Step Sale and Velocity

- little_sparky

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 16

29 Nov 2019 11:28 #151492

by little_sparky

Replied by little_sparky on topic Step Sale and Velocity

Ahhh yes, my apologies.

I will do that then, I’m following your calculations as we speak and they are spot on, and I’ll edit the ini rather than the PNC, I think it’s just making life harder.

Thanks so much for your help. It is appreciated more than you know

I will do that then, I’m following your calculations as we speak and they are spot on, and I’ll edit the ini rather than the PNC, I think it’s just making life harder.

Thanks so much for your help. It is appreciated more than you know

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11426

- Thank you received: 3833

29 Nov 2019 12:45 #151498

by rodw

No problems. I'm just helping you avoid the silly mistakes I made. I forgot to multiply by pi and made a beautiful direct drive until people here pointed out my mistake and made me remake the drive to use a 3:1 step down.

Then I rolled the pinion along the rack to find it was out by a factor of 3.14

Replied by rodw on topic Step Sale and Velocity

Thanks so much for your help. It is appreciated more than you know

No problems. I'm just helping you avoid the silly mistakes I made. I forgot to multiply by pi and made a beautiful direct drive until people here pointed out my mistake and made me remake the drive to use a 3:1 step down.

Then I rolled the pinion along the rack to find it was out by a factor of 3.14

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1940

- Thank you received: 338

29 Nov 2019 13:14 #151501

by bevins

Nice piece. you make that?

Replied by bevins on topic Step Sale and Velocity

Hello All!

Thanks for taking time to read my post.

I have recently got my motors running and I have them tuned to what I believe is the right settings.

