OLD Lathe conversion to a CNC

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 83

26 May 2024 15:30 #301486

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

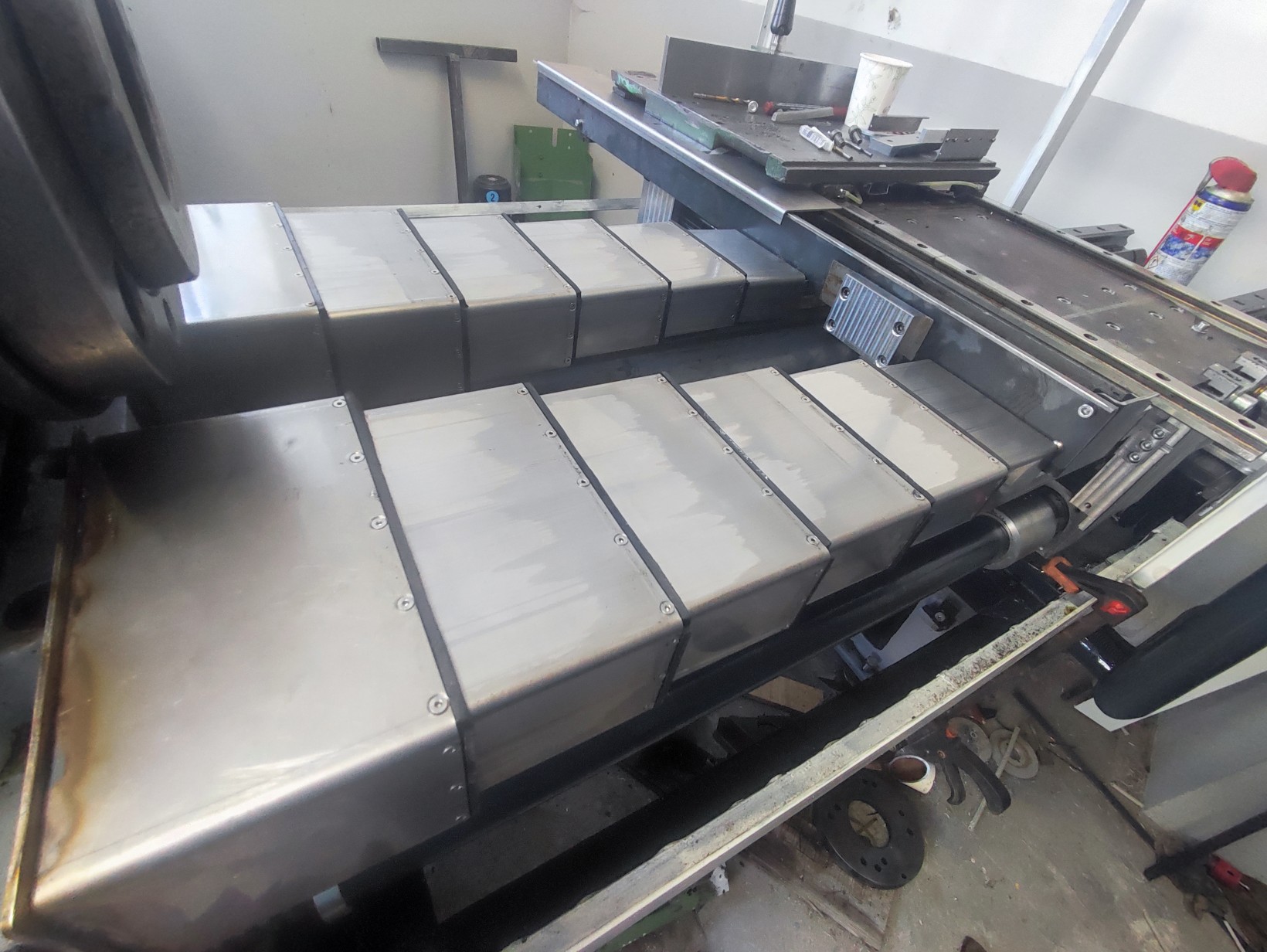

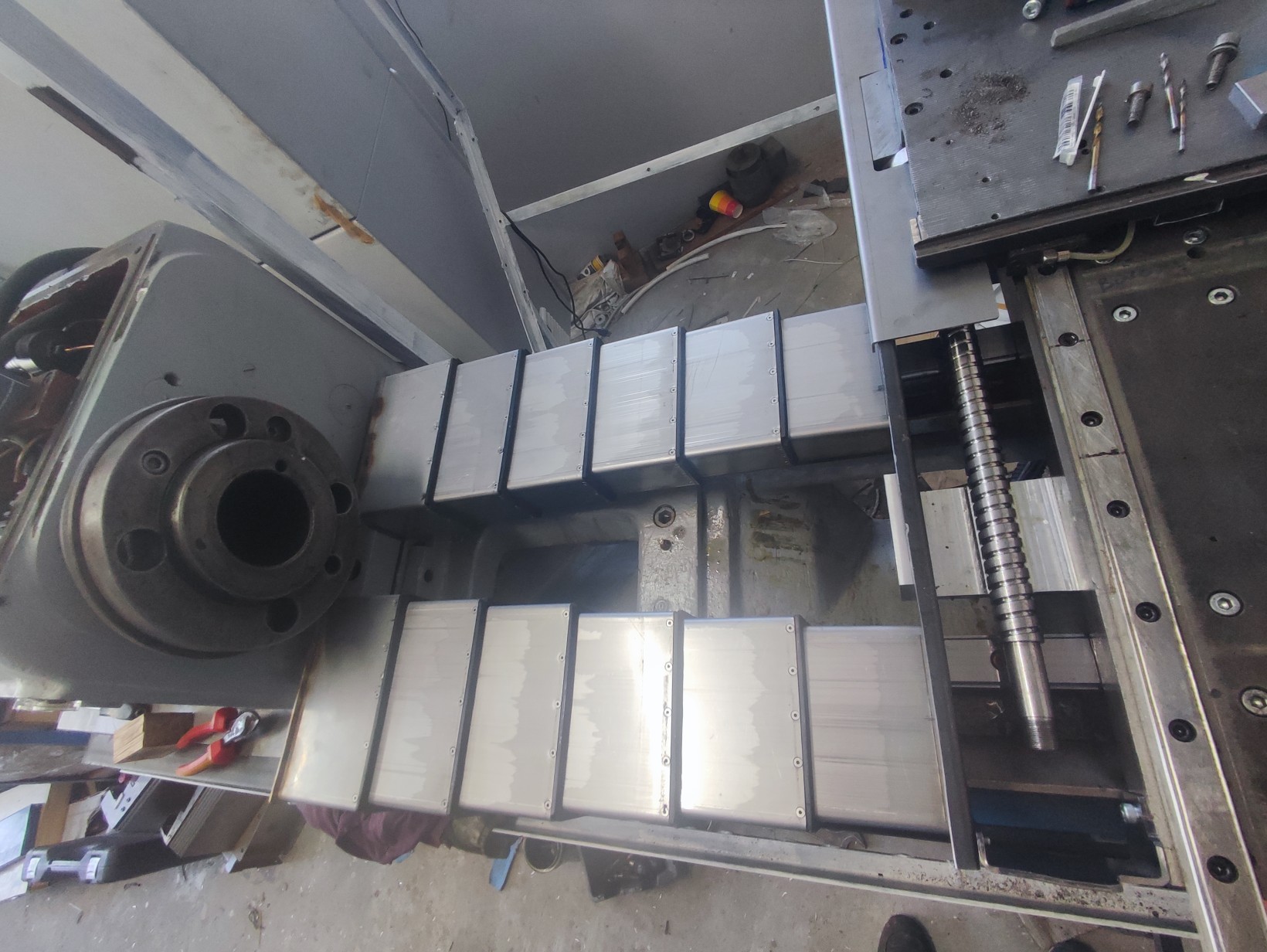

Attachments:

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 83

01 Jul 2024 05:23 - 01 Jul 2024 06:19 #304124

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

Attachments:

Last edit: 01 Jul 2024 06:19 by besriworld.

The following user(s) said Thank You: tommylight, ChironFZ16, Masiwood123

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 83

03 Jul 2024 05:27 - 03 Jul 2024 05:31 #304297

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

Hello, I have a question. I want to emphasize that I am new to LinuxCNC! The spindle has separate oil lubrication. I want the pump to not run all the time. Only when the spindle is rotating. A pressure sensor is installed.

I want to do before the spindle turns to turn on the lubrication pump and wait for the enabling signal from the pressure sensor. When true to rotate the spindle. If during rotation the signal from the sensor changes its state, it is not true to trigger an alarm. What is the right way? Is there an example? I'm sorry, but I couldn't find a similar topic.

