6040 7i76 Conversion

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17740

- Thank you received: 5189

06 Aug 2023 21:08 #277167

by PCW

Replied by PCW on topic 6040 7i76 Conversion

Right, so the spindle stepgen should be deleted from the setup

When you get 3.98V, what is the spindle speed set to?

Printing the results of

halcmd show all spindle > spindle.txt might help debug further

When you get 3.98V, what is the spindle speed set to?

Printing the results of

halcmd show all spindle > spindle.txt might help debug further

Please Log in or Create an account to join the conversation.

- spacestate1

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 9

06 Aug 2023 22:07 #277170

by spacestate1

Replied by spacestate1 on topic 6040 7i76 Conversion

removed the spindle stuff from the conf

here's what I get when the spindle is running and 3.98v is seen on the VFD

cat spindle.txt

Loaded HAL Components:

ID Type Name PID State

Component Pins:

Owner Type Dir Value Name

29 bit IN FALSE spindle.0.amp-fault-in

29 bit IN TRUE spindle.0.at-speed <== spindle-at-speed

29 bit OUT FALSE spindle.0.brake ==> spindle-brake

29 bit OUT FALSE spindle.0.forward ==> spindle-cw

29 bit I/O FALSE spindle.0.index-enable <=> spindle-index-enable

29 bit IN FALSE spindle.0.inhibit

29 bit IN FALSE spindle.0.is-oriented

29 bit OUT FALSE spindle.0.locked

29 bit OUT TRUE spindle.0.on ==> spindle-enable

29 bit OUT FALSE spindle.0.orient

29 float OUT 0 spindle.0.orient-angle

29 s32 IN 0 spindle.0.orient-fault

29 s32 OUT 0 spindle.0.orient-mode

29 bit OUT TRUE spindle.0.reverse ==> spindle-ccw

29 float IN 0 spindle.0.revs <== spindle-revs

29 float OUT -5.016667 spindle.0.speed-cmd-rps

29 float IN 0 spindle.0.speed-in <== spindle-vel-fb-rps

29 float OUT -301 spindle.0.speed-out ==> spindle-vel-cmd-rpm

29 float OUT 301 spindle.0.speed-out-abs ==> spindle-vel-cmd-rpm-abs

29 float OUT -5.016667 spindle.0.speed-out-rps ==> spindle-vel-cmd-rps

29 float OUT 5.016667 spindle.0.speed-out-rps-abs ==> spindle-vel-cmd-rps-abs

Pin Aliases:

Alias Original Name

Signals:

Type Value Name (linked to)

bit TRUE spindle-at-speed

==> spindle.0.at-speed

bit FALSE spindle-brake

<== spindle.0.brake

bit TRUE spindle-ccw

==> hm2_7i92.0.7i76.0.0.spindir

<== spindle.0.reverse

bit FALSE spindle-cw

<== spindle.0.forward

bit TRUE spindle-enable

==> hm2_7i92.0.7i76.0.0.spinena

==> pid.s.enable

<== spindle.0.on

bit FALSE spindle-index-enable

==> pid.s.index-enable

<=> spindle.0.index-enable

bit FALSE spindle-manual-ccw

==> halui.spindle.0.reverse

bit FALSE spindle-manual-cw

==> halui.spindle.0.forward

bit FALSE spindle-manual-stop

==> halui.spindle.0.stop

float -301 spindle-output

==> hm2_7i92.0.7i76.0.0.spinout

<== pid.s.output

float 0 spindle-revs

==> spindle.0.revs

float -301 spindle-vel-cmd-rpm

==> pid.s.command

<== spindle.0.speed-out

float 301 spindle-vel-cmd-rpm-abs

<== spindle.0.speed-out-abs

float -5.016667 spindle-vel-cmd-rps

<== spindle.0.speed-out-rps

float 5.016667 spindle-vel-cmd-rps-abs

<== spindle.0.speed-out-rps-abs

float 0 spindle-vel-fb-rpm

==> pid.s.feedback

float 0 spindle-vel-fb-rps

==> spindle.0.speed-in

Parameters:

Owner Type Dir Value Name

Parameter Aliases:

Alias Original Name

Exported Functions:

Owner CodeAddr Arg FP Users Name

Realtime Threads:

Period FP Name ( Time, Max-Time )

here's what I get when the spindle is running and 3.98v is seen on the VFD

cat spindle.txt

Loaded HAL Components:

ID Type Name PID State

Component Pins:

Owner Type Dir Value Name

29 bit IN FALSE spindle.0.amp-fault-in

29 bit IN TRUE spindle.0.at-speed <== spindle-at-speed

29 bit OUT FALSE spindle.0.brake ==> spindle-brake

29 bit OUT FALSE spindle.0.forward ==> spindle-cw

29 bit I/O FALSE spindle.0.index-enable <=> spindle-index-enable

29 bit IN FALSE spindle.0.inhibit

29 bit IN FALSE spindle.0.is-oriented

29 bit OUT FALSE spindle.0.locked

29 bit OUT TRUE spindle.0.on ==> spindle-enable

29 bit OUT FALSE spindle.0.orient

29 float OUT 0 spindle.0.orient-angle

29 s32 IN 0 spindle.0.orient-fault

29 s32 OUT 0 spindle.0.orient-mode

29 bit OUT TRUE spindle.0.reverse ==> spindle-ccw

29 float IN 0 spindle.0.revs <== spindle-revs

29 float OUT -5.016667 spindle.0.speed-cmd-rps

29 float IN 0 spindle.0.speed-in <== spindle-vel-fb-rps

29 float OUT -301 spindle.0.speed-out ==> spindle-vel-cmd-rpm

29 float OUT 301 spindle.0.speed-out-abs ==> spindle-vel-cmd-rpm-abs

29 float OUT -5.016667 spindle.0.speed-out-rps ==> spindle-vel-cmd-rps

29 float OUT 5.016667 spindle.0.speed-out-rps-abs ==> spindle-vel-cmd-rps-abs

Pin Aliases:

Alias Original Name

Signals:

Type Value Name (linked to)

bit TRUE spindle-at-speed

==> spindle.0.at-speed

bit FALSE spindle-brake

<== spindle.0.brake

bit TRUE spindle-ccw

==> hm2_7i92.0.7i76.0.0.spindir

<== spindle.0.reverse

bit FALSE spindle-cw

<== spindle.0.forward

bit TRUE spindle-enable

==> hm2_7i92.0.7i76.0.0.spinena

==> pid.s.enable

<== spindle.0.on

bit FALSE spindle-index-enable

==> pid.s.index-enable

<=> spindle.0.index-enable

bit FALSE spindle-manual-ccw

==> halui.spindle.0.reverse

bit FALSE spindle-manual-cw

==> halui.spindle.0.forward

bit FALSE spindle-manual-stop

==> halui.spindle.0.stop

float -301 spindle-output

==> hm2_7i92.0.7i76.0.0.spinout

<== pid.s.output

float 0 spindle-revs

==> spindle.0.revs

float -301 spindle-vel-cmd-rpm

==> pid.s.command

<== spindle.0.speed-out

float 301 spindle-vel-cmd-rpm-abs

<== spindle.0.speed-out-abs

float -5.016667 spindle-vel-cmd-rps

<== spindle.0.speed-out-rps

float 5.016667 spindle-vel-cmd-rps-abs

<== spindle.0.speed-out-rps-abs

float 0 spindle-vel-fb-rpm

==> pid.s.feedback

float 0 spindle-vel-fb-rps

==> spindle.0.speed-in

Parameters:

Owner Type Dir Value Name

Parameter Aliases:

Alias Original Name

Exported Functions:

Owner CodeAddr Arg FP Users Name

Realtime Threads:

Period FP Name ( Time, Max-Time )

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17740

- Thank you received: 5189

06 Aug 2023 22:18 - 06 Aug 2023 22:21 #277172

by PCW

Replied by PCW on topic 6040 7i76 Conversion

Looks like you selected the "use +-10 for direction" spindle option in pncconf:

float -301 spindle-vel-cmd-rpm

==> pid.s.command

<== spindle.0.speed-out

This does not work because the 7I76 spindle interface expects only unsigned (positive) values

A quick fix is to replace

net spindle-vel-cmd-rpm => pid.s.command

with

net spindle-vel-cmd-rpm-abs => pid.s.command

float -301 spindle-vel-cmd-rpm

==> pid.s.command

<== spindle.0.speed-out

This does not work because the 7I76 spindle interface expects only unsigned (positive) values

A quick fix is to replace

net spindle-vel-cmd-rpm => pid.s.command

with

net spindle-vel-cmd-rpm-abs => pid.s.command

Last edit: 06 Aug 2023 22:21 by PCW.

Please Log in or Create an account to join the conversation.

