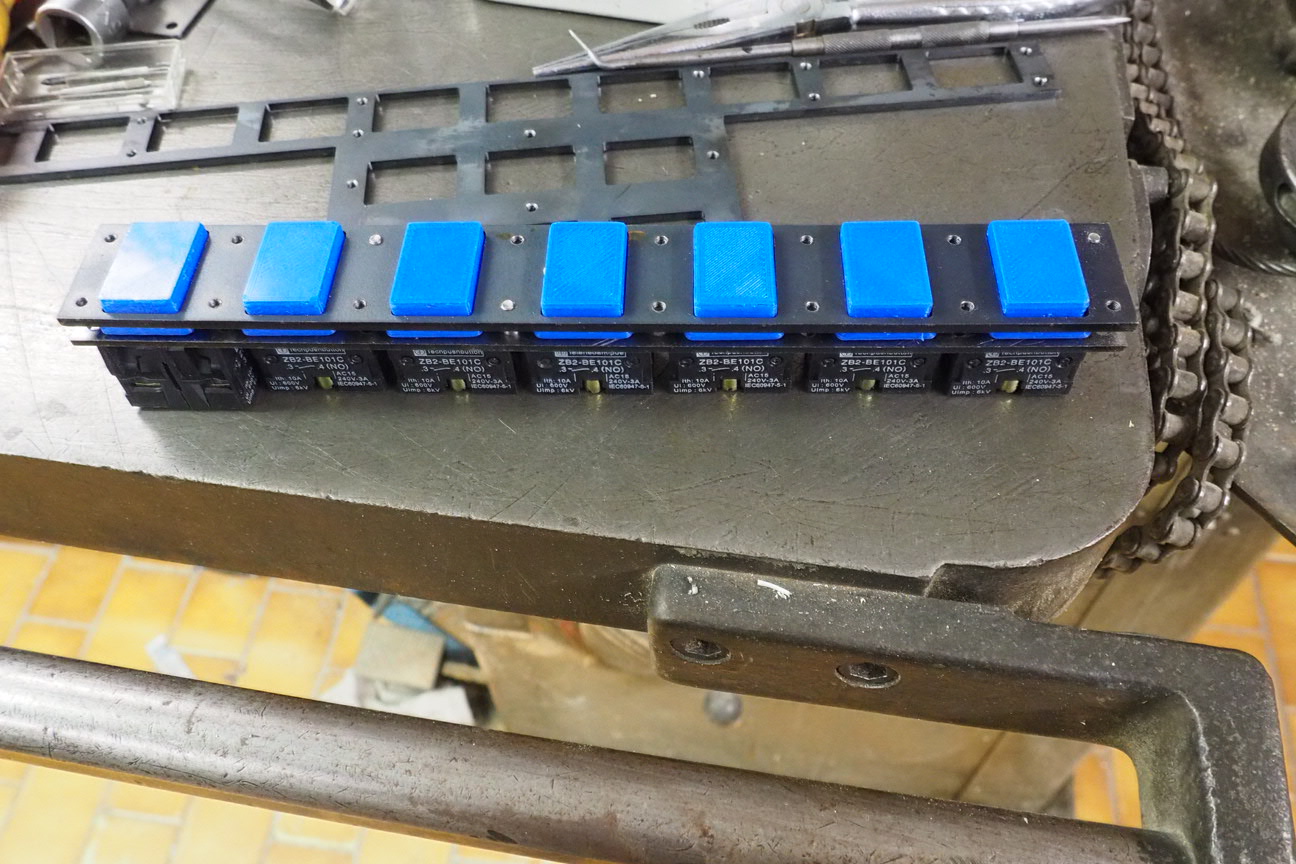

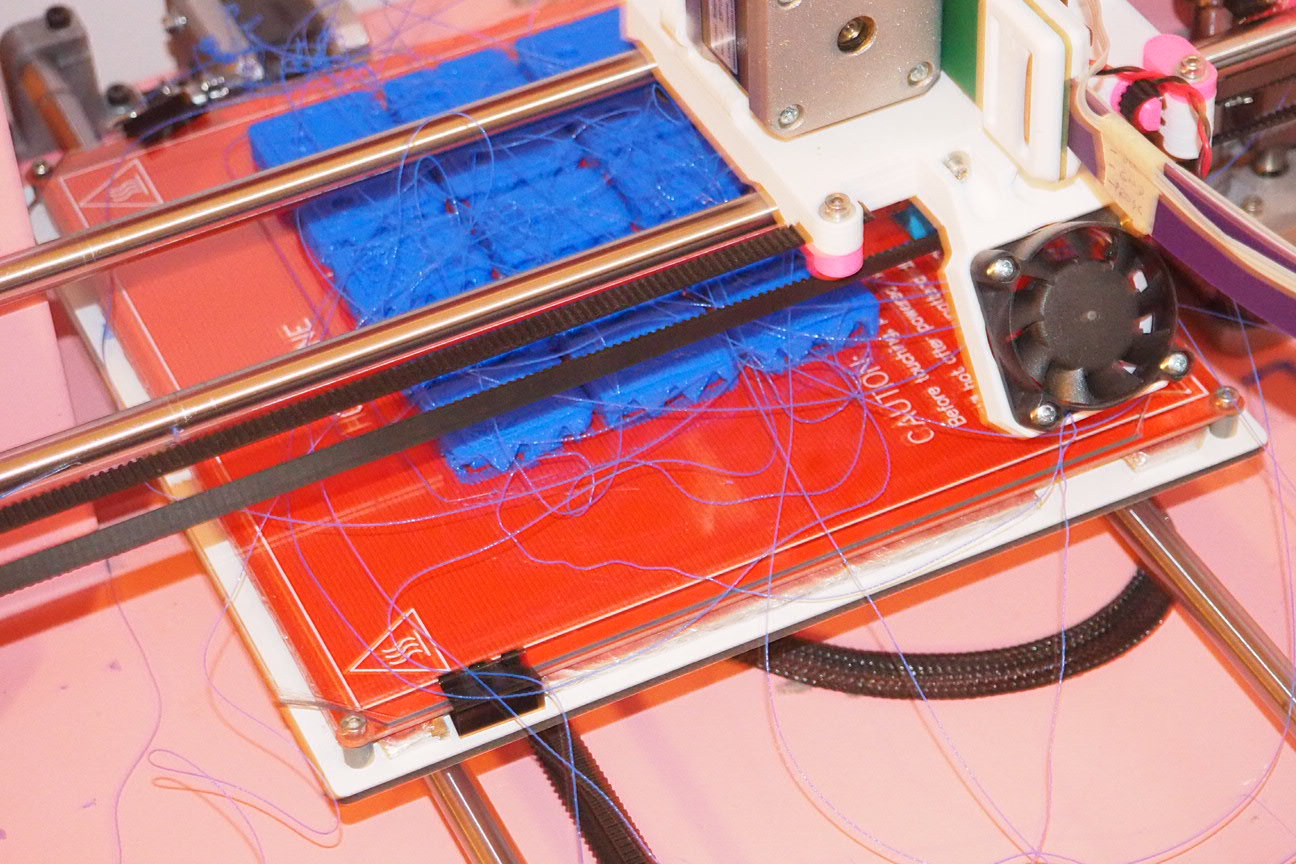

Also printing the first of the control panel buttons on the 3D printer.

Mark

I was looking at remapping S, as the Linuxcnc G code remapping widget uses Python, which I have a little bit of experience with. If I understand correctly, then the setspeed_prolog and setspeed_epilog could be used to call and wrap your ladder logic.

Here is my block diagram for that plan. Any comments and suggestions are appreciated.

I started bogging the defects on the housing, but didn't use enough hardener, and it's cold in the basement, so I put it by the furnance in the hope that is goes hard.

Also printing the first of the control panel buttons on the 3D printer.

Mark

Last edit: 28 Dec 2017 16:55 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1571

- Thank you received: 580

01 Jan 2018 15:09 #103922

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Prosit neu Jahr.

