Another "what do I need" thread. Vmc retrofit

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23496

- Thank you received: 4994

22 Apr 2015 21:22 #58009

by andypugh

I have had a look and that seems like a promising starting point. Could I ask you to winnow out a lot of the surplus files, though? This would make it clearer how the system fits together.

(I don't even know what a .halshow file does

Replied by andypugh on topic Another "what do I need" thread. Vmc retrofit

Hi,

if you like to go the component router i made a solution which uses Gcode rewrite and for time critical stuff an component maybe it fits you needs

wiki.linuxcnc.org/cgi-bin/wiki.pl?Contri...er_and_configuration

I have had a look and that seems like a promising starting point. Could I ask you to winnow out a lot of the surplus files, though? This would make it clearer how the system fits together.

(I don't even know what a .halshow file does

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

Less

More

- Posts: 567

- Thank you received: 325

22 Apr 2015 22:10 - 22 Apr 2015 22:12 #58013

by dgarrett

Example:

Ref: www.linuxcnc.org/docs/2.7/html/hal/tools...w_a_id_sec_halshow_a

Replied by dgarrett on topic Another "what do I need" thread. Vmc retrofit

$ halshow --help

Usage:

halshow [Options] [watchfile]

Options:

--help (this help)

Notes:

Create watchfile in halshow using: 'File/Save Watch List'

linuxcnc must be running for standalone usage$ halshow aaspindleorient2.halshowRef: www.linuxcnc.org/docs/2.7/html/hal/tools...w_a_id_sec_halshow_a

Last edit: 22 Apr 2015 22:12 by dgarrett. Reason: fix link

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23496

- Thank you received: 4994

22 Apr 2015 22:31 #58014

by andypugh

I have been cursing that there was no way to do that for years.

Now I am going to start cursing myself for not reading the docs and finding it

Replied by andypugh on topic Another "what do I need" thread. Vmc retrofit

Create watchfile in halshow using: 'File/Save Watch List'

I have been cursing that there was no way to do that for years.

Now I am going to start cursing myself for not reading the docs and finding it

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

Less

More

- Posts: 567

- Thank you received: 325

22 Apr 2015 22:35 #58015

by dgarrett

Replied by dgarrett on topic Another "what do I need" thread. Vmc retrofit

Halshow, halscope, sim_pin and other applications useful for testing can be started in

an ini file too

Ref: www.linuxcnc.org/docs/2.7/html/config/in...APPLICATIONS-section

an ini file too

Ref: www.linuxcnc.org/docs/2.7/html/config/in...APPLICATIONS-section

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23496

- Thank you received: 4994

22 Apr 2015 22:43 #58016

by andypugh

I didn't realise that either

But I do frequently have HAL files that open halmeters for specific items:

loadusr halmeter -s pin motion.spindle-speed-in

for example.

Replied by andypugh on topic Another "what do I need" thread. Vmc retrofit

Ref: www.linuxcnc.org/docs/2.7/html/config/in...APPLICATIONS-section

I didn't realise that either

But I do frequently have HAL files that open halmeters for specific items:

loadusr halmeter -s pin motion.spindle-speed-in

for example.

Please Log in or Create an account to join the conversation.

- thewho

- Offline

- Premium Member

-

Less

More

- Posts: 128

- Thank you received: 2

23 Apr 2015 01:24 - 23 Apr 2015 01:25 #58020

by thewho

I was reverse engineering the spindle encoder today. I found A and B but I don't know witch is witch but I know witch is the index.

So I now have a 1024 line encoder on the spindle. Should be 4096/rev.

That solves the spindle orienting right? At least mechanically. The spindle drive is +/-10V so that should not be a problem to hook up.

