6x6 Stewart (Parallel Kinematic Machine Tool)

- andypugh

-

- Offline

- Moderator

-

- Posts: 19770

- Thank you received: 4601

sudo find / -name genhexkins.ko

Please Log in or Create an account to join the conversation.

- ommar

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 31

- Thank you received: 0

I defined my hexapod joints coordinates in the kinematics.ini file. (linuxcnc/configs/sim.axis.vismach.hexapod-sim/)

Will i edit additionally files ? Is it enough for the kinematic calculation ?

On the other hand;

I tested all of the motors in pncconfig successfully. I can move them. I have one 6i25 and two 7i76 mesa cards.

I am planning that;

I will define X,Y,Z axis in Pncconfig for one mesa 7i76 card and

i will define A,B,C axis for the other mesa 7i76card.

Pnconfig will create two ini file.

Will i copy these ini files into linuxcnc/configs/sim.axis.vismach.hexapod-sim/hexapd.ini ?

Thank you.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19770

- Thank you received: 4601

To save confusion, it is probably better to talk about joints 0, 1, 2,..5 for each leg of the hexapod. The axes XYZABC define the position in space and the orientation of the platform, not the leg lengths.

Please Log in or Create an account to join the conversation.

- ommar

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 31

- Thank you received: 0

To save confusion, it is probably better to talk about joints 0, 1, 2,..5 for each leg of the hexapod. The axes XYZABC define the position in space and the orientation of the platform, not the leg lengths.

You are right. I am confused.

I will not use pncconfig in that case. I will only edit hexapod.ini. Am i true ?

May you explain step by step.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19770

- Thank you received: 4601

Setting up as an XYZABC config in pncconf will probably get you close, but then you will need to edit the hal and ini to suit a genhexkins configuration.

I would set the machine up as XYZABC first, and get the motors all responding in the right way to G-code moves in those directions with the motors _not_ connected to the platform.

Then, and only then, change the machine to genhexkins and make sure that the motors still move in the right sort of way. Then, and only then, you can connect the motors to the frame.

I have slightly lost track, are you using 2.7.4 or Joints_Axes14?

Please Log in or Create an account to join the conversation.

- ommar

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 31

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19770

- Thank you received: 4601

I am using 2.7.4. My hexapod has got six motors. 6 axes.

In that case you should probably start with pncconf to get all the motors moving, and them look at the hexapos sample files to see how a hexapod configuration is different from a trivkins configuration.

Note that the number of Axes and the number of motors are not necessarily the same.

Please Log in or Create an account to join the conversation.

- ommar

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 31

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19770

- Thank you received: 4601

linuxcnc.org/docs/2.7/html/motion/kinematics.html

Please Log in or Create an account to join the conversation.

- ommar

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 31

- Thank you received: 0

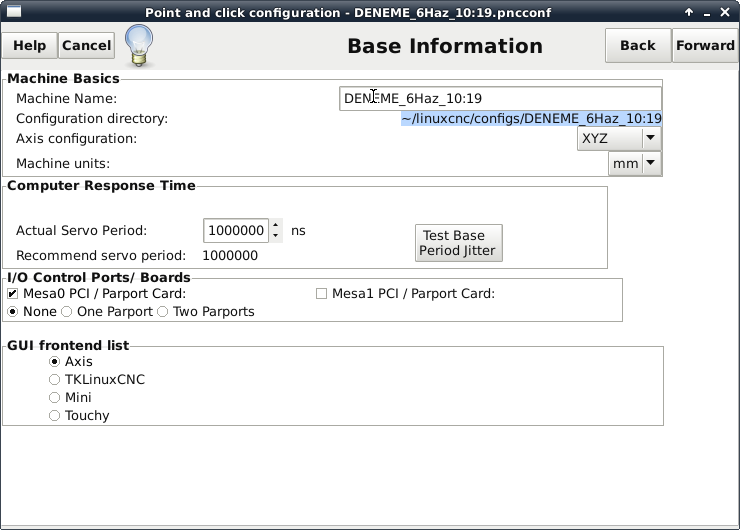

Here are the windows;

