OLD Lathe conversion to a CNC

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

14 May 2024 05:53 #300553

by besriworld

OLD Lathe conversion to a CNC was created by besriworld

It's one of those stupid/crazy CNC lathe projects. If I could turn back time, this project would not exist.I will try to upload more pictures but not everything is documented ..

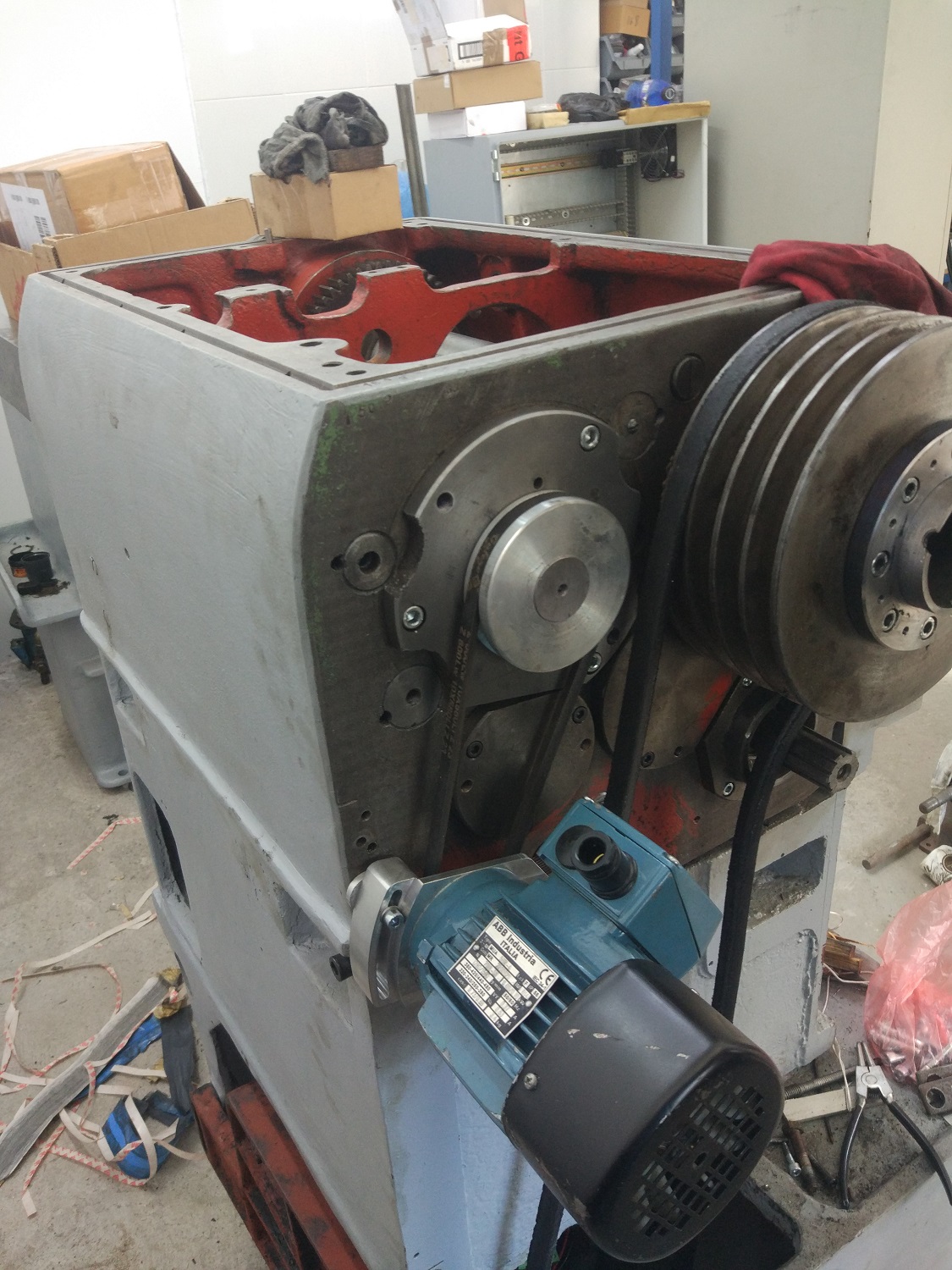

We bought an old machine probably 2 tons of iron and immediately begins disassembly, washing and painting