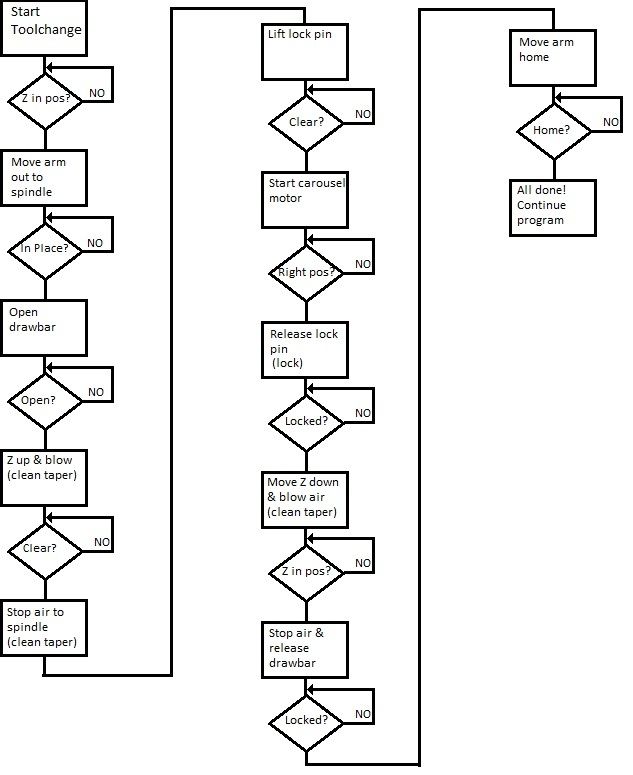

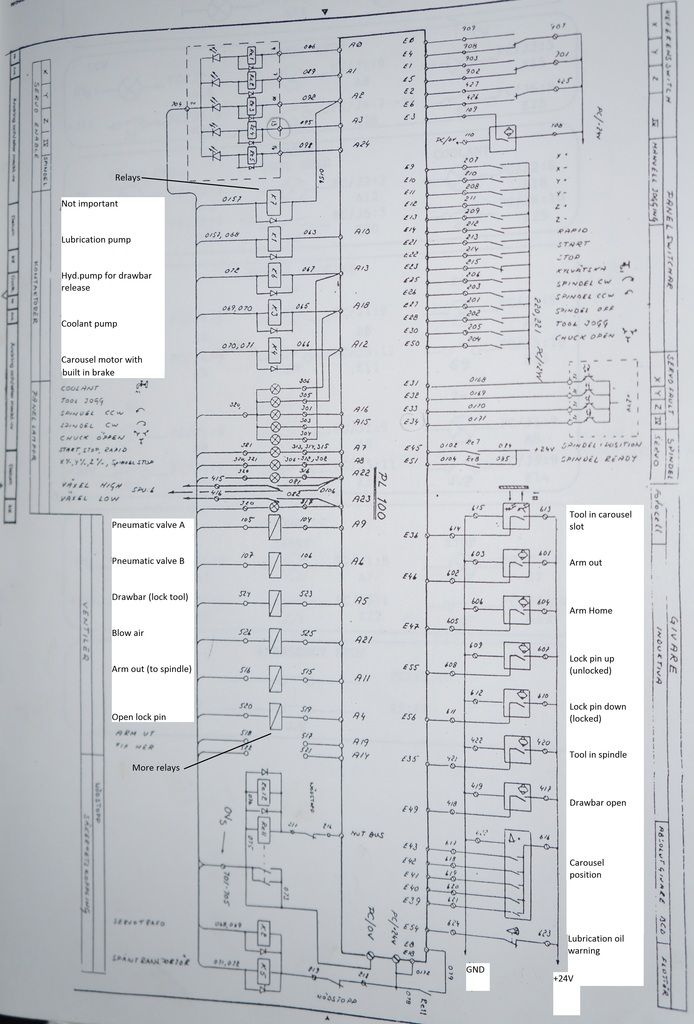

I translated some of the original documentation I got with the machine.

Replied by thewho on topic Another "what do I need" thread. Vmc retrofit

If you take the time to write the code then I'll absolutely test it!As I think that the custom HAL component will be generically useful I am happy to write that, if you are happy to test it

I was reverse engineering the spindle encoder today. I found A and B but I don't know witch is witch but I know witch is the index.

So I now have a 1024 line encoder on the spindle. Should be 4096/rev.

That solves the spindle orienting right? At least mechanically. The spindle drive is +/-10V so that should not be a problem to hook up.

I translated some of the original documentation I got with the machine.

Last edit: 23 Apr 2015 01:25 by thewho.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23496

- Thank you received: 4994

23 Apr 2015 01:38 - 23 Apr 2015 01:38 #58021

by andypugh

It doesn't matter. You can either swap them if the encoder counts the wrong way, or make the encoder counter scale negative to achieve the same effect.

That flow chart is rather helpful. The only thing that isn't a simple "wait for switch" is the carousel positioning, and that is what I am proposing a generic HAL component for.

Replied by andypugh on topic Another "what do I need" thread. Vmc retrofit

I was reverse engineering the spindle encoder today. I found A and B but I don't know witch is witch but I know witch is the index.

