- Configuring LinuxCNC

- Configuration Tools

- StepConf Wizard

- Linuxcnc - plasma router - joint 2 flolowing error

×

Forum Header

Linuxcnc - plasma router - joint 2 flolowing error

- kofaki

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 0

03 Feb 2021 21:25 - 03 Feb 2021 21:26 #197595

by kofaki

Replied by kofaki on topic Linuxcnc - plasma router - joint 2 flolowing error

Thanks, mr. Rodw ...i try post processor for sheetcam for Plasmac (i see on this forum  )

)

So, please, can you some send me procedure, how calibrate the THC PROMA 150 ?

Many thanks,

So, please, can you some send me procedure, how calibrate the THC PROMA 150 ?

Many thanks,

Last edit: 03 Feb 2021 21:26 by kofaki.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21211

- Thank you received: 7245

03 Feb 2021 21:51 #197599

by tommylight

Replied by tommylight on topic Linuxcnc - plasma router - joint 2 flolowing error

HYS 2

DEL 0.1

H V 240

DEL 0.1

H V 240

The following user(s) said Thank You: kofaki

Please Log in or Create an account to join the conversation.

- kofaki

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 0

04 Feb 2021 11:14 #197635

by kofaki

Replied by kofaki on topic Linuxcnc - plasma router - joint 2 flolowing error

Hi Tommy, you are best !! . It seems, that THC works !!!. I am very happy ....

