what to do with a free scrap dumpster find ?

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

19 Dec 2021 09:40 #229477

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

needed some tubing for bearing spaces for this project and all i have to say is WOW prices are crazy right now. almost $ 100 for 2 different12" lengths. these material prices in the current market suck.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

09 Jan 2022 12:52 #231244

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

i have been waiting for 3 weeks for some DOM tube so i can make outer race spacers and this material still has not shipped yet? prices are a bit out of control on tube and everything else for that matter but it is what it is i guess.

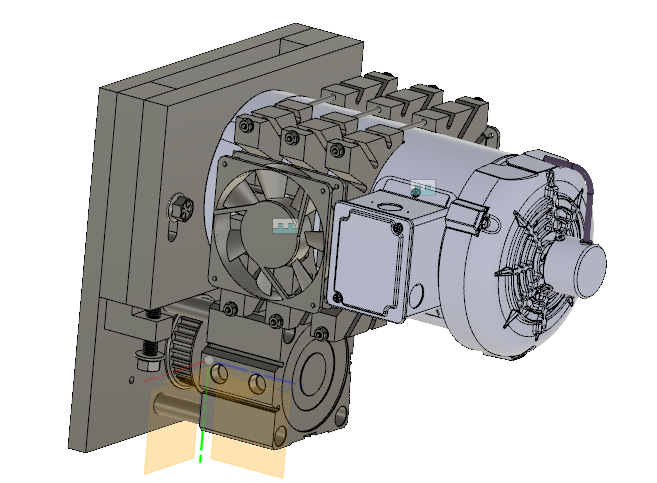

i do have enough finished that i can sort the motor mounting and everything else. this is still in the rough design phase and i still have a few things to sort out but the major stuff i think i have sorted out and did a screen grab to post for the basic plan.

since i would like to do rigid tapping this 3 phase motor needs some feed back so coming up with a way to get an encoder on the motor was a bit of a thinking process but i think i have a good plan, the motor has a plastic fan for cooling on the back side of the shaft so the plan is to attach an encoder directly to the shaft and loose the plastic fan altogether. these motors cool ok at high speeds but when you run slower the cooling drops off. so to make it better at all speeds the plan is to heatsink the motor and use 2 DC fans to cool everything. most likely they will just run all the time when the machine is running.

i have a simple belt tension system worked out and now know what length of belt i need. the one belt i have is too short but getting one that will work is not a problem.

this is still a work in progress but the screen grab explains things better than i can i think

i do have enough finished that i can sort the motor mounting and everything else. this is still in the rough design phase and i still have a few things to sort out but the major stuff i think i have sorted out and did a screen grab to post for the basic plan.

since i would like to do rigid tapping this 3 phase motor needs some feed back so coming up with a way to get an encoder on the motor was a bit of a thinking process but i think i have a good plan, the motor has a plastic fan for cooling on the back side of the shaft so the plan is to attach an encoder directly to the shaft and loose the plastic fan altogether. these motors cool ok at high speeds but when you run slower the cooling drops off. so to make it better at all speeds the plan is to heatsink the motor and use 2 DC fans to cool everything. most likely they will just run all the time when the machine is running.

i have a simple belt tension system worked out and now know what length of belt i need. the one belt i have is too short but getting one that will work is not a problem.

this is still a work in progress but the screen grab explains things better than i can i think