It doesn't matter. You can either swap them if the encoder counts the wrong way, or make the encoder counter scale negative to achieve the same effect.

That flow chart is rather helpful. The only thing that isn't a simple "wait for switch" is the carousel positioning, and that is what I am proposing a generic HAL component for.

Last edit: 23 Apr 2015 01:38 by andypugh.

Please Log in or Create an account to join the conversation.

- thewho

- Offline

- Premium Member

-

Less

More

- Posts: 128

- Thank you received: 2

23 Apr 2015 03:11 #58022

by thewho

Replied by thewho on topic Another "what do I need" thread. Vmc retrofit

Is it a bad idea to use a Arduino in you guys opinion?

If I went that route Linuxcnc would only need to position the spindle then tell the Arduino what tool is selected and move the Z axis when needed. I could also add a display for debugging and maybe show load on X/Y/Z/spindle as a fancy bar graph

I really appreciate the help I'm getting here!

If I went that route Linuxcnc would only need to position the spindle then tell the Arduino what tool is selected and move the Z axis when needed. I could also add a display for debugging and maybe show load on X/Y/Z/spindle as a fancy bar graph

I really appreciate the help I'm getting here!

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23496

- Thank you received: 4994

23 Apr 2015 04:05 #58023

by andypugh

Not a _bad_ idea as such, just a bit pointless.

If you can write Arduino C to do the job you can write LinuxCNC .comp C to do the job.

And without the added complications of communicating between two processors. Debugging is easier in HAL too, you can watch what the inputs and outputs are doing, scope them in Halscope etc etc.

I am an Arduino fan, I am doing quite a lot of work with them at work and I wrote a Resolver converter for LinuxCNC and the Arduino, including fast serial comms to the Mesa UART.

And I wouldn't consider using one in this role.

Replied by andypugh on topic Another "what do I need" thread. Vmc retrofit

Is it a bad idea to use a Arduino in you guys opinion?

Not a _bad_ idea as such, just a bit pointless.

If you can write Arduino C to do the job you can write LinuxCNC .comp C to do the job.

And without the added complications of communicating between two processors. Debugging is easier in HAL too, you can watch what the inputs and outputs are doing, scope them in Halscope etc etc.

I am an Arduino fan, I am doing quite a lot of work with them at work and I wrote a Resolver converter for LinuxCNC and the Arduino, including fast serial comms to the Mesa UART.

And I wouldn't consider using one in this role.

Please Log in or Create an account to join the conversation.

- tkamsker

- Offline

- Premium Member

-

Less

More

- Posts: 129

- Thank you received: 5

23 Apr 2015 16:25 #58033

by tkamsker

Replied by tkamsker on topic Another "what do I need" thread. Vmc retrofit

Hi mr who

I think you chart is wrong if i follow that right the arm would crash into the spindle ,..

I made for better read an script which is called for tool change i just posted it in here

first i check if tool pocket actual is ok you might be able to rotate the carousel !!

i put all in sub ngc files for better maintenance because from comp to drive Z axis was not possible for me ,..

Spindle stop

get Z axis out of their way therefore i have a subprogram called get_put move

Then orient Spindle wait and Check M19 Stuff this is what you need to get with your encoder done !!!!

Move Z axis in right position for change (if there is an tool in )

then arm_danger means arm goes forward where it can collide with spindle

release the tool

move z axis up

then i set switches to call my component which does the real time for rotating the carousel in right direction (shorts way) error handling to ensure right position for pocket

of course all with error handling

then i open collet go down

set blow relays for cleaning the taper

then close collet

put arm in save position

proceed with cutting

thomas

; copy von haberler examples

;2014.01.05 V1.00 TK First version to get Z Axis and Arm in

;2014.02.15 V1.00B TK Eigentlicher umbau für Componente

;2014.03.23 V2.00 TK Umbau für Komponente nccarousel.comp 1.05b 27.3

;2014.04.20 V2.01 TK Anpassung Errohandling und Move für BP412!