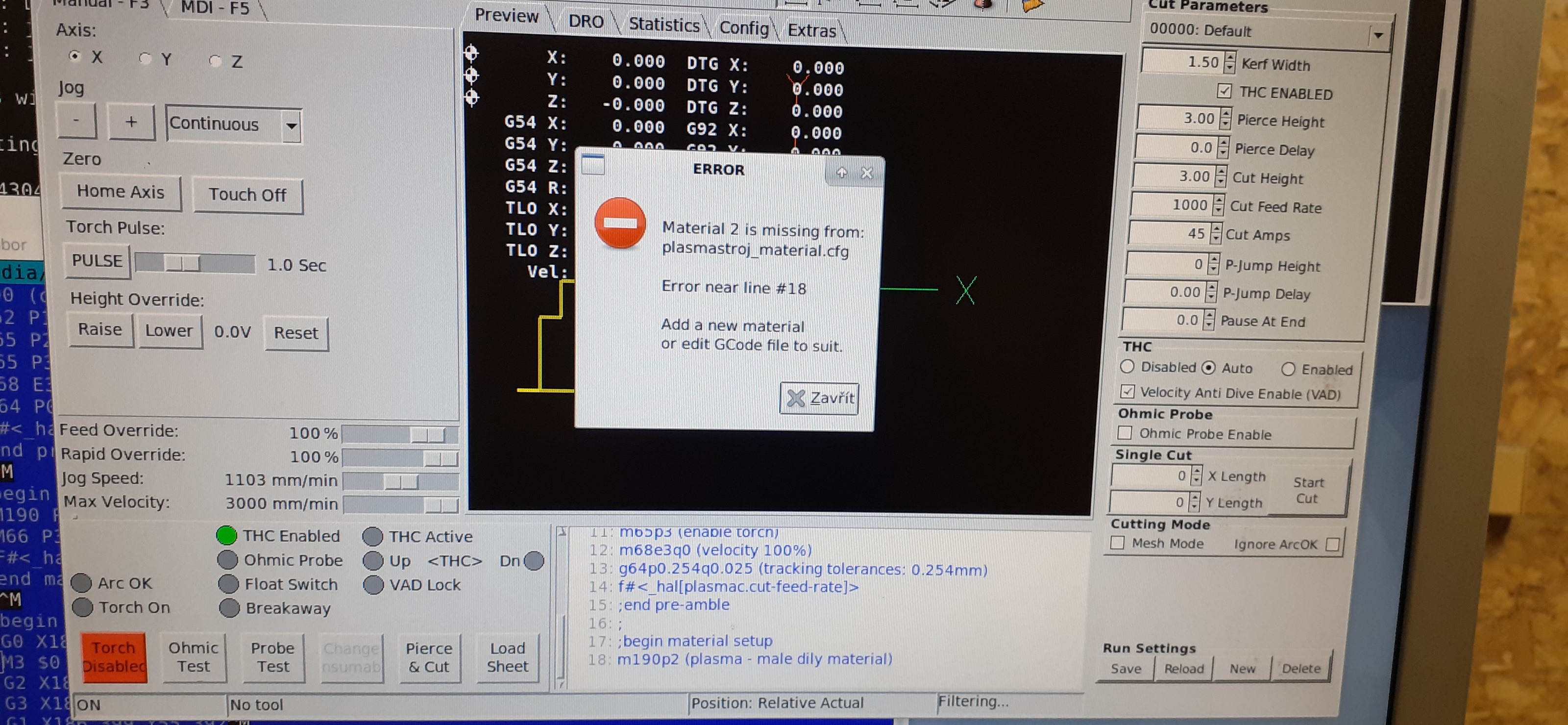

Now .... i am newbie user of Sheetcam. I use this post for PlasmaC (github.com/DenkBrettl/plasmac_sheetcam_postprocessor)

So, i created some G-Code and now i try upload this to LinuxCNC and i have this error.

Now .... i am newbie user of Sheetcam. I use this post for PlasmaC (github.com/DenkBrettl/plasmac_sheetcam_postprocessor)

So, i created some G-Code and now i try upload this to LinuxCNC and i have this error.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

04 Feb 2021 11:19 #197637

by rodw

Replied by rodw on topic Linuxcnc - plasma router - joint 2 flolowing error

Why wouldn't you use the post processor from the author of Plasmac?

forum.linuxcnc.org/plasmac/38438-plasmac-post-processors

forum.linuxcnc.org/plasmac/38438-plasmac-post-processors

Please Log in or Create an account to join the conversation.

- kofaki

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 0

04 Feb 2021 11:53 #197642

by kofaki

Replied by kofaki on topic Linuxcnc - plasma router - joint 2 flolowing error

i don't know,,,,but i try it  ......thank you Rodw

......thank you Rodw

Please Log in or Create an account to join the conversation.

- kofaki

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 0

04 Feb 2021 20:18 - 04 Feb 2021 20:19 #197676

by kofaki

Replied by kofaki on topic Linuxcnc - plasma router - joint 2 flolowing error

Ok, sheetcam is fine, now i have still problem with torch height.

If i cut some small holes, then i have the error " Valid Arc Lost" or "Float Switch Activated Program Paused"

I think, that if i try cutting through small steel plate (thick 2mm), then the problem is more frequent, because the steel still bended.

Maybe some bad settings .....i tried change the 'cut height' from 2 - 4 mm and 'feed rate' from 200 - 2000 mm/min.

If i tried cut for example "STAR" into big steel plate (thick 3 mm), then all is OK.

My last question is : the PROMA THC is set now for 162V. This voltage must be changed for different thick of steel plate or is the stable one value ?

Many thanks,

If i cut some small holes, then i have the error " Valid Arc Lost" or "Float Switch Activated Program Paused"

I think, that if i try cutting through small steel plate (thick 2mm), then the problem is more frequent, because the steel still bended.

Maybe some bad settings .....i tried change the 'cut height' from 2 - 4 mm and 'feed rate' from 200 - 2000 mm/min.

If i tried cut for example "STAR" into big steel plate (thick 3 mm), then all is OK.

My last question is : the PROMA THC is set now for 162V. This voltage must be changed for different thick of steel plate or is the stable one value ?

Many thanks,

Last edit: 04 Feb 2021 20:19 by kofaki.

Please Log in or Create an account to join the conversation.

- kofaki

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 0

04 Feb 2021 20:21 #197678

by kofaki

Replied by kofaki on topic Linuxcnc - plasma router - joint 2 flolowing error

Additional information: I do not have a water bath yet ...

Please Log in or Create an account to join the conversation.

- razplaz

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 1

08 Feb 2021 14:55 - 08 Feb 2021 14:56 #198006

by razplaz

Replied by razplaz on topic Linuxcnc - plasma router - joint 2 flolowing error

"My last question is : the PROMA THC is set now for 162V. This voltage must be changed for different thick of steel plate or is the stable one value ?"

Hi, on my Proma SD I change the voltage settings for different thicknesses of steel. For mine with Hypertherm Powermax 45XP using 50:1 voltage divider; 99v for 11 ga, 103v for 7 ga, 105v for 1/4", 110v for 1/2".

Hi, on my Proma SD I change the voltage settings for different thicknesses of steel. For mine with Hypertherm Powermax 45XP using 50:1 voltage divider; 99v for 11 ga, 103v for 7 ga, 105v for 1/4", 110v for 1/2".

Last edit: 08 Feb 2021 14:56 by razplaz. Reason: add detail

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Configuration Tools

- StepConf Wizard

- Linuxcnc - plasma router - joint 2 flolowing error

Time to create page: 0.108 seconds