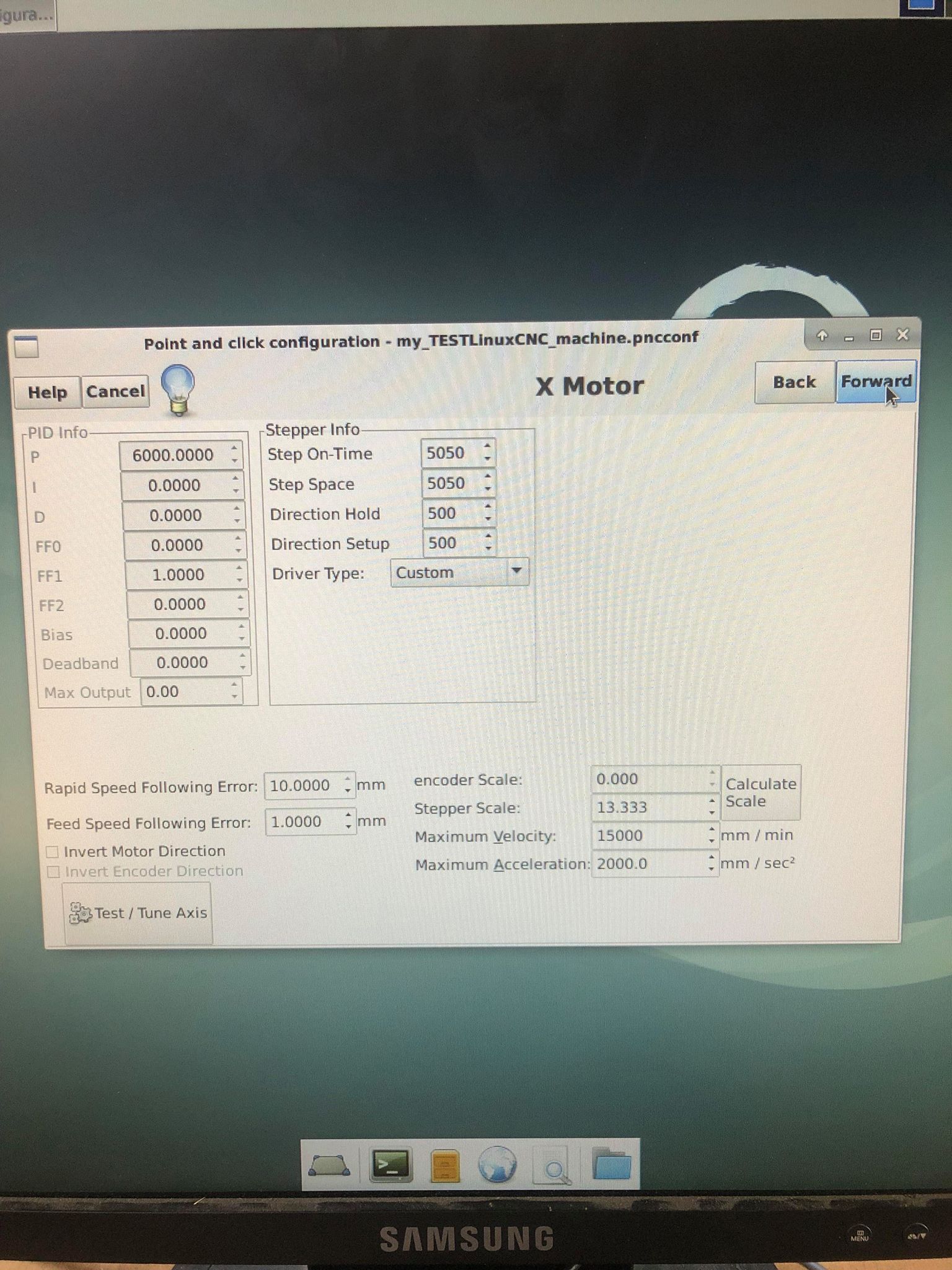

I have a DM542T at step time = 5050 step direction = 5050 direction hold = 500 direction setup = 500.

I had them sitting on the bench and they sounded beautiful, then i plugged them to my machine and they were very jittery with what I thought was the right step scale. However I corrected it by a factor of 10 and they ran absolutely beautifully.

The problem with this however is that I cant seem to run my motors fast enough.

