Manual tool change problem

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 506

- Thank you received: 212

28 Aug 2018 18:52 #116730

by MaHa

Replied by MaHa on topic Manual tool change problem

G53 is only active for the current block, changes only by homing at other position possible. Otherwise the programmed offset is active, in your example G54. After M6 , G54 is selected. Make shure this offset is touched off correct, normally on top of material. You should see the position in the DRO.

The following user(s) said Thank You: derekmac

Please Log in or Create an account to join the conversation.

- curtisa

- Offline

- Premium Member

-

Less

More

- Posts: 88

- Thank you received: 15

29 Aug 2018 01:17 #116754

by curtisa

Replied by curtisa on topic Manual tool change problem

I've been able to run your G-code on a simulated machine and it appears to work OK, although the use of G43 to call tool length offsets with a collet/tools that can't be indexed seems a bit odd.

Tool load does shift the cutter down to Z minus TLO in the backplot when called without an associated move on the physical Z axis, which to me seems correct provided the actual TLO is exactly what is described in the tool table.

Could the problem be that you're touching off with the first tool you're wanting to use to set your G54 offsets, and then invoking a G43 for that same tool in the first tool change? That could add an extra 1.553" to your Z moves that you don't need and screw up all your offsets from that point forward. What happens if you install T21 in the collet and touch off with that, but instead of specifying Z=0 as the touchoff value, you specify Z=1.553 (ie, the length of your first tool used)?

Tool load does shift the cutter down to Z minus TLO in the backplot when called without an associated move on the physical Z axis, which to me seems correct provided the actual TLO is exactly what is described in the tool table.

Could the problem be that you're touching off with the first tool you're wanting to use to set your G54 offsets, and then invoking a G43 for that same tool in the first tool change? That could add an extra 1.553" to your Z moves that you don't need and screw up all your offsets from that point forward. What happens if you install T21 in the collet and touch off with that, but instead of specifying Z=0 as the touchoff value, you specify Z=1.553 (ie, the length of your first tool used)?

Please Log in or Create an account to join the conversation.

- curtisa

- Offline

- Premium Member

-

Less

More

- Posts: 88

- Thank you received: 15

29 Aug 2018 03:57 - 29 Aug 2018 04:00 #116761

by curtisa

Replied by curtisa on topic Manual tool change problem

Here's some screenshots of what I'm seeing. Maybe if you can confirm it's the same behaviour you're experiencing.

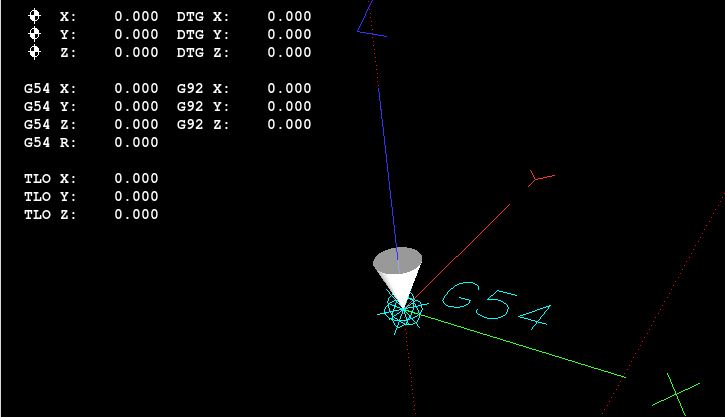

1. Initial tool position, all axes zeroed, no offsets, no TLO, touchoff completed at X0 Y0 Z0. The assumption here is that tool length at this point is irrelevant. The tool could be 2mm long or 10 miles long. The tip of the tool is sitting at exactly Z0, both on the machine and in the backplot:

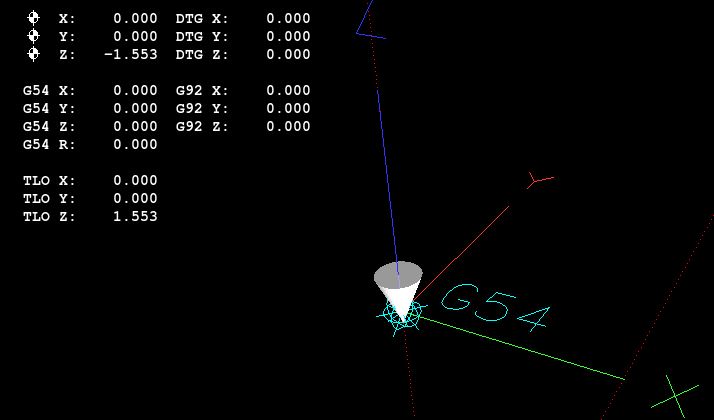

2. G43 H21 invoked to apply tool offset. Tool drops down Z axis by 1.553" in backplot (ie, the tool now has a defined length of 1.553" extending below the starting position). TLO reports Z=1.553". DRO reports Z=-1.553". Machine has not moved:

