Driver NUM GEC MK2S

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17650

- Thank you received: 5163

20 Aug 2024 18:43 #308237

by PCW

Replied by PCW on topic Driver NUM GEC MK2S

There is a bug in MesaCT that does not connect the PID output

to the PWM value pin. You could try updating to the latest

MesaCT or patch the hal file.

Check out this thread:

forum.linuxcnc.org/49-basic-configuration/53561-7i97t-retrofit

to the PWM value pin. You could try updating to the latest

MesaCT or patch the hal file.

Check out this thread:

forum.linuxcnc.org/49-basic-configuration/53561-7i97t-retrofit

Please Log in or Create an account to join the conversation.

- greg23_78

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 7

21 Aug 2024 09:34 - 21 Aug 2024 10:06 #308274

by greg23_78

Replied by greg23_78 on topic Driver NUM GEC MK2S

indeed it was missing

net joint.0.output => hm2_[MESA](BOARD).0.pwmgen.00.value

and I made the change, but my drivers still don't jog.

I tried my drivers by applying a DC power supply to my analog input (driver) and the driver works correctly.

HAL

INI

I have another question: what does [JOINT_1]SCALE correspond to, since we can see that the signal is scaled in relation to this variable?

SCALE = 1

setp hm2_[MESA](BOARD).0.pwmgen.00.scale [JOINT_0]SCALE

but what's the point of the

ANALOG_SCALE_MAX = 10

ANALOG_MIN_LIMIT = -10

ANALOG_MAX_LIMIT = 10

MAX_OUTPUT = 10

net joint.0.output => hm2_[MESA](BOARD).0.pwmgen.00.value

and I made the change, but my drivers still don't jog.

I tried my drivers by applying a DC power supply to my analog input (driver) and the driver works correctly.

HAL

# Axis: Z Joint: 1 Output: 1

# PID Setup

setp pid.z.Pgain [JOINT_1](P)

setp pid.z.Igain [JOINT_1](I)

setp pid.z.Dgain [JOINT_1](D)

setp pid.z.bias [JOINT_1](BIAS)

setp pid.z.FF0 [JOINT_1](FF0)

setp pid.z.FF1 [JOINT_1](FF1)

setp pid.z.FF2 [JOINT_1](FF2)

setp pid.z.deadband [JOINT_1](DEADBAND)

setp pid.z.maxoutput [JOINT_1](MAX_OUTPUT)

setp pid.z.error-previous-target True

# joint-1 enable chain

net joint-1-index-enable <=> pid.z.index-enable

net joint-1-index-enable <=> joint.1.index-enable

net joint-1-index-enable <=> hm2_[MESA](BOARD).0.encoder.01.index-enable

net joint-1-enable <= joint.1.amp-enable-out

net joint-1-enable => pid.z.enable

# PWM Generator setup

setp hm2_[MESA](BOARD).0.pwmgen.01.dither true

setp hm2_[MESA](BOARD).0.pwmgen.01.output-type 1 #PWM pin0

setp hm2_[MESA](BOARD).0.pwmgen.01.offset-mode 1 # offset mode so 50% = 0

setp hm2_[MESA](BOARD).0.pwmgen.01.scale [JOINT_1]SCALE

# ---Encoder feedback signals/setup---

setp hm2_[MESA](BOARD).0.encoder.01.counter-mode 0

setp hm2_[MESA](BOARD).0.encoder.01.filter 1

setp hm2_[MESA](BOARD).0.encoder.01.index-invert 0

setp hm2_[MESA](BOARD).0.encoder.01.index-mask 0

setp hm2_[MESA](BOARD).0.encoder.01.index-mask-invert 0

setp hm2_[MESA](BOARD).0.encoder.01.scale [JOINT_1]ENCODER_SCALE

# position command and feedback

net joint-1-pos-cmd <= joint.1.motor-pos-cmd

net joint-1-pos-cmd => pid.z.command

net joint-1-pos-fb <= hm2_[MESA](BOARD).0.encoder.01.position

net joint-1-pos-fb => joint.1.motor-pos-fb

net joint-1-pos-fb => pid.z.feedback

net joint.1.output <= pid.z.output

net joint.1.output => hm2_[MESA](BOARD).0.pwmgen.01.value

# Encoder Setup

setp hm2_[MESA](BOARD).0.encoder.01.scale [JOINT_1](ENCODER_SCALE)