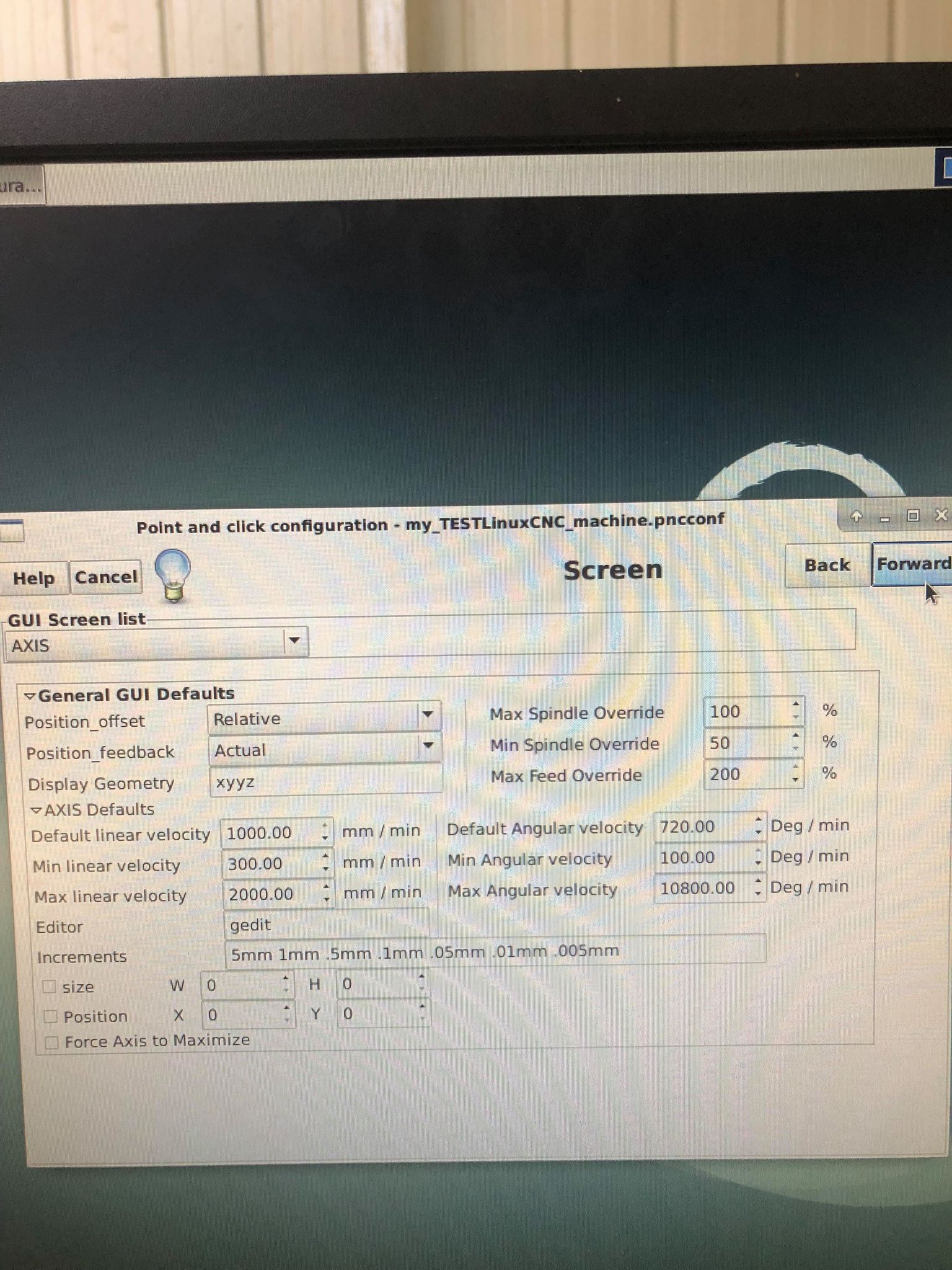

In the PNCconf wizard with axis selected I cant set the default linear velocity above 1000mm/min and the max linear velocity above 2000mm/min however I would like to jog at 9000mm/min and cut up to 6000mm/min for 2.5mm steel (making a plasma cutter with PlasmaC).

IMAGES AND INFO.

