6040 7i76 Conversion

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 973

- Thank you received: 429

10 May 2023 21:09 - 11 May 2023 13:08 #271131

by my1987toyota

Replied by my1987toyota on topic 6040 7i76 Conversion

Thanks for clearing that up PCW.

spacestate1 if you use the TB6600 use a 36 volt power supply ( say Meanwell LRS-450-36 ). If you use something like the DM556

you can use a 48 volt ( say LRS-450-48 or NDR-480-48 which is din rail mountable) and you will have more top end speed in your

steppers but check the motor temps

when under load If the steppers get hot enough that they get uncomfortable to hold your hand on

drop your amp setting on your drives until they get warm but not uncomfortable to hold. Also the

DM556 has the setting for half current when idle ( I think dip switch 4 ) so your motors will cool

when not turning . The TB6600 doesn't have that feature so they hammer your steppers with the

max set current as soon as the drive is powered.

spacestate1 if you use the TB6600 use a 36 volt power supply ( say Meanwell LRS-450-36 ). If you use something like the DM556

you can use a 48 volt ( say LRS-450-48 or NDR-480-48 which is din rail mountable) and you will have more top end speed in your

steppers but check the motor temps

when under load If the steppers get hot enough that they get uncomfortable to hold your hand on

drop your amp setting on your drives until they get warm but not uncomfortable to hold. Also the

DM556 has the setting for half current when idle ( I think dip switch 4 ) so your motors will cool

when not turning . The TB6600 doesn't have that feature so they hammer your steppers with the

max set current as soon as the drive is powered.

Last edit: 11 May 2023 13:08 by my1987toyota. Reason: adding information

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 973

- Thank you received: 429

10 May 2023 22:00 #271136

by my1987toyota

Replied by my1987toyota on topic 6040 7i76 Conversion

E-Stop.

The way I do it is the circuit is always connected or normally closed unless I hit the E-Stop switch or

in a rare case of the wire failing, the E-Stop will be triggered. How I normally do it is I use a multi

contact relay that when the E-Stop is triggered it cuts power to the relay coil which in turn-

1 shuts off power to the coolant,

2 disables the spindle drive,

3 tells the computer an Estop event has occurred, (through the 7i76)

4 disables the stepper drives

You could wire in more relays to do more things if needed but in my case this covers all my bases.

I prefer hardware type of E-Stop over software so that in the event of a program crash when an

E-Stop button is triggered the machine will stop moving regardless of what the computer is doing.

When designing any machine it is always best practice to fail safe.

The way I do it is the circuit is always connected or normally closed unless I hit the E-Stop switch or

in a rare case of the wire failing, the E-Stop will be triggered. How I normally do it is I use a multi

contact relay that when the E-Stop is triggered it cuts power to the relay coil which in turn-

1 shuts off power to the coolant,

2 disables the spindle drive,

3 tells the computer an Estop event has occurred, (through the 7i76)

4 disables the stepper drives

You could wire in more relays to do more things if needed but in my case this covers all my bases.

I prefer hardware type of E-Stop over software so that in the event of a program crash when an

E-Stop button is triggered the machine will stop moving regardless of what the computer is doing.

When designing any machine it is always best practice to fail safe.

Please Log in or Create an account to join the conversation.

- spacestate1

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 9

24 May 2023 02:50 #272070

by spacestate1

Replied by spacestate1 on topic 6040 7i76 Conversion

I can connect and flash the 7i92 with a bin file for the 7i76 board, and it seems to apply things as expected. But now I'm not sure what to do to get the steppers going. I know there's a ton of info out there on this, but I think I'm missing something simple.

I bought a DM556 and wired it up a 48volt power supply with the stepper coils wired, and the step pins to the 7i76 like this:

Step 0- -> PUL-

Step0+ -> Pul+

Dir0- -> DIR-

DIR0+ -> DIR+

I then used steppconf to get the board and settings into the ini file, but I cannot get the X-axis to move in LinuxCNC, or in the test menus.

Am I missing something like an enable switch or another pin? Or is the 7i92 not setup correctly?

Attached are ini config files and the readhmid output

thanks again

I bought a DM556 and wired it up a 48volt power supply with the stepper coils wired, and the step pins to the 7i76 like this:

Step 0- -> PUL-

Step0+ -> Pul+

Dir0- -> DIR-

DIR0+ -> DIR+

I then used steppconf to get the board and settings into the ini file, but I cannot get the X-axis to move in LinuxCNC, or in the test menus.

Am I missing something like an enable switch or another pin? Or is the 7i92 not setup correctly?

Attached are ini config files and the readhmid output

thanks again

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 973

- Thank you received: 429

24 May 2023 20:43 - 24 May 2023 20:45 #272112

by my1987toyota

Replied by my1987toyota on topic 6040 7i76 Conversion

first things first . Don't use steppconf when using a Mesa board use pncconf. The rest of the board setup should be pretty easy.

Personally when I did my first one I made the simplest setup possible then played around with adding more stuff so I didn't hit information

overload.

Personally when I did my first one I made the simplest setup possible then played around with adding more stuff so I didn't hit information

overload.

Last edit: 24 May 2023 20:45 by my1987toyota. Reason: correcting spelling

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

24 May 2023 21:54 #272118

by PCW

Replied by PCW on topic 6040 7i76 Conversion

Also, as a quick sanity check of the setup,

check that the direction pins on the 7I76

change states when jogging in different

directions.

check that the direction pins on the 7I76

change states when jogging in different

directions.