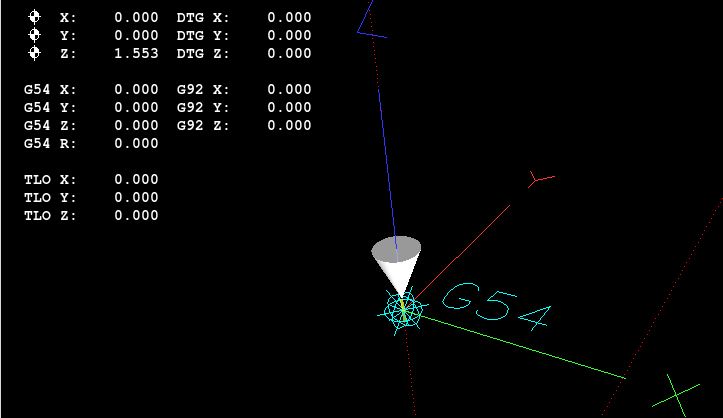

3. G0 Z0 command given. Tool tip raises to Z=0. DRO reports Z=0. Machine raises Z axis by corresponding 1.553", so tool would physically now be 1.553" above the actual Z=0 position:

4. G49 invoked. All offsets cancelled. Backplot now shows tool 1.553" above Z=0. DRO also reflects this reporting Z=1.553". Machine has not moved:

As far as I can tell this should be the correct behaviour provided the use of G43 H21 is not offsetting an existing offset introduced by the application of G54.

1. Initial tool position, all axes zeroed, no offsets, no TLO, touchoff completed at X0 Y0 Z0. The assumption here is that tool length at this point is irrelevant. The tool could be 2mm long or 10 miles long. The tip of the tool is sitting at exactly Z0, both on the machine and in the backplot:

2. G43 H21 invoked to apply tool offset. Tool drops down Z axis by 1.553" in backplot (ie, the tool now has a defined length of 1.553" extending below the starting position). TLO reports Z=1.553". DRO reports Z=-1.553". Machine has not moved:

3. G0 Z0 command given. Tool tip raises to Z=0. DRO reports Z=0. Machine raises Z axis by corresponding 1.553", so tool would physically now be 1.553" above the actual Z=0 position:

4. G49 invoked. All offsets cancelled. Backplot now shows tool 1.553" above Z=0. DRO also reflects this reporting Z=1.553". Machine has not moved:

As far as I can tell this should be the correct behaviour provided the use of G43 H21 is not offsetting an existing offset introduced by the application of G54.

Last edit: 29 Aug 2018 04:00 by curtisa. Reason: Typos.

The following user(s) said Thank You: derekmac

Please Log in or Create an account to join the conversation.

- derekmac

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 1

29 Aug 2018 09:11 #116766

by derekmac

Replied by derekmac on topic Manual tool change problem

Thanks MaHa - setting TOOL_CHANGE_POSITION = 0 0 4 has fixed the tool change position problem

Thanks curtisa - it is now doing exactly as per your screen shots (apart from the absence of the G54 & symbol)

The problem now is that it is driving the mill z-axis down to Z minus TLO prior to each toolchange. NOT good - the tool tips should never go below the values specified on the G81 & G83 lines -

i.e. Tool 21 -0.0567, Tool 52 (first time) -0.3313, Tool 50 -0.721, Tool 60 -0.71 & Tool 52 (again) -0.805 - anything lower is going to mess up the material and the mill bed.

This tool descent is not only wrong but a total waste of time as it should be going UP to change the tool.

I am not using the tool touch off at all yet - no material, no tool in test run, and the touch-off button is disabled once the program starts.

I have not yet checked the headstock for correct position with each tool as the above problem is running me out of Z-axis height!