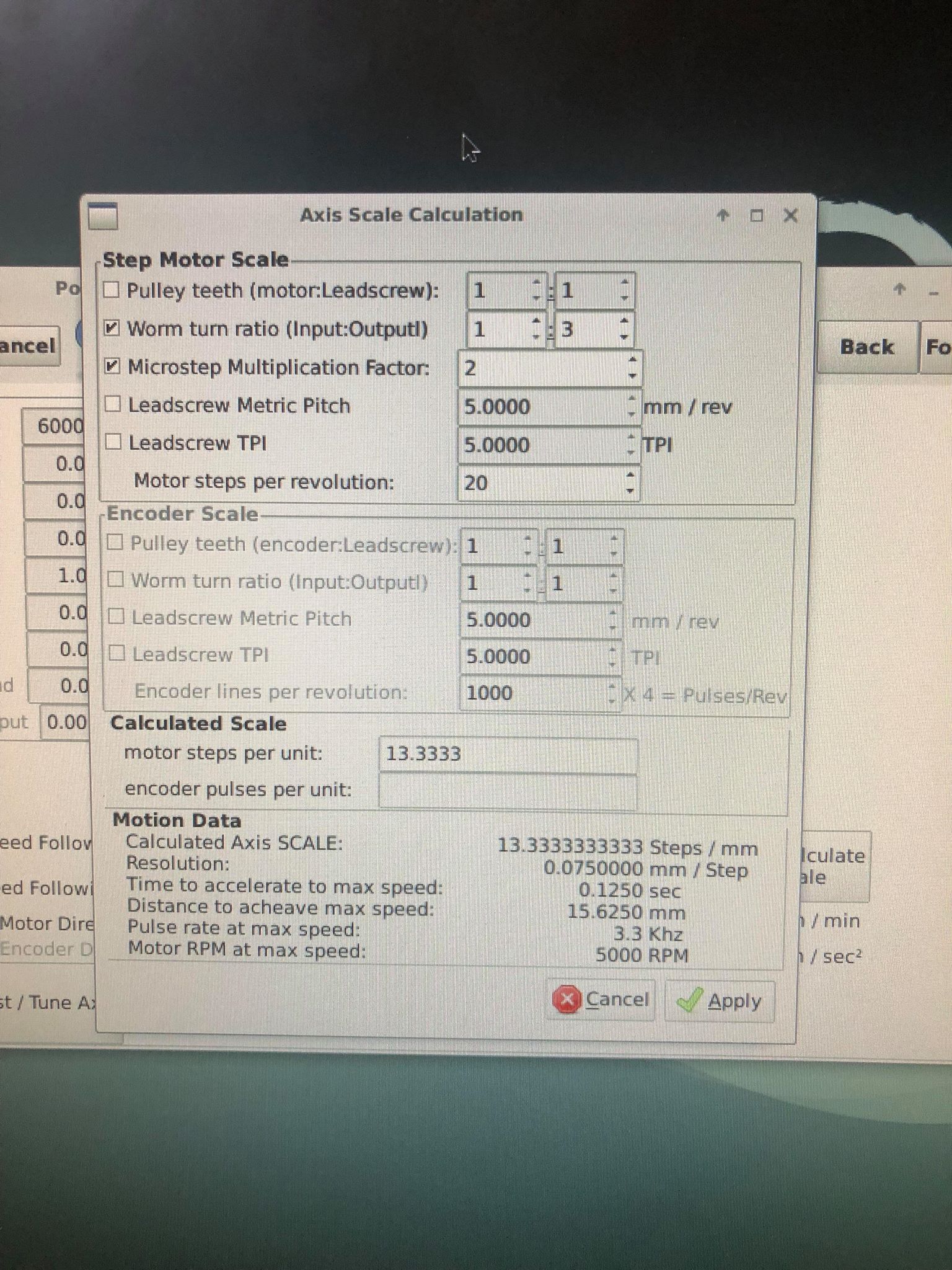

motor steps per revolution= 200

microstepping= 2

gear reduction= 3:1

mod 1.5 20T pinion drive with 30mm pitch circumference.

So my step scale really should be 1200 steps/rev (of pinion) and 40 steps per mm but this doesnt seem to match up. I had to change my motor steps per revolution to 20 instead of 200 which is obviously wrong.

Any help is very much appreciated

Nice piece. you make that?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17320

- Thank you received: 5038

29 Nov 2019 19:37 #151518

by PCW

Replied by PCW on topic Step Sale and Velocity

A couple other suggested .ini file changes:

Set all P terms to 1000 (6000 will cause instabilities)

Set all direction setup and hold times to 20000

(this has no effect on performance and guarantees operation with almost any drive)

And as suggested by others, increase the microstep ratio of the drives

a 2-1 microstep ratio will have the motors running as smoothly as a pig on stilts

Set all P terms to 1000 (6000 will cause instabilities)

Set all direction setup and hold times to 20000

(this has no effect on performance and guarantees operation with almost any drive)

And as suggested by others, increase the microstep ratio of the drives

a 2-1 microstep ratio will have the motors running as smoothly as a pig on stilts

Please Log in or Create an account to join the conversation.

- little_sparky

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 16

29 Nov 2019 22:16 #151526

by little_sparky

Sure did! Pretty simple design but it works an absolute treat, super happy with it. Made 3 for less than the price of purchasing 1.

Replied by little_sparky on topic Step Sale and Velocity

Nice piece. you make that?