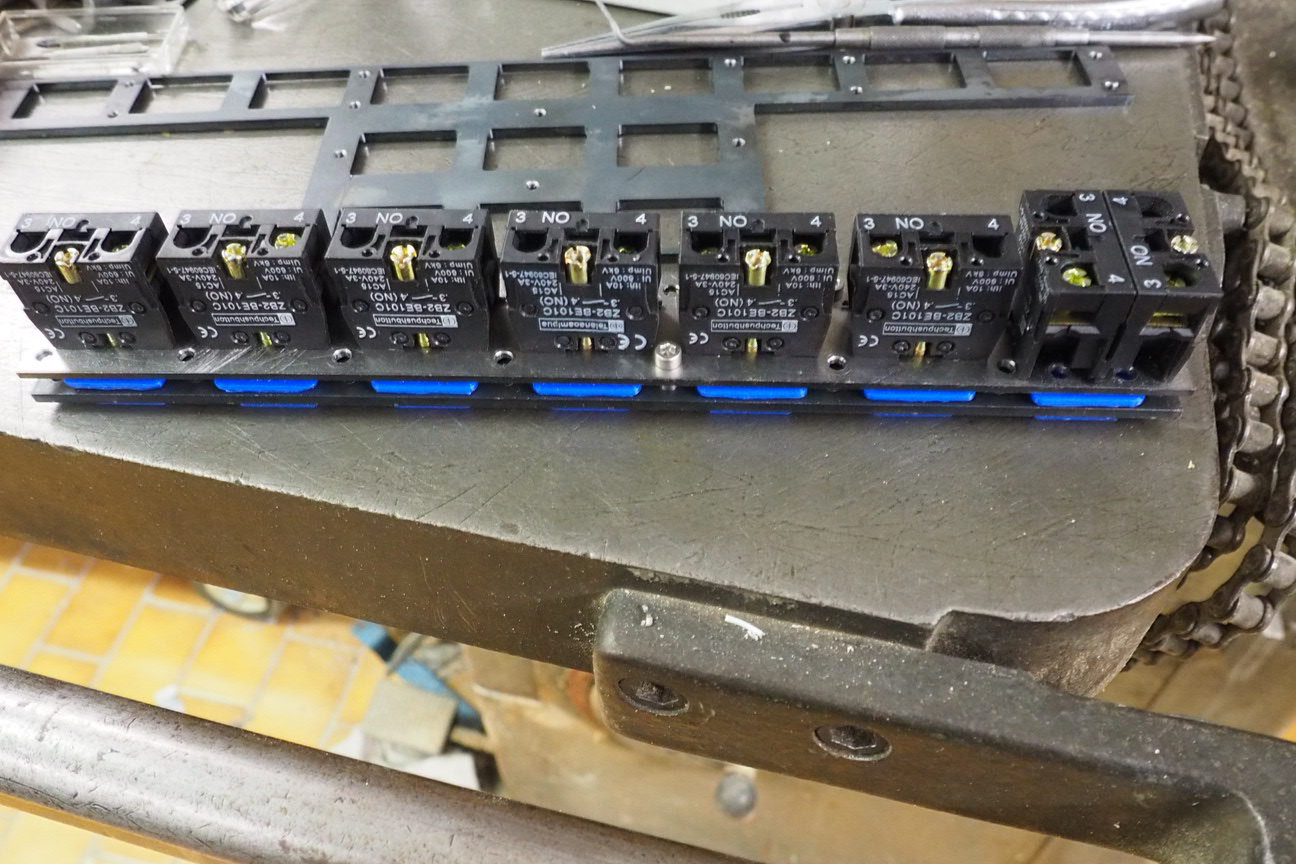

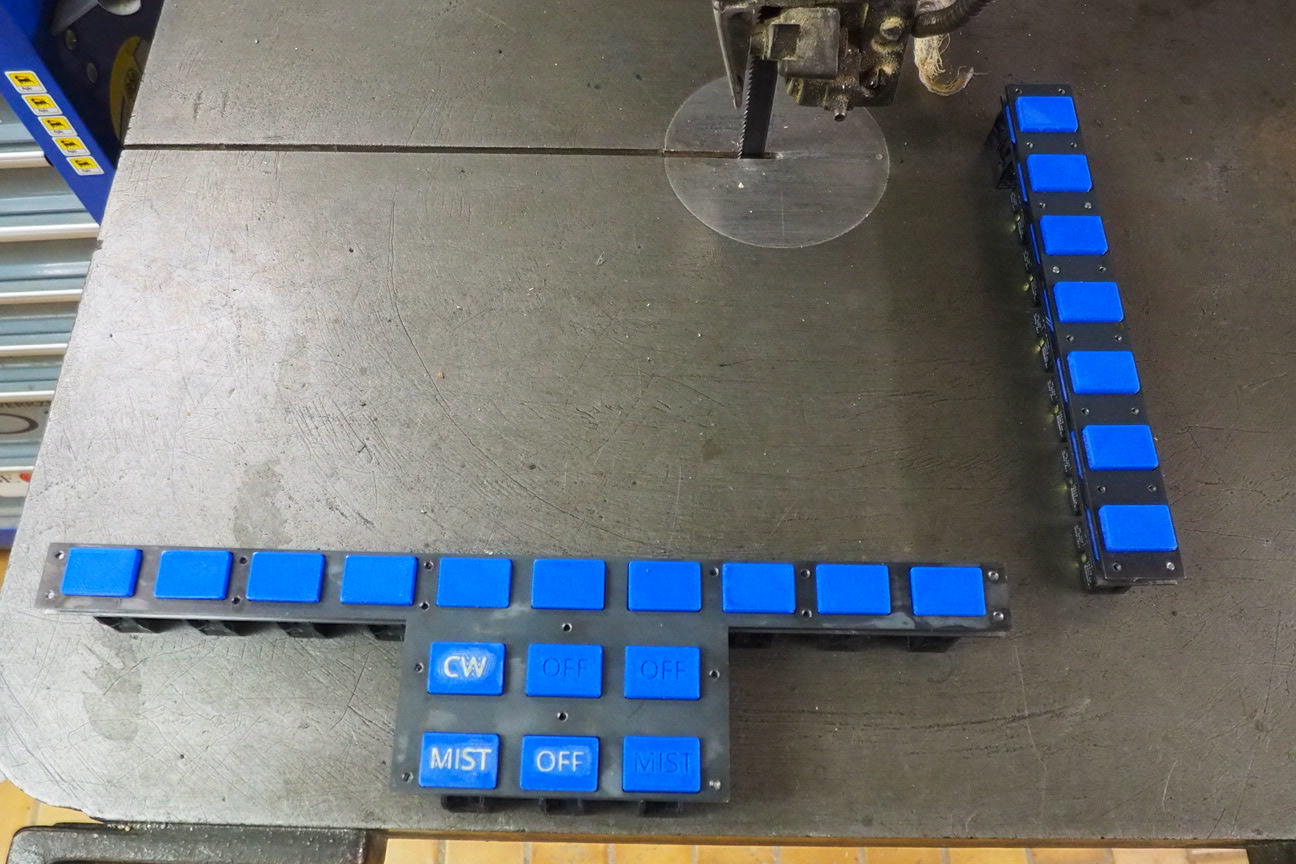

I am working on my control panel,

...and want to use Matrix_KB to interface the 26 keys with a 5x5 matrix.

I am a little unsure of the syntax from the documention, and couldn't find examples in the forum here. Appreciate any feedback on this.

loadrt matrix_kb config=R5C5s names=MAHO_Panel # 5x5 Matrix, in scan generation mode.

addf matrix_kb.MAHO_Panel servo-thread

net matrix_kb.MAHO_Panel.col-1-in hm2_5i25.0.7i77.0.0.output-00 # does the column numbering start at 0 or 1? I am netting a pin to a pin. Don't I need a signal?

net matrix_kb.MAHO_Panel.col-2-in hm2_5i25.0.7i77.0.0.output-01

net matrix_kb.MAHO_Panel.col-3-in hm2_5i25.0.7i77.0.0.output-02

net matrix_kb.MAHO_Panel.col-4-in hm2_5i25.0.7i77.0.0.output-03

net matrix_kb.MAHO_Panel.col-5-in hm2_5i25.0.7i77.0.0.output-04

net gmoccapy.v-button-0 matrix_kb.MAHO_Panel.key.r1c1 # same question as above, does the row numbering begin with 1 or 0?

net gmoccapy.v-button-5 matrix_kb.MAHO_Panel.key.r2c1 # What about the net of the five input pins from the 7i77? I feel I've completely missunderstood this syntax

matrix_kb.N.key.rRcC bit out

The pin corresponding to the key at row R column C of the matrix.

from the documentation.

