Threading problem

- brianbonedoc

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 2

16 Nov 2015 01:55 #65308

by brianbonedoc

Replied by brianbonedoc on topic Threading problem

Joe - Thanks for that - it really confirmed what I was thinking.

So I kept the quadrature encoder as it is and adjusted the scale to 4114 (up from 4096) based on 20 hand revolutions of the spindle and dividing the spindle count by 20.

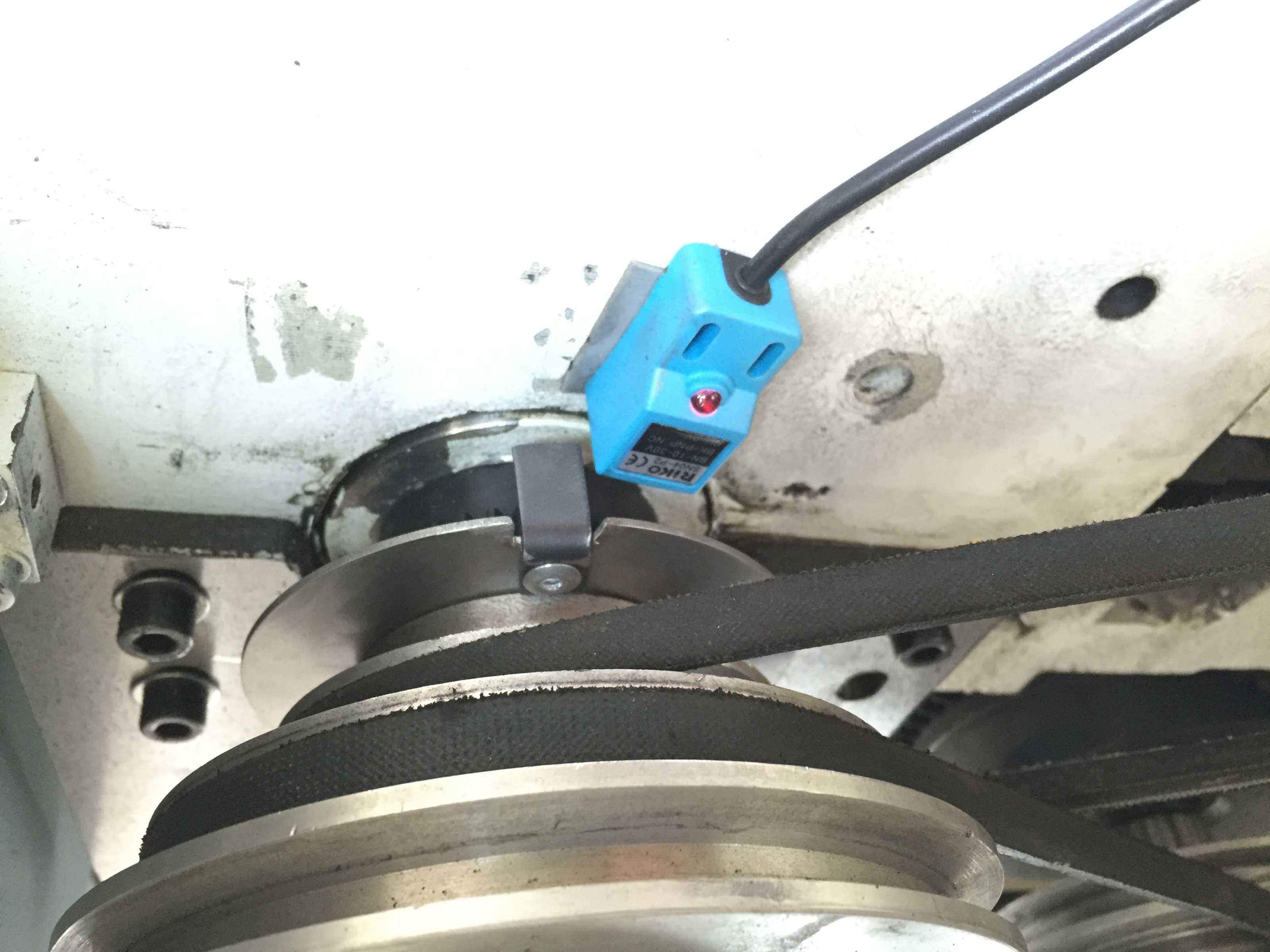

I added this for the index pulse:

and as you can see the results are much better:

Here's the video as well.

Thanks for everyones help!

So I kept the quadrature encoder as it is and adjusted the scale to 4114 (up from 4096) based on 20 hand revolutions of the spindle and dividing the spindle count by 20.

I added this for the index pulse:

and as you can see the results are much better:

Here's the video as well.

Thanks for everyones help!

Please Log in or Create an account to join the conversation.

- joekline9

-

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 9

16 Nov 2015 14:16 #65327

by joekline9

Replied by joekline9 on topic Threading problem

Looks great.

May I suggest starting your thread at Z.100" or even Z.200" to be sure everything is up to speed at the actual thread.

May I suggest starting your thread at Z.100" or even Z.200" to be sure everything is up to speed at the actual thread.

Please Log in or Create an account to join the conversation.