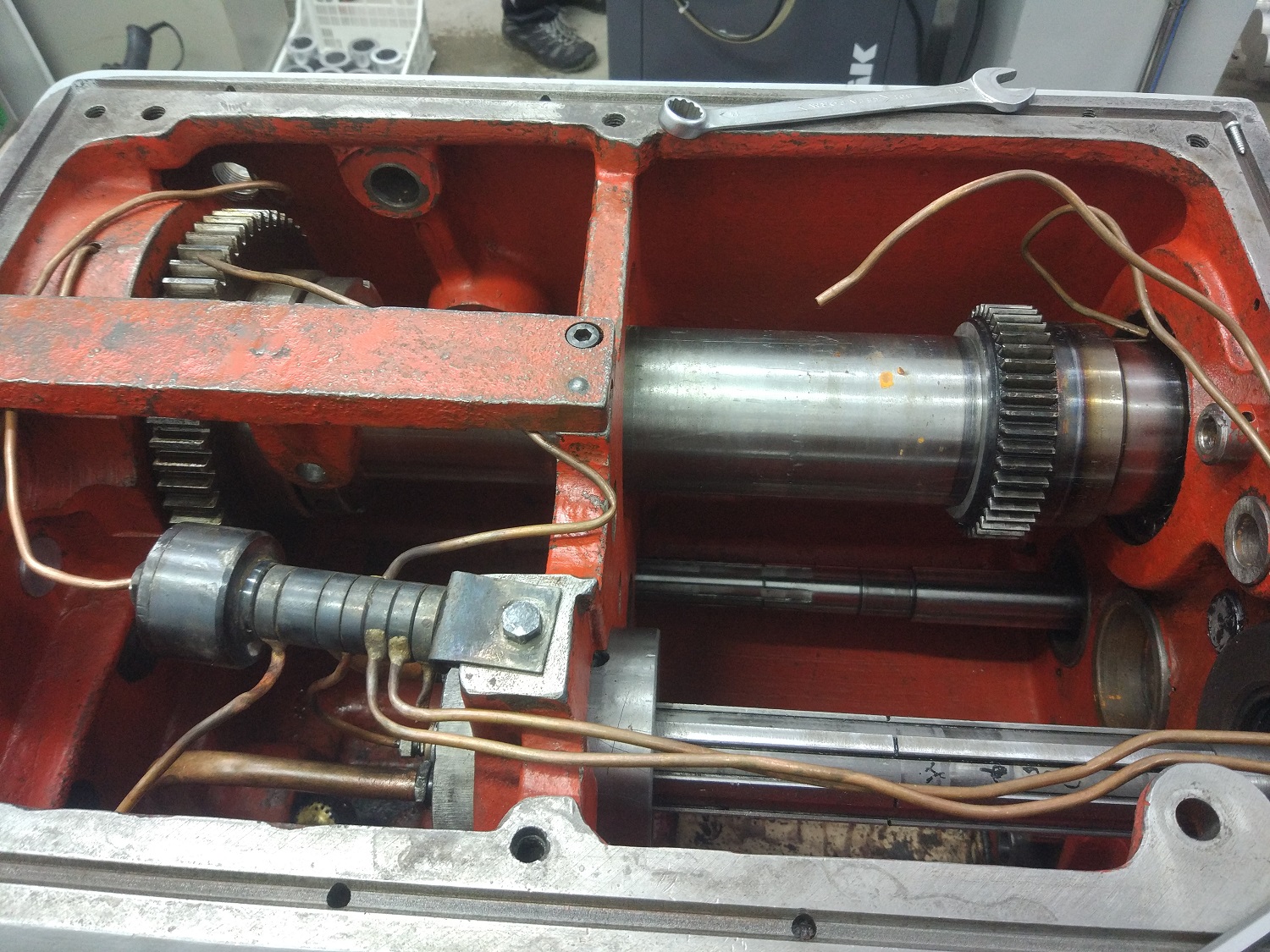

I threw out a lot of parts from the gearbox

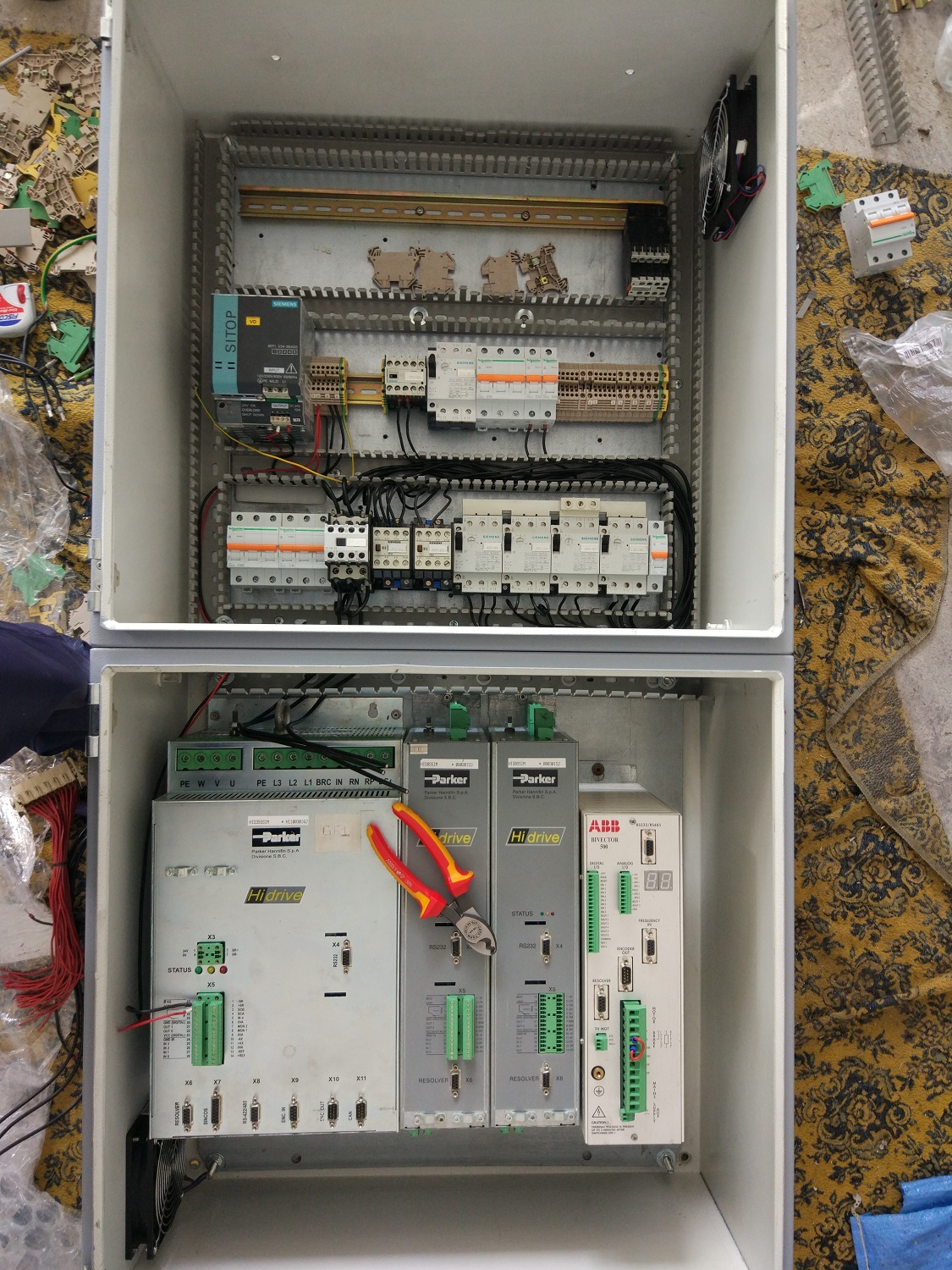

