hobbing helical gear

- jefsaro

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 104

- Thank you received: 4

01 Sep 2020 05:25 #180254

by jefsaro

hobbing helical gear was created by jefsaro

hello everyone, after a few years of using spur gears, i need to make helicals, i transformed my pfauter 10 years ago, i work with parallel port.

i think i need to add coder, but i dont know how, someone to help me.

have a nice day

jef

i think i need to add coder, but i dont know how, someone to help me.

have a nice day

jef

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4621

- Thank you received: 2045

01 Sep 2020 06:13 #180258

by Aciera

Replied by Aciera on topic hobbing helical gear

Maybe tell us what your machine is capable of. You would need to be able to tilt the cutter in reference to the gear I would imagine?

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21123

- Thank you received: 7216

01 Sep 2020 10:14 #180294

by tommylight

Replied by tommylight on topic hobbing helical gear

We would need much more information to be able to help.

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

01 Sep 2020 15:46 #180338

by CORBETT

Replied by CORBETT on topic hobbing helical gear

@Tom and Aciera

Me and Dad have a 18" Gould & Eberhardt gear hobber and will eventually retrofit it, so will be checking and watching this.

(Aciera) Yes you are correct, it will need to tilt the hob a few degrees, and he could be talking about an encoder getting it super accurate for the tilt, but he may be talking about encoding the hob rotation and tying the hob to the gear drive so that he can eliminate the change gears... this is what I want to do in the future.

Robert

Me and Dad have a 18" Gould & Eberhardt gear hobber and will eventually retrofit it, so will be checking and watching this.

(Aciera) Yes you are correct, it will need to tilt the hob a few degrees, and he could be talking about an encoder getting it super accurate for the tilt, but he may be talking about encoding the hob rotation and tying the hob to the gear drive so that he can eliminate the change gears... this is what I want to do in the future.

Robert

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- jefsaro

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 104

- Thank you received: 4

02 Sep 2020 14:09 #180435

by jefsaro

Replied by jefsaro on topic hobbing helical gear

Hello ,

here is the file of my gear cutter, it has been working for 10 years for spur gears without problem, I would like to be able to make the helicals.

I think that it is necessary to add an encoder at the level of the table to be able to make the differential with linucnc.

the gears have 24 teeth at 30 ° and 48 teeth at 60 ° module 2.

here is the file of my gear cutter, it has been working for 10 years for spur gears without problem, I would like to be able to make the helicals.

I think that it is necessary to add an encoder at the level of the table to be able to make the differential with linucnc.

the gears have 24 teeth at 30 ° and 48 teeth at 60 ° module 2.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4621

- Thank you received: 2045

02 Sep 2020 15:29 #180443

by Aciera

Replied by Aciera on topic hobbing helical gear

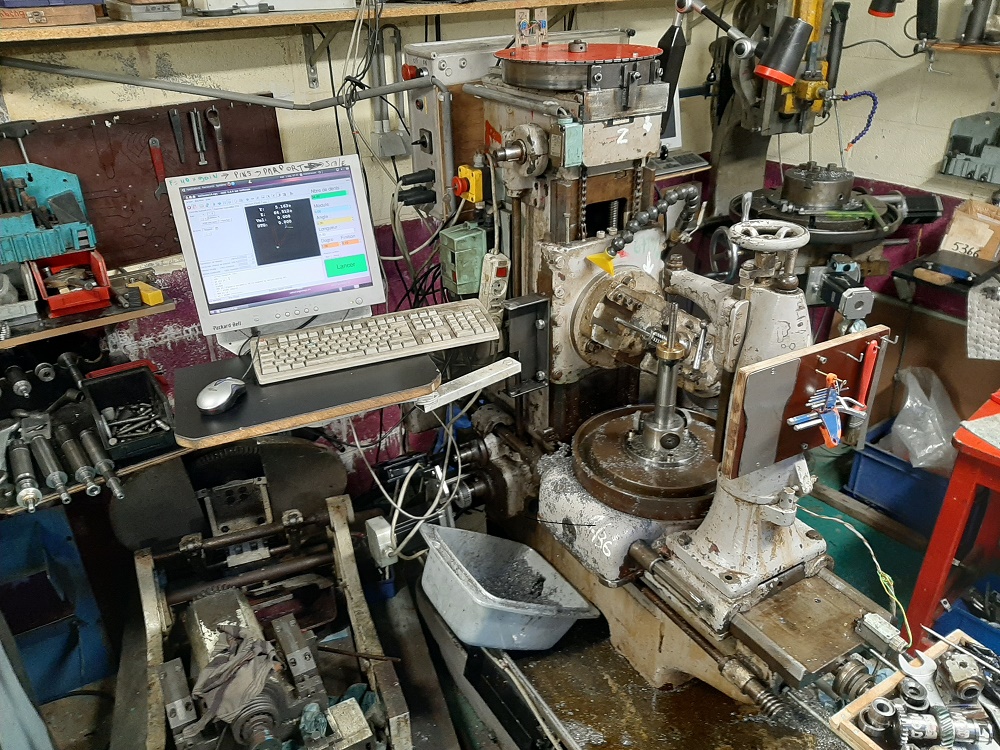

Well, now we know what your config looks like, that's good but I still have no idea what your machine looks like physically. Show us some photographs of the machine so we get an idea of its kinematics, axis and geometry.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- jefsaro

