Remora - ethernet NVEM / EC300 / EC500 cnc board

- BrysonW

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 2

19 Dec 2023 07:38 - 19 Dec 2023 08:19 #288552

by BrysonW

Replied by BrysonW on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Hello, this is a reply to beauxnez post from few days ago.

"hello, is it possible to make an nvem card work with qtplasmac?"

The answer is yes, another friend and myself are right at the end of a plasma machine build, were using a ec500 as the controller and it works fantastic with qtplasmac. I will say the THC is the only thing that we don't have working at the moment. On ours the plasma output is just on output 1, torch is either on or off. It goes from the board and turns a relay on and off which is the actual switch. For ours we have a Everlast 82i for the plasma cutter which has a 50:1 voltage divider, that gives us a 0 - 5v output for the torch voltage but from my understanding there aren't any analog inputs on these boards. A analog to digital converter may be a option. I'm not sure what the output of the mesa THCAD boards looks like, there may be a way to use one of those. I'm just getting started on trying to setup a arduino to take the analog voltage, work some magic on it, and send the info to linuxcnc that way using modbus. The downside I'm seeing to this approach is effectively I'm setting up a second controller to take just one analog input, and I'll have to put a switch inline on the ethernet cables. The upside is another controller and analog input, so now I can dream up more features to add to this machine (During our build process it started as a basic machine, we now have individual limit switches for every axis, probing, etc. , touchscreen interface, and so on..)

"hello, is it possible to make an nvem card work with qtplasmac?"

The answer is yes, another friend and myself are right at the end of a plasma machine build, were using a ec500 as the controller and it works fantastic with qtplasmac. I will say the THC is the only thing that we don't have working at the moment. On ours the plasma output is just on output 1, torch is either on or off. It goes from the board and turns a relay on and off which is the actual switch. For ours we have a Everlast 82i for the plasma cutter which has a 50:1 voltage divider, that gives us a 0 - 5v output for the torch voltage but from my understanding there aren't any analog inputs on these boards. A analog to digital converter may be a option. I'm not sure what the output of the mesa THCAD boards looks like, there may be a way to use one of those. I'm just getting started on trying to setup a arduino to take the analog voltage, work some magic on it, and send the info to linuxcnc that way using modbus. The downside I'm seeing to this approach is effectively I'm setting up a second controller to take just one analog input, and I'll have to put a switch inline on the ethernet cables. The upside is another controller and analog input, so now I can dream up more features to add to this machine (During our build process it started as a basic machine, we now have individual limit switches for every axis, probing, etc. , touchscreen interface, and so on..)

Last edit: 19 Dec 2023 08:19 by BrysonW.

Please Log in or Create an account to join the conversation.

- BrysonW

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 2

19 Dec 2023 07:51 - 19 Dec 2023 18:58 #288554

by BrysonW

Replied by BrysonW on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Here's the ini and hal files of of my machine. These are off of a plasma running a ec500 and QTPlasmaC, machine is fully operational with the exception of THC. I'm in the us so the machine is set up for imperial units. The machine has two motors on the x axis moving the gantry (Joint 0 and 3). Other things to note is the breakaway on the torch has two prox switches on in hence the need for the and2 component on those and we have a WHB04 wireless pendant so that is loaded in the ini file. The limits are all micro switches, and there are separate prox switches for homing on the x and y axis. The z axis uses the same switch for limit + and homing. If I remember right I started with the generic hal that came with remora and tweaked it from there. Just take it one input at a time.

If I remember in the next day or so, I'll post the .ini and .hal for our machine. I have a working machine running on a ec500. That way you can dig through it and be totally confused by it, lol.

If I remember in the next day or so, I'll post the .ini and .hal for our machine. I have a working machine running on a ec500. That way you can dig through it and be totally confused by it, lol.

Last edit: 19 Dec 2023 18:58 by BrysonW. Reason: Added files

The following user(s) said Thank You: beauxnez

Please Log in or Create an account to join the conversation.

- beauxnez

- Offline

- Premium Member

-

Less

More

- Posts: 149

- Thank you received: 10

19 Dec 2023 19:43 #288610

by beauxnez

Replied by beauxnez on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

hello, thank you for your help I will receive my card in a week

did you go through the stepconf?

