10.5 x 25 cnc plasma table retrofit

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 12

12 Apr 2025 17:01 #326177

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

looks hot with a fresh coat of paint. Need to put some sort of solution in the water to keep it from rusting. i blew the old hypertherm out yesterday and just about got it all rigged up today may try to put power to it and see what happens. The cable chain adds ALOT of resistance to the machine should I be concerned with this?

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21227

- Thank you received: 7249

12 Apr 2025 17:31 #326181

by tommylight

Replied by tommylight on topic 10.5 x 25 cnc plasma table retrofit

baking soda

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

13 Apr 2025 12:56 #326220

by vre

Replied by vre on topic 10.5 x 25 cnc plasma table retrofit

why baking and sodium hydroxide that is cheaper and it is more alkaline?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21227

- Thank you received: 7249

13 Apr 2025 15:18 #326222

by tommylight

Replied by tommylight on topic 10.5 x 25 cnc plasma table retrofit

Very cheap and very easy to find, and it works fine, for a long time.

Please Log in or Create an account to join the conversation.

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 12

13 Apr 2025 19:44 #326229

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

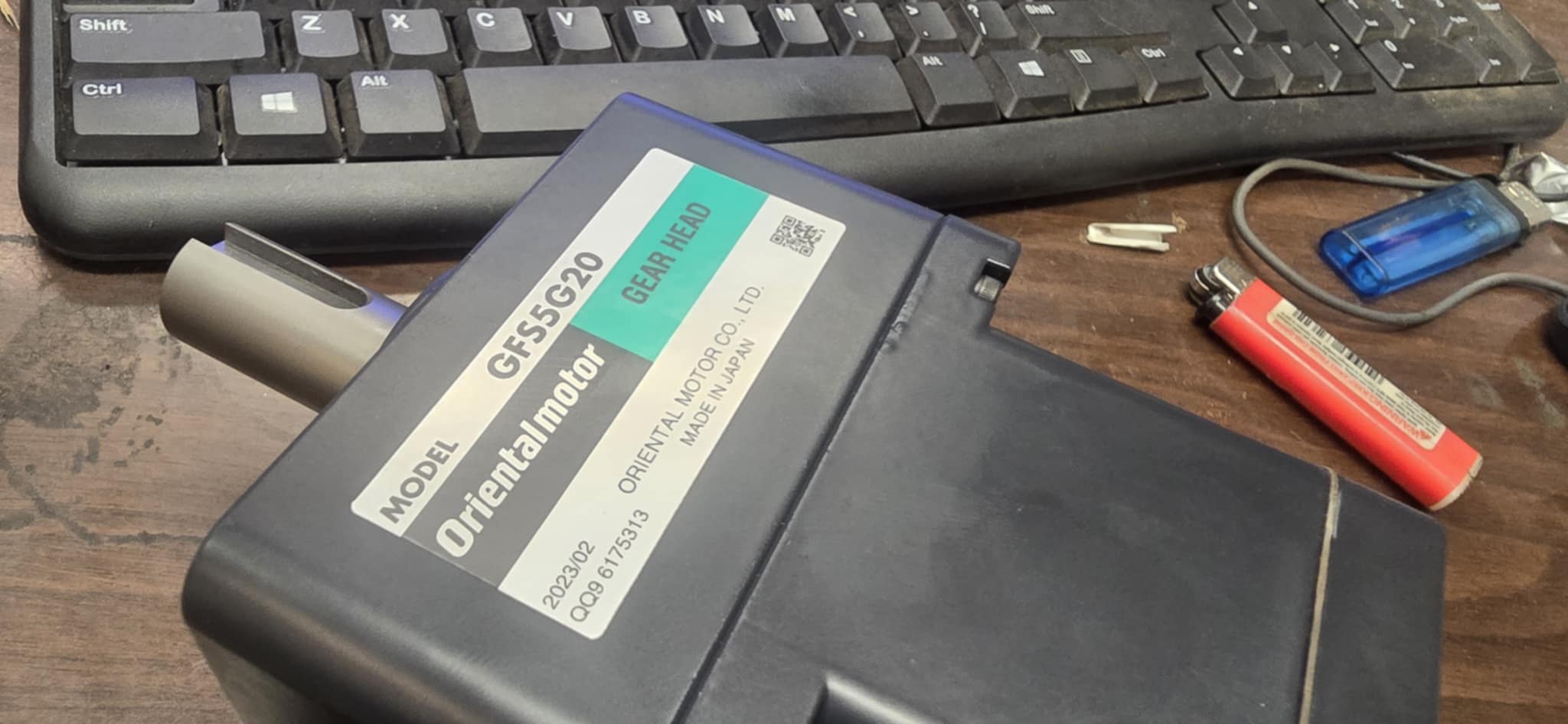

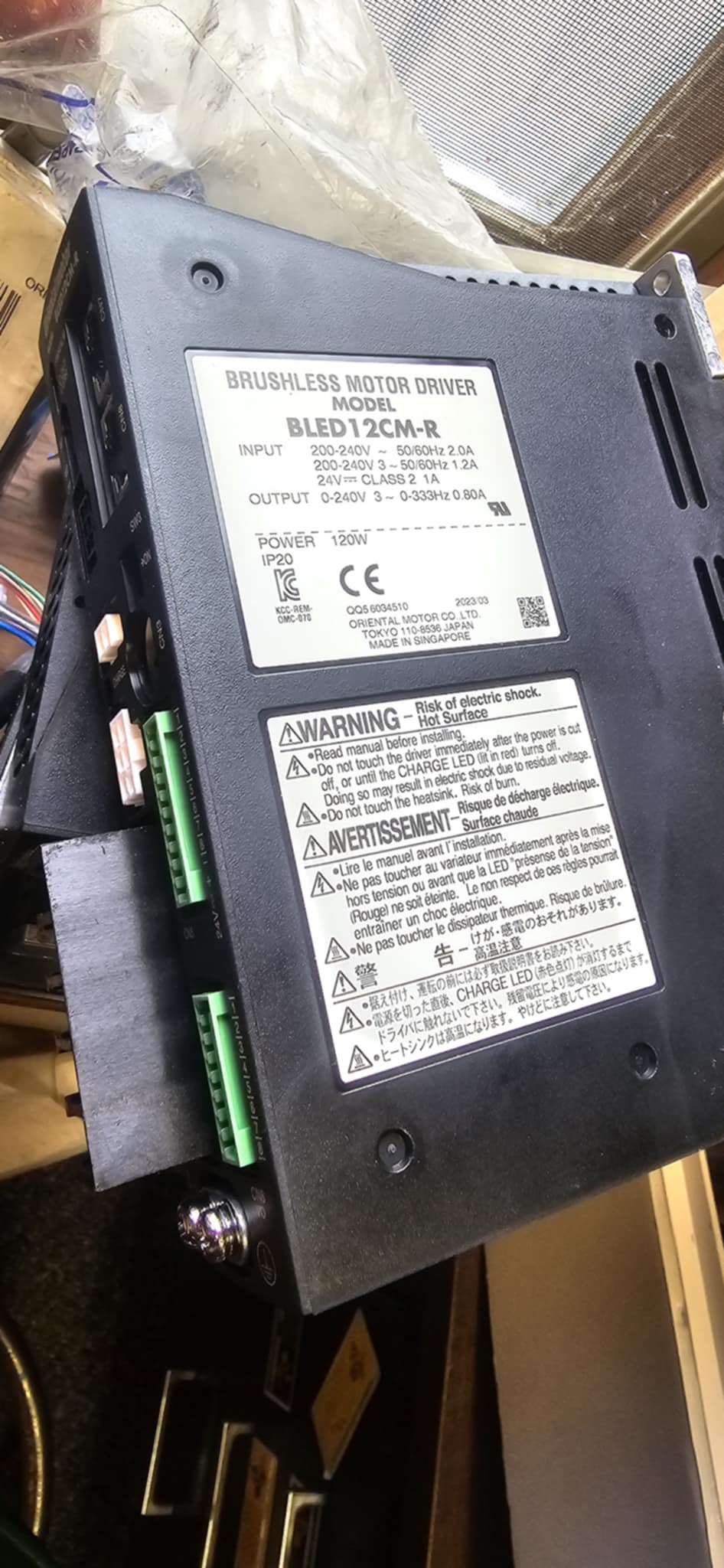

I loaded the table up with as much baking soda as we could buy from walgreens. Man did they give me a funny look when I bought them out of baking soda.... My freind came by and dropped off the motors all brand new. He says next month they may have some larger brother motors coming in close to a 1000w he thinks. These ones are 120w with a 20-1 gear ratio. Brushless stepper motors. What do you guys think, do you think its enough to power the gantry two of them for the Y direction? or should I hold off and wait for the larger motors or buy some new ones. I dont need crazy rapid speeds but being able to cut 16 g would be nice.