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 104

- Thank you received: 4

03 Sep 2020 05:43 - 03 Sep 2020 05:44 #180493

by jefsaro

Replied by jefsaro on topic hobbing helical gear

Last edit: 03 Sep 2020 05:44 by jefsaro.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4621

- Thank you received: 2045

03 Sep 2020 06:33 - 03 Sep 2020 09:41 #180496

by Aciera

Replied by Aciera on topic hobbing helical gear

You are still not providing enough information. If you want people to help it might be worth your while to elaborate a bit more. Maybe there are people here who have a hobber and know what you want but I don't.

I guess the Z axis is the vertical slide with the hob and the X is the horizontal slide with the limit switch that has wires coming out of it?

To me it looks like the hob is already slanted.

Where does LinuxCNC come in here? Do you want to motorize the angle of the hob?

[edit]

Are you aiming to replace the gear mechanism between the hob and the gear as CORBETT has guessed?

Have a look at this:

forum.linuxcnc.org/10-advanced-configura...e-electronic-gearing

and

wiki.linuxcnc.org/cgi-bin/wiki.pl?Hobbing

Here is Andys video of his setup:

Or also here:

I guess the Z axis is the vertical slide with the hob and the X is the horizontal slide with the limit switch that has wires coming out of it?

To me it looks like the hob is already slanted.

Where does LinuxCNC come in here? Do you want to motorize the angle of the hob?

[edit]

Are you aiming to replace the gear mechanism between the hob and the gear as CORBETT has guessed?

Have a look at this:

forum.linuxcnc.org/10-advanced-configura...e-electronic-gearing

and

wiki.linuxcnc.org/cgi-bin/wiki.pl?Hobbing

Here is Andys video of his setup:

Or also here:

Last edit: 03 Sep 2020 09:41 by Aciera.

Please Log in or Create an account to join the conversation.

- jefsaro

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 104

- Thank you received: 4

03 Sep 2020 14:23 #180551

by jefsaro

Replied by jefsaro on topic hobbing helical gear

yes I understand for people who do not know helical cutting it is not easy.

Originally the machine has a mechanical differential, which we adjust according to the helix angle, but there is no longer any on my machine, I would like to replace it with linuxcnc.

Originally the machine has a mechanical differential, which we adjust according to the helix angle, but there is no longer any on my machine, I would like to replace it with linuxcnc.

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

03 Sep 2020 20:34 #180582

by CORBETT

Replied by CORBETT on topic hobbing helical gear

@jefsaro

Aciera is right, need a little more info to give good answer.

I have not cut helical gears before, but I thought that there was not really any difference between Spur and Helical hobbing other than tilting the hob more degrees to get the tooth angle. Is this wrong? If wrong, what other process that needs to happen other than Hob rotation tied to the gear blank drive, and hob spindle movement.

When you say "originally the machine has a mechanical differential", are you referring to the change gears between the hob and the gear blank?

My machine is almost identical to yours and mine has the hob head move up and down for the cutting process. Is there any other movement other than these three: 1= Hob rotation, 2= gear blank rotation, 3= hob spindle movement?

I have a really good Barber-Colman book that explains all the different ways to setup a manual machine for hobbing, but I can't get my hands on it at the moment...

Robert

Aciera is right, need a little more info to give good answer.

I have not cut helical gears before, but I thought that there was not really any difference between Spur and Helical hobbing other than tilting the hob more degrees to get the tooth angle. Is this wrong? If wrong, what other process that needs to happen other than Hob rotation tied to the gear blank drive, and hob spindle movement.

When you say "originally the machine has a mechanical differential", are you referring to the change gears between the hob and the gear blank?

My machine is almost identical to yours and mine has the hob head move up and down for the cutting process. Is there any other movement other than these three: 1= Hob rotation, 2= gear blank rotation, 3= hob spindle movement?

I have a really good Barber-Colman book that explains all the different ways to setup a manual machine for hobbing, but I can't get my hands on it at the moment...

Robert

Please Log in or Create an account to join the conversation.

Time to create page: 0.099 seconds