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

13 Jan 2022 06:53 #231633

by machinedude

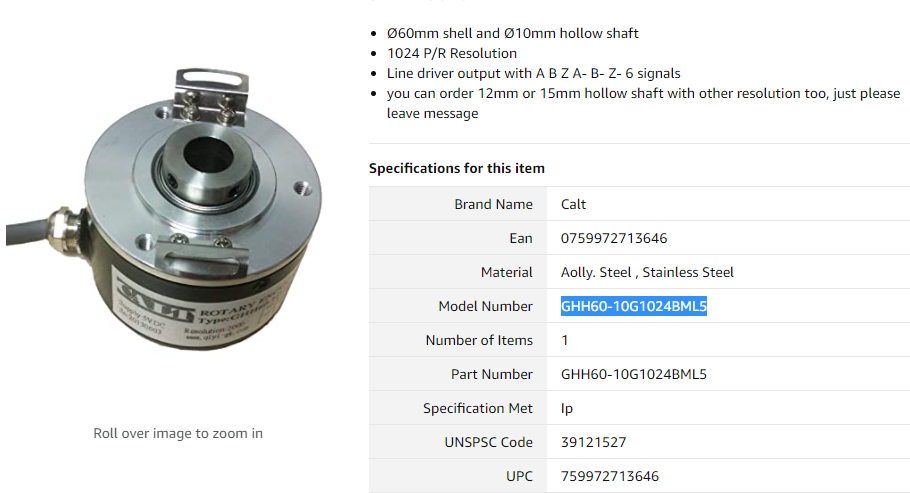

decided to go with this encoder it looked to be about the same as a glass linear scale as far as signals go and figured it would work for my needs here. seems to be rated for 6000 rpm as far as i can tell but some of the info i seen was conflicting? i figured it was cheap enough to try at $55 so time will tell i was looking for one that would drop right on the shaft as is but to get into that size would cost way to much so i will have to alter the end of the shaft to make this one work but it's not that big of a deal for me. this is a tight budget minded project. the hollolw shaft design should fit under the cover of the motor once the original cooling fan is removed. the fact that i have a 1:1 ratio on the drive makes this simple and i like simple

i was looking for one that would drop right on the shaft as is but to get into that size would cost way to much so i will have to alter the end of the shaft to make this one work but it's not that big of a deal for me. this is a tight budget minded project. the hollolw shaft design should fit under the cover of the motor once the original cooling fan is removed. the fact that i have a 1:1 ratio on the drive makes this simple and i like simple  direct attachment does not get much simpler and less parts are needed so i like that part

direct attachment does not get much simpler and less parts are needed so i like that part

Replied by machinedude on topic what to do with a free scrap dumpster find ?

decided to go with this encoder it looked to be about the same as a glass linear scale as far as signals go and figured it would work for my needs here. seems to be rated for 6000 rpm as far as i can tell but some of the info i seen was conflicting? i figured it was cheap enough to try at $55 so time will tell

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

19 Jan 2022 07:00 - 19 Jan 2022 07:21 #232407

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

started to wrap my head around this GS20 family of VFD's from Automation direct and i have to say it took a while to understand it with all the features this VFD has. couple of points on this VFD it has some features that are beyond me at the moment. it has a RS485 port and i'm not sure if that would be a gain or not? the e-stop circuit has a built in relay so you don't have to add some sort of contactor to kill the power so that seems useful since you need less space in the cabinet with that built in. the VFD has a built in PLC but i don't see a use for it at the moment. one of the control inputs does PWM but has a Limit of 33kH but could be used for encoder feedback. the downside to the PWM input is you need a low resolution encoder to use it at higher speeds and my thoughts were the 7i97 i have at the moment seemed like it would take the place of the built in PWM input so as of now it seems like the VFD can do a lot in an application where it was in a stand alone situation but with Linux cnc and a Mesa card it gets bypassed in a remote control mode being run form Mesa and LInux cnc it would seem. this drive seems to have a lot of options for control as well for basic to more advanced. it does V/Hz being the most basic to SVC and FOC. from what i seen so far at this point SVC gets used often in CT applications which is what you want in a spindle drive but the FOC is better than SVC running at lower speeds it seems? so right now it's going to be 1 of the 2 later options? so does anybody have any input on the better of the two options?0 to10V analog control is looking how this will go since the drive can scale things in a % value to the 0 to 10V analog signal. the STO(safe torque off ) as this dive calls it for the e-stop uses 24V the drive has a built in 24v supply which they jumper2 pins from the 24V power from the factory so it is enabled so it seem like this would be the place to enable the VFD? these VFD's have different terminology than what i am use to seeing so forgive me in advance  i was going to attach the quick start guide which has the basic stuff covered but that seems to be to large to post so hopefully this link works in case anyone has any interest in these drives? the full manual is around 650 pages i'm sure nobody wants to see that