- spacestate1

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 9

07 Aug 2023 00:09 #277179

by spacestate1

Replied by spacestate1 on topic 6040 7i76 Conversion

made the change and went back to the config wizard and tried a couple other settings, but it still gets the same behavior:

# Generated by PNCconf at Sun Aug 6 20:07:31 2023

# Using LinuxCNC version: 2.8

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_eth board_ip="192.168.1.121" config="num_encoders=1 num_pwmgens=0 num_stepgens=5 sserial_port_0=00xxxxxx"

setp hm2_7i92.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.s

loadrt near

addf hm2_7i92.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf near.0 servo-thread

addf hm2_7i92.0.write servo-thread

setp hm2_7i92.0.dpll.01.timer-us -50

setp hm2_7i92.0.stepgen.timer-number 1

# external output signals

# external input signals

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i92.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i92.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i92.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i92.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i92.0.stepgen.00.step_type 0

setp hm2_7i92.0.stepgen.00.control-type 1

setp hm2_7i92.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => hm2_7i92.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i92.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_7i92.0.stepgen.00.enable

# ---setup home / limit switch signals---

net x-home-sw => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y.maxerror 0.012700

net y-index-enable => pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_7i92.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_7i92.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_7i92.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_7i92.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_7i92.0.stepgen.01.step_type 0

setp hm2_7i92.0.stepgen.01.control-type 1

setp hm2_7i92.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output => hm2_7i92.0.stepgen.01.velocity-cmd

net y-pos-fb <= hm2_7i92.0.stepgen.01.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => hm2_7i92.0.stepgen.01.enable

# ---setup home / limit switch signals---

net y-home-sw => joint.1.home-sw-in

net y-neg-limit => joint.1.neg-lim-sw-in

net y-pos-limit => joint.1.pos-lim-sw-in

#*******************

# AXIS Z JOINT 2

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp hm2_7i92.0.stepgen.02.dirhold [JOINT_2]DIRHOLD

setp hm2_7i92.0.stepgen.02.steplen [JOINT_2]STEPLEN

setp hm2_7i92.0.stepgen.02.stepspace [JOINT_2]STEPSPACE

setp hm2_7i92.0.stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp hm2_7i92.0.stepgen.02.step_type 0

setp hm2_7i92.0.stepgen.02.control-type 1

setp hm2_7i92.0.stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.2.motor-pos-cmd

net z-vel-cmd <= joint.2.vel-cmd

net z-output => hm2_7i92.0.stepgen.02.velocity-cmd

net z-pos-fb <= hm2_7i92.0.stepgen.02.position-fb

net z-pos-fb => joint.2.motor-pos-fb

net z-enable <= joint.2.amp-enable-out

net z-enable => hm2_7i92.0.stepgen.02.enable

# ---setup home / limit switch signals---

net z-home-sw => joint.2.home-sw-in

net z-neg-limit => joint.2.neg-lim-sw-in

net z-pos-limit => joint.2.pos-lim-sw-in

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-output <= pid.s.output

# ---digital potentiometer output signals/setup---

setp hm2_7i92.0.7i76.0.0.spinout-minlim [SPINDLE_0]OUTPUT_MIN_LIMIT

setp hm2_7i92.0.7i76.0.0.spinout-maxlim [SPINDLE_0]OUTPUT_MAX_LIMIT

setp hm2_7i92.0.7i76.0.0.spinout-scalemax [SPINDLE_0]OUTPUT_SCALE

net spindle-output => hm2_7i92.0.7i76.0.0.spinout

net spindle-enable => hm2_7i92.0.7i76.0.0.spinena

net spindle-ccw => hm2_7i92.0.7i76.0.0.spindir

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-y halui.axis.y.select

net jog-y-pos halui.axis.y.plus

net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

net y-is-homed halui.joint.1.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.2.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

# ---manual tool change signals---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---Use external manual tool change dialog---

loadusr -W hal_manualtoolchange

net tool-change-request => hal_manualtoolchange.change

net tool-change-confirmed <= hal_manualtoolchange.changed

net tool-number => hal_manualtoolchange.number

# ---ignore tool prepare requests---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

# Generated by PNCconf at Sun Aug 6 20:07:31 2023

# Using LinuxCNC version: 2.8

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_eth board_ip="192.168.1.121" config="num_encoders=1 num_pwmgens=0 num_stepgens=5 sserial_port_0=00xxxxxx"

setp hm2_7i92.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.s

loadrt near

addf hm2_7i92.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf near.0 servo-thread

addf hm2_7i92.0.write servo-thread

setp hm2_7i92.0.dpll.01.timer-us -50

setp hm2_7i92.0.stepgen.timer-number 1

# external output signals

# external input signals

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i92.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i92.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i92.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i92.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i92.0.stepgen.00.step_type 0

setp hm2_7i92.0.stepgen.00.control-type 1

setp hm2_7i92.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => hm2_7i92.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i92.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_7i92.0.stepgen.00.enable

# ---setup home / limit switch signals---

net x-home-sw => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y.maxerror 0.012700

net y-index-enable => pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_7i92.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_7i92.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_7i92.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_7i92.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_7i92.0.stepgen.01.step_type 0

setp hm2_7i92.0.stepgen.01.control-type 1

setp hm2_7i92.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output => hm2_7i92.0.stepgen.01.velocity-cmd

net y-pos-fb <= hm2_7i92.0.stepgen.01.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => hm2_7i92.0.stepgen.01.enable

