- LinuxCNC

- General LinuxCNC Questions

- FPGA (field programmable gate array) programmed for linuxcnc motion

FPGA (field programmable gate array) programmed for linuxcnc motion

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

06 Jul 2018 09:24 #113549

by andypugh

I am a bit confused by this. The external offsets branch ought to be a better way to apply the offsets, even if your HAL components setup is a better way to calculate the offsets. Using External-Offfsets also should guarantee that the machine stays within the travel and velocity/accel limits.

If you are finding that an alternative way to apply the offsets is working better then perhaps you have not set up the external-offsets limits optimally?

Replied by andypugh on topic FPGA (field programmable gate array) programmed for linuxcnc motion

While I am still running my plasma table on an external offsets build I am not using any of the features for torch height control. I am actually planning on moving back to the straight master branch next week when I get some time. I never could get good THC using the external offsets branch and the eoffset_pid component. Right now I am using hal components to build a THC solution that works far better than the commercial system I have ever did.

I am a bit confused by this. The external offsets branch ought to be a better way to apply the offsets, even if your HAL components setup is a better way to calculate the offsets. Using External-Offfsets also should guarantee that the machine stays within the travel and velocity/accel limits.

If you are finding that an alternative way to apply the offsets is working better then perhaps you have not set up the external-offsets limits optimally?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11679

- Thank you received: 3937

06 Jul 2018 11:15 - 06 Jul 2018 11:16 #113560

by rodw

Replied by rodw on topic FPGA (field programmable gate array) programmed for linuxcnc motion

Andy,

I think a few of us have given the external offsets a good workout for plasma (3 I know of) and we could never get it to get good control of the torch height. The best I could get was when Dewey had missed something with metric v's imperial and we had some settings out by a factor of 25.4. (I seem to remember you thought it was running like a drunken sailor) Dewey has since added a deadband to his hpid component at my suggestion but I've been lazy (or busy) and have not tested it. I feel a bit guilty becasue Dewey has put so much work into helping me understand such a complex subject and taking my feedback and putting it back into the eoffsets branch.

Anyway, maybe this weekend as I've got a bit of a lull for a change.

I think a few of us have given the external offsets a good workout for plasma (3 I know of) and we could never get it to get good control of the torch height. The best I could get was when Dewey had missed something with metric v's imperial and we had some settings out by a factor of 25.4. (I seem to remember you thought it was running like a drunken sailor) Dewey has since added a deadband to his hpid component at my suggestion but I've been lazy (or busy) and have not tested it. I feel a bit guilty becasue Dewey has put so much work into helping me understand such a complex subject and taking my feedback and putting it back into the eoffsets branch.

Anyway, maybe this weekend as I've got a bit of a lull for a change.

Last edit: 06 Jul 2018 11:16 by rodw.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

06 Jul 2018 20:53 #113606

by andypugh

Replied by andypugh on topic FPGA (field programmable gate array) programmed for linuxcnc motion

I still think you might be erroneously conflating how the offsets are calculated and how they are applied.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11679

- Thank you received: 3937

06 Jul 2018 22:27 - 06 Jul 2018 22:30 #113611

by rodw

I don't think the work I did contained config errors

The eoffset-pid component Dewey wrote is a HAL Lib component that the user does not touch it or its connections

github.com/LinuxCNC/linuxcnc/blob/dgarr/...nts/eoffset_pid.comp

The config I was using was based on Deweys. hpid_mm.ini sim

github.com/LinuxCNC/linuxcnc/tree/dgarr/..._offsets/eoffset_pid

All my setup was in accordance with the documentation Dewey wrote.

I think its more of a case that we don't fully understand torch voltage behaviour and also from what Islander261 has done indicated that any additional filtering of torch voltage whether it is done in hardware or software, introduces delays into the signal which caused tracking problems for him. He spent a lot of effort optimising his physical plasma environment to achieve maximum signal response..