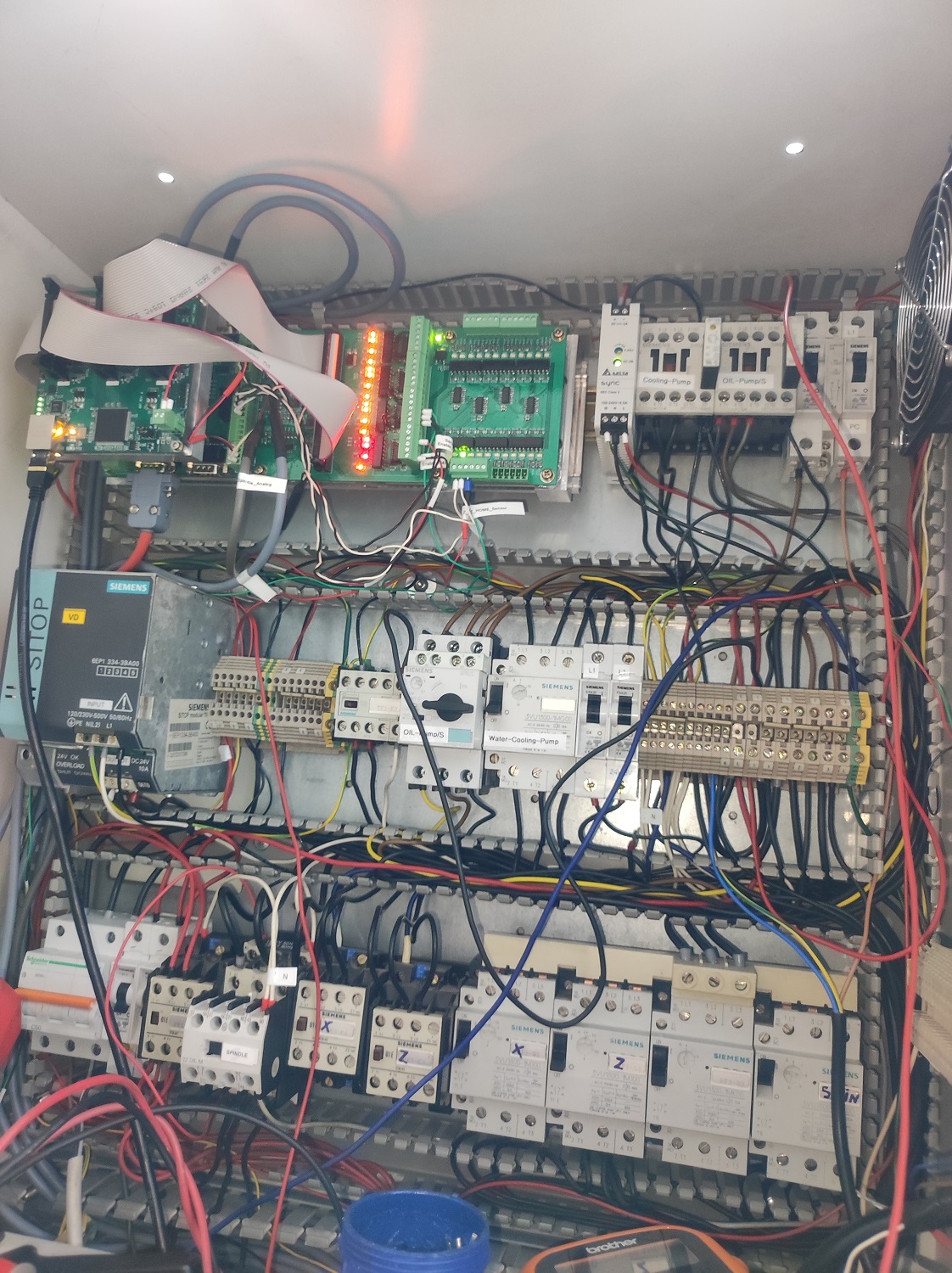

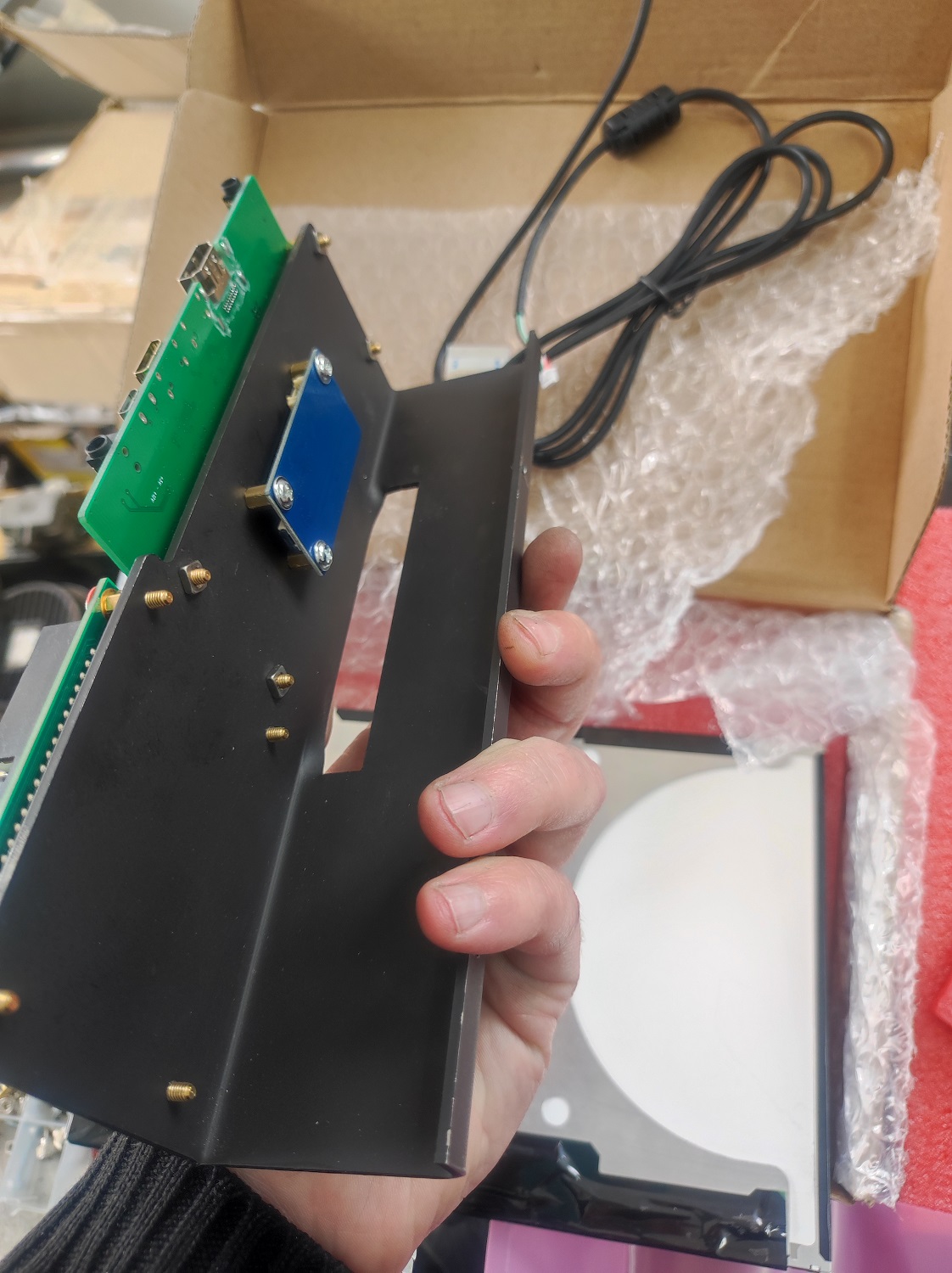

This is the first layout of the electrical cabinet

I have reached the maximum number of files allowed .I will continue in the next post