1. Base information

Are the settings suitable in the I/O Control Ports / Boards ? (6i25+7i76+7i76)

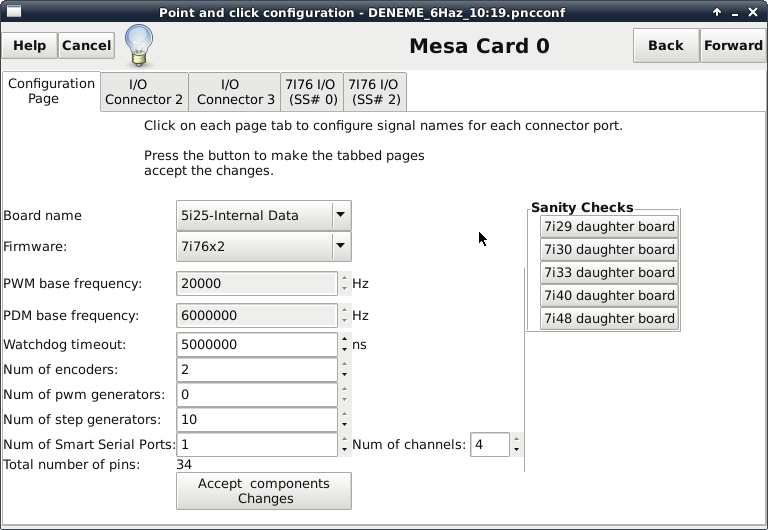

2. Mesa Card

Are the selections of the board name and firmware true for my combination ?

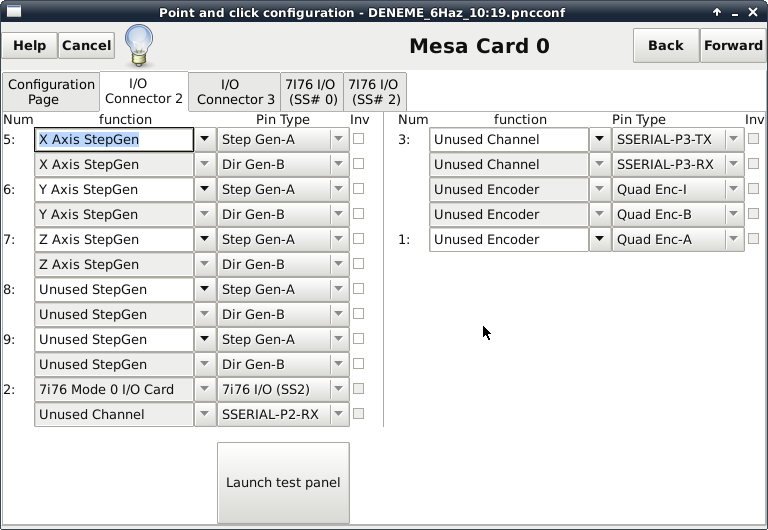

3. I/O Connector 2

I think that I/O connector 2 is part of one of 7i76 card. Is it true ? I defined 3 motor in this page.

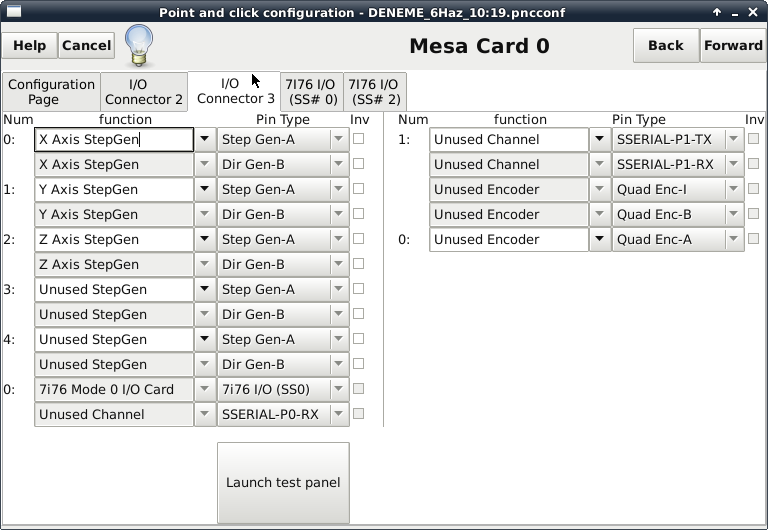

4. I/O Connector 3

I think that I/O connector 2 is part of the another 7i76 card. Is it true ? I defined other 3 motors in this page but i can only test the perivous 3 motors.