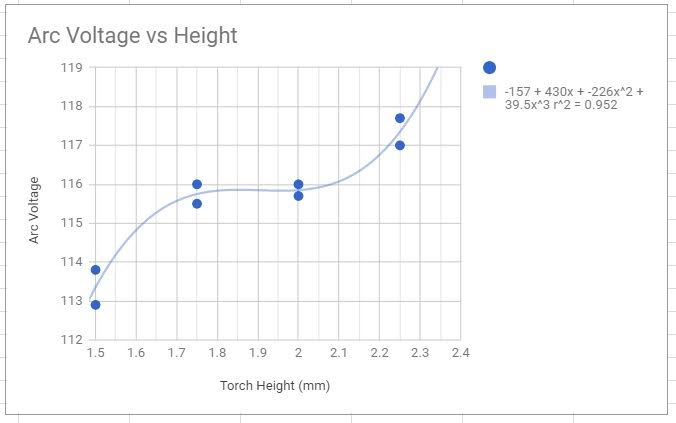

Its always been assumed that there is a linear relationship between torch height and voltage. One test I did with a very limited data set indicated that the torch voltage was a 3rd order polynomial as this graph shows with a 95% confidence level

The next step is to use halsampler to collect a much bigger dataset with a gcode program that initially probes the test area to account for surface irregularities and then does a single cut at varying height over about 150mm. Then load the cut data and the probe data into a spreadsheet, adjust Z height with probe data and repeat the regression analysis with a few thousand data points and see if the trend is confirmed.

So with this graph, applying a deadband around the plateau makes sense.

If the plateau is confirmed, it will be a good way to determine ideal cut height on a given material with a single cut as it will be in the centre of the plateau.

So that is todays' task if nothing goes wrong.

Replied by rodw on topic FPGA (field programmable gate array) programmed for linuxcnc motion

I still think you might be erroneously conflating how the offsets are calculated and how they are applied.

I don't think the work I did contained config errors

The eoffset-pid component Dewey wrote is a HAL Lib component that the user does not touch it or its connections

github.com/LinuxCNC/linuxcnc/blob/dgarr/...nts/eoffset_pid.comp

The config I was using was based on Deweys. hpid_mm.ini sim

github.com/LinuxCNC/linuxcnc/tree/dgarr/..._offsets/eoffset_pid

All my setup was in accordance with the documentation Dewey wrote.

I think its more of a case that we don't fully understand torch voltage behaviour and also from what Islander261 has done indicated that any additional filtering of torch voltage whether it is done in hardware or software, introduces delays into the signal which caused tracking problems for him. He spent a lot of effort optimising his physical plasma environment to achieve maximum signal response..

Its always been assumed that there is a linear relationship between torch height and voltage. One test I did with a very limited data set indicated that the torch voltage was a 3rd order polynomial as this graph shows with a 95% confidence level

The next step is to use halsampler to collect a much bigger dataset with a gcode program that initially probes the test area to account for surface irregularities and then does a single cut at varying height over about 150mm. Then load the cut data and the probe data into a spreadsheet, adjust Z height with probe data and repeat the regression analysis with a few thousand data points and see if the trend is confirmed.

So with this graph, applying a deadband around the plateau makes sense.

If the plateau is confirmed, it will be a good way to determine ideal cut height on a given material with a single cut as it will be in the centre of the plateau.

So that is todays' task if nothing goes wrong.

Last edit: 06 Jul 2018 22:30 by rodw.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

06 Jul 2018 23:26 #113616

by islander261

Replied by islander261 on topic FPGA (field programmable gate array) programmed for linuxcnc motion

Hi

I really want to have a fresh go at the EO branch. The last commit I have is several months old now. How do I get a version that current to the 2.8.1-pre version?

I have to generally agree that for THC work the EO branch and eoffest_pid component should in theory work well. I just have never been able to get it to work well. I am willing to give it another try because it takes care of the following error problems you have with other approaches.

John

I really want to have a fresh go at the EO branch. The last commit I have is several months old now. How do I get a version that current to the 2.8.1-pre version?

I have to generally agree that for THC work the EO branch and eoffest_pid component should in theory work well. I just have never been able to get it to work well. I am willing to give it another try because it takes care of the following error problems you have with other approaches.