We bought an old machine probably 2 tons of iron and immediately begins disassembly, washing and painting

I threw out a lot of parts from the gearbox

This is the first layout of the electrical cabinet

I have reached the maximum number of files allowed .I will continue in the next post

Attachments:

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

14 May 2024 06:21 #300554

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

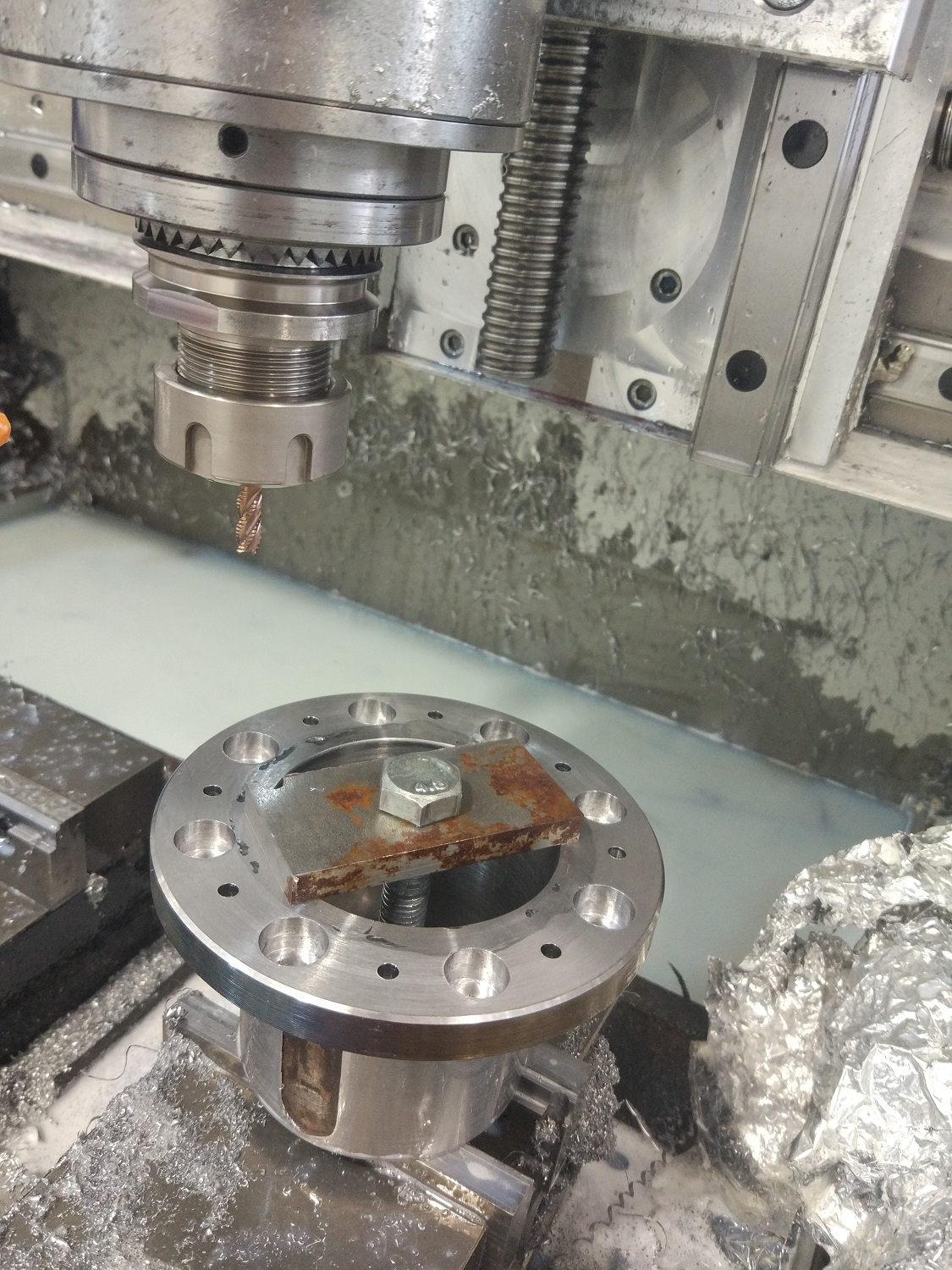

Here I am sanding the back end of the spindle.