Mark

I am working on my control panel,

...and want to use Matrix_KB to interface the 26 keys with a 5x5 matrix.

I am a little unsure of the syntax from the documention, and couldn't find examples in the forum here. Appreciate any feedback on this.

loadrt matrix_kb config=R5C5s names=MAHO_Panel # 5x5 Matrix, in scan generation mode.

addf matrix_kb.MAHO_Panel servo-thread

net matrix_kb.MAHO_Panel.col-1-in hm2_5i25.0.7i77.0.0.output-00 # does the column numbering start at 0 or 1? I am netting a pin to a pin. Don't I need a signal?

net matrix_kb.MAHO_Panel.col-2-in hm2_5i25.0.7i77.0.0.output-01

net matrix_kb.MAHO_Panel.col-3-in hm2_5i25.0.7i77.0.0.output-02

net matrix_kb.MAHO_Panel.col-4-in hm2_5i25.0.7i77.0.0.output-03

net matrix_kb.MAHO_Panel.col-5-in hm2_5i25.0.7i77.0.0.output-04

net gmoccapy.v-button-0 matrix_kb.MAHO_Panel.key.r1c1 # same question as above, does the row numbering begin with 1 or 0?

net gmoccapy.v-button-5 matrix_kb.MAHO_Panel.key.r2c1 # What about the net of the five input pins from the 7i77? I feel I've completely missunderstood this syntax

matrix_kb.N.key.rRcC bit out

The pin corresponding to the key at row R column C of the matrix.

from the documentation.

Mark

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17753

- Thank you received: 5190

01 Jan 2018 15:29 - 01 Jan 2018 16:05 #103925

by PCW

Replied by PCW on topic Retrofitting a 1986 Maho MH400E

When I am unsure about a component pins and names I use halcmd to list them:

(this is with linuxcnc running but without the matrix_kb hal file additions )

pcw@pcw-G41M-Combo:~/linuxcnc$ halcmd loadrt matrix_kb config=5x5 names=MAHO_Panel

pcw@pcw-G41M-Combo:~/linuxcnc$ halcmd show pin MAHO

Component Pins:

Owner Type Dir Value Name

42 bit OUT FALSE MAHO_Panel.key.r0c0

42 bit OUT FALSE MAHO_Panel.key.r0c1

42 bit OUT FALSE MAHO_Panel.key.r0c2

42 bit OUT FALSE MAHO_Panel.key.r0c3

42 bit OUT FALSE MAHO_Panel.key.r0c4

42 bit OUT FALSE MAHO_Panel.key.r1c0

42 bit OUT FALSE MAHO_Panel.key.r1c1

42 bit OUT FALSE MAHO_Panel.key.r1c2

42 bit OUT FALSE MAHO_Panel.key.r1c3

42 bit OUT FALSE MAHO_Panel.key.r1c4

42 bit OUT FALSE MAHO_Panel.key.r2c0

42 bit OUT FALSE MAHO_Panel.key.r2c1

42 bit OUT FALSE MAHO_Panel.key.r2c2

42 bit OUT FALSE MAHO_Panel.key.r2c3

42 bit OUT FALSE MAHO_Panel.key.r2c4

42 bit OUT FALSE MAHO_Panel.key.r3c0

42 bit OUT FALSE MAHO_Panel.key.r3c1

42 bit OUT FALSE MAHO_Panel.key.r3c2

42 bit OUT FALSE MAHO_Panel.key.r3c3

42 bit OUT FALSE MAHO_Panel.key.r3c4

42 bit OUT FALSE MAHO_Panel.key.r4c0

42 bit OUT FALSE MAHO_Panel.key.r4c1

42 bit OUT FALSE MAHO_Panel.key.r4c2

42 bit OUT FALSE MAHO_Panel.key.r4c3

42 bit OUT FALSE MAHO_Panel.key.r4c4

42 u32 IN 0x00000000 MAHO_Panel.keycode

42 s32 OUT 0 MAHO_Panel.time

And yes, all net commands need a signal and the first token after the "net" command

( you can also verify this with halcmd)

This can save a lot of time by quickly testing hal commands and components without re-editing

your hal file over and over (once you have things working you can copy/paste names/commands from your

terminal history into you hal file)