Sure did! Pretty simple design but it works an absolute treat, super happy with it. Made 3 for less than the price of purchasing 1.

Please Log in or Create an account to join the conversation.

- little_sparky

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 16

29 Nov 2019 22:18 #151527

by little_sparky

Hahahha okay, I’ll change all the values as suggested by all and see what I can get. Thank you all

Replied by little_sparky on topic Step Sale and Velocity

a 2-1 microstep ratio will have the motors running as smoothly as a pig on stilts

Hahahha okay, I’ll change all the values as suggested by all and see what I can get. Thank you all

Please Log in or Create an account to join the conversation.

- little_sparky

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 16

30 Nov 2019 00:40 #151544

by little_sparky

I’ve set my microstepping to 10, just wondering why you multiplied the steps per mm by 5 and not 10?

Replied by little_sparky on topic Step Sale and Velocity

I'd try and increase your microstepping to at least 10:1 and adust the steps per mm accordingly (say 10x microsteping = 31.265 *5 steps per mm which will be about 156 steps per mm.

I’ve set my microstepping to 10, just wondering why you multiplied the steps per mm by 5 and not 10?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11426

- Thank you received: 3833

30 Nov 2019 00:54 #151547

by rodw

Replied by rodw on topic Step Sale and Velocity

Because you said you were doing 2 x microstepping now so 2 x 5 = 10

Please Log in or Create an account to join the conversation.

- little_sparky

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 16

30 Nov 2019 01:58 - 30 Nov 2019 02:16 #151553

by little_sparky

Ahhh yes! Didnt realise you used the value with the step scale aready calculated.