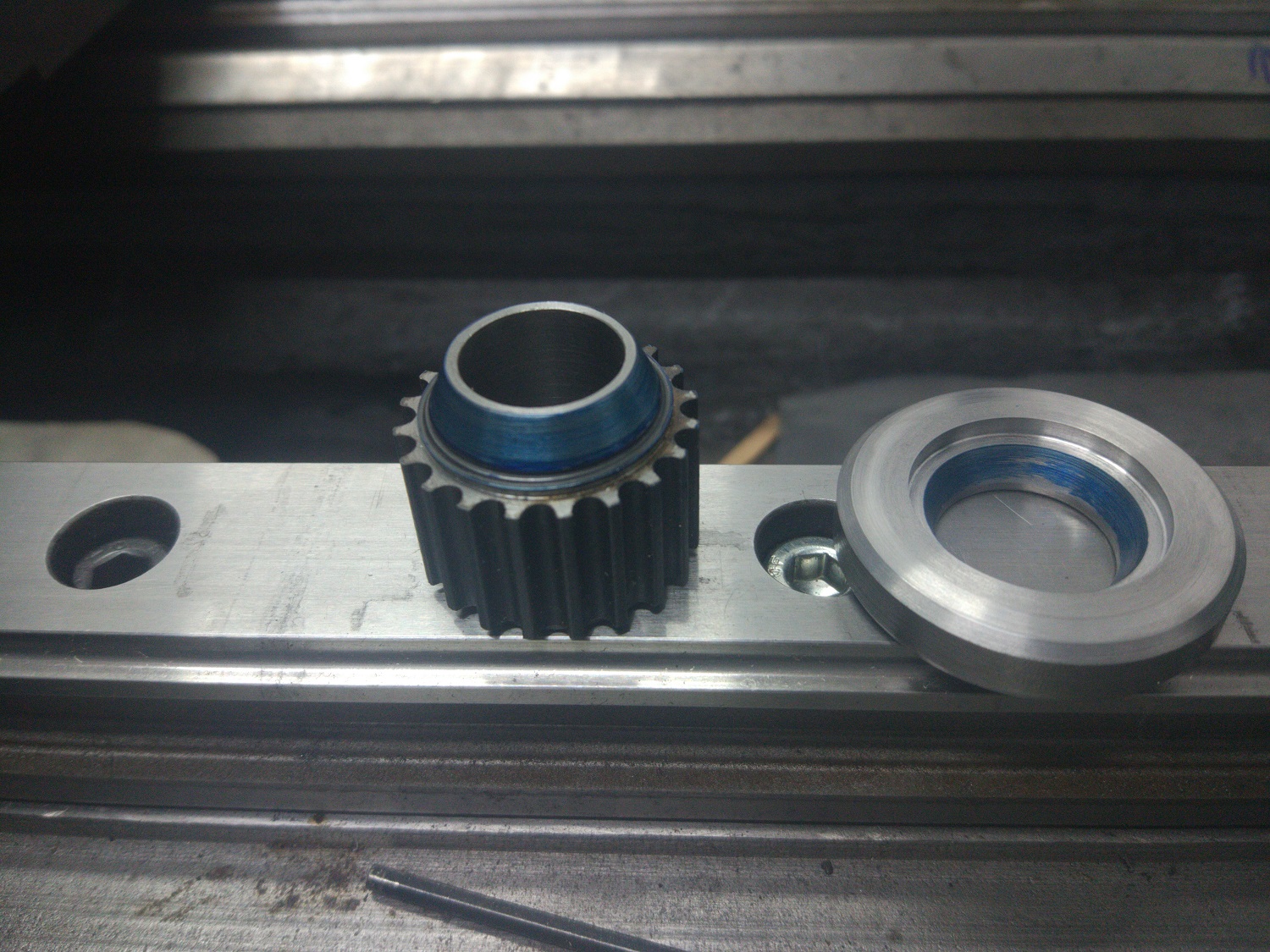

I made two parts that grip the spindle Pulley V-groove .This part has a cone from the outer part, the second part (not in the pictures) presses the first part to the axis of the spindle.

I keep the original oil pump. It was necessary to make several parts.

