LinuxCNC S-Curve Accelerations

- ruediger123

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 19

29 Jan 2026 10:12 #342154

by ruediger123

Replied by ruediger123 on topic LinuxCNC S-Curve Accelerations

@grandixximo

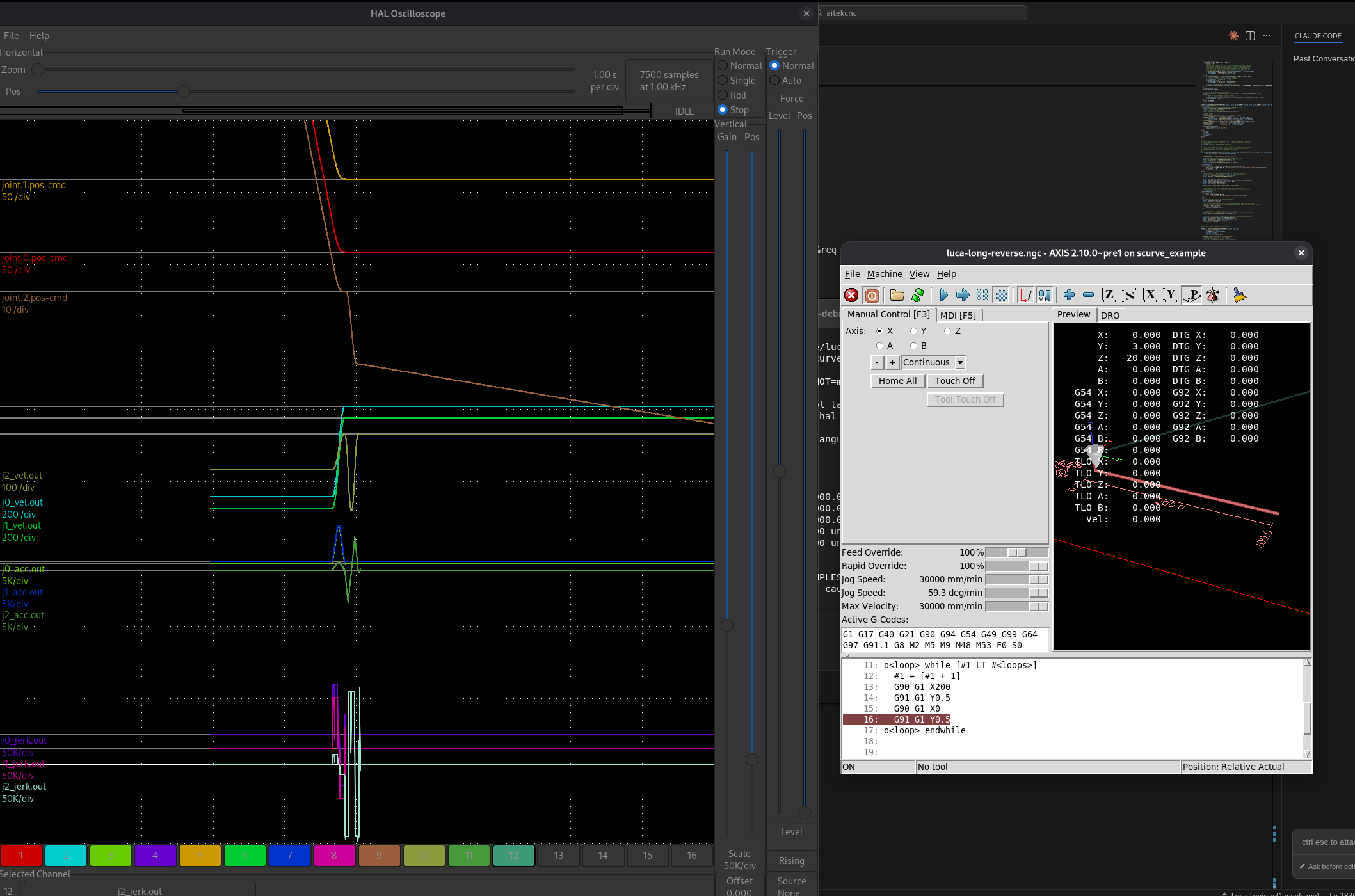

After commenting out " || (dx - moveL <= dlen2)", the scope looks like this.

After commenting out " || (dx - moveL <= dlen2)", the scope looks like this.

Please Log in or Create an account to join the conversation.