setp hm2_[MESA](BOARD).0.encoder.01.counter-mode 0

setp hm2_[MESA](BOARD).0.encoder.01.filter 1

setp hm2_[MESA](BOARD).0.encoder.01.index-invert 0

setp hm2_[MESA](BOARD).0.encoder.01.index-mask 0

setp hm2_[MESA](BOARD).0.encoder.01.index-mask-invert 0

INI

[AXIS_Z]

MIN_LIMIT = 0

MAX_LIMIT = 1000

MAX_VELOCITY = 333.333

MAX_ACCELERATION = 400

[JOINT_1]

CARD = 0

TAB = 1

AXIS = Z

MIN_LIMIT = 0

MAX_LIMIT = 1000

MAX_VELOCITY = 333.333

MAX_ACCELERATION = 400

TYPE = LINEAR

SCALE = 1

ANALOG_SCALE_MAX = 10

ANALOG_MIN_LIMIT = -10

ANALOG_MAX_LIMIT = 10

ENCODER_SCALE = 1000

FERROR = 10000

MIN_FERROR = 1000

DEADBAND = 0

P = 1

I = 0

D = 0

FF0 = 0

FF1 = 0

FF2 = 0

BIAS = 0

MAX_OUTPUT = 10

MAX_ERROR = 0.0127

HOME = 10

HOME_OFFSET = 0

HOME_SEARCH_VEL = 5

HOME_LATCH_VEL = 0.5

HOME_FINAL_VEL = 20

HOME_SEQUENCE = 1

HOME_USE_INDEX = True

SCALE = 1

setp hm2_[MESA](BOARD).0.pwmgen.00.scale [JOINT_0]SCALE

but what's the point of the

ANALOG_SCALE_MAX = 10

ANALOG_MIN_LIMIT = -10

ANALOG_MAX_LIMIT = 10

MAX_OUTPUT = 10

Attachments:

Last edit: 21 Aug 2024 10:06 by greg23_78.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17650

- Thank you received: 5163

21 Aug 2024 14:07 #308290

by PCW

Replied by PCW on topic Driver NUM GEC MK2S

Looks like the PWM enables are missing also:

net joint-1-enable <= joint.1.amp-enable-out

net joint-1-enable => pid.z.enable

net joint-1-enable => hm2_[MESA](BOARD).0.pwmgen.01.enable

net joint-1-enable <= joint.1.amp-enable-out

net joint-1-enable => pid.z.enable

net joint-1-enable => hm2_[MESA](BOARD).0.pwmgen.01.enable

Please Log in or Create an account to join the conversation.

- greg23_78

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 7

21 Aug 2024 15:31 #308304

by greg23_78

Replied by greg23_78 on topic Driver NUM GEC MK2S

thank you, I hadn't noticed that was missing.

now, when activating the drivers, the motor goes into Z+ at high speed.

now, when activating the drivers, the motor goes into Z+ at high speed.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17650

- Thank you received: 5163

21 Aug 2024 15:44 - 21 Aug 2024 15:45 #308307

by PCW

Replied by PCW on topic Driver NUM GEC MK2S

That's probably expected.

You have about a 50% chance of an initial

runaway because the feedback direction is

wrong, that is you have positive feedback = runaway

rather than negative feedback = position control.

If the encoder direction is correct, you fix this by

changing the sign of the PWM scale.

You have about a 50% chance of an initial

runaway because the feedback direction is

wrong, that is you have positive feedback = runaway

rather than negative feedback = position control.

If the encoder direction is correct, you fix this by

changing the sign of the PWM scale.

