what to do with a free scrap dumpster find ?

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Jul 2021 00:43 #216168

by machinedude

what to do with a free scrap dumpster find ? was created by machinedude

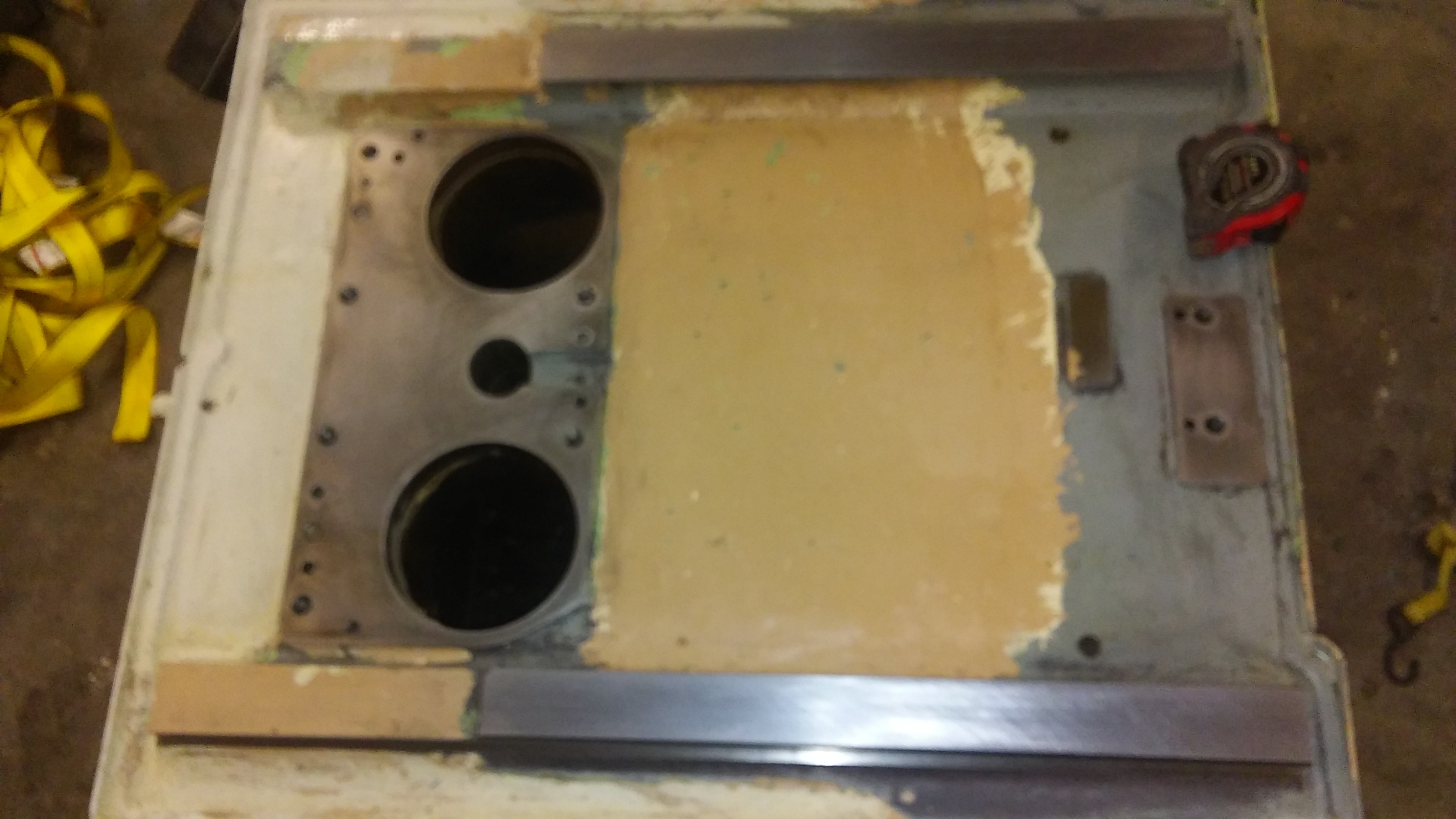

picked up a DoAll vs618-1 or what is left of one for free so now what to do with it  the grinder has seen better days and after busting down the machine and finding Rulon film lining some of the saddle ways and pricing the material and finding out it is not cheap by any means to replace it adds to the concern of is it worth it to restore as a grinder? the machine is missing some big price items like the hydraulic pump that drove the table and the magnetic chuck, the machine had a coolant tank at one point but not now.

