Build: XZero Predator... With more teeth!

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

16 Jun 2019 21:59 #137063

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

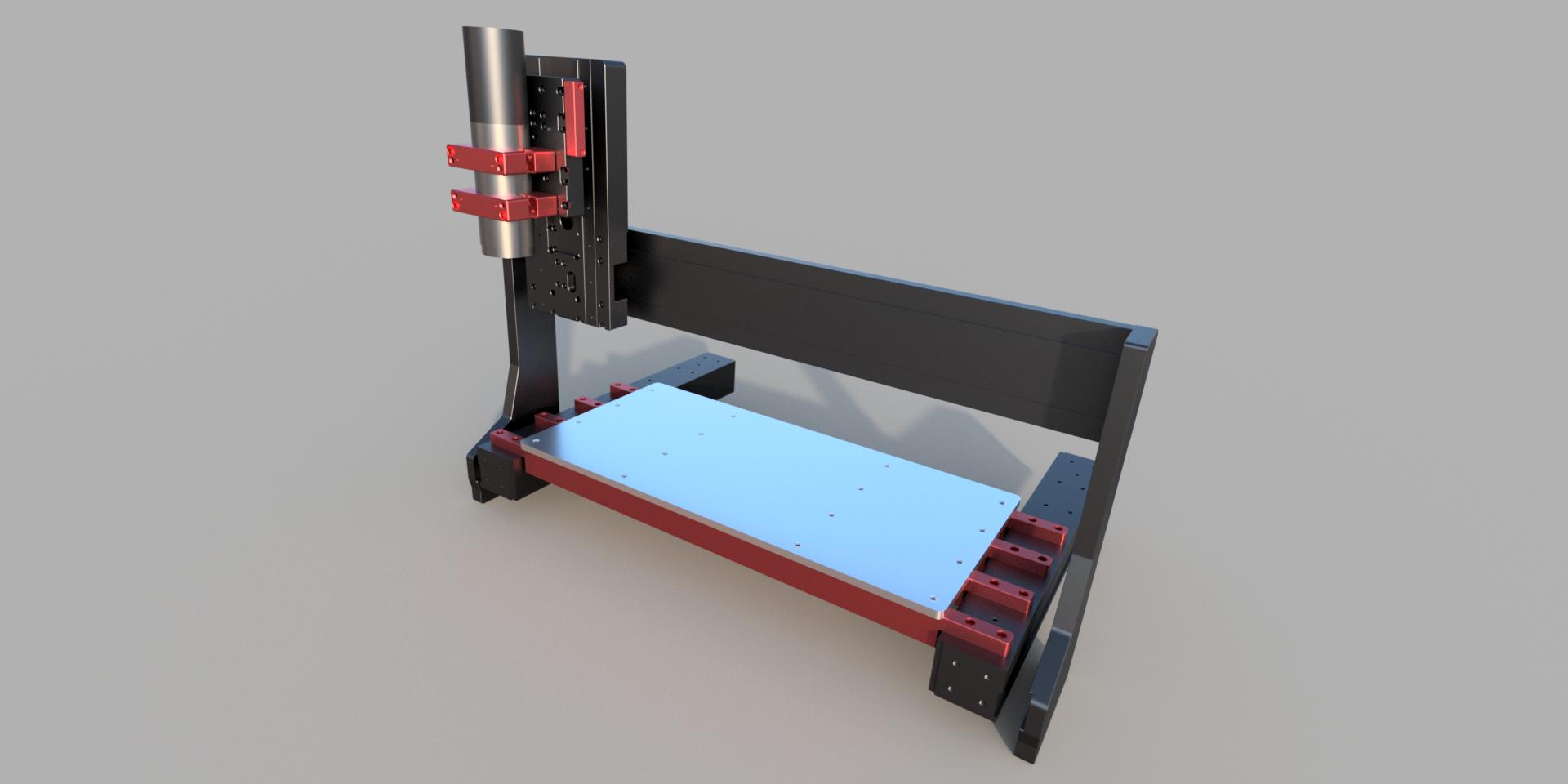

A little mockup of the frame with the new Z

Should have all the fasteners to assemble the lower frame in a few days.

The spindle is an 80mm diam 1.5kw 24000rpm ISO20 model. Price is decent and it is low power enough to run on the delta single phase.VFD. I debated getting the 2.5kw ISO25 model, but its about 8kg more weight and would push the cutter out an extra 10mm. right now, the spindle centre is right at the edge of the linear guides on the x. the old Z and teknomotor were a few inches overhanging. I never liked that - too much leverage especially when it had an extrusion base frame.

The table on there is a proxy model of this:

www.worldofclamping.com/vacuum-table-VT7535-R

I have to drill mounting holes into it. it's 1/2" solid plate, sitting on 1" x 2" bars spaced every 100mm, so it should wind up very rigid. It worked out to be the perfect size. same Y travel, and a little shorter in the X to leave room for the tool tray.