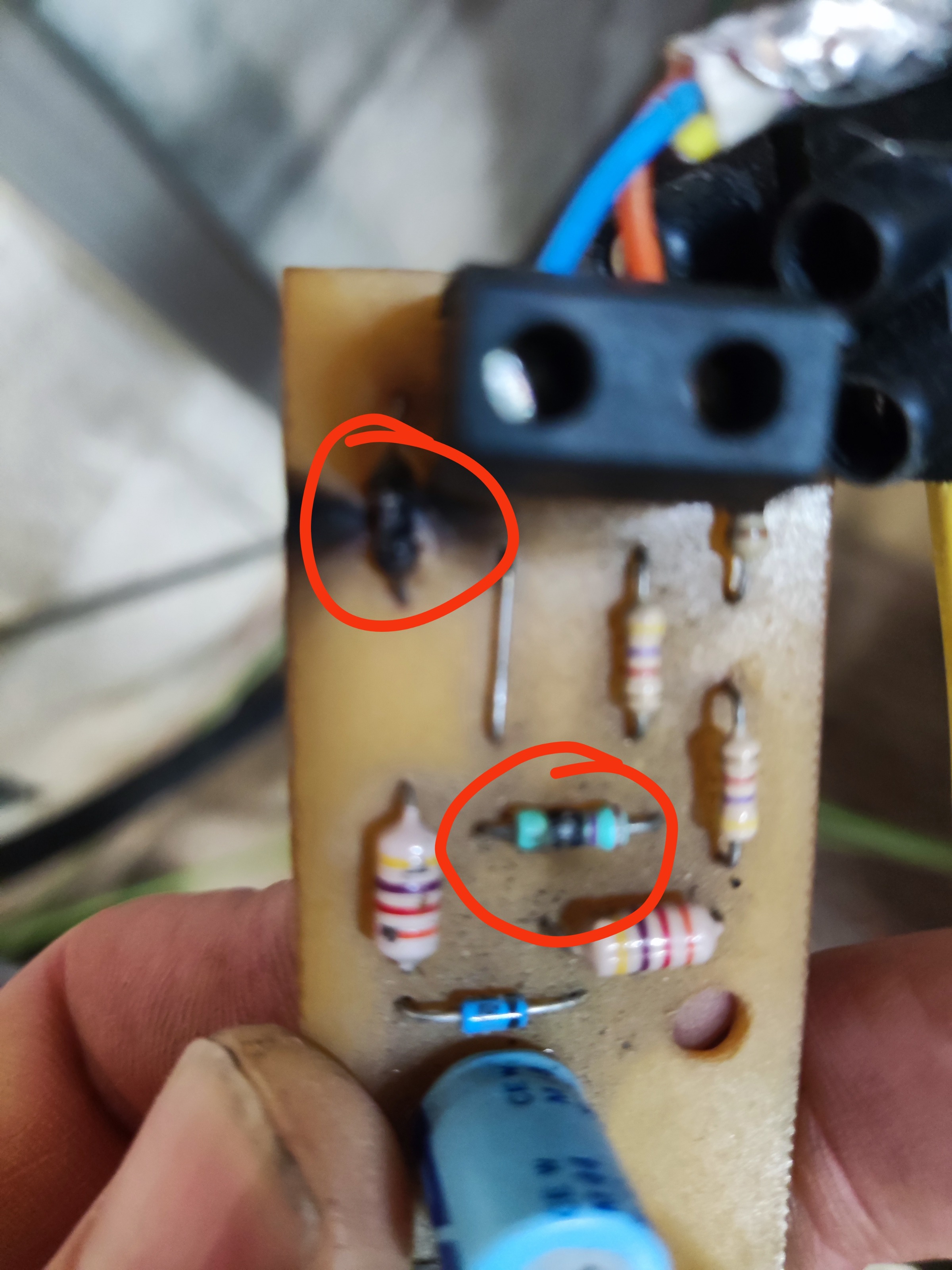

you can try that. I tested it works but the voltage divider gave up the ghost

github.com/memisibram/Arduino-Plasma-THC...r%20all%20controller

did you go through the stepconf?

you can try that. I tested it works but the voltage divider gave up the ghost

github.com/memisibram/Arduino-Plasma-THC...r%20all%20controller

Attachments:

Please Log in or Create an account to join the conversation.

- beauxnez

- Offline

- Premium Member

-

Less

More

- Posts: 149

- Thank you received: 10

19 Dec 2023 19:55 - 19 Dec 2023 19:56 #288611

by beauxnez

Replied by beauxnez on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Attachments:

Last edit: 19 Dec 2023 19:56 by beauxnez.

Please Log in or Create an account to join the conversation.

- BrysonW

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 2

19 Dec 2023 21:17 - 19 Dec 2023 21:27 #288617

by BrysonW

Replied by BrysonW on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

The configuration wizards don't really work for this application. If I remember right I ran one config just to look at the files it produced it think I told it a 7i96 mesa. You'll end up with a bunch of stuff that is clearly mesa specific. I'm thinking I copied the qtplasmac stuff out of that file though. But the files I posted I just started with the basic config that comes with the remora files from github. Hence why they are still named ec-500, I left the remora related stuff in there pretty much untouched, and just started adding to it. From there I started working through it adding one pin at a time. Using halshow in qtplasmac is going to be one of your best friends through that process. Did you build.your own divider? The plasma cutter were using has one built into it. We currently have a standalone thc (proma sd, it came with the machine, wouldn't have been my choice) on our machine but it doesn't want to play nice with the divider that is in the cutter. Plus having the thc on the main control screen would be much better that a standalone thc unit. What I'm currently thinking is to put the arduino in the box that our current thc is occupying and where using modbus comes into play is I should be able to send the data back to the computer over ethernet. I'm trying to avoid using usb to avoid as much potential for interference as possible.

Last edit: 19 Dec 2023 21:27 by BrysonW.

Please Log in or Create an account to join the conversation.