(this is with linuxcnc running but without the matrix_kb hal file additions )

pcw@pcw-G41M-Combo:~/linuxcnc$ halcmd loadrt matrix_kb config=5x5 names=MAHO_Panel

pcw@pcw-G41M-Combo:~/linuxcnc$ halcmd show pin MAHO

Component Pins:

Owner Type Dir Value Name

42 bit OUT FALSE MAHO_Panel.key.r0c0

42 bit OUT FALSE MAHO_Panel.key.r0c1

42 bit OUT FALSE MAHO_Panel.key.r0c2

42 bit OUT FALSE MAHO_Panel.key.r0c3

42 bit OUT FALSE MAHO_Panel.key.r0c4

42 bit OUT FALSE MAHO_Panel.key.r1c0

42 bit OUT FALSE MAHO_Panel.key.r1c1

42 bit OUT FALSE MAHO_Panel.key.r1c2

42 bit OUT FALSE MAHO_Panel.key.r1c3

42 bit OUT FALSE MAHO_Panel.key.r1c4

42 bit OUT FALSE MAHO_Panel.key.r2c0

42 bit OUT FALSE MAHO_Panel.key.r2c1

42 bit OUT FALSE MAHO_Panel.key.r2c2

42 bit OUT FALSE MAHO_Panel.key.r2c3

42 bit OUT FALSE MAHO_Panel.key.r2c4

42 bit OUT FALSE MAHO_Panel.key.r3c0

42 bit OUT FALSE MAHO_Panel.key.r3c1

42 bit OUT FALSE MAHO_Panel.key.r3c2

42 bit OUT FALSE MAHO_Panel.key.r3c3

42 bit OUT FALSE MAHO_Panel.key.r3c4

42 bit OUT FALSE MAHO_Panel.key.r4c0

42 bit OUT FALSE MAHO_Panel.key.r4c1

42 bit OUT FALSE MAHO_Panel.key.r4c2

42 bit OUT FALSE MAHO_Panel.key.r4c3

42 bit OUT FALSE MAHO_Panel.key.r4c4

42 u32 IN 0x00000000 MAHO_Panel.keycode

42 s32 OUT 0 MAHO_Panel.time

And yes, all net commands need a signal and the first token after the "net" command

( you can also verify this with halcmd)

This can save a lot of time by quickly testing hal commands and components without re-editing

your hal file over and over (once you have things working you can copy/paste names/commands from your

terminal history into you hal file)

Last edit: 01 Jan 2018 16:05 by PCW.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1571

- Thank you received: 580

01 Jan 2018 16:20 - 02 Jan 2018 09:32 #103928

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks. That is very helpful. I forgot that hal pins get automatically created by the function, and thought I needed to define them.

Thanks for confirming that the numbering of columns and rows starts with 0.

Now I understand better this line of the documentation.

In the optional scan-generation mode the matrix_kb.N.keycode pin changes to an output pin and a set of output row pins and input column pins are created.

So my HAL entry will be:

loadrt matrix_kb config=5x5s names=MAHO_Panel

When the signal is irrelevant, and is only used as glue bettweens pins, like in this case...

net signal name MAHO_Panel.col-2-in hm2_5i25.0.7i77.0.0.output-01

... is there a convention or standard in the the linuxcnc community for signal naming?

Here is my button matrix

And a rough wiring diagram.

Mark

Thanks for confirming that the numbering of columns and rows starts with 0.

Now I understand better this line of the documentation.

In the optional scan-generation mode the matrix_kb.N.keycode pin changes to an output pin and a set of output row pins and input column pins are created.

So my HAL entry will be:

loadrt matrix_kb config=5x5s names=MAHO_Panel

When the signal is irrelevant, and is only used as glue bettweens pins, like in this case...

net signal name MAHO_Panel.col-2-in hm2_5i25.0.7i77.0.0.output-01

... is there a convention or standard in the the linuxcnc community for signal naming?

Here is my button matrix

And a rough wiring diagram.

Mark

Last edit: 02 Jan 2018 09:32 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1571

- Thank you received: 580

04 Jan 2018 17:23 - 04 Jan 2018 17:26 #104028

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I've been working on the button assemblies.