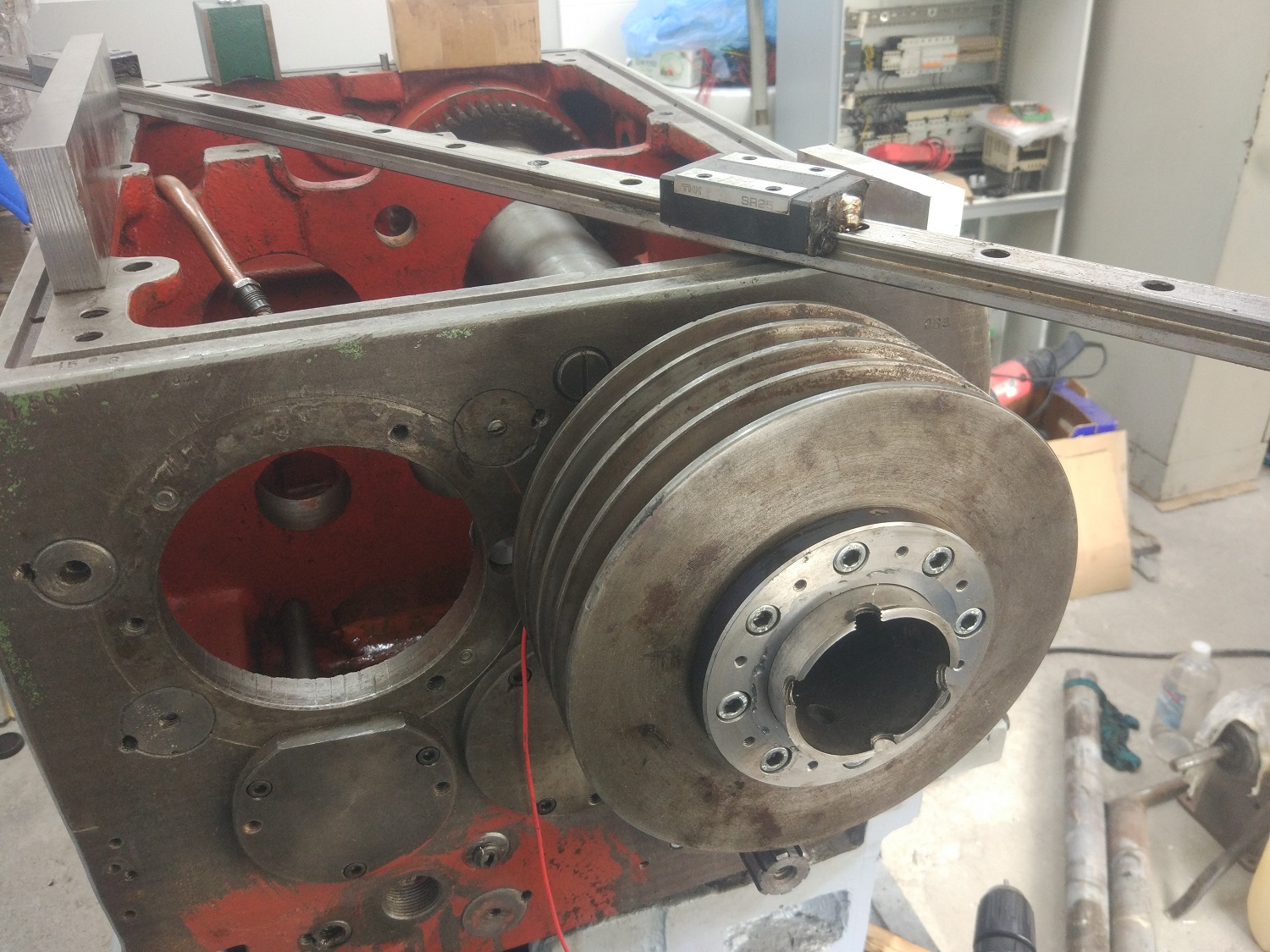

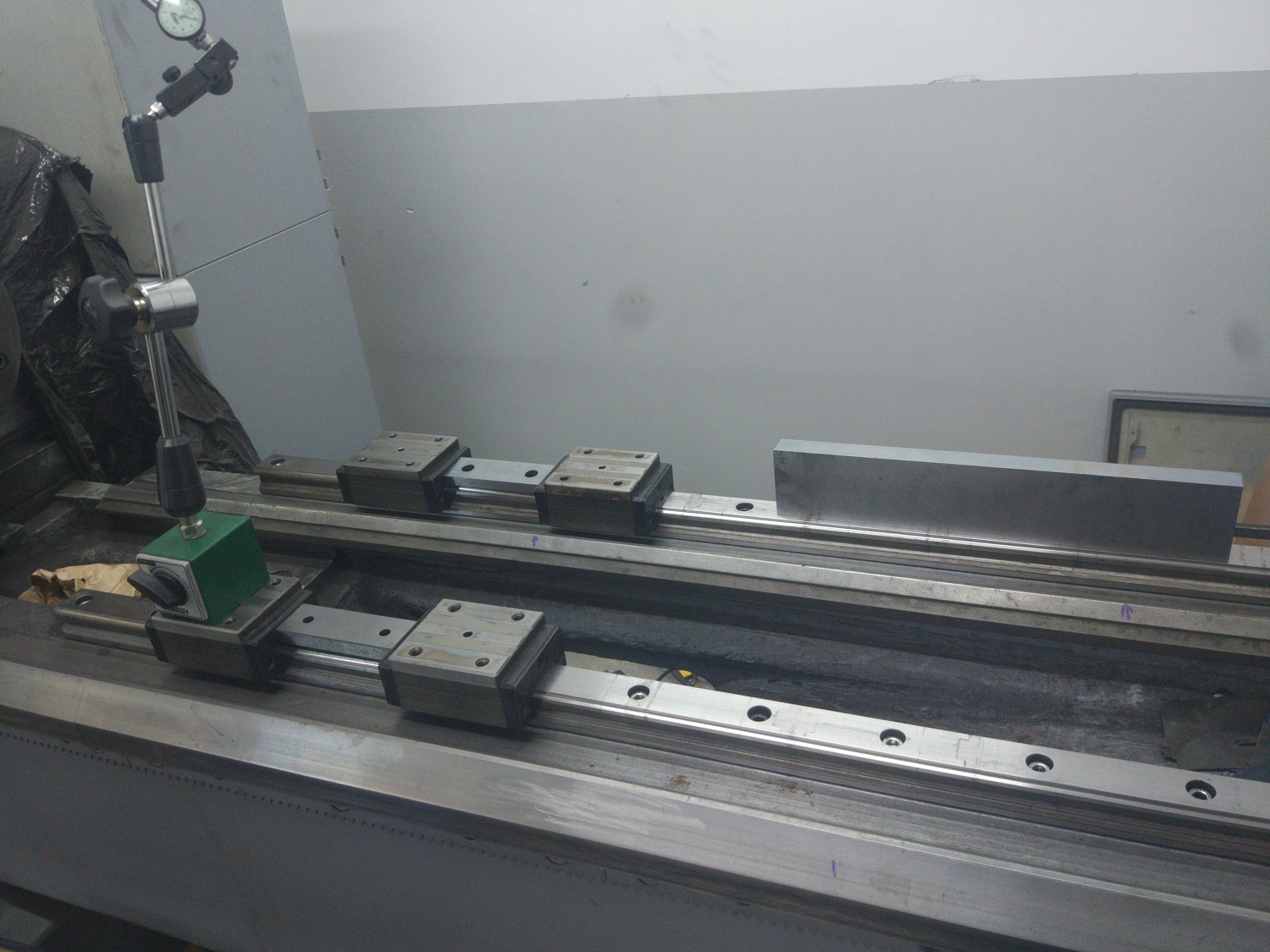

We put linear guides. They had to be level and make holes for threads.

I made two parts that grip the spindle Pulley V-groove .This part has a cone from the outer part, the second part (not in the pictures) presses the first part to the axis of the spindle.

I keep the original oil pump. It was necessary to make several parts.

We put linear guides. They had to be level and make holes for threads.

Attachments:

The following user(s) said Thank You: tommylight, Aciera

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

14 May 2024 19:49 #300596

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

Attachments:

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

14 May 2024 20:00 #300597

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

Attachments:

The following user(s) said Thank You: RotarySMP, tommylight, COFHAL, Unlogic

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21300

- Thank you received: 7274

14 May 2024 20:57 #300606

by tommylight

Replied by tommylight on topic OLD Lathe conversion to a CNC

Looking nice.

And i need help, professional help, i was looking at pictures and started thinking "hey i could do this to my manual lathe"... i have to go past the Mazak to get to manual lathe, Mazak being already CNC and retrofitted and working, sans the hydraulic chuck!

And i need help, professional help, i was looking at pictures and started thinking "hey i could do this to my manual lathe"... i have to go past the Mazak to get to manual lathe, Mazak being already CNC and retrofitted and working, sans the hydraulic chuck!

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

15 May 2024 06:28 - 15 May 2024 06:40 #300656

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

Thanks!

Yes, we all seem to have a professional distortions

A few more pictures of the control panel.

It's not perfect but I like it

First there is a primer, then a paint base and clear varnish. Then I engraved it on the router. I used a white paint base for filling. But it would be better with a white body filler

Yes, we all seem to have a professional distortions