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11679

- Thank you received: 3937

07 Jul 2018 08:56 #113649

by rodw

Replied by rodw on topic FPGA (field programmable gate array) programmed for linuxcnc motion

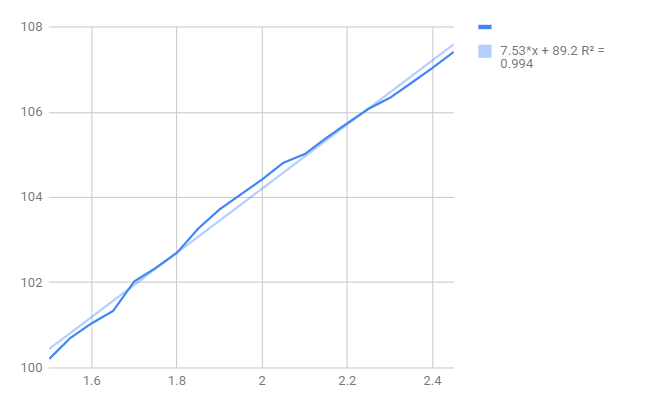

Well, it seems I shot my earlier theory down in flames. I used Halsampler to capture about 9200 readings and plotted the results. (Torch height in mm vs torch voltage.)

.

You can see the torch voltage is linear across a large height range. But at least I know that my plasma cutter changes at the rate of 7.53 volts per mm. There are about 450 readings per reading in 0.05mm increments from 1.5mm to 2.45mm

.

You can see the torch voltage is linear across a large height range. But at least I know that my plasma cutter changes at the rate of 7.53 volts per mm. There are about 450 readings per reading in 0.05mm increments from 1.5mm to 2.45mm

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

07 Jul 2018 16:44 - 07 Jul 2018 16:44 #113685

by andypugh

Yes, but, eoffset_pid isn't the External_Offsets branch. External_Offsets adds extra HAL pins that allow you to apply an external offset to any axis.

I have used it on my lathe to do things this

Regardless of whether eoffset_pid (which is a HAL component that could be used with any branch) gives the correct THC behaviour I think that the External_Offsets branch is the correct way to _apply_ external offsets even if eoffset_pid isn't the optimum way to calculate those offsets.

If you have a bunch of HAL that works well to calculate the required offset then I think that you should probably use that as the input to the external_offset pins.

Replied by andypugh on topic FPGA (field programmable gate array) programmed for linuxcnc motion

I still think you might be erroneously conflating how the offsets are calculated and how they are applied.

I don't think the work I did contained config errors

The eoffset-pid component Dewey wrote is a HAL Lib component that the user does not touch it or its connections

github.com/LinuxCNC/linuxcnc/blob/dgarr/...nts/eoffset_pid.comp

Yes, but, eoffset_pid isn't the External_Offsets branch. External_Offsets adds extra HAL pins that allow you to apply an external offset to any axis.

I have used it on my lathe to do things this

Regardless of whether eoffset_pid (which is a HAL component that could be used with any branch) gives the correct THC behaviour I think that the External_Offsets branch is the correct way to _apply_ external offsets even if eoffset_pid isn't the optimum way to calculate those offsets.

If you have a bunch of HAL that works well to calculate the required offset then I think that you should probably use that as the input to the external_offset pins.

Last edit: 07 Jul 2018 16:44 by andypugh.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11679

- Thank you received: 3937

07 Jul 2018 21:02 #113720

by rodw

Replied by rodw on topic FPGA (field programmable gate array) programmed for linuxcnc motion

Andy, correct but eoffset_pid is only distributed as part of the external offsets branch as it depends on it and it was envisaged as a standard mechanism to use the external offsets for torch height control.

Islander261 used the external offsets exactly as you suggested and it was working quite nicely for him. So I think what you are saying that the eoffset_pid algorithm is probably the road block, not external offsets itself. eoffset_pid contains its own PID routine so I'm now wondering if it can't be revised to use an external LinuxCNC PID which is more sophisticated.

Regardless I am going to give it one more go. I realised I need to redo my live config as the latest eoffset_pid example has changed since I built it. I don't think its anything significant, but the configuration methodology in the ini has changed to make it cleaner and easier to configure.

It would be nice if the external offsets branch was rebased to master again. It seems the last time was back in February and there are a few enhancements in master branch we'd like to be able to use.

Islander261 used the external offsets exactly as you suggested and it was working quite nicely for him. So I think what you are saying that the eoffset_pid algorithm is probably the road block, not external offsets itself. eoffset_pid contains its own PID routine so I'm now wondering if it can't be revised to use an external LinuxCNC PID which is more sophisticated.

Regardless I am going to give it one more go. I realised I need to redo my live config as the latest eoffset_pid example has changed since I built it. I don't think its anything significant, but the configuration methodology in the ini has changed to make it cleaner and easier to configure.