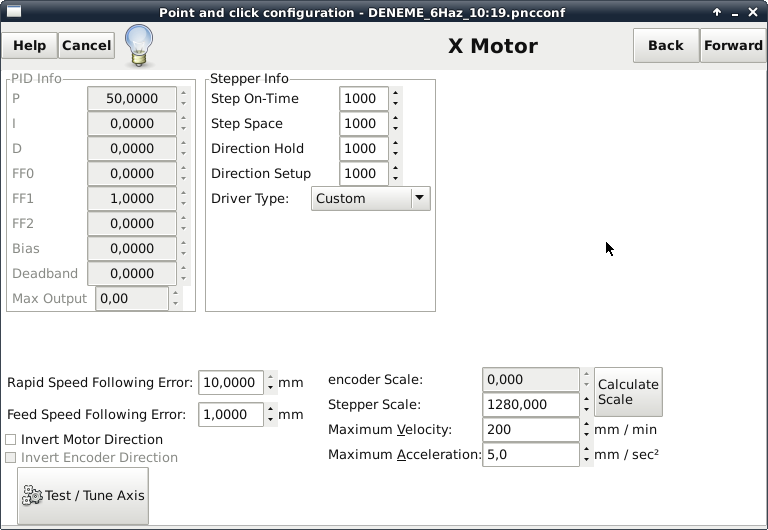

5. X Motor

Here are the stepper parameters. I can move the motor.

I can move the y and z motors like these. Pncconfig created hal and ini file. Here are the files.

HAL File;

# Generated by PNCconf at Mon Jun 6 10:24:33 2016

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt trivkins

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=2 num_pwmgens=0 num_stepgens=10 sserial_port_0=0000xx"

setp hm2_5i25.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.s

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_5i25.0.write servo-thread

# external output signals

# external input signals

#*******************

# AXIS X

#*******************

setp pid.x.Pgain [AXIS_0]P

setp pid.x.Igain [AXIS_0]I

setp pid.x.Dgain [AXIS_0]D

setp pid.x.bias [AXIS_0]BIAS

setp pid.x.FF0 [AXIS_0]FF0

setp pid.x.FF1 [AXIS_0]FF1

setp pid.x.FF2 [AXIS_0]FF2

setp pid.x.deadband [AXIS_0]DEADBAND

setp pid.x.maxoutput [AXIS_0]MAX_OUTPUT

setp pid.x.error-previous-target true

setp pid.x.maxerror .0005

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.05.dirsetup [AXIS_0]DIRSETUP

setp hm2_5i25.0.stepgen.05.dirhold [AXIS_0]DIRHOLD

setp hm2_5i25.0.stepgen.05.steplen [AXIS_0]STEPLEN

setp hm2_5i25.0.stepgen.05.stepspace [AXIS_0]STEPSPACE

setp hm2_5i25.0.stepgen.05.position-scale [AXIS_0]STEP_SCALE

setp hm2_5i25.0.stepgen.05.step_type 0

setp hm2_5i25.0.stepgen.05.control-type 1

setp hm2_5i25.0.stepgen.05.maxaccel [AXIS_0]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.05.maxvel [AXIS_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= axis.0.motor-pos-cmd