The top RH button needs two switches, one for 110VAC physical E-Stop release, and the other 24VDC to the 7i77 and Linuxcnc.

When I designed the laser part, I didn't realise that those buttons are stackable. Duh!

I'll need to reprint the entire set of buttons one more time, as they need to be another 2mm thicker to avoid jamming in the the front panel cut outs.

Using my daughters yellow nail polish to bring out the text doesn't really work, as the solvent in the polish attacks the PLA. Next attempt will be with acylic paint.

Mark

The top RH button needs two switches, one for 110VAC physical E-Stop release, and the other 24VDC to the 7i77 and Linuxcnc.

When I designed the laser part, I didn't realise that those buttons are stackable. Duh!

I'll need to reprint the entire set of buttons one more time, as they need to be another 2mm thicker to avoid jamming in the the front panel cut outs.

Using my daughters yellow nail polish to bring out the text doesn't really work, as the solvent in the polish attacks the PLA. Next attempt will be with acylic paint.

Mark

Last edit: 04 Jan 2018 17:26 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1571

- Thank you received: 580

06 Jan 2018 20:27 #104088

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

03 Feb 2018 01:34 #105348

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Have been wanting to send this information about glass scale cleaning. Better late than never? From what I have read-seen and had my hands on, be very careful when messing with glass scales. they are easy to damage and big cost to replace. When removing the scale ,check the mounting places for tiny shims between the machine and the scale body/spar. Think about getting new replacement lip seals before the scale removal. To me , the hard part is getting the scale and read head aligned correctly when remounting to the machine. Remember those very tiny shims when the spar an read head were removed from the machine ?

When the read head is removed from the spar ,have a good look at the tiny light bulbs and think about how they could be replaced if it became necessary For a real adventure try finding a LED to replace the grain of wheat bulbs.

The spar end caps have a small hole that is intended. for attachment of a air hose. this is so clean dry air can help keep junk out of or entering the scale/spar.. Note the pressurized air has to be clean an dry an no oil,also the lip seals need to be in good condition.

For testing the scale, all I have seen is to use a O-scope to compare the scales output sin/cos values . Using either sin or cos for Horizontal sweep input and the other for Vertical input the display should be a circle. The rounder the displayed circle the better..

Do not fry the scale because of O-scope or power supply AC input ground loops,please..

Have been wondering if there has been any thought on checking all the lub-oil lines for quantity of flow. Have read that useing the wrong type of lub-oil causing the rulon glue ,rulon or the other plastic used on the machine ways, to deteriorate.

A very big Thank - You for all of your effort in documenting this conversion/retrofit. Hope to see more of the progress.

When the read head is removed from the spar ,have a good look at the tiny light bulbs and think about how they could be replaced if it became necessary For a real adventure try finding a LED to replace the grain of wheat bulbs.

The spar end caps have a small hole that is intended. for attachment of a air hose. this is so clean dry air can help keep junk out of or entering the scale/spar.. Note the pressurized air has to be clean an dry an no oil,also the lip seals need to be in good condition.

For testing the scale, all I have seen is to use a O-scope to compare the scales output sin/cos values . Using either sin or cos for Horizontal sweep input and the other for Vertical input the display should be a circle. The rounder the displayed circle the better..

Do not fry the scale because of O-scope or power supply AC input ground loops,please..

Have been wondering if there has been any thought on checking all the lub-oil lines for quantity of flow. Have read that useing the wrong type of lub-oil causing the rulon glue ,rulon or the other plastic used on the machine ways, to deteriorate.

A very big Thank - You for all of your effort in documenting this conversion/retrofit. Hope to see more of the progress.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1571

- Thank you received: 580

03 Feb 2018 10:11 #105356

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks J,Sorry, I have been using analysis paralysis to (so far successfully) procrastinate on that task.

Life got in the way for the last month, so I haven't been working on the MAHO, other than a couple of minor tasks like drilling the face sheet for mounting the button plates. Not sure what grade of stainless that face sheet it, but it was a real bitch to drill. Slightly too slow ->> instant work hardening, followed by broken drill, slightly too fast -->nasty break through, accompanied by broken drill.

I undercoated all the control panel parts last, weekend, so they should be dry enough in the cold basement for some more paint this weekend.