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- spacestate1

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 9

24 May 2023 23:45 #272122

by spacestate1

Replied by spacestate1 on topic 6040 7i76 Conversion

Typo, I set it up with pncconf

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- spacestate1

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 9

25 May 2023 00:58 #272125

by spacestate1

Replied by spacestate1 on topic 6040 7i76 Conversion

Just double checked my wiring I had the DB556 wired wrong, moved the wires down a peg and now it works. Thanks for help once again though.

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 973

- Thank you received: 429

25 May 2023 09:41 - 25 May 2023 09:42 #272143

by my1987toyota

Replied by my1987toyota on topic 6040 7i76 Conversion

Something else you may want to take a look at is some of the Tormach manuals. More specifically their electrical wiring and

schematics near the end of their manuals. It will give you an Idea of what should be used for a more reliable and more

importantly safe machine . It helped me a lot .

link for PDF download of the 24R Operators manual

tormach.com/support/router/24r-cnc-router-documents

Link for PDF download of the 1100M Operators Manual

tormach.com/support/mill/1100m-documents

schematics near the end of their manuals. It will give you an Idea of what should be used for a more reliable and more

importantly safe machine . It helped me a lot .

link for PDF download of the 24R Operators manual

tormach.com/support/router/24r-cnc-router-documents

Link for PDF download of the 1100M Operators Manual

tormach.com/support/mill/1100m-documents

Last edit: 25 May 2023 09:42 by my1987toyota. Reason: correcting spelling

Please Log in or Create an account to join the conversation.

- spacestate1

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 9

29 May 2023 14:12 - 29 May 2023 14:15 #272432

by spacestate1

Replied by spacestate1 on topic 6040 7i76 Conversion

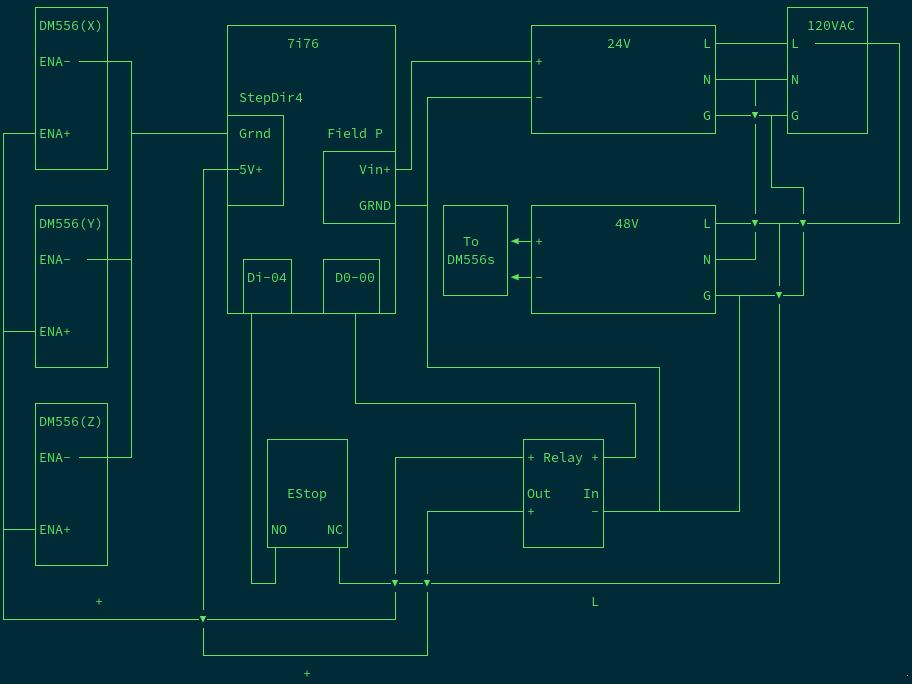

Posting to see if there's problems with this plan on how to wire up the E-stop, and also just from my own reference. This is based on what I've read on the forums and from the hardware I'm working with.Again any input is appreciated.Note: So far the DM556s have been great they're very smooth with tons of power.

Attachments:

Last edit: 29 May 2023 14:15 by spacestate1. Reason: Outdated diagram

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 973

- Thank you received: 429

29 May 2023 21:31 #272457

by my1987toyota

Replied by my1987toyota on topic 6040 7i76 Conversion

Just making sure I am understanding your diagram. Are you tying in the DC ground from your relay to A/C Main ground?

if so don't. just return all of the DC- or Common back to the DC negative of your 24 volt power supply. The main reason being is

you want to avoid creating ground loops which introduces electrical noise into your controller (7i76). I would recommend

checking out this link for Wiring Best Practices

linuxcnc.org/docs/stable/html/integrator/wiring.html The wiring from the 48 volt power supply to the Stepper drives looks ok but I would recommend adding fuses in line .

if so don't. just return all of the DC- or Common back to the DC negative of your 24 volt power supply. The main reason being is

you want to avoid creating ground loops which introduces electrical noise into your controller (7i76). I would recommend

checking out this link for Wiring Best Practices

linuxcnc.org/docs/stable/html/integrator/wiring.html The wiring from the 48 volt power supply to the Stepper drives looks ok but I would recommend adding fuses in line .

Please Log in or Create an account to join the conversation.

Time to create page: 0.334 seconds