;2014.08.09 V2.02 TK Anpassung Armmove und Zeit

;2014.11.16 V2.03 TK Anpassung G43 Hx weil Anpassung nicht übernommen wird

;2014.11.21 V2.04 TK I6 Anpassung debian pc

o<rack_change> sub

o100 if [#<_current_tool> EQ #<_selected_tool>]

(print, current_tool = selected no action )

; succeed by returning a positive value

o<rack_change> endsub [1]

o100 endif

;

Normalfall change weitermachen

M73 (auto-restore modal settings on return)

;

(print, rack_change: loaded tool=#<_current_tool> current pocket: #<_current_pocket>)

(print, rack_change: selected tool=#<_selected_tool> selected pocket: #<_selected_pocket>)

; get z Axis in Safe Haven

M5; spindle stop

;nicht hier o<move_z_safe> call

o<tool_getput_move> call

;here Spindel Orientation !!!! for now we dont care

(print, Do M19 spindle orient here )

M19 R0

G4 P #<_ini[dwell]orient>

; unload previous tool

; check if initialized

; unload previous tool

;

carousel init zum testen----

;o200 if [#<_current_pocket> EQ 0]

;(print, current_pocket = 0 bedeutet init Carousel! )

;M68 E3 Q1 ;Qx = Pocket

;M64 P3 ; Jetzt drehen

;(print, o200 drehen)

;M66 P1 L3 Q10 ; Warte auf Digital in1 10Sek

;o200 endif

;

Normalfall bei 2en Tool

o300 if [#<_current_pocket> GT 0]

; We adjust Carousel to actual pocket => has to be empty

(print, Unload old ->Carousel has to be at current Pocket)

; no we drive armm in has to be empty

o<tool_getput_move> call [#<_current_pocket>]

o<arm_danger_position> call

M62 P #<_ini[pins]lock> ; set lock pin

G4 P #<_ini[dwell]lock_time>

;Now Z axis high

o<move_z_safe> call

G4 P #<_ini[dwell]POST_UNLOCK>

;orig nix gut o<tool_holder_clear_move> call

; o<arm_safe_position> call

;orig G4 P #<_ini[dwell]mystery> ; unsure what this is for

;? G4 P #<_ini[dwell]mystery> ; unsure what this is for

(print, Unload old Sucess)

o300 endif

;

;hier

o<move_z_safe> call

;Now make Turn Carousel

turn it

(print,Turn carousel for new tool )

M68 E3 Q#<_selected_pocket> ;Qx = Pocket

M64 P3 ; Jetzt drehen

M66 P1 L3 Q16 ; Warte auf Digital in1 18Sek

M65 P3 ; Jetzt nicht mehr drehen

; check motion.digital-in-01 = p1 !

o400 if [#<_hal[motion.digital-in-01]> GT 0]

(print, NEU motion.digital-in-01 GT 0-> 5600 =0 )

#5600 = 0

; go to new tool only if not danger

o<arm_danger_position> call

o400 else

(print, NEU motion.digital-in-01 LE 0 -> 5600 =-1 )

#5600 = -1

o<arm_safe_position> call

; Brutales Ende

o<rack_change> endsub [-1]

o400endif

M64 P #<_ini[pins]lock> ; set lock pin

M64 P #<_ini[pins]flush> ; set flush pin

G4 P #<_ini[dwell]new_tool>

;falsch M65 P #<_ini[pins]flush> ; drop flush pin

o<tool_getput_move> call [#<_selected_pocket>]

;test G4 P 10

M65 P #<_ini[pins]flush> ; drop flush pin

G4 P #<_ini[dwell]post_unlock>

M65 P #<_ini[pins]lock> ; set lock pin

; now remove magazin of spindle

o<arm_safe_position> call

G4 P #<_ini[dwell]armtime>

; now Z axis away

;wozu o<move_z_safe> call

(print,

Finnish

)

(print,#<_selected_tool>)

G43 H#<_selected_pocket>

; succeed by returning a positive value

o<rack_change> endsub [1]

m2

I think you chart is wrong if i follow that right the arm would crash into the spindle ,..

I made for better read an script which is called for tool change i just posted it in here

first i check if tool pocket actual is ok you might be able to rotate the carousel !!

i put all in sub ngc files for better maintenance because from comp to drive Z axis was not possible for me ,..

Spindle stop

get Z axis out of their way therefore i have a subprogram called get_put move

Then orient Spindle wait and Check M19 Stuff this is what you need to get with your encoder done !!!!