net x-vel-cmd <= axis.0.joint-vel-cmd

net x-output <= hm2_5i25.0.stepgen.05.velocity-cmd

net x-pos-fb <= hm2_5i25.0.stepgen.05.position-fb

net x-pos-fb => axis.0.motor-pos-fb

net x-enable <= axis.0.amp-enable-out

net x-enable => hm2_5i25.0.stepgen.05.enable

# ---setup home / limit switch signals---

net x-home-sw => axis.0.home-sw-in

net x-neg-limit => axis.0.neg-lim-sw-in

net x-pos-limit => axis.0.pos-lim-sw-in

#*******************

# AXIS Y

#*******************

setp pid.y.Pgain [AXIS_1]P

setp pid.y.Igain [AXIS_1]I

setp pid.y.Dgain [AXIS_1]D

setp pid.y.bias [AXIS_1]BIAS

setp pid.y.FF0 [AXIS_1]FF0

setp pid.y.FF1 [AXIS_1]FF1

setp pid.y.FF2 [AXIS_1]FF2

setp pid.y.deadband [AXIS_1]DEADBAND

setp pid.y.maxoutput [AXIS_1]MAX_OUTPUT

setp pid.y.error-previous-target true

setp pid.y.maxerror .0005

net y-index-enable <=> pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-vel-cmd => pid.y.command-deriv

net y-pos-fb => pid.y.feedback

net y-output => pid.y.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.06.dirsetup [AXIS_1]DIRSETUP

setp hm2_5i25.0.stepgen.06.dirhold [AXIS_1]DIRHOLD

setp hm2_5i25.0.stepgen.06.steplen [AXIS_1]STEPLEN

setp hm2_5i25.0.stepgen.06.stepspace [AXIS_1]STEPSPACE

setp hm2_5i25.0.stepgen.06.position-scale [AXIS_1]STEP_SCALE

setp hm2_5i25.0.stepgen.06.step_type 0

setp hm2_5i25.0.stepgen.06.control-type 1

setp hm2_5i25.0.stepgen.06.maxaccel [AXIS_1]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.06.maxvel [AXIS_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= axis.1.motor-pos-cmd

net y-vel-cmd <= axis.1.joint-vel-cmd

net y-output <= hm2_5i25.0.stepgen.06.velocity-cmd

net y-pos-fb <= hm2_5i25.0.stepgen.06.position-fb

net y-pos-fb => axis.1.motor-pos-fb

net y-enable <= axis.1.amp-enable-out

net y-enable => hm2_5i25.0.stepgen.06.enable

# ---setup home / limit switch signals---

net y-home-sw => axis.1.home-sw-in

net y-neg-limit => axis.1.neg-lim-sw-in

net y-pos-limit => axis.1.pos-lim-sw-in

#*******************

# AXIS Z

#*******************

setp pid.z.Pgain [AXIS_2]P

setp pid.z.Igain [AXIS_2]I

setp pid.z.Dgain [AXIS_2]D

setp pid.z.bias [AXIS_2]BIAS

setp pid.z.FF0 [AXIS_2]FF0

setp pid.z.FF1 [AXIS_2]FF1

setp pid.z.FF2 [AXIS_2]FF2

setp pid.z.deadband [AXIS_2]DEADBAND

setp pid.z.maxoutput [AXIS_2]MAX_OUTPUT

setp pid.z.error-previous-target true

setp pid.z.maxerror .0005

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.07.dirsetup [AXIS_2]DIRSETUP

setp hm2_5i25.0.stepgen.07.dirhold [AXIS_2]DIRHOLD

setp hm2_5i25.0.stepgen.07.steplen [AXIS_2]STEPLEN

setp hm2_5i25.0.stepgen.07.stepspace [AXIS_2]STEPSPACE

setp hm2_5i25.0.stepgen.07.position-scale [AXIS_2]STEP_SCALE

setp hm2_5i25.0.stepgen.07.step_type 0

setp hm2_5i25.0.stepgen.07.control-type 1

setp hm2_5i25.0.stepgen.07.maxaccel [AXIS_2]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.07.maxvel [AXIS_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= axis.2.motor-pos-cmd