I want to do before the spindle turns to turn on the lubrication pump and wait for the enabling signal from the pressure sensor. When true to rotate the spindle. If during rotation the signal from the sensor changes its state, it is not true to trigger an alarm. What is the right way? Is there an example? I'm sorry, but I couldn't find a similar topic.

Last edit: 03 Jul 2024 05:31 by besriworld.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21167

- Thank you received: 7231

03 Jul 2024 08:50 - 03 Jul 2024 08:50 #304312

by tommylight

Replied by tommylight on topic OLD Lathe conversion to a CNC

Probably by remaping M3 would be the best way, but no idea if M3 can be remaped.

I am sure it can be done in hal but that is quite a journey.

Using M6 or M7 is much easier, see mist/coolant use, requires adding an output for it in wizard, be it StepConf or PncConf.

I am sure it can be done in hal but that is quite a journey.

Using M6 or M7 is much easier, see mist/coolant use, requires adding an output for it in wizard, be it StepConf or PncConf.

Last edit: 03 Jul 2024 08:50 by tommylight.

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4601

03 Jul 2024 13:19 #304325

by andypugh

Replied by andypugh on topic OLD Lathe conversion to a CNC

I don't think it would be that hard in HAL.

This will also stop the spindle if the pressure falls, which probably isn't desirable, so you could add a latch:

linuxcnc.org/docs/stable/html/man/man9/flipflop.9.html

in addition to (most of) the above

This will turn the spindle motor on when there is pressure and the spindle is on, but will only turn the motor off when the spindle-off (inverted spindle on) goes true and resets the latch.

If you want an alarm too, then that would be based on the latched output being on, and the pressure being low.

Add another not, used to create an output that is high when the pressure is low, and another and2

linuxcnc.org/docs/stable/html/man/man9/message.9.html

net spindle-on spindle.0.on <lube pump on> and2.0.in0

net lube-pressure <lube swith output> and2.0.in1

net spindle-enable and2.0.out <spindle motor on>This will also stop the spindle if the pressure falls, which probably isn't desirable, so you could add a latch:

linuxcnc.org/docs/stable/html/man/man9/flipflop.9.html

in addition to (most of) the above

loadrt flipflop

loadrt not

addf flipflop.0 servo-thread

addf not.0 servo-thread

net spindle-on not.0.in

net spindle-off not.0.out

setp flipflop.0.data 1

net spindle-enable flipflop.0.clk

net spindle-off flipflop.0.reset

net spindle-latched flipflop.0.out <spindle motor on> This will turn the spindle motor on when there is pressure and the spindle is on, but will only turn the motor off when the spindle-off (inverted spindle on) goes true and resets the latch.

If you want an alarm too, then that would be based on the latched output being on, and the pressure being low.

Add another not, used to create an output that is high when the pressure is low, and another and2

linuxcnc.org/docs/stable/html/man/man9/message.9.html

loadrt message messages="Low lube pressure!"

net lube-pressure not.1.in

net lube-pressure-not and2.1.in0

net spindle-latched and2.1.in1

net alarum and2.1.out message.0.trigger

The following user(s) said Thank You: tommylight, besriworld, ChironFZ16

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 83

03 Jul 2024 14:00 #304328

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

Many thanks for the quick and detailed reply. I will try soon.

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 83

09 Jul 2024 10:10 - 09 Jul 2024 10:12 #304739

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

What's missing from my HAL file. I cannot do protection if the requested RPM of the spindle do not follow the current RPM from the encoder.

The problem is that the machine should automatically stop if the pump is not working. The spindle is large and if left without lubrication the bearings will break.

The problem is that the machine should automatically stop if the pump is not working. The spindle is large and if left without lubrication the bearings will break.

Attachments:

Last edit: 09 Jul 2024 10:12 by besriworld.

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 83

11 Jul 2024 19:33 #304941

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

Can anyone help. I can't find where the error is..

I am attaching the new files!

I start the spindle with Gmoccapy gui

I am attaching the new files!

I start the spindle with Gmoccapy gui

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17593

- Thank you received: 5145

12 Jul 2024 03:06 #304957

by PCW

Replied by PCW on topic OLD Lathe conversion to a CNC

What is the actual issue with the current hal/ini file set?

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 83

12 Jul 2024 04:20 - 12 Jul 2024 04:21 #304962

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

Hello, when I start the spindle with S1000 m3. The spindle rotates without the set acceleration and if I simulate a deceleration or stop of the spindle there is no following error. The machine/spindle works without errors!

Last edit: 12 Jul 2024 04:21 by besriworld.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.264 seconds