It would be nice if the external offsets branch was rebased to master again. It seems the last time was back in February and there are a few enhancements in master branch we'd like to be able to use.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

08 Jul 2018 17:44 #113824

by islander261

Replied by islander261 on topic FPGA (field programmable gate array) programmed for linuxcnc motion

Rod

Thanks for putting in the time to put the arc voltage linearity question to bed.

All

I think that the most of the THCs that operate successfully actually generate a velocity command from the arc voltage error. With eoffset_pid we are creating a position error correction command that is then put into the hal pid which operates in a bang bang fashion (look at the gains and clipping used)to get a velocity command for the step generator (this is for Mesa hardware). I will try and get my current configurations drawn up and posted in the plasma section later this week.

I must admit that even when I used the features of the External Offsets branch to keep the following error to a minimum while using regular hal components to correct the arc voltage error I didn't

about not using the eoffset_pid componenet.

John

Thanks for putting in the time to put the arc voltage linearity question to bed.

All

I think that the most of the THCs that operate successfully actually generate a velocity command from the arc voltage error. With eoffset_pid we are creating a position error correction command that is then put into the hal pid which operates in a bang bang fashion (look at the gains and clipping used)to get a velocity command for the step generator (this is for Mesa hardware). I will try and get my current configurations drawn up and posted in the plasma section later this week.

I must admit that even when I used the features of the External Offsets branch to keep the following error to a minimum while using regular hal components to correct the arc voltage error I didn't

about not using the eoffset_pid componenet.

John

Please Log in or Create an account to join the conversation.

- Grotius

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

10 Jul 2018 20:14 - 10 Jul 2018 20:45 #113967

by Grotius

Replied by Grotius on topic FPGA (field programmable gate array) programmed for linuxcnc motion

Hi,

This is what i get on a 10mm mild steel plate with linuxcnc. The tiny hole is 10mm. The plate is cut at 100x100mm.

Plasma source : Thermal Dynamics ultracut 100xt

Material : mild steel 10mm

Speed 2000 mm/min

Power 100 amp

Cutting gas : Oxygen

Shield : Compressed air

Cutting angle : less 1 degrees

This is the test machine with the linuxcnc hard disk. Accuracy machine 0.1mm in movement, stepper + 2x ltp1 machine.

Okey now turn your monitor 90 degrees

Okey now turn your monitor back in orginal direction.

Plasma inverter :

So be conviedent. Linuxcnc is almost master kenobi with plasma....

There are a few little things to solve for linuxcnc. No problem. It is free, open source !!

I will read your last post's carefully. islander, rodw, andy, in coming time.

It will be great to have an add on FPGA chip for a simple ltp1 superport card.

For islander, if you use a non chinese or non italian plasma source, normally you can use a pci slot without burning your pc.

Cebora is italian and very bad. There is a italian ellettro source, that can be used. But for both countries, for me the same rule. They are all cheap copy masters.

This is what i get on a 10mm mild steel plate with linuxcnc. The tiny hole is 10mm. The plate is cut at 100x100mm.

Plasma source : Thermal Dynamics ultracut 100xt

Material : mild steel 10mm

Speed 2000 mm/min

Power 100 amp

Cutting gas : Oxygen

Shield : Compressed air

Cutting angle : less 1 degrees

This is the test machine with the linuxcnc hard disk. Accuracy machine 0.1mm in movement, stepper + 2x ltp1 machine.

Okey now turn your monitor 90 degrees

Okey now turn your monitor back in orginal direction.

Plasma inverter :

So be conviedent. Linuxcnc is almost master kenobi with plasma....

There are a few little things to solve for linuxcnc. No problem. It is free, open source !!

I will read your last post's carefully. islander, rodw, andy, in coming time.

It will be great to have an add on FPGA chip for a simple ltp1 superport card.

For islander, if you use a non chinese or non italian plasma source, normally you can use a pci slot without burning your pc.

Cebora is italian and very bad. There is a italian ellettro source, that can be used. But for both countries, for me the same rule. They are all cheap copy masters.

Last edit: 10 Jul 2018 20:45 by Grotius.

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- FPGA (field programmable gate array) programmed for linuxcnc motion

Time to create page: 0.183 seconds