i was going to attach the quick start guide which has the basic stuff covered but that seems to be to large to post so hopefully this link works in case anyone has any interest in these drives? the full manual is around 650 pages i'm sure nobody wants to see that  maybe if you would end up using one of these you might for this i doubt it

maybe if you would end up using one of these you might for this i doubt it

cdn.automationdirect.com/static/manuals/...nserts/gs20quick.pdf

cdn.automationdirect.com/static/manuals/...nserts/gs20quick.pdf

Last edit: 19 Jan 2022 07:21 by machinedude.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

19 Jan 2022 15:58 - 19 Jan 2022 16:00 #232443

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

ok now some stuff is making sense  you need to add a two channel rely to control the FWD and REV signal and the DCM is common on those two. the A11 is an analog input for the 0-10V from and analog output on the Mesa board and the ACM is the ground on the Mesa Analog output.

you need to add a two channel rely to control the FWD and REV signal and the DCM is common on those two. the A11 is an analog input for the 0-10V from and analog output on the Mesa board and the ACM is the ground on the Mesa Analog output.

so the question is now about enable on the Analog output on the Mesa card? i am not sure where to tie that part in? the VFD is enabled with the jumper but that should be taken out and have an e-stop which is not an issue they have a video tutorial on that topic so i can sort that part out myself. i'm just stumped on the enable pins on the Analog output on the Mesa card. would that supply the 24V to the relays to switch between FWD & REV? i think i seen a post here somewhere where they act like switches and measure 24V in one state and like .06V in the other state and i'm guessing that's like an active high and low field power Logic? so the enable is actually like a logic enable rather than a drive enable?

so the question is now about enable on the Analog output on the Mesa card? i am not sure where to tie that part in? the VFD is enabled with the jumper but that should be taken out and have an e-stop which is not an issue they have a video tutorial on that topic so i can sort that part out myself. i'm just stumped on the enable pins on the Analog output on the Mesa card. would that supply the 24V to the relays to switch between FWD & REV? i think i seen a post here somewhere where they act like switches and measure 24V in one state and like .06V in the other state and i'm guessing that's like an active high and low field power Logic? so the enable is actually like a logic enable rather than a drive enable?

Last edit: 19 Jan 2022 16:00 by machinedude.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20992

- Thank you received: 7158

19 Jan 2022 17:30 #232451

by tommylight

Replied by tommylight on topic what to do with a free scrap dumpster find ?

ena+ to DCM or common

ena- to middle pin on a NO/NC relay

NC from relay to FWD

NO from relay to REV

Any output pin on Mesa set as spindle direction to control that relay.

Also double check the ena+ and ena-, it depends on DCM/common being a ground or a positive (+24V or whatever VFD uses).

ena- to middle pin on a NO/NC relay

NC from relay to FWD

NO from relay to REV

Any output pin on Mesa set as spindle direction to control that relay.

Also double check the ena+ and ena-, it depends on DCM/common being a ground or a positive (+24V or whatever VFD uses).