- grandixximo

-

Topic Author

Topic Author

- Away

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 171

29 Jan 2026 10:54 #342155

by grandixximo

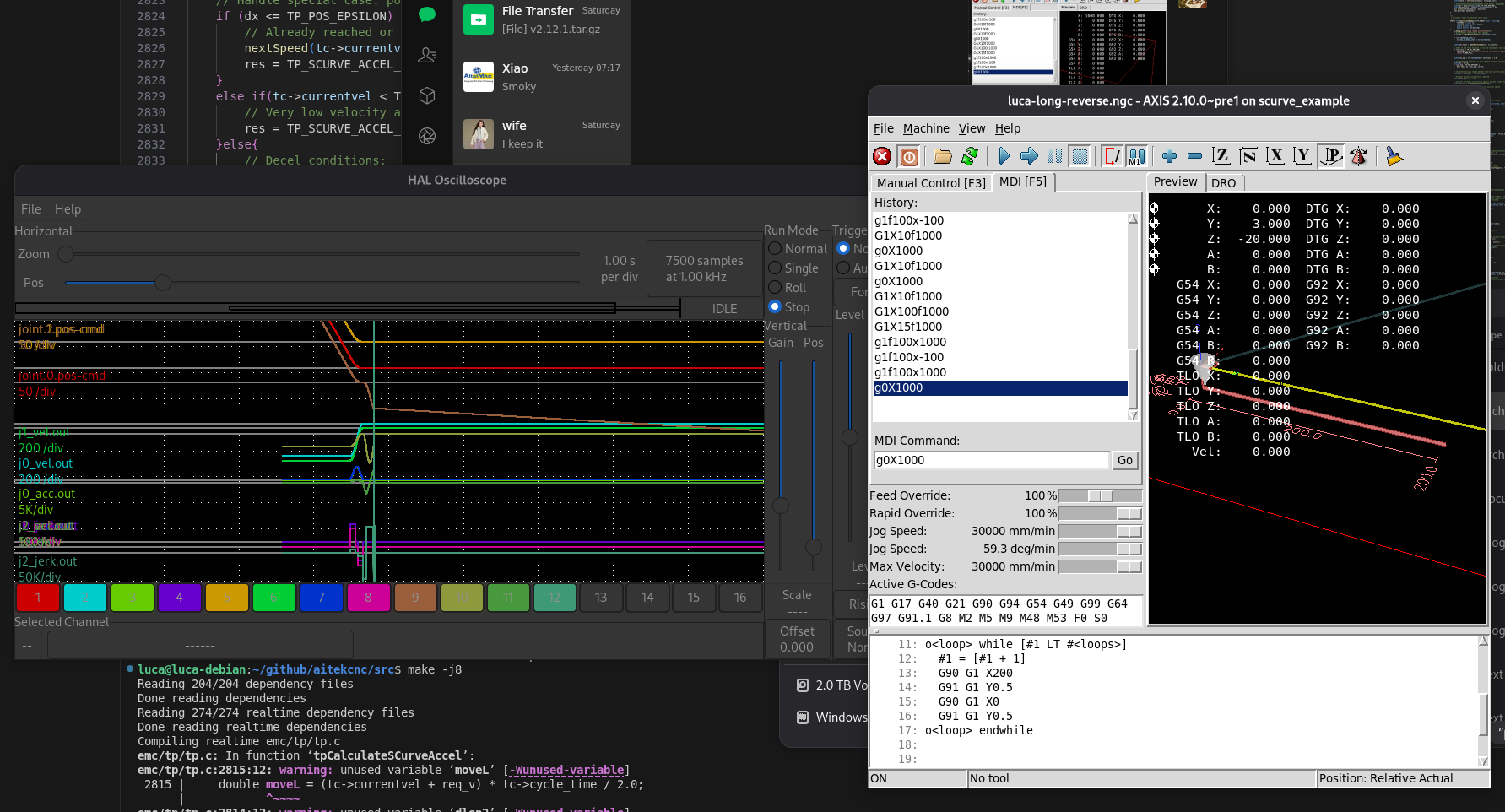

test with this, this is dlen2 code

this is without

we know is not ideal, but at the moment, best we can do

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

test with this, this is dlen2 code

this is without

we know is not ideal, but at the moment, best we can do

Attachments:

The following user(s) said Thank You: endian

Please Log in or Create an account to join the conversation.

- endian

-

- Away

- Elite Member

-

Less

More

- Posts: 295

- Thank you received: 99

29 Jan 2026 17:44 #342163

by endian

it should be solution for everyone who not understand it soo well as you guys... my solution of compensation will be even more inaccurate when scurve will be done and implemented ...

I can not say you what to do, your job, your rules, your output ... thanks for your upgrade to curving

Replied by endian on topic LinuxCNC S-Curve Accelerations

I can understand You and YangYang, its added job, but I openly disagree ... its the best time to improve lcnc and solve it at native level for ever, no other proforma hobby solution as now my is...

My apologize ... sorry I can not show same speed test because I am currently weeks out of office but we can just multiply or devide values ... because it is linear dependecy during constant speed movemet ... I can just customize current images to show exact difference ... compensation off ferror = 0.125mm at 15m/min ... compensation on ferror = 0.00009028mm at 1m/min and multiply it by 15 we get 0,0013542mm which is significantly less then 0.125 .. What I remember from testing by my short eyes it whas something near 0.001mm during that 15m/min testing was done with bentch top setup without any load presented... just AX5106 with AM8xxx motor but I can go home for testing this weekend to create exact speed difference testing if it is neccessary No apologies needed [img]/media/kunena/emoticons/wink.png[/img]

it should be solution for everyone who not understand it soo well as you guys... my solution of compensation will be even more inaccurate when scurve will be done and implemented ...

I can not say you what to do, your job, your rules, your output ... thanks for your upgrade to curving

Please Log in or Create an account to join the conversation.

Time to create page: 0.279 seconds