the grinder has seen better days and after busting down the machine and finding Rulon film lining some of the saddle ways and pricing the material and finding out it is not cheap by any means to replace it adds to the concern of is it worth it to restore as a grinder? the machine is missing some big price items like the hydraulic pump that drove the table and the magnetic chuck, the machine had a coolant tank at one point but not now.

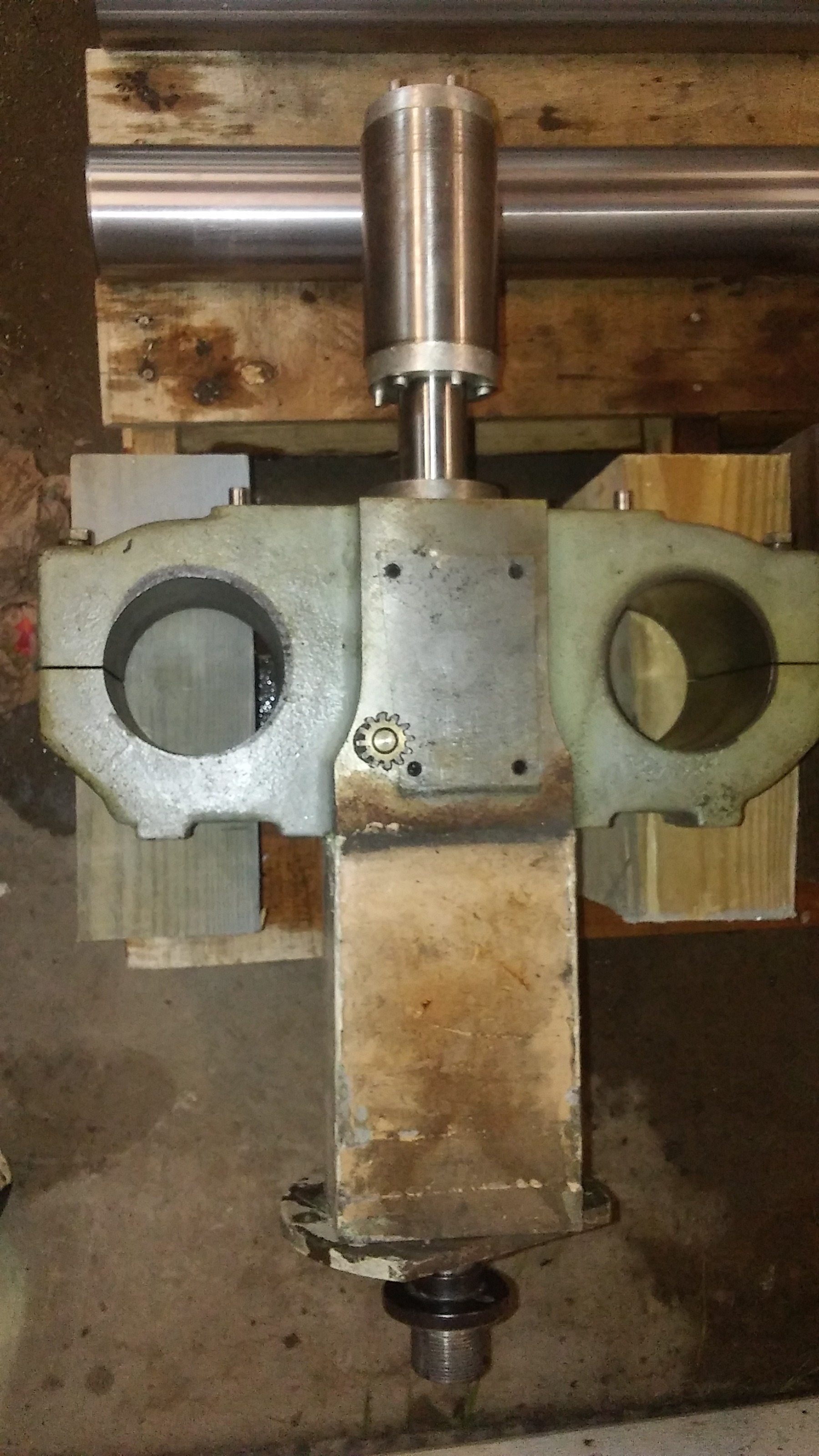

after looking at the castings and how the machine was made i am leaning hard in the direction of turning this thing into a horizonal mill which i would have far more use for than a grinder. the spindle would need to be redone but the casting could be modified for a new design on the spindle.