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

19 Jan 2022 18:07 #232460

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

Thanks Tommy.

i was looking at relay boards and it looks like they can be wired as NO or NC so that part is pretty universal. they make breakout boards for this with relays built in but the ones i have seen took a PWM signal and converted it to analog which is not what i need on that end of it. so a plain relay board seems like a cheaper solution. i think i will look into singles rather than a multi channel board just to make replacing one easier if one should go bad too.

i was looking at relay boards and it looks like they can be wired as NO or NC so that part is pretty universal. they make breakout boards for this with relays built in but the ones i have seen took a PWM signal and converted it to analog which is not what i need on that end of it. so a plain relay board seems like a cheaper solution. i think i will look into singles rather than a multi channel board just to make replacing one easier if one should go bad too.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

21 Jan 2022 17:31 #232660

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

Actually i think the polarity is reversed on this VFD for the enable, NPN is the default configuration. i came across another topic here about this and PCW had the enable - going to DCM / common,

The 0-10 V was different since it was for a 7i76e and was a little more involved for the control on that part than what i need for the 7i97 but the rest was pretty much the same as this GS21-23P0 drive i am using. but the topic was just about pin connections. no mention of relays.

i have been working on wiring diagrams just to have some kind of reference to work from when the time comes. but basically i am thinking the circuit has 2 relays and one is used for the start/stop and another is used for the forward / rev

PCW stated having the enable+ tied to the FWD connection but i was thinking it made more sense to me to have the enable on the run / start side so when the spindle stops the drive is disabled until it is turned on again. and doing it this way would use 2 outputs from the 7i97 for the logic signal on the relay board.

as for the size of relay board it would appear that you need 24V relay boards since that seems to be what the vfd circuit is so that's what i have coming. if i messed up on the size no big deal they are pretty cheap since a 4 pack was under $10

the only thing i have to wait and see about is how they react with no power? i am not sure if the are unlatched with no connection to either NO OR NC or if the are latched in one direction with no power? once i have them i can test them to find out but until then that part is up in the air until i get them.

but if all my circuits are correct and it works right i will post the wiring diagram to leave a bread crumb for the next guy.

The 0-10 V was different since it was for a 7i76e and was a little more involved for the control on that part than what i need for the 7i97 but the rest was pretty much the same as this GS21-23P0 drive i am using. but the topic was just about pin connections. no mention of relays.

i have been working on wiring diagrams just to have some kind of reference to work from when the time comes. but basically i am thinking the circuit has 2 relays and one is used for the start/stop and another is used for the forward / rev

PCW stated having the enable+ tied to the FWD connection but i was thinking it made more sense to me to have the enable on the run / start side so when the spindle stops the drive is disabled until it is turned on again. and doing it this way would use 2 outputs from the 7i97 for the logic signal on the relay board.

as for the size of relay board it would appear that you need 24V relay boards since that seems to be what the vfd circuit is so that's what i have coming. if i messed up on the size no big deal they are pretty cheap since a 4 pack was under $10

the only thing i have to wait and see about is how they react with no power? i am not sure if the are unlatched with no connection to either NO OR NC or if the are latched in one direction with no power? once i have them i can test them to find out but until then that part is up in the air until i get them.

but if all my circuits are correct and it works right i will post the wiring diagram to leave a bread crumb for the next guy.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

03 Feb 2022 22:05 #233918

by machinedude

Replied by machinedude on topic what to do with a free scrap dumpster find ?