net z-vel-cmd <= axis.2.joint-vel-cmd

net z-output <= hm2_5i25.0.stepgen.07.velocity-cmd

net z-pos-fb <= hm2_5i25.0.stepgen.07.position-fb

net z-pos-fb => axis.2.motor-pos-fb

net z-enable <= axis.2.amp-enable-out

net z-enable => hm2_5i25.0.stepgen.07.enable

# ---setup home / limit switch signals---

net z-home-sw => axis.2.home-sw-in

net z-neg-limit => axis.2.neg-lim-sw-in

net z-pos-limit => axis.2.pos-lim-sw-in

#*******************

# SPINDLE S

#*******************

setp pid.s.Pgain [SPINDLE_9]P

setp pid.s.Igain [SPINDLE_9]I

setp pid.s.Dgain [SPINDLE_9]D

setp pid.s.bias [SPINDLE_9]BIAS

setp pid.s.FF0 [SPINDLE_9]FF0

setp pid.s.FF1 [SPINDLE_9]FF1

setp pid.s.FF2 [SPINDLE_9]FF2

setp pid.s.deadband [SPINDLE_9]DEADBAND

setp pid.s.maxoutput [SPINDLE_9]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-enable <= motion.spindle-on

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net joint-select-a halui.joint.0.select

net x-is-homed halui.joint.0.is-homed

net jog-x-pos halui.jog.0.plus

net jog-x-neg halui.jog.0.minus

net jog-x-analog halui.jog.0.analog

net joint-select-b halui.joint.1.select

net y-is-homed halui.joint.1.is-homed

net jog-y-pos halui.jog.1.plus

net jog-y-neg halui.jog.1.minus

net jog-y-analog halui.jog.1.analog

net joint-select-c halui.joint.2.select

net z-is-homed halui.joint.2.is-homed

net jog-z-pos halui.jog.2.plus

net jog-z-neg halui.jog.2.minus

net jog-z-analog halui.jog.2.analog

net jog-selected-pos halui.jog.selected.plus

net jog-selected-neg halui.jog.selected.minus

net spindle-manual-cw halui.spindle.forward

net spindle-manual-ccw halui.spindle.reverse

net spindle-manual-stop halui.spindle.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

# ---manual tool change signals---

loadusr -W hal_manualtoolchange

net tool-change-request iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-change-confirmed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

INI file

# Generated by PNCconf at Mon Jun 6 10:24:33 2016

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = DENEME_6Haz_10:19

DEBUG = 0

[DISPLAY]

DISPLAY = axis

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/egmach/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 0.250000

MAX_LINEAR_VELOCITY = 1.000000

MIN_LINEAR_VELOCITY = 0.010000

DEFAULT_ANGULAR_VELOCITY = 0.250000

MAX_ANGULAR_VELOCITY = 1.000000

MIN_ANGULAR_VELOCITY = 0.010000

EDITOR = gedit

GEOMETRY = xyz

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

COMM_WAIT = 0.010

SERVO_PERIOD = 1000000

[HOSTMOT2]

# **** This is for info only ****

# DRIVER0=hm2_pci

# BOARD0=5i25

[HAL]

HALUI = halui

HALFILE = DENEME_6Haz_10:19.hal

HALFILE = custom.hal

POSTGUI_HALFILE = postgui_call_list.hal

SHUTDOWN = shutdown.hal

[HALUI]

[TRAJ]

AXES = 3

COORDINATES = X Y Z

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

CYCLE_TIME = 0.010

DEFAULT_VELOCITY = 0.33

MAX_LINEAR_VELOCITY = 3.33

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#********************

# Axis X

#********************

[AXIS_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 3.33333333333

MAX_ACCELERATION = 5.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 4.17

STEPGEN_MAXACCEL = 6.25

P = 50.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 1000

STEPSPACE = 1000

STEP_SCALE = 1280.0

MIN_LIMIT = -0.01

MAX_LIMIT = 200.0

HOME_OFFSET = 0.0

#********************

# Axis Y

#********************

[AXIS_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 3.33333333333

MAX_ACCELERATION = 5.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 4.17

STEPGEN_MAXACCEL = 6.25

P = 50.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 1000

STEPSPACE = 1000

STEP_SCALE = 1280.0

MIN_LIMIT = -0.01

MAX_LIMIT = 200.0

HOME_OFFSET = 0.0

#********************

# Axis Z

#********************

[AXIS_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 3.33333333333

MAX_ACCELERATION = 5.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 4.17

STEPGEN_MAXACCEL = 6.25

P = 50.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 1000

STEPSPACE = 1000

STEP_SCALE = 1280.0

MIN_LIMIT = -100.0

MAX_LIMIT = 0.01

HOME_OFFSET = 0.0

#********************

# Spindle

#********************

[SPINDLE_9]