Should have all the fasteners to assemble the lower frame in a few days.

The spindle is an 80mm diam 1.5kw 24000rpm ISO20 model. Price is decent and it is low power enough to run on the delta single phase.VFD. I debated getting the 2.5kw ISO25 model, but its about 8kg more weight and would push the cutter out an extra 10mm. right now, the spindle centre is right at the edge of the linear guides on the x. the old Z and teknomotor were a few inches overhanging. I never liked that - too much leverage especially when it had an extrusion base frame.

The table on there is a proxy model of this:

www.worldofclamping.com/vacuum-table-VT7535-R

I have to drill mounting holes into it. it's 1/2" solid plate, sitting on 1" x 2" bars spaced every 100mm, so it should wind up very rigid. It worked out to be the perfect size. same Y travel, and a little shorter in the X to leave room for the tool tray.

Attachments:

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

17 Jun 2019 16:25 #137136

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

Mouser order arrived. Time to see if i can make this servo turn - or at least program the drive. I'm 50% on weather it will run the motor on 110v. We'll see.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

17 Jun 2019 18:26 #137141

by Grotius

Replied by Grotius on topic Build: XZero Predator... With more teeth!

Terence,

My compliments for your visualisation.

What kind of cad program do you use to make this?

My compliments for your visualisation.

What kind of cad program do you use to make this?

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

17 Jun 2019 18:35 #137142

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

This is in fusion 360. I'm just quickly rendering them out as I model them to be machined.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

17 Jun 2019 18:52 - 17 Jun 2019 19:16 #137143

by Grotius

Replied by Grotius on topic Build: XZero Predator... With more teeth!

Terence,

It just looks so real.

If i would see this on alibaba or ali express, i would buy it.

What is your system price for export?

To make this product on your machine :

Can you add a 4th axis horizontal rotary table, and a 5th and 6th axis milling head to your machine with a coolant supply ?

Maybe a 4th and 5th axis rotary table is more stable and faster in your config.

This would be a nice option. The fusion post processor's are ready for this option so far i know.... Isn't it?

The Predator is a very nice name for a tiny 6 axis milling machine. And for linux user's not over the top !!

It just looks so real.

If i would see this on alibaba or ali express, i would buy it.

What is your system price for export?

To make this product on your machine :

Can you add a 4th axis horizontal rotary table, and a 5th and 6th axis milling head to your machine with a coolant supply ?

Maybe a 4th and 5th axis rotary table is more stable and faster in your config.

This would be a nice option. The fusion post processor's are ready for this option so far i know.... Isn't it?

The Predator is a very nice name for a tiny 6 axis milling machine. And for linux user's not over the top !!

Attachments:

Last edit: 17 Jun 2019 19:16 by Grotius.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

17 Jun 2019 19:17 #137146

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

Haha. Well they don't give me emmy's for sucking

I have no really idea what price things will be if/when i sell them.

As a point of reference, the original predator machine (see video early on) ran about $5500US for the frame, with TBI screws, SBC rails, and not much else. To run the same machine today would be over $1000US more because of aluminium prices and a few other things. My modifications would balance out to an extra $1500US (remove one ball screw, add 4 linear blocks, add some Z material and anodising).

So $9000US, and still just a bare frame with no spindle, no control, no motors. My panel is worth under $500US in bits (if you print the main parts). Delta servos are under $2000US. vac table is $400US. ATC spindle is $1400US shipped. Delta drive is $350US. Add $1000US for extra bits like cabling, cable chain, hoses, air fittings, water cooling system, PC, MESA card, etc... A bit shy of $15000US in parts.

Maybe too much for this market... Or maybe not. I don't really know yet.

The MINI is a different topic. My wishful target is $5000US for a running machine when made in volume (100 a year or more), but I have a number of parts to source still to make that possible.

I have no really idea what price things will be if/when i sell them.

As a point of reference, the original predator machine (see video early on) ran about $5500US for the frame, with TBI screws, SBC rails, and not much else. To run the same machine today would be over $1000US more because of aluminium prices and a few other things. My modifications would balance out to an extra $1500US (remove one ball screw, add 4 linear blocks, add some Z material and anodising).

So $9000US, and still just a bare frame with no spindle, no control, no motors. My panel is worth under $500US in bits (if you print the main parts). Delta servos are under $2000US. vac table is $400US. ATC spindle is $1400US shipped. Delta drive is $350US. Add $1000US for extra bits like cabling, cable chain, hoses, air fittings, water cooling system, PC, MESA card, etc... A bit shy of $15000US in parts.

Maybe too much for this market... Or maybe not. I don't really know yet.