Move Z axis in right position for change (if there is an tool in )

then arm_danger means arm goes forward where it can collide with spindle

release the tool

move z axis up

then i set switches to call my component which does the real time for rotating the carousel in right direction (shorts way) error handling to ensure right position for pocket

of course all with error handling

then i open collet go down

set blow relays for cleaning the taper

then close collet

put arm in save position

proceed with cutting

thomas

; copy von haberler examples

;2014.01.05 V1.00 TK First version to get Z Axis and Arm in

;2014.02.15 V1.00B TK Eigentlicher umbau für Componente

;2014.03.23 V2.00 TK Umbau für Komponente nccarousel.comp 1.05b 27.3

;2014.04.20 V2.01 TK Anpassung Errohandling und Move für BP412!

;2014.08.09 V2.02 TK Anpassung Armmove und Zeit

;2014.11.16 V2.03 TK Anpassung G43 Hx weil Anpassung nicht übernommen wird

;2014.11.21 V2.04 TK I6 Anpassung debian pc

o<rack_change> sub

o100 if [#<_current_tool> EQ #<_selected_tool>]

(print, current_tool = selected no action )

; succeed by returning a positive value

o<rack_change> endsub [1]

o100 endif

;

Normalfall change weitermachen

M73 (auto-restore modal settings on return)

;

(print, rack_change: loaded tool=#<_current_tool> current pocket: #<_current_pocket>)

(print, rack_change: selected tool=#<_selected_tool> selected pocket: #<_selected_pocket>)

; get z Axis in Safe Haven

M5; spindle stop

;nicht hier o<move_z_safe> call

o<tool_getput_move> call

;here Spindel Orientation !!!! for now we dont care

(print, Do M19 spindle orient here )

M19 R0

G4 P #<_ini[dwell]orient>

; unload previous tool

; check if initialized

; unload previous tool

;

carousel init zum testen----

;o200 if [#<_current_pocket> EQ 0]

;(print, current_pocket = 0 bedeutet init Carousel! )

;M68 E3 Q1 ;Qx = Pocket

;M64 P3 ; Jetzt drehen

;(print, o200 drehen)

;M66 P1 L3 Q10 ; Warte auf Digital in1 10Sek

;o200 endif

;

Normalfall bei 2en Tool

o300 if [#<_current_pocket> GT 0]

; We adjust Carousel to actual pocket => has to be empty

(print, Unload old ->Carousel has to be at current Pocket)

; no we drive armm in has to be empty

o<tool_getput_move> call [#<_current_pocket>]

o<arm_danger_position> call

M62 P #<_ini[pins]lock> ; set lock pin

G4 P #<_ini[dwell]lock_time>

;Now Z axis high

o<move_z_safe> call

G4 P #<_ini[dwell]POST_UNLOCK>

;orig nix gut o<tool_holder_clear_move> call

; o<arm_safe_position> call

;orig G4 P #<_ini[dwell]mystery> ; unsure what this is for

;? G4 P #<_ini[dwell]mystery> ; unsure what this is for

(print, Unload old Sucess)

o300 endif

;

;hier

o<move_z_safe> call

;Now make Turn Carousel

turn it

(print,Turn carousel for new tool )

M68 E3 Q#<_selected_pocket> ;Qx = Pocket

M64 P3 ; Jetzt drehen

M66 P1 L3 Q16 ; Warte auf Digital in1 18Sek

M65 P3 ; Jetzt nicht mehr drehen

; check motion.digital-in-01 = p1 !

o400 if [#<_hal[motion.digital-in-01]> GT 0]

(print, NEU motion.digital-in-01 GT 0-> 5600 =0 )

#5600 = 0

; go to new tool only if not danger

o<arm_danger_position> call

o400 else

(print, NEU motion.digital-in-01 LE 0 -> 5600 =-1 )

#5600 = -1

o<arm_safe_position> call

; Brutales Ende

o<rack_change> endsub [-1]

o400endif

M64 P #<_ini[pins]lock> ; set lock pin

M64 P #<_ini[pins]flush> ; set flush pin

G4 P #<_ini[dwell]new_tool>

;falsch M65 P #<_ini[pins]flush> ; drop flush pin

o<tool_getput_move> call [#<_selected_pocket>]

;test G4 P 10

M65 P #<_ini[pins]flush> ; drop flush pin

G4 P #<_ini[dwell]post_unlock>

M65 P #<_ini[pins]lock> ; set lock pin

; now remove magazin of spindle

o<arm_safe_position> call

G4 P #<_ini[dwell]armtime>

; now Z axis away

;wozu o<move_z_safe> call

(print,

Finnish

)

(print,#<_selected_tool>)

G43 H#<_selected_pocket>

; succeed by returning a positive value

o<rack_change> endsub [1]

m2

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 1.020 seconds