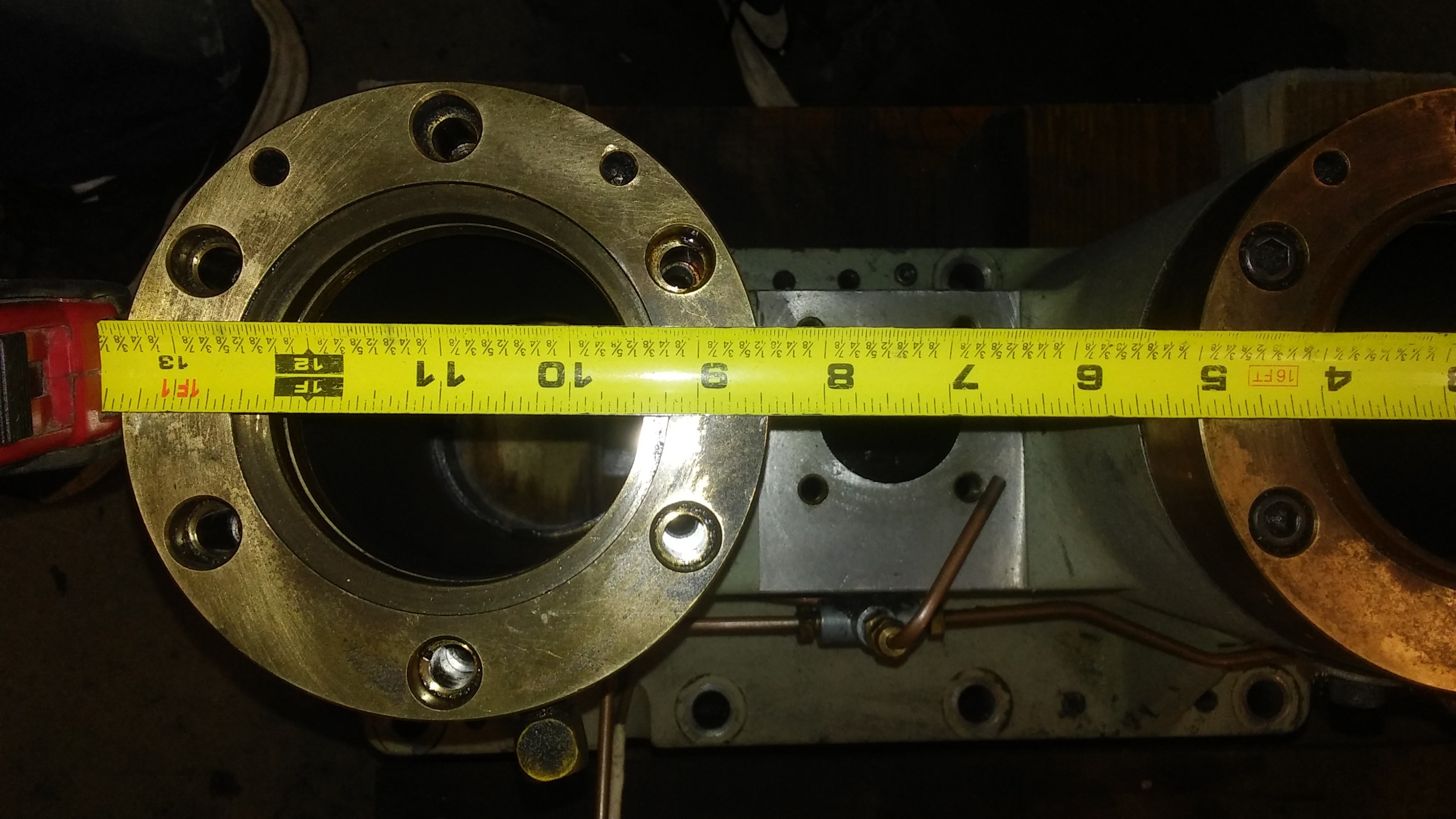

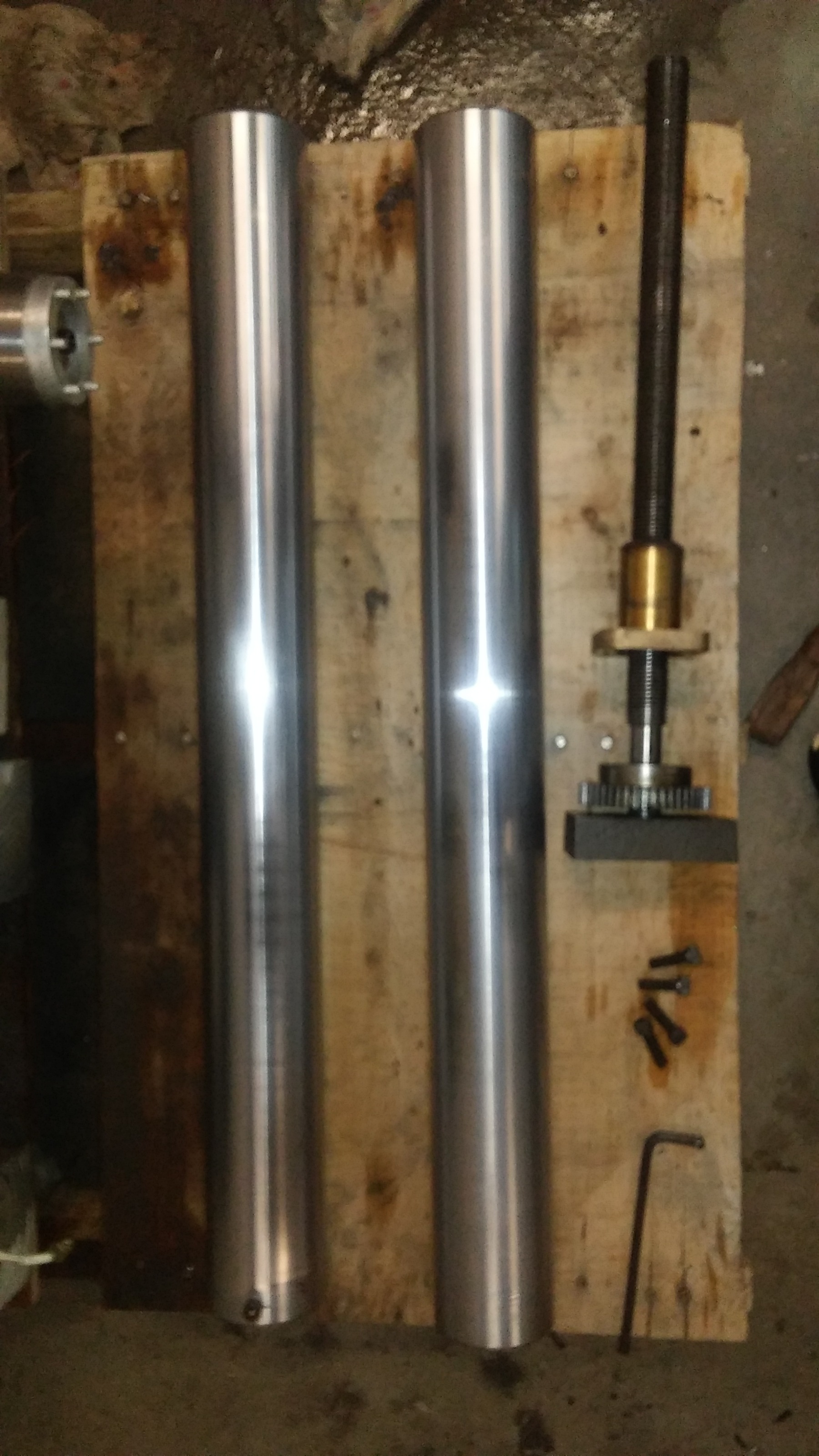

last ting i need right now is another project but this was one of those deals where you take it or leave it and free was hard for me to pass up as is the machine is about 1600 lbs and the two columns are 3 " daimeter thick walled tube with a 3/4 wall thickness. i think the columns are pretty substantial for the size of the machine.

as is the machine is about 1600 lbs and the two columns are 3 " daimeter thick walled tube with a 3/4 wall thickness. i think the columns are pretty substantial for the size of the machine.

after looking at the castings and how the machine was made i am leaning hard in the direction of turning this thing into a horizonal mill which i would have far more use for than a grinder. the spindle would need to be redone but the casting could be modified for a new design on the spindle.

last ting i need right now is another project but this was one of those deals where you take it or leave it and free was hard for me to pass up

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

29 Jul 2021 00:56 #216171

by andypugh

Replied by andypugh on topic what to do with a free scrap dumpster find ?

I accidentally bought a 2.8kw frameless motor from eBay recently (I thought that it was _much_ smaller) and have been thinking that the 2" through shaft diameter would make a great grinding spindle.

Can you teleport your stuff to me, for free?

Can you teleport your stuff to me, for free?

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Jul 2021 01:06 #216172

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

