Secondary spindle on 7i76e

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11696

- Thank you received: 3950

22 Apr 2019 12:28 #131494

by rodw

Replied by rodw on topic Secondary spindle on 7i76e

Well Andy assures us it upgrades itself but if it fails, it is not that hard really. Should be able to knock it over in 1-2 hours. I personally think master branch is the way to go now. 2.7 is really long in the tooth and the lack of an upgrade schedule just pushes things out.

Has to be a lot easier than me migrating to Plasmac which only took a morning amd a couple more hours tidying up my config which had become quite messy with all of the experiemnts. So once you build your controller for your plasma cutter it will all be easy! In fact, Phill rolled out 2 update today (maybe more) and it wa sa 30 second job to recompile the changed code.

Has to be a lot easier than me migrating to Plasmac which only took a morning amd a couple more hours tidying up my config which had become quite messy with all of the experiemnts. So once you build your controller for your plasma cutter it will all be easy! In fact, Phill rolled out 2 update today (maybe more) and it wa sa 30 second job to recompile the changed code.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7252

22 Apr 2019 12:44 #131497

by tommylight

Replied by tommylight on topic Secondary spindle on 7i76e

Todd is much better at explaining this ( so are some other users but i remember Todd answering to spindle stuff very often ), but i think you can use the "gearbox" system that many use, and remove everything except the part where it enables one or the other spindle. So for a set of speeds it enables spindle 1 and for the other set of speeds it enables spindle 2. Also you would have to add some offsets attached to those outputs so you do not have to centre the spindles manually, to have it fully automated.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11696

- Thank you received: 3950

22 Apr 2019 12:50 #131498

by rodw

Replied by rodw on topic Secondary spindle on 7i76e

Don't go there Tommy! I remember Bengt was in a lot of pain getting a gearbox working when he converted his mill! I could not bear to watch on the sidelines again!

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

22 Apr 2019 13:20 #131501

by tecno

Enclosed find my hal and gearbox comp

And yes Rod I had a struggle to get this all working

Replied by tecno on topic Secondary spindle on 7i76e

Todd is much better at explaining this ( so are some other users but i remember Todd answering to spindle stuff very often ), but i think you can use the "gearbox" system that many use, and remove everything except the part where it enables one or the other spindle. So for a set of speeds it enables spindle 1 and for the other set of speeds it enables spindle 2. Also you would have to add some offsets attached to those outputs so you do not have to centre the spindles manually, to have it fully automated.

Enclosed find my hal and gearbox comp

And yes Rod I had a struggle to get this all working

Attachments:

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

22 Apr 2019 13:51 #131503

by pl7i92

Replied by pl7i92 on topic Secondary spindle on 7i76e

it woudt be far better to know what CAD Cam he is using

as it can be interfeared there by Mcode easy to get secondary spindle

the other way is IF the Tolnumbers are fixed to interfear the M6 as a remap and control from there

the RPM go to the both VFD and only the enable and forward reverse are controlled

EVEN as i use on the Woodmill the VFD only got power as they are called by Tx

its just a G4 P3 into toolchange to get time the VFD gets up from sleep

i got alot of pins on the 6axis setup

or on the standard 10 axis bit file

via the 7i92

as it can be interfeared there by Mcode easy to get secondary spindle

the other way is IF the Tolnumbers are fixed to interfear the M6 as a remap and control from there

the RPM go to the both VFD and only the enable and forward reverse are controlled