A few more pictures of the control panel.

It's not perfect but I like it

First there is a primer, then a paint base and clear varnish. Then I engraved it on the router. I used a white paint base for filling. But it would be better with a white body filler

Attachments:

Last edit: 15 May 2024 06:40 by besriworld.

The following user(s) said Thank You: tommylight, TangentAudio

Please Log in or Create an account to join the conversation.

- TangentAudio

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 29

20 May 2024 16:55 #301016

by TangentAudio

Replied by TangentAudio on topic OLD Lathe conversion to a CNC

Great project, and nice workmanship! The control panel looks great in the photo!

Is the board with the orange heat sink an HDMI to LVDS board for the display?

Is the board with the orange heat sink an HDMI to LVDS board for the display?

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

20 May 2024 18:39 #301021

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

Yes, this is the display board. By modern standards the display is very small 10.1"  with 2k resolution .

with 2k resolution .

Please Log in or Create an account to join the conversation.

- jimmyrig

- Offline

- Premium Member

-

Less

More

- Posts: 135

- Thank you received: 42

25 May 2024 05:11 #301373

by jimmyrig

Replied by jimmyrig on topic OLD Lathe conversion to a CNC

Looks great, love the control panel design.

The following user(s) said Thank You: RotarySMP, besriworld

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

25 May 2024 10:11 #301397

by andypugh

Replied by andypugh on topic OLD Lathe conversion to a CNC

My CNC lathe is a converted manual, but I kept it a lot more original in some ways, and much less so in others (I had a bunch of custom castings made to replace the apron and the feeds gearbox, for example)

For the kind of projects I do the layout of a conventional lathe, without full enclosure, makes more sense.

bodgesoc.blogspot.com/2015/08/holbrook1.html

For the kind of projects I do the layout of a conventional lathe, without full enclosure, makes more sense.

bodgesoc.blogspot.com/2015/08/holbrook1.html

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 1.211 seconds