# ---setup home / limit switch signals---

net y-home-sw => joint.1.home-sw-in

net y-neg-limit => joint.1.neg-lim-sw-in

net y-pos-limit => joint.1.pos-lim-sw-in

#*******************

# AXIS Z JOINT 2

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp hm2_7i92.0.stepgen.02.dirhold [JOINT_2]DIRHOLD

setp hm2_7i92.0.stepgen.02.steplen [JOINT_2]STEPLEN

setp hm2_7i92.0.stepgen.02.stepspace [JOINT_2]STEPSPACE

setp hm2_7i92.0.stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp hm2_7i92.0.stepgen.02.step_type 0

setp hm2_7i92.0.stepgen.02.control-type 1

setp hm2_7i92.0.stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.2.motor-pos-cmd

net z-vel-cmd <= joint.2.vel-cmd

net z-output => hm2_7i92.0.stepgen.02.velocity-cmd

net z-pos-fb <= hm2_7i92.0.stepgen.02.position-fb

net z-pos-fb => joint.2.motor-pos-fb

net z-enable <= joint.2.amp-enable-out

net z-enable => hm2_7i92.0.stepgen.02.enable

# ---setup home / limit switch signals---

net z-home-sw => joint.2.home-sw-in

net z-neg-limit => joint.2.neg-lim-sw-in

net z-pos-limit => joint.2.pos-lim-sw-in

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-output <= pid.s.output

# ---digital potentiometer output signals/setup---

setp hm2_7i92.0.7i76.0.0.spinout-minlim [SPINDLE_0]OUTPUT_MIN_LIMIT

setp hm2_7i92.0.7i76.0.0.spinout-maxlim [SPINDLE_0]OUTPUT_MAX_LIMIT

setp hm2_7i92.0.7i76.0.0.spinout-scalemax [SPINDLE_0]OUTPUT_SCALE

net spindle-output => hm2_7i92.0.7i76.0.0.spinout

net spindle-enable => hm2_7i92.0.7i76.0.0.spinena

net spindle-ccw => hm2_7i92.0.7i76.0.0.spindir

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-y halui.axis.y.select

net jog-y-pos halui.axis.y.plus

net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

net y-is-homed halui.joint.1.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.2.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

# ---manual tool change signals---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---Use external manual tool change dialog---

loadusr -W hal_manualtoolchange

net tool-change-request => hal_manualtoolchange.change

net tool-change-confirmed <= hal_manualtoolchange.changed

net tool-number => hal_manualtoolchange.number

# ---ignore tool prepare requests---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17740

- Thank you received: 5189

07 Aug 2023 00:37 #277180

by PCW

Replied by PCW on topic 6040 7i76 Conversion

Is the output voltage 0 (or close to 0) when LinuxCNC is not running?

Please Log in or Create an account to join the conversation.

- spacestate1

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 9

07 Aug 2023 00:40 #277181

by spacestate1

Replied by spacestate1 on topic 6040 7i76 Conversion

It is yes, but I can double check later. I might try just setting up a whole new config and see if I can get that working with a fresh start as well.

Please Log in or Create an account to join the conversation.

- spacestate1

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 9

07 Aug 2023 21:44 #277285

by spacestate1

Replied by spacestate1 on topic 6040 7i76 Conversion

Actually it is not 0 it is 3.98v even when the spindle is not engaged in linuxcnc

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17740

- Thank you received: 5189

07 Aug 2023 22:14 #277286

by PCW

Replied by PCW on topic 6040 7i76 Conversion

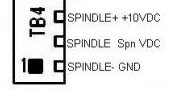

That sounds like the analog TB4 pins are not connected properly

to the three VFD pins:

SPIN+ --> VFD 5VOUT

SPINOUT --> VFD 5VIN

SPIN- --> VFD GND

to the three VFD pins:

SPIN+ --> VFD 5VOUT

SPINOUT --> VFD 5VIN

SPIN- --> VFD GND

Please Log in or Create an account to join the conversation.

- spacestate1

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 9

07 Aug 2023 23:14 #277289

by spacestate1

Replied by spacestate1 on topic 6040 7i76 Conversion

Attachments:

Please Log in or Create an account to join the conversation.

- spacestate1

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 9

07 Aug 2023 23:17 #277290

by spacestate1

Replied by spacestate1 on topic 6040 7i76 Conversion

well 5v on 5v out on the VFD

Please Log in or Create an account to join the conversation.

Time to create page: 0.230 seconds