10.5 x 25 cnc plasma table retrofit

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 18

21 Nov 2024 08:32 #314970

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

Little update I completed the sheet metal storage rack for my plate processing operation. Posted a few pics below. Going to get started on setting up the plasma table. I need to design a water table so I know what height to build the gantry to. Do you think it's worth it to obtain a few more of those steppers? I can hunt down more of these redbox machines to rob them from. Do you think they would have the power required to drive the gantry? I estimate it's 3-500 lbs I like the idea of high precision. I don't think I would save much money after wasting the time to aquire the redboxs tear them down etc but if there high quality components and really special it may be worth it. Got any expereince with water tables? Know of any good designs to work off of? Seems like a good amount of engineering is required to make sure it's strong enough to not collapse alot of weight is put on em aswell as I want to be able to raise and lower water height automatically, maybe even control it electronicly with electro pnumatic valves.

Please Log in or Create an account to join the conversation.

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 18

21 Nov 2024 08:44 #314972

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

For $214 a pop I can purchase 1000w 220v servo motors with drivers. Really does not seem to unreasonable I'm not really sure tho if this would be way overkill but I figure it's better to go bigger and work the motor less. I included a link below. Is there any disadvantage to running a set up like this? I think I will stick with the original motors to get the machine running but I'd like to understand more about servo vs stepper.

www.amazon.com/RATTMMOTOR-Encoder-Contro...54&sr=8-4&th=1&psc=1

www.amazon.com/RATTMMOTOR-Encoder-Contro...54&sr=8-4&th=1&psc=1

Please Log in or Create an account to join the conversation.

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 18

03 Dec 2024 07:03 #315860

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

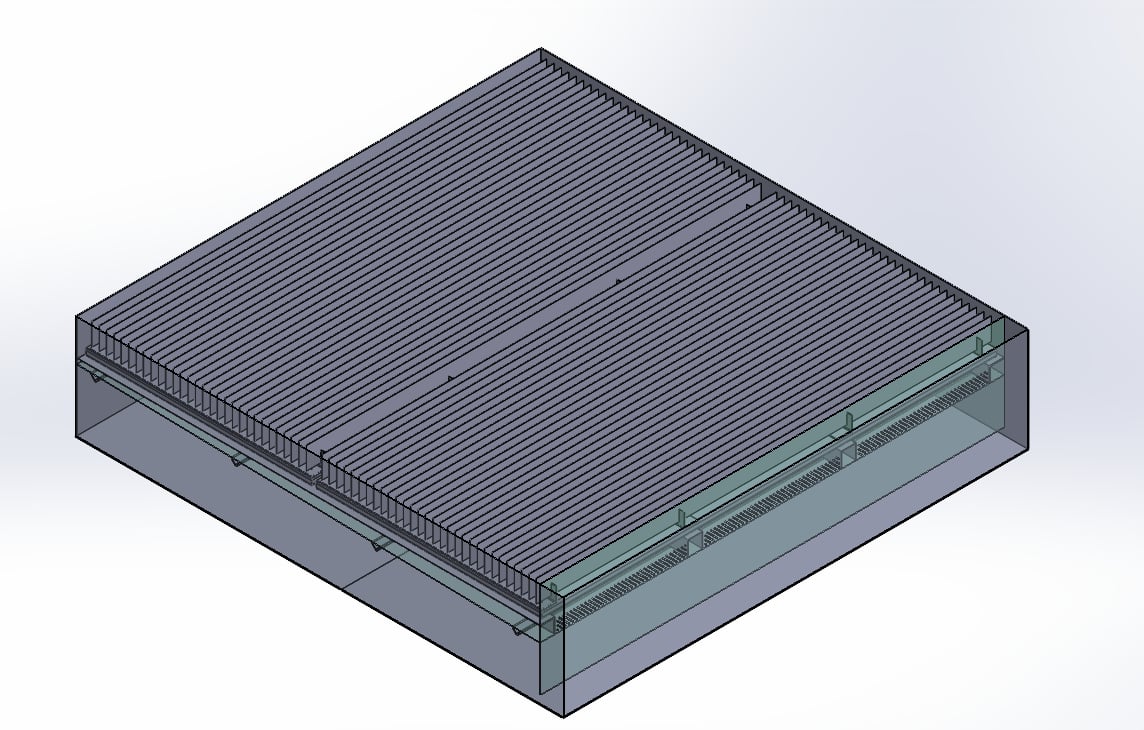

Heres the latest update on the project. I designed a water table 10.5 x 10.5 made from quarter inch thick Steel. I may increase size to 10.5 x 15.5 but not sure yet. It's pricy in material table so far weighs in at around 7000 lb and I am still going to add more support to it. It has removable slat bases that can be picked out of the bed with the crane for cleaning. I am designing for about 12 inches of water from lower to raise and shooting to be able to keep the slats 2 inch under water. I made the slats 6 inches long 1/8 thick every 2 inch. Do you think this is overkill???