P = 0

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 2000

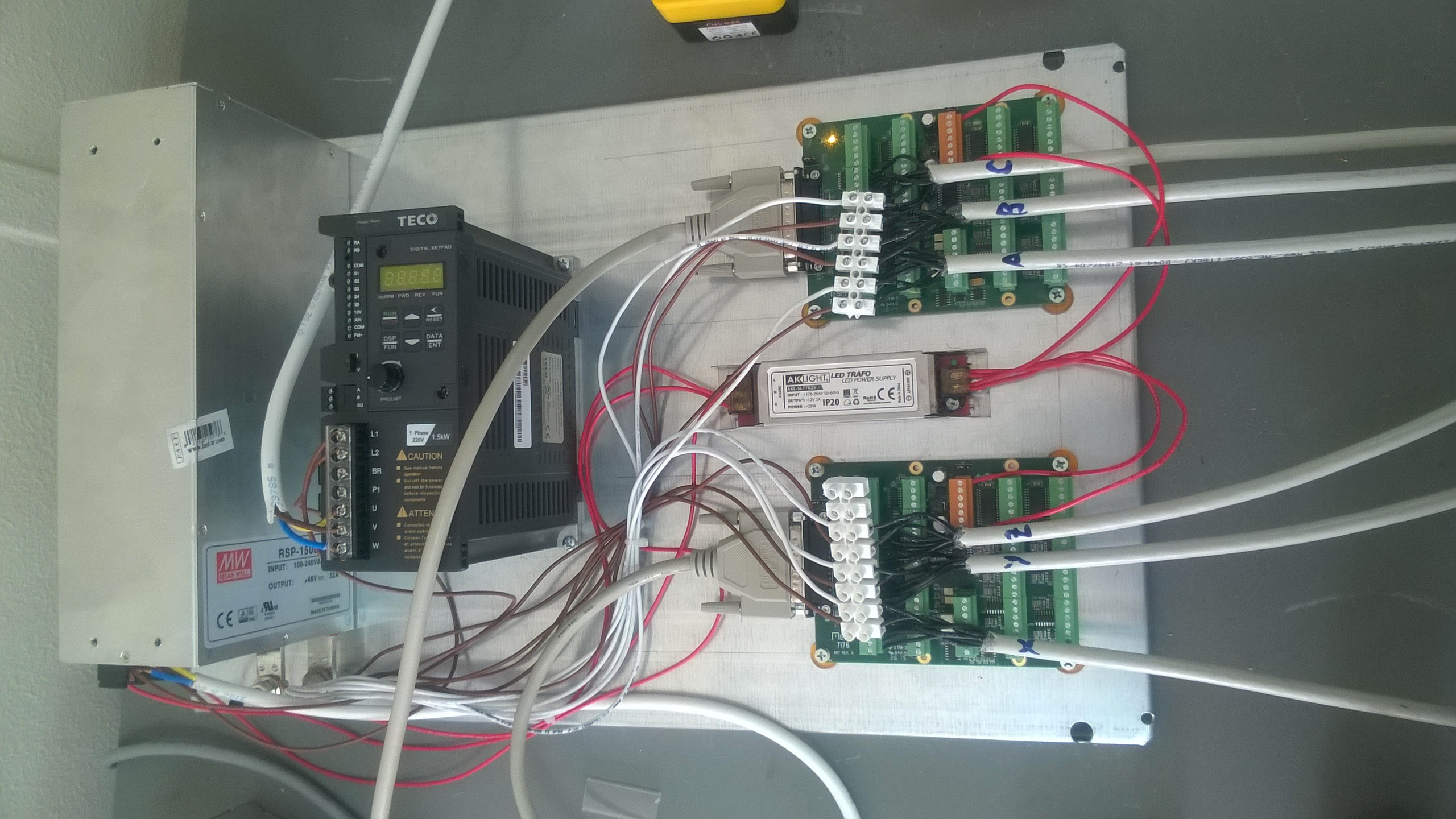

Harware connections.

Please Log in or Create an account to join the conversation.