EVEN as i use on the Woodmill the VFD only got power as they are called by Tx

its just a G4 P3 into toolchange to get time the VFD gets up from sleep

i got alot of pins on the 6axis setup

or on the standard 10 axis bit file

via the 7i92

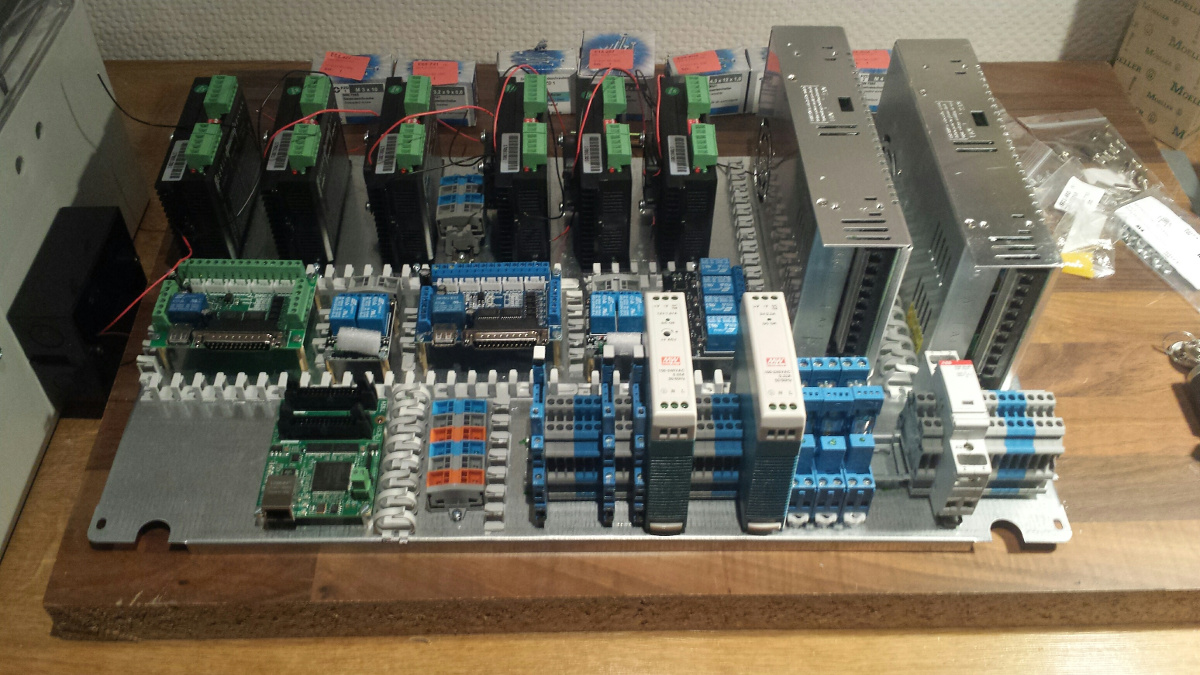

Attachments:

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

22 Apr 2019 14:33 #131511

by tecno

Replied by tecno on topic Secondary spindle on 7i76e

I use 2 CAD/CAM

More and more Fusion 360 but also my Dolphin Partmaster.

Occasional simple 2D can be via SheetCam TNG

More and more Fusion 360 but also my Dolphin Partmaster.

Occasional simple 2D can be via SheetCam TNG

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

22 Apr 2019 17:11 #131530

by Todd Zuercher

Replied by Todd Zuercher on topic Secondary spindle on 7i76e

If you don't want to try to use the multi spindle capability in Master. Probably one of the easier ways and one I've used, is to use custom M-codes that control which spindle is receiving the spindle commands from Linuxcnc. But the Hal logic programming can get a little complicated. (That said using Master would probably be easier.) The multi-spindle machines I set up were completed long before the multi-spindle addition to Master and I have no experience with it.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

22 Apr 2019 19:18 #131540

by tecno

Replied by tecno on topic Secondary spindle on 7i76e

Todd,

As I have the gearbox up and running and what you suggest is my cup of tea.

Custom M code to act on S12000 to S 56000 and reroute the spindle to IO pins on P2 on 7i76e.

As I have the gearbox up and running and what you suggest is my cup of tea.

Custom M code to act on S12000 to S 56000 and reroute the spindle to IO pins on P2 on 7i76e.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

22 Apr 2019 20:23 #131544

by Todd Zuercher

Replied by Todd Zuercher on topic Secondary spindle on 7i76e

I know you've struggled with hal programming before, so My guess would be the 2.8 route would be simpler. Hopefully Andy Pugh will weigh in. (The Multi Spindle addition was his baby.) I would think your configurations are not too complex that the auto reconfiguration script should not have any trouble converting your config from 2.7 to 2.8. Then you would only need to add the connections to run your new spindle, and learn and use the G-codes to operate it.

That all sounds easier than it probably is.

That all sounds easier than it probably is.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

23 Apr 2019 00:20 #131578

by JohnnyCNC

I just added a 24K spindle to my mill and that is exactly how I did it. I also have a 7i83 which has five 0~10v analog outputs. I use one for the DYN4 servo on my main spindle and another one for the 24K water cooled spindle. I created two shortcuts that point to different .ini and .hal files. Both spindles are never powered up at the same time. So far it is working great.

John

Replied by JohnnyCNC on topic Secondary spindle on 7i76e

I'm dreaming to have a high-speed spindle in a similar way.. Some day.

I think you will never use both spindles in same lot. So why not using two ini/hal's?

I just added a 24K spindle to my mill and that is exactly how I did it. I also have a 7i83 which has five 0~10v analog outputs. I use one for the DYN4 servo on my main spindle and another one for the 24K water cooled spindle. I created two shortcuts that point to different .ini and .hal files. Both spindles are never powered up at the same time. So far it is working great.

John

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.105 seconds