Retrofitting a 1986 Maho MH400E

- tecno

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

07 Jan 2019 11:29 #123695

by tecno

Replied by tecno on topic Retrofitting a 1986 Maho MH400E

Spindel Speeders are expensive and a compromise. The 'popular' china spindles are compromises as well but less expensive. All depends on what you want to do.

So maybe a complete new spindle cartridge type with more torque is the way to go?

ATC at the same time maybe?

So maybe a complete new spindle cartridge type with more torque is the way to go?

ATC at the same time maybe?

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1538

- Thank you received: 571

07 Jan 2019 11:50 - 07 Jan 2019 12:41 #123696

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

No ATC for me. Getting the mill up and running was a big goal for me. As I have now sort of reached that goal, I need to work out what to use it for. I really don't have any plans to produce multiples of anything such that an ATC would be warranted.

The MAHO's vertical spindle bearings are lubricated for life, whatever that means. Since mine sat unused for probably 20 years, I have vague concerns about those bearings. Paying €265 for a 1.5kW ER16 chinese HF spindle and VFD seems for the occasional engraving job makes more sense to me that risking the main spindle bearings and a fragile expensive assessory.

Then again I already have a set of P4 spindle bearings I picked up when I was planning to make my own 30 taper mill spindle for my Deckel GiL frame. Maybe making my own spindle would be a good time waster

The MAHO's vertical spindle bearings are lubricated for life, whatever that means. Since mine sat unused for probably 20 years, I have vague concerns about those bearings. Paying €265 for a 1.5kW ER16 chinese HF spindle and VFD seems for the occasional engraving job makes more sense to me that risking the main spindle bearings and a fragile expensive assessory.

Then again I already have a set of P4 spindle bearings I picked up when I was planning to make my own 30 taper mill spindle for my Deckel GiL frame. Maybe making my own spindle would be a good time waster

Last edit: 07 Jan 2019 12:41 by RotarySMP.

Please Log in or Create an account to join the conversation.

- tecno

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

07 Jan 2019 12:09 #123698

by tecno

If you can easily get a motor mounted to drive this it may be better solution. Been looking at that option but I have no easy way to mount a separate motor to drive the extra spindle on my milling machine.

Replied by tecno on topic Retrofitting a 1986 Maho MH400E

Maybe maknig my own spindle would be a good time waster

If you can easily get a motor mounted to drive this it may be better solution. Been looking at that option but I have no easy way to mount a separate motor to drive the extra spindle on my milling machine.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1538

- Thank you received: 571

07 Jan 2019 12:45 #123700

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

It seems all hobby machinist sooner or later develop a perverse attraction for making spindles

Andy, would you mind sharing your scalering.ngc macro please? Do it just do the ticks, or also the numerical markings?

I need scales on a couple of jobs which are already mostly done like my drill press downfeed knob, or the universal tool holder on the Clarkson.

Mark

Andy, would you mind sharing your scalering.ngc macro please? Do it just do the ticks, or also the numerical markings?

I need scales on a couple of jobs which are already mostly done like my drill press downfeed knob, or the universal tool holder on the Clarkson.

Mark

Please Log in or Create an account to join the conversation.

- andypugh

-

- Online

- Moderator

-

Less

More

- Posts: 19764

- Thank you received: 4589

07 Jan 2019 12:55 #123701

by andypugh

forum.linuxcnc.org/20-g-code/27169-g-cod...ders?start=10#116888

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

Andy, would you mind sharing your scalering.ngc macro please? Do it just do the ticks, or also the numerical markings?

forum.linuxcnc.org/20-g-code/27169-g-cod...ders?start=10#116888

The following user(s) said Thank You: RotarySMP, J Green

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1538

- Thank you received: 571

07 Jan 2019 13:29 #123705

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks. I only searched for scalering.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1538

