Another "what do I need" thread. Vmc retrofit

- andypugh

-

- Offline

- Moderator

-

- Posts: 23550

- Thank you received: 5017

Please Log in or Create an account to join the conversation.

- thewho

- Offline

- Premium Member

-

- Posts: 128

- Thank you received: 2

It seems to be working now

Please Log in or Create an account to join the conversation.

- thewho

- Offline

- Premium Member

-

- Posts: 128

- Thank you received: 2

The computer I have there for cad/cam and now for reading lots of pdf's was bluescreening like crazy today

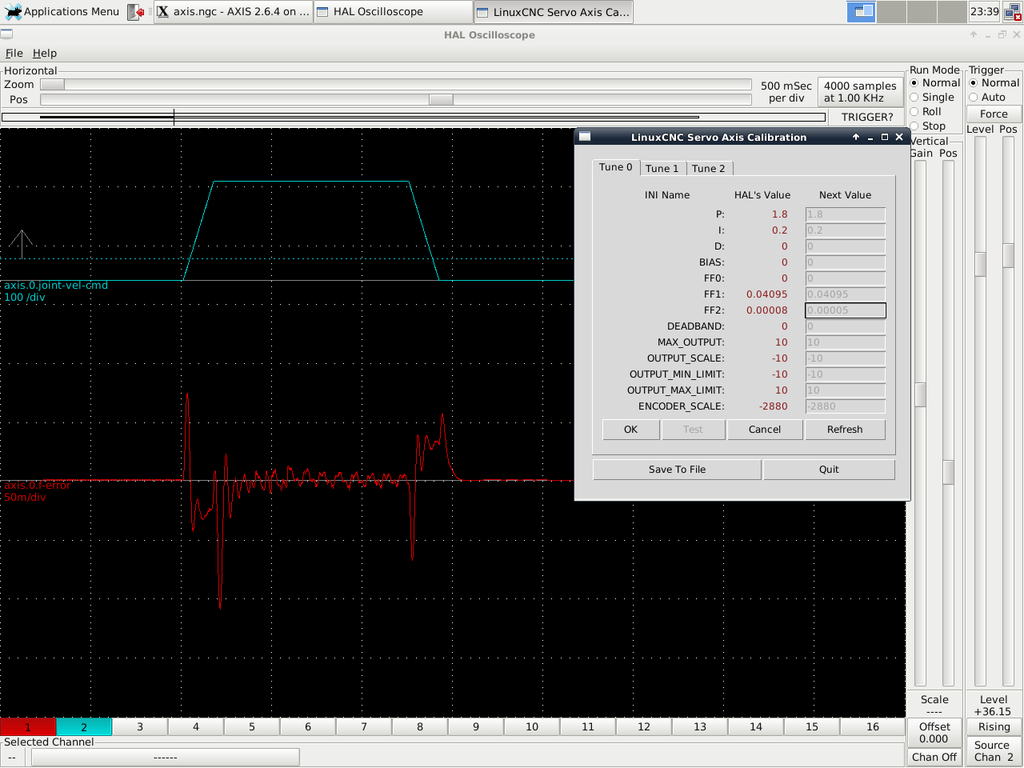

I did almost go mad when I was trying to tune the PID settings today.. Got it quite good, forgot to save and restarted Linuxcnc

Max velocity is set to 10m/min

Acceleration is set to 1000mm/s²

I got those numbers from the machine manual.

This is where I left it anyway. If I read the graph correctly then the axis is off by ~0.18mm under acceleration. Suggestions are appreciated

I did get homing to work though.

And some more info on the tool changer:

-It takes 8 seconds for the carousel to do a full revolution.

-The carousel can be quite off position and still be "pushed" to the correct spot by the lock pin

-The hydraulic pump that activates the drawbar has one way valve in series so the pump only need to run until the "drawbar is fully extended" sensor senses that. Then a electronic valve releases the pressure when you want to retract the drawbar.

- Z needs to be at +10 from its home switch to clear tools in the carousel

Please Log in or Create an account to join the conversation.

- atrex77

-

- Offline

- Senior Member

-

- Posts: 46

- Thank you received: 24

this sample is for 3 axis machine with joint 0,1,2

first need to put in your ini file:

[POSTGUI_PARAMS]

# this is the minimum acceleration limit, your machine is set this in startup

MINIMUM_ACCELERATION = 350

# this is the limit of maximum acceleration

MAXIMUM_ACCELERATION = 700

and add this to postgui halfile,

or make a new file named "postgui_halfile.hal" :

loadrt wcomp count=1

loadrt mux4 count=1

addf wcomp.0 servo-thread

addf mux4.0 servo-thread

setp wcomp.0.min [POSTGUI_PARAMS]MINIMUM_ACCELERATION

setp wcomp.0.max [POSTGUI_PARAMS]MAXIMUM_ACCELERATION

net accel-out-mux-sel0 mux4.0.sel0 <= wcomp.0.under

net accel-out-mux-sel1 mux4.0.sel1 <= wcomp.0.over

net m68-e0-q wcomp.0.in <= mux4.0.in0 <= motion.analog-out-00

setp mux4.0.in1 [POSTGUI_PARAMS]MINIMUM_ACCELERATION

setp mux4.0.in2 [POSTGUI_PARAMS]MAXIMUM_ACCELERATION

setp mux4.0.in3 [POSTGUI_PARAMS]MAXIMUM_ACCELERATION

net accel-out-mux ini.0.max_acceleration <= ini.1.max_acceleration <= ini.2.max_acceleration <= mux4.0.out

last thing is check your ini file HAL section POSTGUI_HALFILE = postgui_halfile.hal

now program "M68 E0 Q###"

Q number is the acceleration

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

- Posts: 567

- Thank you received: 325

a program is not running

The per-axis max_velocity and max_acceleration pins are sampled when the machine is on and the motion_state is free (homing or jogging) but are not sampled when in a program is running (auto mode) or in mdi mode. Consequently, changing the pin values when a program is running will not have effect until the program is stopped and the motion_state is again free.

Ref: (2.7) www.linuxcnc.org/docs/2.7/html/config/em...l.html#_ini_settings

The pins may still be useful for changing the max_acceleration values without restarting, example, in

a terminal:

$ sim_pin ini.0.max_acceleration ini.1.max_accelerationPlease Log in or Create an account to join the conversation.

- thewho

- Offline

- Premium Member

-

- Posts: 128

- Thank you received: 2

Do anyone have any suggestions on what to change to further decrease the following error? If I increase FF2 then the initial "peak" decreases but it overshoots like crazy just after. (the big dip on the graph)

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 23550

- Thank you received: 5017

Do anyone have any suggestions on what to change to further decrease the following error?

You could try a faster servo-thread rate.

You might also find some of the discussion here interesting:

thread.gmane.org/gmane.linux.distributions.emc.devel/8816

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 23550

- Thank you received: 5017

I did get homing to work though.

To save valuable seconds you can give X and Y the same home-sequence number.

Please Log in or Create an account to join the conversation.

- thewho

- Offline

- Premium Member

-

- Posts: 128

- Thank you received: 2

How much following error is acceptable?

Nice trick to home both X and Y at the same time

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 23550

- Thank you received: 5017

How much should I increase it? 20%?

I was thinking that you could try doubling the rate, ie 2kHz servo-thread not 1kHz.

PCW has reported that that helps.

Also try plotting position-cmd and position-fb, see if it really is as bad as f-error suggests, the email discussion suggested that f-error calcs might be a bit wrong.

Please Log in or Create an account to join the conversation.