Thanks curtisa - it is now doing exactly as per your screen shots (apart from the absence of the G54 & symbol)

The problem now is that it is driving the mill z-axis down to Z minus TLO prior to each toolchange. NOT good - the tool tips should never go below the values specified on the G81 & G83 lines -

i.e. Tool 21 -0.0567, Tool 52 (first time) -0.3313, Tool 50 -0.721, Tool 60 -0.71 & Tool 52 (again) -0.805 - anything lower is going to mess up the material and the mill bed.

This tool descent is not only wrong but a total waste of time as it should be going UP to change the tool.

I am not using the tool touch off at all yet - no material, no tool in test run, and the touch-off button is disabled once the program starts.

I have not yet checked the headstock for correct position with each tool as the above problem is running me out of Z-axis height!

Please Log in or Create an account to join the conversation.

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 506

- Thank you received: 212

29 Aug 2018 09:49 #116767

by MaHa

Replied by MaHa on topic Manual tool change problem

It is because of this line, before the toolchange:

N25G0G53X0Y0Z0

Machine goes to Z0, but now your toolchangeüposition is at 4. It means the machine dives 4 minus. You Need to Change all the lines with G0G53X0Y0Z0 to G0G53X0Y0Z4

N25G0G53X0Y0Z0

Machine goes to Z0, but now your toolchangeüposition is at 4. It means the machine dives 4 minus. You Need to Change all the lines with G0G53X0Y0Z0 to G0G53X0Y0Z4

Please Log in or Create an account to join the conversation.

- curtisa

- Offline

- Premium Member

-

Less

More

- Posts: 88

- Thank you received: 15

29 Aug 2018 10:38 #116768

by curtisa

If the machine is attempting to go lower than the material when it is returning to the 'park-to-toolchange' position (G53 X0 Y0 Z0), the only other thing I can think of is that your machine home position is specified to be lower than the material to begin with.

When you home your machine is Z=0 at the top of the axis, somewhere in the middle or at the bottom of the axis? In my mill G53 Z0 is at the highest point my Z axis will raise to before crashing into the limit switch, and is also the home position of that axis. My Z axis is also specified in the INI file as having range limits of -110 min to 0 max, rather than say -55 to +55 or 0 to 110. Any movement of the Z axis towards the bed is therefore negative. Once I touch off on to the material, my G54 Z is set = zero to coincide with the top surface of the material being worked. Thus if I issue:

The cutter will move from whatever height it was currently at to come to rest exactly on top of the surface of the material. If however I issue:

It doesn't matter what height the cutter was at or what offsets were in G54, it will always rise up to the maximum height on the gantry where the top limit switch is and stop.

So...

The short suggestion I have is to try replacing any line in your G-code mentioning G53 X0 Y0 Z0 with something like G53 X0 Y0 Z3. See if that gets your tool change position in a slightly better location for starters. Long term, if G53 Z0 is normally somewhere other than well away from the mill table, then you may need to rethink how the Z-axis min and max limits in your INI file have been defined, and/or where you position the mill head when you home the machine for Z=0 after first powering up, or living with the fact that the tool change position in your G-codes will need to be G53...Z+something.

Replied by curtisa on topic Manual tool change problem

Thanks curtisa - it is now doing exactly as per your screen shots (apart from the absence of the G54 & symbol)

The problem now is that it is driving the mill z-axis down to Z minus TLO prior to each toolchange. NOT good - the tool tips should never go below the values specified on the G81 & G83 lines -

i.e. Tool 21 -0.0567, Tool 52 (first time) -0.3313, Tool 50 -0.721, Tool 60 -0.71 & Tool 52 (again) -0.805 - anything lower is going to mess up the material and the mill bed.

This tool descent is not only wrong but a total waste of time as it should be going UP to change the tool.

I am not using the tool touch off at all yet - no material, no tool in test run, and the touch-off button is disabled once the program starts.

I have not yet checked the headstock for correct position with each tool as the above problem is running me out of Z-axis height!

If the machine is attempting to go lower than the material when it is returning to the 'park-to-toolchange' position (G53 X0 Y0 Z0), the only other thing I can think of is that your machine home position is specified to be lower than the material to begin with.