Attachments:

Please Log in or Create an account to join the conversation.

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 12

14 Apr 2025 00:08 #326238

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

The first issue I run into is that my gear track is 5 TPI The shaft diameter to the motor is 18mm does anyone build gears with metric bores and imperial gear pitch? buy a 5/8 bore pinion chuck it up in the lathe and bore it out to 18mm? hand file to broach out the keyway? a 20 T pinion should get me to about 600 ipm if my calculations are correct. which is honestly to fast but I am worried a 10t will not have enough contact and skip or slop.

Please Log in or Create an account to join the conversation.

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 12

14 Apr 2025 05:43 #326243

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

Upon further investigation I think these motors do not have the ability to speed control at the precision required. They are more for like a conveyor system pre set the speed and let er rip or control it with a potentiometer. I think they could still be very useful for projects around the shop maybe to power a few bridge Cranes that don't roll as nicely as they should anymore.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21227

- Thank you received: 7249

14 Apr 2025 07:29 #326250

by tommylight

Replied by tommylight on topic 10.5 x 25 cnc plasma table retrofit

Those motors do not seem to have encoders at all, so will not do for CNC control as you found out and i am late to point out.

You can try adding encoders as the lid is easy to open, but i fear it might be way to much work to attach them due to short shaft and limited space.

Might be possible using those magnetic encoders as they are simply glued to the shaft, so only drilling a hole for it and for the electronic on the lid, but i never used them so i have no idea how good and reliable they are.

You can try adding encoders as the lid is easy to open, but i fear it might be way to much work to attach them due to short shaft and limited space.

Might be possible using those magnetic encoders as they are simply glued to the shaft, so only drilling a hole for it and for the electronic on the lid, but i never used them so i have no idea how good and reliable they are.

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

14 Apr 2025 11:04 #326266

by vre

Replied by vre on topic 10.5 x 25 cnc plasma table retrofit

120watt is too low i think.

I plan to build a machine like this and am thinking to put 2 x 750w for y axis 1x750w x axis 1x600w z axis.

With servobelt transmission system with std s5m belts.

I plan to build a machine like this and am thinking to put 2 x 750w for y axis 1x750w x axis 1x600w z axis.

With servobelt transmission system with std s5m belts.

Please Log in or Create an account to join the conversation.

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 12

14 Apr 2025 18:00 #326306

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

Okay so here is what I'm thinking of buying.

www.aliexpress.us/item/3256808075045002....798396400003024786_1

For a set of 3 1000w motors it came out to being around $1000 usd shipped with gear reducers. I think 1000w might be a little large and I may go down to 750w. Do you think it's worth it to go absolute vs increment? They also asked about communication step dir vs "communication" I think they mean some sort of ethercat sort of deal. Waiting to here back from the salesman to clarify

I did alot of research last night and found the gear rack i have is 16 pitch with i belive a 20 dp I will still have the deal of a metric shaft to a imperial pinion size. But I'm not too concerned I can machine it out and proably hand file or even broach the keyway out.

www.aliexpress.us/item/3256808075045002....798396400003024786_1

For a set of 3 1000w motors it came out to being around $1000 usd shipped with gear reducers. I think 1000w might be a little large and I may go down to 750w. Do you think it's worth it to go absolute vs increment? They also asked about communication step dir vs "communication" I think they mean some sort of ethercat sort of deal. Waiting to here back from the salesman to clarify

I did alot of research last night and found the gear rack i have is 16 pitch with i belive a 20 dp I will still have the deal of a metric shaft to a imperial pinion size. But I'm not too concerned I can machine it out and proably hand file or even broach the keyway out.

Please Log in or Create an account to join the conversation.

Time to create page: 0.194 seconds