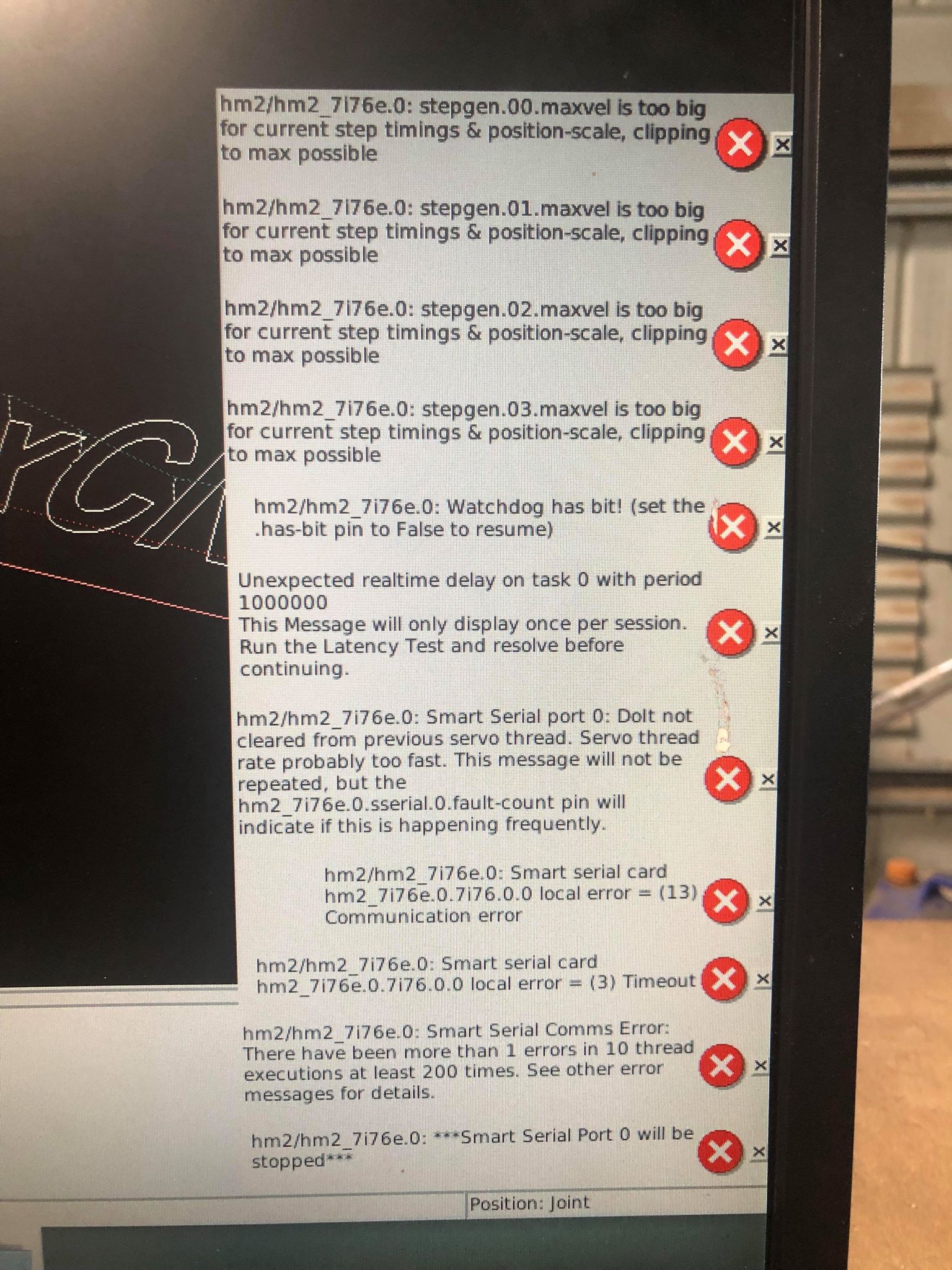

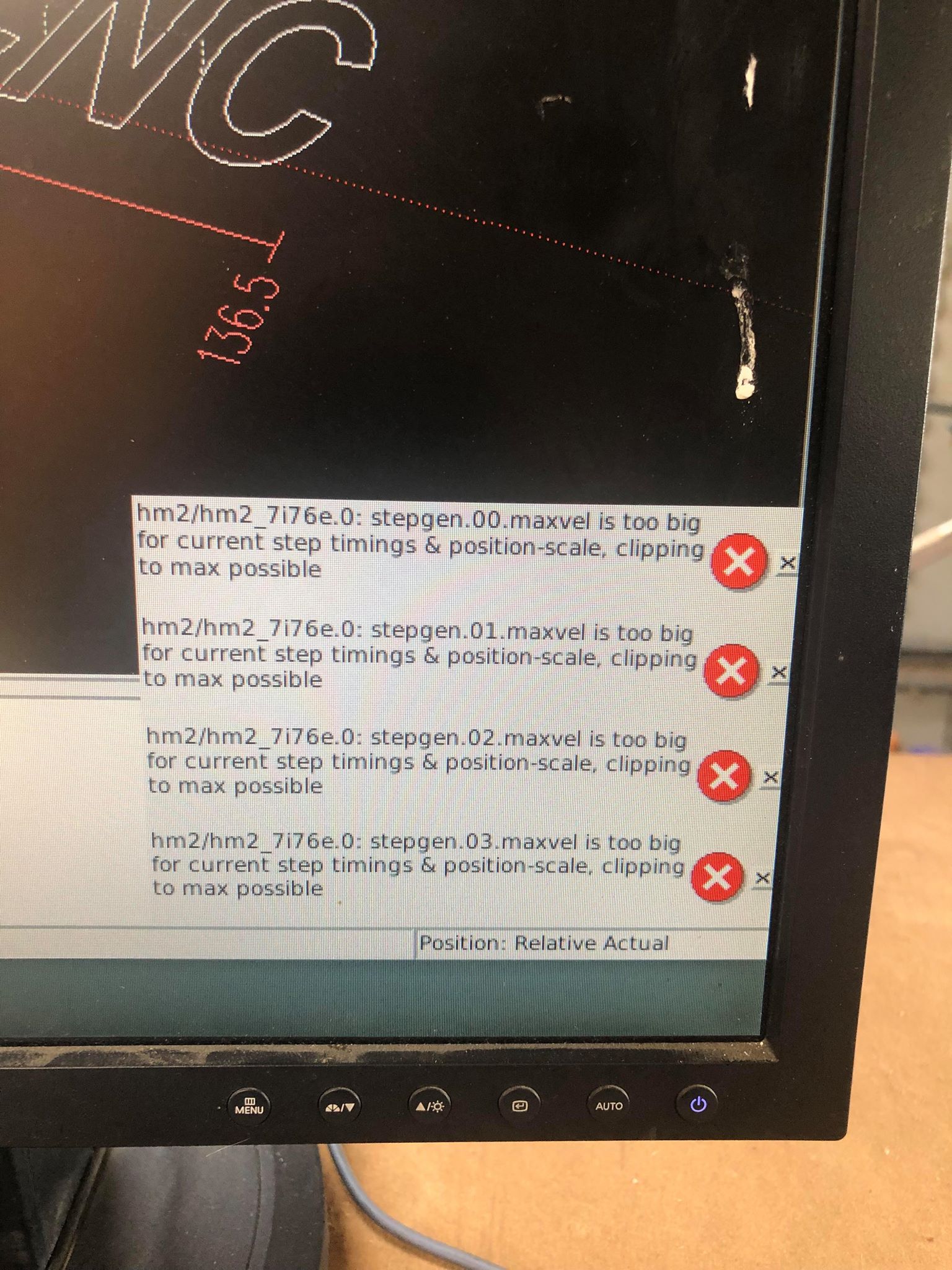

So I changed a few things in the .ini file (this is so much better than PNCconf), however I have experienced a couple of errors.

The first image is the initial error I encountered so I dropped the velocity values from 250 to 200 and then the second image is from further changing to 150 in each of the joints.

.ini and .hal

also on a side note, what are people who are running plasma using as their z-axis limits? I cant seem to get the file to run if I use 200 or -200 as is says line 11 exceeds the Z-axis limit, but if i put in +100 and -100 from limit in the PCNconf i can get it to run.

Edit: changed the P from 6000 to 1000 after uploading files

Replied by little_sparky on topic Step Sale and Velocity

Because you said you were doing 2 x microstepping now so 2 x 5 = 10

Ahhh yes! Didnt realise you used the value with the step scale aready calculated.

So I changed a few things in the .ini file (this is so much better than PNCconf), however I have experienced a couple of errors.

The first image is the initial error I encountered so I dropped the velocity values from 250 to 200 and then the second image is from further changing to 150 in each of the joints.

.ini and .hal

also on a side note, what are people who are running plasma using as their z-axis limits? I cant seem to get the file to run if I use 200 or -200 as is says line 11 exceeds the Z-axis limit, but if i put in +100 and -100 from limit in the PCNconf i can get it to run.

Edit: changed the P from 6000 to 1000 after uploading files

Attachments:

Last edit: 30 Nov 2019 02:16 by little_sparky.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17320

- Thank you received: 5038

30 Nov 2019 02:33 #151554

by PCW

Replied by PCW on topic Step Sale and Velocity

Setting all steplen and stepspace values back to 5000 should fix the clipping warnings

( I suggested setting the direction setup and hold settings to 20000 not the step length and

step space settings )

The other errors are related to real time performance ( the watchdog bit which means the card was not accessed for 5 ms )

This probably means you need to do some latency testing and make sure that the BIOS setup has all power saving options disabled

( I suggested setting the direction setup and hold settings to 20000 not the step length and

step space settings )

The other errors are related to real time performance ( the watchdog bit which means the card was not accessed for 5 ms )

This probably means you need to do some latency testing and make sure that the BIOS setup has all power saving options disabled

Please Log in or Create an account to join the conversation.

Time to create page: 0.482 seconds