I think my post has delve past the computers and hardware category on this board and more so turned into a full on build thread. If a mod wants to move the thread it would proably make sense.

I think my post has delve past the computers and hardware category on this board and more so turned into a full on build thread. If a mod wants to move the thread it would proably make sense.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21348

- Thank you received: 7285

03 Dec 2024 13:53 #315888

by tommylight

Replied by tommylight on topic 10.5 x 25 cnc plasma table retrofit

Move it to plasma section or to show your stuff?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

04 Dec 2024 11:02 #315941

by rodw

Replied by rodw on topic 10.5 x 25 cnc plasma table retrofit

75 pages of build thread and I can't find what I want so this will have to do.

forum.linuxcnc.org/show-your-stuff/32029...ild?start=310#124765

I suggest you slats are only mounted each side and in the middle. Then you can put a bend in them and have the slat ends pushed against the frame which stiffens them up so they don't wobble. I copied this design from a swiftcut machine on the show room floor.

The slots holding the slats here are very shallow, maybe only 10-15mm laser cut into some 16mm strips

forum.linuxcnc.org/show-your-stuff/32029...ild?start=310#124765

I suggest you slats are only mounted each side and in the middle. Then you can put a bend in them and have the slat ends pushed against the frame which stiffens them up so they don't wobble. I copied this design from a swiftcut machine on the show room floor.

The slots holding the slats here are very shallow, maybe only 10-15mm laser cut into some 16mm strips

Please Log in or Create an account to join the conversation.

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 18

06 Dec 2024 06:55 #316077

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

Yea your right. My old plasma table was like that I had the slats curved. Although I may still be able to curve the slats with 4 points of contact vs 3 I'm not sure how much I like the idea of super short slats. I figure they will get burnt up on a high amperage cut. It's possible in the future I may starter cutting 200 amp cuts over a inch of material thick. Today I got the table moved and started to clean up. Purchased new bearings man they are not cheap. Makes me second guess buying such a pos and not buying a complete working machine from a auction but here we are. I may reduce the thickness of the water table to 3/16 from 1/4 inch. Its about 7000 lbs of material which gets pricey. I kindof want the strength tho so it can handle getting banged up. I am going to order the parts list Tommy put together for the control tonight and try to get it to run on the original dc servos for now. I gutted the z axis the linear guides were super frozen up I got them to atleast move with only a few lbs of force on em. Tommorow more lubing and cleaning. I was looking at the original motors and the drives seems I do not have a plug for y axis encoders only for x axis into the box with all the drives. Tommorow i will post more pictures. Just want to make sure it's possible before I go down the route of trying to save the original motors.

Please Log in or Create an account to join the conversation.

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 18

11 Dec 2024 03:28 #316448

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 18

11 Jan 2025 05:40 #318683

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

Making more progress on water table. If I was to ever building something like this again I would build a stronger support frame to on the inside and underside of the table. I kindof skimped out there and it lead to lots of steel warping and bowing. I don't think it will matter much because I am going to build slat frames that can be leveled. Hopefully it's strong enough to hold all the water and up to 1.5 inch plate. Seems to be to me.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 18

16 Jan 2025 06:38 #319093

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

Hey I've got some questions for anyone following. I have a mechanical press brake I am looking to add cnc function basicly just jog two stepper motors to raise and lower the screws that control the height of the die to my designated position. Maybe a back guage that would be pretty much the same. Is linux cnc a good way to go for this or would it be better off to use a plc?

Please Log in or Create an account to join the conversation.

- tcbmetalworks

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 18

10 Apr 2025 21:23 #326046

by tcbmetalworks

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

I got the gantry together was alot of work and planning to make sure it was all straight. It rolls pretty nicely you can feel the hop between rails a little but I think with the size of the machine the vibrations will smooth out. If it appears in the cut quality I will switch to linear rails. We are painting it right now looks like a brand new machine! A friend of mine may have some brushless dc motors hes getting from work for me, we will see otherwise likely going to go with china brand servo motors. Still alot of work ahead of me on this project, im hoping it will be a reliable machine cut around the clock without issues.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.361 seconds