Last edit: 21 Aug 2024 15:45 by PCW.

Please Log in or Create an account to join the conversation.

- greg23_78

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 7

22 Aug 2024 13:59 #308398

by greg23_78

Replied by greg23_78 on topic Driver NUM GEC MK2S

I changed the output-scale sign and now it works.

I've tried tuning my motor but I can't get it to work properly.

I find it strange that my motor remains stable when I activate my drivers with a P of 0.1. Above that, when I activate the motor, it races and oscillates.

After several searches, I find the same behavior as H bridge drives running PM DC motors.

I actually have a PM DC motor

I came across your procedure

and that of IRAK

forum.linuxcnc.org/10-advanced-configura...ge-tuning-servo-loop

What procedure should I follow for my driver and motor?

In the IRAK procedure, it says “Set P to low value - about 1/4 any possible oscillation.” oscillation when enable the drive or i jog? because when I set P to 0.9 sometimes the axis oscillates and sometimes it remains stable (I'm not talking about jog because in all cases it oscillates even before P=0.2).

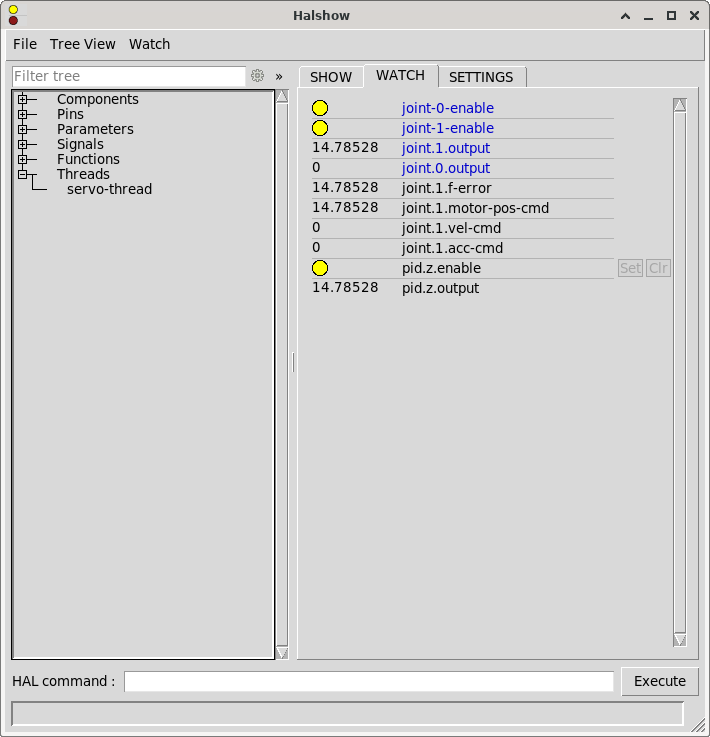

then as I understand it I need to “Set OUTPUT_SCALE to encoder.N.velocity” to know maximum speed the table (I presume I need to look at the speed through the encoder).

How do you do “Set OUTPUT_SCALE to encoder.N.velocity”?

I've tried tuning my motor but I can't get it to work properly.

I find it strange that my motor remains stable when I activate my drivers with a P of 0.1. Above that, when I activate the motor, it races and oscillates.

After several searches, I find the same behavior as H bridge drives running PM DC motors.

I actually have a PM DC motor

I came across your procedure

Blatantly copied and pasted from a post made by PCW regarding H bridge drives:

Bare H-bridge drives running PM DC motors behave somewhat like velocity mode servos

(with quite low velocity feedback gain) So they end up being somewhere between velocity

and torque mode.

That is, you are setting the average motor drive voltage with the PWM value. This sets the

approximate motor velocity because the motor will accelerate to a velocity where the generated

back EMF is close to the supplied voltage. If the motor impedance was zero, you would have close

to a perfect velocity mode servo, but the impedance is substantial which leads to the low

inherent feedback gain.