- Thank you received: 571

08 Jan 2019 07:35 - 08 Jan 2019 07:42 #123756

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

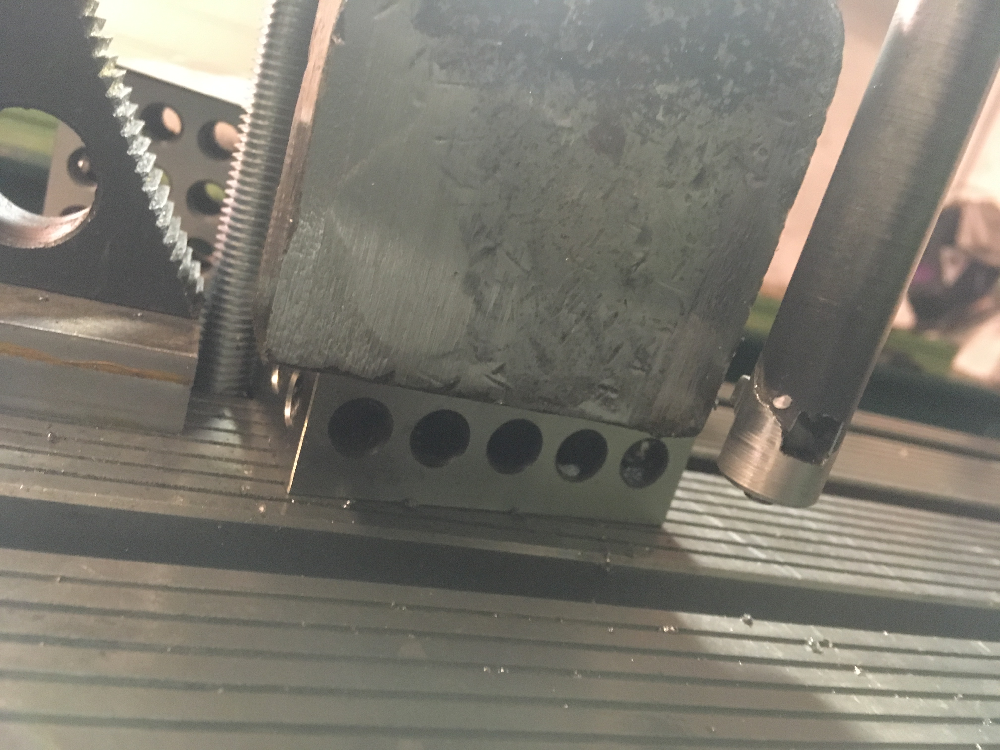

I need to surface this old anvil, but clamped to the table it is not high enough to reach it with the horizontal spindle. Good excuse to have a play with the slotting head. I ground up a cutting tool with quite positive rake to keep the cutting forces low. The stoke on the slotting head needed adjustment to the maximum of 80mm, which limits the stroke rate to 50, so I used 40 rpm / 40 strokes/min here. 0.1 Ap- depth of cut, and 10mm/min feed rate.

Only got the first pass done yesterday, and it looks like there might be hard spots in the surface, so I might have to give up on shaping it. I'll do a couple more passes and see. Sorry about the crappy photo, but I had to reach behind it with the phone.

Mark

Only got the first pass done yesterday, and it looks like there might be hard spots in the surface, so I might have to give up on shaping it. I'll do a couple more passes and see. Sorry about the crappy photo, but I had to reach behind it with the phone.

Mark

Attachments:

Last edit: 08 Jan 2019 07:42 by RotarySMP.

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

08 Jan 2019 12:40 #123772

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Guys, I have a question. After ordering the schematics for my machine I also asked the DMG reps about other available documents for my machine. The response I got today was they can sell me the manuals I already have and a spare parts catalogue. Does anybody have a catalogue like that (for any type of machine, not just MAHO) to tell me whether I can expect to find anything useful in it? Presumably, there aren't any drawings and it's just a list of stuff?

I inquired about these documents just in case they might have something I could use during a rebuild (which I'd love to do this year), but that doesn't seem to be the case. I was inspired by this American mill rebuild video in which you can see the guy has a booklet with drawings of all the assemblies that seem to be a fantastic help for repairs:

I'd appreciate any input.

I inquired about these documents just in case they might have something I could use during a rebuild (which I'd love to do this year), but that doesn't seem to be the case. I was inspired by this American mill rebuild video in which you can see the guy has a booklet with drawings of all the assemblies that seem to be a fantastic help for repairs:

I'd appreciate any input.

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

08 Jan 2019 12:44 #123773

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Also Mark, I haven't the faintest clue on how to use a shaper but it's really cool you can do that setup! Prior to your mentioning it, I've never seen anybody use that attachment before.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- andypugh

-

- Online

- Moderator

-

Less

More

- Posts: 19764

- Thank you received: 4589

08 Jan 2019 12:56 - 08 Jan 2019 12:57 #123774

by andypugh

They are often called a "slotting head" as they convert the mill to a slotter.

www.lathes.co.uk/rothley/

Typically used for keyways and splines.

There is a slotting head for my Harrison mill, but I let one escape on eBay last year and haven't seen another since.

But I have been giving seriois consideration to making my own from scratch, with the added feature of a CNC rotation for the cutter.

This would allow for the generation of internal gears like this:

However I don't think that there is any need for the 5th axis, circular interpolation ought to work just fine.

I think that to re face that anvil I would have used the lathe and 4-jaw chuck, though.

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

Also Mark, I haven't the faintest clue on how to use a shaper but it's really cool you can do that setup! Prior to your mentioning it, I've never seen anybody use that attachment before.

They are often called a "slotting head" as they convert the mill to a slotter.

www.lathes.co.uk/rothley/

Typically used for keyways and splines.

There is a slotting head for my Harrison mill, but I let one escape on eBay last year and haven't seen another since.

But I have been giving seriois consideration to making my own from scratch, with the added feature of a CNC rotation for the cutter.

This would allow for the generation of internal gears like this:

However I don't think that there is any need for the 5th axis, circular interpolation ought to work just fine.

I think that to re face that anvil I would have used the lathe and 4-jaw chuck, though.

Last edit: 08 Jan 2019 12:57 by andypugh.

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.199 seconds