the spindle on this was fine as a grinder, it has a 1 HP direct drive 3 phase that can run on 220 or 440 so part of me hates to mess with that part but when you look at cost to bring the rest up to speed that's where i am on the fence

moving it 13 miles was hard enough sending it all the way across the pond would be about impossible these old machines are build well so saving it from the scrap yard was a plus. i'm sure i can turn it into something useful in the end

these old machines are build well so saving it from the scrap yard was a plus. i'm sure i can turn it into something useful in the end

moving it 13 miles was hard enough sending it all the way across the pond would be about impossible

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

29 Jul 2021 01:17 #216174

by andypugh

Replied by andypugh on topic what to do with a free scrap dumpster find ?

Do you have the table? It is useful with it, and scrap without it.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Jul 2021 01:27 #216175

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

yeah the saddle and table are with it the only thing missing was the magnetic chuck that was on it. the saddle has out riggers cast into it that extend around the bearing assembly so i think i can get around 30" x 18" x 16" of travel as a horizonal machine. this grinder has quite a bit of head height @ 18". i was talking to one of the guys at work about travel on the Mazak machines and his only has about a 20" x 20" x 20" envelope. so i could make a small Bridgeport size horizonal i think with close to what the Mazak's at my work have in relation to travel.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

29 Jul 2021 01:31 #216176

by andypugh

Replied by andypugh on topic what to do with a free scrap dumpster find ?

Keep it as a grinder. I gave away a grinder 10 years ago and tried to claim it back last week. Eventually you will want a grinder

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Jul 2021 01:42 #216177

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

they are all over the place here used in good shape and can be bought cheap, i think it would cost as much to restore this one to a good condition honestly. that's why i am thinking about converting it. would i go buy one to convert probably not but since it was free it makes the idea more attractive. i have most of the parts needed already too. i probably might end up with one later because they are useful when you have the need for them but my needs for one right now are not enough to sink the kind of money into this to make it right.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Jul 2021 02:04 #216179

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

i think i will hold off on messing with the grinding head for now but work on the table section to automate it into a CNC. if i can keep things tight and keep things close enough it might be useful to have a grinder that could be programmed to grind tapers and do some contouring?

i do know this for sure i do not want to swing handles and do it all manually been there done that and it's no fun

been there done that and it's no fun

i do know this for sure i do not want to swing handles and do it all manually

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

01 Aug 2021 00:43 #216552

by andypugh

Replied by andypugh on topic what to do with a free scrap dumpster find ?