I really need to get a moving dolly designed and made up to move the whole thig from the garage through in the machine shop, as then I will also pull off the main control cabinet and cross slide, to get through the door, which will also expose the Z glass scale encoder, which hasn't given any signs of life.

Mark

Life got in the way for the last month, so I haven't been working on the MAHO, other than a couple of minor tasks like drilling the face sheet for mounting the button plates. Not sure what grade of stainless that face sheet it, but it was a real bitch to drill. Slightly too slow ->> instant work hardening, followed by broken drill, slightly too fast -->nasty break through, accompanied by broken drill.

I undercoated all the control panel parts last, weekend, so they should be dry enough in the cold basement for some more paint this weekend.

I really need to get a moving dolly designed and made up to move the whole thig from the garage through in the machine shop, as then I will also pull off the main control cabinet and cross slide, to get through the door, which will also expose the Z glass scale encoder, which hasn't given any signs of life.

Mark

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

16 Feb 2018 05:16 - 16 Feb 2018 05:26 #106003

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Been reading your thread from #1-#32 again as it's cold here too. An I am a wimp. Was wondering what a "432/10 manual"is? Is

this one of those does not exist for the public Phillips manuals or is it a MAHO manual? Also, what other manuals and or documentation are you looking/wishing for? All I have is limited stuff for the MH600E & E2. The E2 uses brush-less servo motors,even on the spindle motor.

As to future using a VFD on spindle drive,is there any consideration being given for the earlier DC motor drive ? I have seen

earlier MAHOs with the DC spindle motors and side mounted blower motor. I have never been able to look at what their DC

control amounts too. Just wondering what a compare-contrast-cost of a used DC drive system veers 380volt VFD system might be?

I wrote 380volt as us heathens are only permitted to have 220volt single phase.

Noticed on my spare Heidenhain LS403 scale it has a zero pulse label at each end. I don't know but wonder if those scales could

or would work with a later model read head. The prices of used scales for a MAHO seem very high to me.

Drimaropoylos noted his MAHO vertical spindle quill being stuck. I had to remove the (vertical head left side) quill lock device

and poured a rust freeing liquid in there and also replaced the spindle drive tangs with a steel bar to finally get the quill to

free up. The quill uses a Hecker Werke rod scraper ABR1 series for a seal. Parts list also notes a Brusk O-ring used with the seal.

As to the workshop door--- my vote is for jack hammering the wall out for a double door . One never knows if a Fehlmann a

Hermle or some other desperate machine might be looking for a nice safe home. Summertime the good behavior machines can be walked out to bask in the sunshine-- smell the roses ! Are you glad I am not your neighbour---

this one of those does not exist for the public Phillips manuals or is it a MAHO manual? Also, what other manuals and or documentation are you looking/wishing for? All I have is limited stuff for the MH600E & E2. The E2 uses brush-less servo motors,even on the spindle motor.

As to future using a VFD on spindle drive,is there any consideration being given for the earlier DC motor drive ? I have seen

earlier MAHOs with the DC spindle motors and side mounted blower motor. I have never been able to look at what their DC

control amounts too. Just wondering what a compare-contrast-cost of a used DC drive system veers 380volt VFD system might be?

I wrote 380volt as us heathens are only permitted to have 220volt single phase.

Noticed on my spare Heidenhain LS403 scale it has a zero pulse label at each end. I don't know but wonder if those scales could

or would work with a later model read head. The prices of used scales for a MAHO seem very high to me.

Drimaropoylos noted his MAHO vertical spindle quill being stuck. I had to remove the (vertical head left side) quill lock device

and poured a rust freeing liquid in there and also replaced the spindle drive tangs with a steel bar to finally get the quill to

free up. The quill uses a Hecker Werke rod scraper ABR1 series for a seal. Parts list also notes a Brusk O-ring used with the seal.

As to the workshop door--- my vote is for jack hammering the wall out for a double door . One never knows if a Fehlmann a

Hermle or some other desperate machine might be looking for a nice safe home. Summertime the good behavior machines can be walked out to bask in the sunshine-- smell the roses ! Are you glad I am not your neighbour---

Last edit: 16 Feb 2018 05:26 by J Green.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.568 seconds