- beauxnez

- Offline

- Premium Member

-

Less

More

- Posts: 149

- Thank you received: 10

19 Dec 2023 21:25 #288618

by beauxnez

Replied by beauxnez on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

the voltage divider was made by a friend, I ordered the components to make this one

github.com/memisibram/Plasma_Voltage_Divider

github.com/memisibram/Plasma_Voltage_Divider

The following user(s) said Thank You: BrysonW

Please Log in or Create an account to join the conversation.

- beauxnez

- Offline

- Premium Member

-

Less

More

- Posts: 149

- Thank you received: 10

20 Dec 2023 08:57 #288656

by beauxnez

Replied by beauxnez on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

I'm going to try, I had started but the first modification I made I had an error message. So that made me give up a bit

I started with the ini file by modifying axis by qtplaslac and first error

I started with the ini file by modifying axis by qtplaslac and first error

Please Log in or Create an account to join the conversation.

- frayja2002

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 13

24 Dec 2023 04:29 #288965

by frayja2002

Replied by frayja2002 on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Hi all

I was wondering if someone could give some further advise on joint following errors.

I am getting errors the first time i try to jog. Sometimes if I adjust the job speed the problem goes away.

The problem always seems to happen after the EC500 box has been power cycled.

If I exit LinuxCNC & re-enter it the problem (generally) goes away. Once I am able to jog the first time it never drops out again, even at max jog speed.

As per my previous post I have an EC500 box flashed with the latest firmware, LinuxCNC 2.9 on Debian 12.

I have tried playing with the PRU value in the hal file but that doesn't seem to make any difference.

I've included the relevant files

Thanks

Alex

I was wondering if someone could give some further advise on joint following errors.

I am getting errors the first time i try to jog. Sometimes if I adjust the job speed the problem goes away.

The problem always seems to happen after the EC500 box has been power cycled.

If I exit LinuxCNC & re-enter it the problem (generally) goes away. Once I am able to jog the first time it never drops out again, even at max jog speed.

As per my previous post I have an EC500 box flashed with the latest firmware, LinuxCNC 2.9 on Debian 12.

I have tried playing with the PRU value in the hal file but that doesn't seem to make any difference.

I've included the relevant files

Thanks

Alex

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 956

- Thank you received: 486

25 Dec 2023 20:14 #289039

by scotta

Replied by scotta on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

The latest v3+ firmware changed to an absolute position count feedback to LinuxCNC vs the previous version that used an incremental count feedback. This stops count errors being accumulated in the position but has the effect you are seeing.

eg, EC500 is sending a position count of 50000 say to LinuxCNC, you power cycle the board and it then is sending a position count of 0. LinuxCNC sees this big position count change as a following error.

eg, EC500 is sending a position count of 50000 say to LinuxCNC, you power cycle the board and it then is sending a position count of 0. LinuxCNC sees this big position count change as a following error.

Please Log in or Create an account to join the conversation.

- frayja2002

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 13

26 Dec 2023 10:52 #289083

by frayja2002

Replied by frayja2002 on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

The latest v3+ firmware changed to an absolute position count.....

So is there a way to reset this? Every time I power cycle the EC500 box now I have to start LinuxCNC twice.

Not really a problem but a little inconvenient.

On a side note...

I updated one of my computers to LinuxCNC 2.10 & now when I hit the Estop (hardware) button I cannot take it out of estop without restarting.

I'm guessing the is some change in the way Estop should be done in the hal file.

Does anyone have any ideas on this? Here is the relavent code.

#Estop and SPI comms enable and feedback

net estop-button => estop-latch.0.fault-in <= remora.input.00

net estop-tripped-by-gui <= remora.status => and2.0.in0

net estop-gui-button <= estop-latch.0.ok-out => and2.0.in1

net stop-buttons-good <= and2.0.out => iocontrol.0.emc-enable-in

net user-enable-out <= iocontrol.0.user-enable-out => remora.enable => estop-latch.0.ok-in

net user-request-enable <= iocontrol.0.user-request-enable => remora.reset => estop-latch.0.reset

Thanks

Alex

So is there a way to reset this? Every time I power cycle the EC500 box now I have to start LinuxCNC twice.

Not really a problem but a little inconvenient.

On a side note...

I updated one of my computers to LinuxCNC 2.10 & now when I hit the Estop (hardware) button I cannot take it out of estop without restarting.

I'm guessing the is some change in the way Estop should be done in the hal file.

Does anyone have any ideas on this? Here is the relavent code.

#Estop and SPI comms enable and feedback

net estop-button => estop-latch.0.fault-in <= remora.input.00

net estop-tripped-by-gui <= remora.status => and2.0.in0

net estop-gui-button <= estop-latch.0.ok-out => and2.0.in1

net stop-buttons-good <= and2.0.out => iocontrol.0.emc-enable-in

net user-enable-out <= iocontrol.0.user-enable-out => remora.enable => estop-latch.0.ok-in

net user-request-enable <= iocontrol.0.user-request-enable => remora.reset => estop-latch.0.reset

Thanks

Alex

Please Log in or Create an account to join the conversation.

Time to create page: 0.276 seconds