When you home your machine is Z=0 at the top of the axis, somewhere in the middle or at the bottom of the axis? In my mill G53 Z0 is at the highest point my Z axis will raise to before crashing into the limit switch, and is also the home position of that axis. My Z axis is also specified in the INI file as having range limits of -110 min to 0 max, rather than say -55 to +55 or 0 to 110. Any movement of the Z axis towards the bed is therefore negative. Once I touch off on to the material, my G54 Z is set = zero to coincide with the top surface of the material being worked. Thus if I issue:

G54 G0 Z0The cutter will move from whatever height it was currently at to come to rest exactly on top of the surface of the material. If however I issue:

G53 G0 Z0It doesn't matter what height the cutter was at or what offsets were in G54, it will always rise up to the maximum height on the gantry where the top limit switch is and stop.

So...

The short suggestion I have is to try replacing any line in your G-code mentioning G53 X0 Y0 Z0 with something like G53 X0 Y0 Z3. See if that gets your tool change position in a slightly better location for starters. Long term, if G53 Z0 is normally somewhere other than well away from the mill table, then you may need to rethink how the Z-axis min and max limits in your INI file have been defined, and/or where you position the mill head when you home the machine for Z=0 after first powering up, or living with the fact that the tool change position in your G-codes will need to be G53...Z+something.

The following user(s) said Thank You: derekmac

Please Log in or Create an account to join the conversation.

- curtisa

- Offline

- Premium Member

-

Less

More

- Posts: 88

- Thank you received: 15

29 Aug 2018 10:42 #116769

by curtisa

Replied by curtisa on topic Manual tool change problem

MaHa beat me to it

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

29 Aug 2018 16:31 #116785

by andypugh

Just a note that the Fusion360 postprocessor inserts a G53 Z0 before every toolchange. This is a move to absolute Z zero, and that pretty much _requires_ that the Z axis is configured with top at Z=0 and bottom at Z = -5

Replied by andypugh on topic Manual tool change problem

if create a part in Fusion 360 and used 10 different tools for the job I will have 10 files and must have room for 10 tools in the tool table.

Just a note that the Fusion360 postprocessor inserts a G53 Z0 before every toolchange. This is a move to absolute Z zero, and that pretty much _requires_ that the Z axis is configured with top at Z=0 and bottom at Z = -5

Please Log in or Create an account to join the conversation.

- derekmac

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 1

29 Aug 2018 17:33 #116798

by derekmac

Replied by derekmac on topic Manual tool change problem

Finally - nearly there.

I thought you guys may have cracked it, but unfortunately ....

It was still going low on the tool change.

When I try to home the Z axis it always changes the DRO and backplot to Z0, regardless of where it was previously, and rewgardless of where the mill is.

I finally decided to give in and accept that Z0 had to be the top of the Z-axis column.

Set the toolchange position in the .ini back to 0, 0, 0 and subtracted 4 from all the Z and R values in the test file.

It now works almost perfectly - just one small niggle - it is not going back to true Z0 for the toolchanges - it is going to Z0 minus TLO.

I guess it is something to do with the G53X0Y0Z0 command preceding each tool change - is there another G code that takes it back to absolute zero?

The resulting backplot display is a little counter intuitive as my material is now down at Z-4, but I can live with that.

Thanks again for all your help.

I thought you guys may have cracked it, but unfortunately ....

It was still going low on the tool change.

When I try to home the Z axis it always changes the DRO and backplot to Z0, regardless of where it was previously, and rewgardless of where the mill is.

I finally decided to give in and accept that Z0 had to be the top of the Z-axis column.

Set the toolchange position in the .ini back to 0, 0, 0 and subtracted 4 from all the Z and R values in the test file.

It now works almost perfectly - just one small niggle - it is not going back to true Z0 for the toolchanges - it is going to Z0 minus TLO.

I guess it is something to do with the G53X0Y0Z0 command preceding each tool change - is there another G code that takes it back to absolute zero?

The resulting backplot display is a little counter intuitive as my material is now down at Z-4, but I can live with that.

Thanks again for all your help.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

29 Aug 2018 19:02 #116807

by andypugh

Replied by andypugh on topic Manual tool change problem

G53 Z0 wil take the axis right to the top.

But the actual tool tip (in the physical world) and the tool tip and DRO on the monitor will show a z position that takes in to account the Z length.

You can switch to showing absolute coordinates in the display, if you want. That should definitely show zero at top of travel.

But the actual tool tip (in the physical world) and the tool tip and DRO on the monitor will show a z position that takes in to account the Z length.

You can switch to showing absolute coordinates in the display, if you want. That should definitely show zero at top of travel.

The following user(s) said Thank You: derekmac

Please Log in or Create an account to join the conversation.

Time to create page: 0.271 seconds