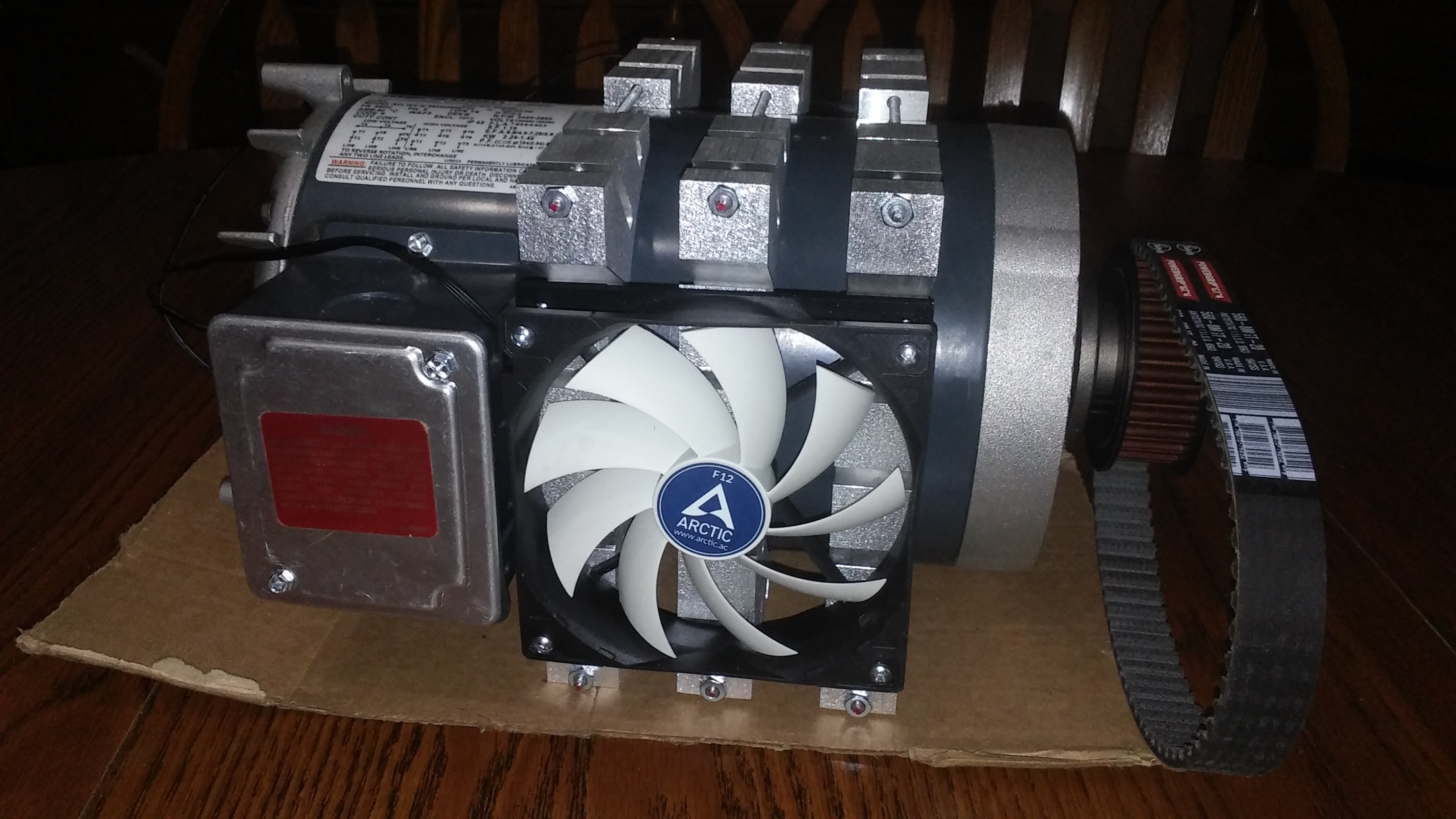

Started to work on my motor cooling plan and got my heat sinks made and the fans mounted. i think this should work better than the stock motor set up. Since I was testing fit and had things together I figured I would take some picture and share. next step is to alter the shaft on the back end for the encoder and open up the center hole of the plastic cover so it clears the rotary encoder and give it a nice tidy look.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20992

- Thank you received: 7158

04 Feb 2022 00:59 #233934

by tommylight

Replied by tommylight on topic what to do with a free scrap dumpster find ?

F12 = Flow 120mm

P12 = Pressure 120mm

Fans from Arctic, very good and very cheap so try the P12, should be better for that job.

Also, if you can choose, P12 CO, bearings are long lasting.

P12 = Pressure 120mm

Fans from Arctic, very good and very cheap so try the P12, should be better for that job.

Also, if you can choose, P12 CO, bearings are long lasting.

The following user(s) said Thank You: machinedude

Please Log in or Create an account to join the conversation.

Time to create page: 0.342 seconds