- brianbonedoc

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 2

16 Nov 2015 19:46 #65342

by brianbonedoc

Replied by brianbonedoc on topic Threading problem

Joe - yes I think you are right about that. Still super excited I got this far!

I am like a blind squirrel looking for a nut. . .

I am like a blind squirrel looking for a nut. . .

Please Log in or Create an account to join the conversation.

- verticalperformance

-

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 11

20 Nov 2015 09:33 #65562

by verticalperformance

Replied by verticalperformance on topic Threading problem

If you are using Linux CNC 2.7.0 and get crappy looking exit moves at the end of the thread when using an exit taper (E>0 in the G76) - put an F0 prior to the G76. This will give a nice clean threads at the exit that progressively reduce in depth. If exiting into a relief groove using E0, you won't see this problem.

Looking at your video there definitely seems a pause at the end of the thread prior to the exit - but that could be you are just using E0 too with no relief groove.

Bug found in new trajectory planner which looks like it will be resolved soon. forum.linuxcnc.org/forum/20-g-code/29685...aper-linux-cnc-2-7-0. 2.6.x does not have this issue.

Looks like you have been having similar fun to me by converting a machine that was not really designed to do this. Mine even less so being a Sherline! But haven't had to put the change gears on since!

Have fun!

Looking at your video there definitely seems a pause at the end of the thread prior to the exit - but that could be you are just using E0 too with no relief groove.

Bug found in new trajectory planner which looks like it will be resolved soon. forum.linuxcnc.org/forum/20-g-code/29685...aper-linux-cnc-2-7-0. 2.6.x does not have this issue.

Looks like you have been having similar fun to me by converting a machine that was not really designed to do this. Mine even less so being a Sherline! But haven't had to put the change gears on since!

Have fun!

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19754

- Thank you received: 4586

20 Nov 2015 10:48 #65565

by andypugh

Replied by andypugh on topic Threading problem

I normally don't use exit taper or relief groove. With CNC you can run threads right up to a shoulder and retract reliably in a fraction of a spindle revolution.

You may need a relief groove in some cases to allow the mating part to pull up tight, of course.

You may need a relief groove in some cases to allow the mating part to pull up tight, of course.

Please Log in or Create an account to join the conversation.

- brianbonedoc

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 2

20 Nov 2015 18:37 #65578

by brianbonedoc

Replied by brianbonedoc on topic Threading problem

I'm using tormachs pathpilot version which is based on 2.6 so I haven't see any weirdness that I didn't cause myself

Please Log in or Create an account to join the conversation.

- brianbonedoc

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 2

22 Nov 2015 16:42 #65660

by brianbonedoc

Replied by brianbonedoc on topic Threading problem

Now that I have everything up and running here are my final ini/hal files - for anyone who needs them.

Please Log in or Create an account to join the conversation.

- Iron-Man

-

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 1

04 Dec 2015 03:42 - 04 Dec 2015 14:29 #66353

by Iron-Man

Brianbonedoc when gcode is running in pathpilot lathe, does the rpm show in the RPM window? If yes then I have one more function to connect.

Thanks,

Iron-Man

Replied by Iron-Man on topic Threading problem

I'm using tormachs pathpilot version which is based on 2.6 so I haven't see any weirdness that I didn't cause myself

Brianbonedoc when gcode is running in pathpilot lathe, does the rpm show in the RPM window? If yes then I have one more function to connect.

Thanks,

Iron-Man

Last edit: 04 Dec 2015 14:29 by Iron-Man.

Please Log in or Create an account to join the conversation.

- brianbonedoc

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 2

04 Dec 2015 04:01 #66354

by brianbonedoc

Replied by brianbonedoc on topic Threading problem

Iron-Man -

Yes the way it works is the desired RPM shows until you start the spindle or G code and then the ACTUAL RPMs show. If u are not seeing actual RPMs when running the code - something is wrong. It uses the actual RPMs to do lots of things including constant surface speed.

Let me know if you have issues getting the RPMs to show - I went thru that for a week or so figuring it out.

Yes the way it works is the desired RPM shows until you start the spindle or G code and then the ACTUAL RPMs show. If u are not seeing actual RPMs when running the code - something is wrong. It uses the actual RPMs to do lots of things including constant surface speed.

Let me know if you have issues getting the RPMs to show - I went thru that for a week or so figuring it out.

The following user(s) said Thank You: Iron-Man

Please Log in or Create an account to join the conversation.

- Iron-Man

-

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 1

04 Dec 2015 14:31 - 04 Dec 2015 14:31 #66382

by Iron-Man

Do you know which function connects the spindle rpm to the pathpilot GUI?

Thanks,

Iron-Man

Replied by Iron-Man on topic Threading problem

Iron-Man -

Yes the way it works is the desired RPM shows until you start the spindle or G code and then the ACTUAL RPMs show. If u are not seeing actual RPMs when running the code - something is wrong. It uses the actual RPMs to do lots of things including constant surface speed.

Let me know if you have issues getting the RPMs to show - I went thru that for a week or so figuring it out.

Do you know which function connects the spindle rpm to the pathpilot GUI?

Thanks,

Iron-Man

Last edit: 04 Dec 2015 14:31 by Iron-Man. Reason: GUI

Please Log in or Create an account to join the conversation.

Time to create page: 0.111 seconds