The MINI is a different topic. My wishful target is $5000US for a running machine when made in volume (100 a year or more), but I have a number of parts to source still to make that possible.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

17 Jun 2019 19:28 #137148

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

Impellers! haha.

Well, you have a little under 200mm clearance above the table beams and 175mm travel. And of course linuxcnc can run all sorts of axes.

Trick if making a reliable trunion table that isn't $25000.

If you go surplus harmonic drives, and cross roller rings, and machine a nice aluminium housing and fixturing plate, you could do well with very small 5 axis parts.

As for fusion, ugh. It has some 5 axis functions, but it is still squirrely. I think you'd want to program as 3+2 and just use 4 and 5 for positioning and not simultaneous machining. For now. It will improve over time.

Also, the predator isn't what i would call "small". It's 400lbs and 740mm x 400mm x 175mm travel. The MINI is small, but it couldn't fit 5 axis, only a 3" chuck 4th realistically.

Well, you have a little under 200mm clearance above the table beams and 175mm travel. And of course linuxcnc can run all sorts of axes.

Trick if making a reliable trunion table that isn't $25000.

If you go surplus harmonic drives, and cross roller rings, and machine a nice aluminium housing and fixturing plate, you could do well with very small 5 axis parts.

As for fusion, ugh. It has some 5 axis functions, but it is still squirrely. I think you'd want to program as 3+2 and just use 4 and 5 for positioning and not simultaneous machining. For now. It will improve over time.

Also, the predator isn't what i would call "small". It's 400lbs and 740mm x 400mm x 175mm travel. The MINI is small, but it couldn't fit 5 axis, only a 3" chuck 4th realistically.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

17 Jun 2019 20:01 #137151

by Grotius

Replied by Grotius on topic Build: XZero Predator... With more teeth!

If you go surplus harmonic drives, and cross roller rings, and machine a nice aluminium housing and fixturing plate, you could do well with very small 5 axis parts.

Impellers! haha.

Well, you have a little under 200mm clearance above the table beams and 175mm travel. And of course linuxcnc can run all sorts of axes.

As for fusion, ugh. It has some 5 axis functions, but it is still squirrely. I think you'd want to program as 3+2 and just use 4 and 5 for positioning and not simultaneous machining. For now. It will improve over time.

The nice thing is. If you know the solution's yourself, you can draw the final 6 axis version into Fusion.

By small, a 740 x 400 mm is a small machine. Take the harmonic drives. If they are to expensive i can contact panasonic robot's for this item.

Impellers! haha.

Well, you have a little under 200mm clearance above the table beams and 175mm travel. And of course linuxcnc can run all sorts of axes.

As for fusion, ugh. It has some 5 axis functions, but it is still squirrely. I think you'd want to program as 3+2 and just use 4 and 5 for positioning and not simultaneous machining. For now. It will improve over time.

The nice thing is. If you know the solution's yourself, you can draw the final 6 axis version into Fusion.

By small, a 740 x 400 mm is a small machine. Take the harmonic drives. If they are to expensive i can contact panasonic robot's for this item.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

17 Jun 2019 20:11 #137152

by andypugh

The Harmoic Drive "FHA" units are a servo motor, harmonic drive and crossed-roller ring assembled as an integrated unit.

They make perfect 4th and 5th axes. And are not _that_ expensive on the eBay market. But that's not a good source for a commercial product.

www.ebay.co.uk/itm/HARMONIC-DRIVE-SYSTEM...ctuator/263813872830

A working setup for the STMBL drive exists for them.

Replied by andypugh on topic Build: XZero Predator... With more teeth!

If you go surplus harmonic drives, and cross roller rings, and machine a nice aluminium housing and fixturing plate, you could do well with very small 5 axis parts.

The Harmoic Drive "FHA" units are a servo motor, harmonic drive and crossed-roller ring assembled as an integrated unit.

They make perfect 4th and 5th axes. And are not _that_ expensive on the eBay market. But that's not a good source for a commercial product.

www.ebay.co.uk/itm/HARMONIC-DRIVE-SYSTEM...ctuator/263813872830

A working setup for the STMBL drive exists for them.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

17 Jun 2019 20:14 #137153

by ihavenofish

Replied by ihavenofish on topic Build: XZero Predator... With more teeth!

Theres lots of harmonic drives on korean ebay sellers stores. Usually $400-$900 each (new). I am looking into one as I want a 4th axis on both the mini and the predator. The mini will be my machine for 7075 Al bike parts (chainrings mostly). The predator is mostly for wood (guitars) and plastic, although its pretty beastly and will have linear scales, so it will still be very accurate if I need to make any larger plate parts in aluminium. (remember I have brother tapping centres for real metal work whenever I get a new building to work in  )

)

Please Log in or Create an account to join the conversation.

Time to create page: 0.352 seconds