Oh yes, fully-manual surface grinders are about as bad as it gets to operate. Been there..

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

01 Aug 2021 06:34 #216583

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

back in the day tool and die was still around in some volume and i got into grinding. i had never done it before hand so i had no clue on how hard it was to swing handles all day. by the time the day was done your arms and shoulders were reduced to jello

the only thing that concerns me with a cnc grinder is a mishap and having a wheel explode in my face plus things would have to be supper tight with absolute zero backlash since the cuts are so small with grinding. anything more than .0001 or .0002 could be a problem.

i was cleaning up the saddle and table and seen the table may not be as easy as i was thinking to put rails on for a conversion so that area will require some more thought before i do anything drastic once i start on a path i'm pretty much stuck going that direction.

most of the wear is in the table. i took the Rulon off the ways on the saddle and under was in very good shape but the Rulon i took off was really bad and the table ways it rode on were really badly worn. with no Rulon liner all the heights off now plus this grinder has been worked on before and some things on the screw have been altered. someone has taken material off the bottom of the brass nut and there where shims under that nut because they must have took to much off?

i can machine things to where they need to be if i convert this thing and keep things close enough for milling but i have my doubts about keeping things close enough for grinding with the equipment i have in my home shop. splitting 1/10 ths is a whole different animal. after taking about 10 layers of paint off this thing i can see machined surfaces that will keep me square to the existing machine so reworking things on a milling level is not a problem. even having room for ball screws is not an issue since the casting has lots of room to work with.

i think the grinding spindle is ok but i can't say for sure i have used this machine as a grinder at work and it had some major finish issues. so i know a little more about the weak points of this machine than most would with a random machine.

i think at the very least you would need a 2 foot x 3 foot class A surface plate and a good indicator half a 1/10 to get this thing back to grinding along with lots of time hand scaping and could find that issues with the spindle might be the problem after all ? although i think it's in the table at this point. i did feel the spindle but have not put an indicator on it at this point yet.

this thing is a distraction but after 2 years of looking at the other stuff it's nice to take a break from it and have something else to look at so it's not all bad.

the only thing that concerns me with a cnc grinder is a mishap and having a wheel explode in my face plus things would have to be supper tight with absolute zero backlash since the cuts are so small with grinding. anything more than .0001 or .0002 could be a problem.

i was cleaning up the saddle and table and seen the table may not be as easy as i was thinking to put rails on for a conversion so that area will require some more thought before i do anything drastic once i start on a path i'm pretty much stuck going that direction.

most of the wear is in the table. i took the Rulon off the ways on the saddle and under was in very good shape but the Rulon i took off was really bad and the table ways it rode on were really badly worn. with no Rulon liner all the heights off now plus this grinder has been worked on before and some things on the screw have been altered. someone has taken material off the bottom of the brass nut and there where shims under that nut because they must have took to much off?

i can machine things to where they need to be if i convert this thing and keep things close enough for milling but i have my doubts about keeping things close enough for grinding with the equipment i have in my home shop. splitting 1/10 ths is a whole different animal. after taking about 10 layers of paint off this thing i can see machined surfaces that will keep me square to the existing machine so reworking things on a milling level is not a problem. even having room for ball screws is not an issue since the casting has lots of room to work with.

i think the grinding spindle is ok but i can't say for sure i have used this machine as a grinder at work and it had some major finish issues. so i know a little more about the weak points of this machine than most would with a random machine.

i think at the very least you would need a 2 foot x 3 foot class A surface plate and a good indicator half a 1/10 to get this thing back to grinding along with lots of time hand scaping and could find that issues with the spindle might be the problem after all ? although i think it's in the table at this point. i did feel the spindle but have not put an indicator on it at this point yet.

this thing is a distraction but after 2 years of looking at the other stuff it's nice to take a break from it and have something else to look at so it's not all bad.

Please Log in or Create an account to join the conversation.

Time to create page: 0.192 seconds