Normally for Hbridges, I would start with a low P value and tune the D term as high as

possible without excessive buzzyness, then set FF1 so that the actual position does

not lead or lag the commanded position at full speed, then I would tune FF2 so that

the actual position does not lead or lag the commanded position during acceleration

Then I would tune P as high as possible without oscillation, overshoot and then when

everything else is close, add as much I term as possible without instability.

Thank you, PCW.

Please feel free to voice your advice, critique, additional info etc.and that of IRAK

forum.linuxcnc.org/10-advanced-configura...ge-tuning-servo-loop

What procedure should I follow for my driver and motor?

In the IRAK procedure, it says “Set P to low value - about 1/4 any possible oscillation.” oscillation when enable the drive or i jog? because when I set P to 0.9 sometimes the axis oscillates and sometimes it remains stable (I'm not talking about jog because in all cases it oscillates even before P=0.2).

then as I understand it I need to “Set OUTPUT_SCALE to encoder.N.velocity” to know maximum speed the table (I presume I need to look at the speed through the encoder).

How do you do “Set OUTPUT_SCALE to encoder.N.velocity”?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17650

- Thank you received: 5163

22 Aug 2024 14:50 #308402

by PCW

Replied by PCW on topic Driver NUM GEC MK2S

1. If you have new drives, the drives themselves likely need

to be tuned first. This includes scaling the tachometer feedback

so you get full speed at 10V. It also means adjusting the drives

velocity loop gain as high as possible while remaining stable.

2. Since these are velocity drives, you should use a velocity mode

tuning guide. Note that for properly tuned velocity mode drives,

the most important LinuxCNC PID term is FF1.

3. As far as output scaling goes, setting the output scale to the machine

units per second of axis velocity at 10V, means that now all PID terms

are normalized to engineering units, and FF1 == 1.0. This also makes

it easier to compare setups.

to be tuned first. This includes scaling the tachometer feedback

so you get full speed at 10V. It also means adjusting the drives

velocity loop gain as high as possible while remaining stable.

2. Since these are velocity drives, you should use a velocity mode

tuning guide. Note that for properly tuned velocity mode drives,

the most important LinuxCNC PID term is FF1.

3. As far as output scaling goes, setting the output scale to the machine

units per second of axis velocity at 10V, means that now all PID terms

are normalized to engineering units, and FF1 == 1.0. This also makes

it easier to compare setups.

Please Log in or Create an account to join the conversation.

- greg23_78

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 7

22 Aug 2024 15:09 - 22 Aug 2024 15:10 #308404

by greg23_78

Replied by greg23_78 on topic Driver NUM GEC MK2S

it's not news, but I prefer to control it.

if i understand correctly, i have just mechanically disconnected my motor from my Z axis.

i put 10V on the drive and control the speed with a tachometer ?

but how adjusting the drives velocity loop gain as high as possible while remaining stable ?

which button should I modify ?

-Zero offset

-Speed stability

-current limit

-Reference input

if i understand correctly, i have just mechanically disconnected my motor from my Z axis.

i put 10V on the drive and control the speed with a tachometer ?

but how adjusting the drives velocity loop gain as high as possible while remaining stable ?

which button should I modify ?

-Zero offset

-Speed stability

-current limit

-Reference input

Last edit: 22 Aug 2024 15:10 by greg23_78.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17650

- Thank you received: 5163

22 Aug 2024 15:29 #308405

by PCW

Replied by PCW on topic Driver NUM GEC MK2S

Is there a tachometer from the motor connected to the drive?

Please Log in or Create an account to join the conversation.

- greg23_78

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 7

22 Aug 2024 15:47 #308407

by greg23_78

Replied by greg23_78 on topic Driver NUM GEC MK2S

yes, the tachometer is connected to the motor.

i wanted to talk about a laser tachometer to measure speed because my encoder is no longer connected to the motor.

I've just put 10V into the analog input and the motor is running correctly.

i wanted to talk about a laser tachometer to measure speed because my encoder is no longer connected to the motor.

I've just put 10V into the analog input and the motor is running correctly.

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.173 seconds