hobbing helical gear

- jefsaro

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 104

- Thank you received: 4

04 Sep 2020 07:08 #180625

by jefsaro

Replied by jefsaro on topic hobbing helical gear

Attachments:

Please Log in or Create an account to join the conversation.

- jefsaro

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 104

- Thank you received: 4

04 Sep 2020 07:08 #180626

by jefsaro

Replied by jefsaro on topic hobbing helical gear

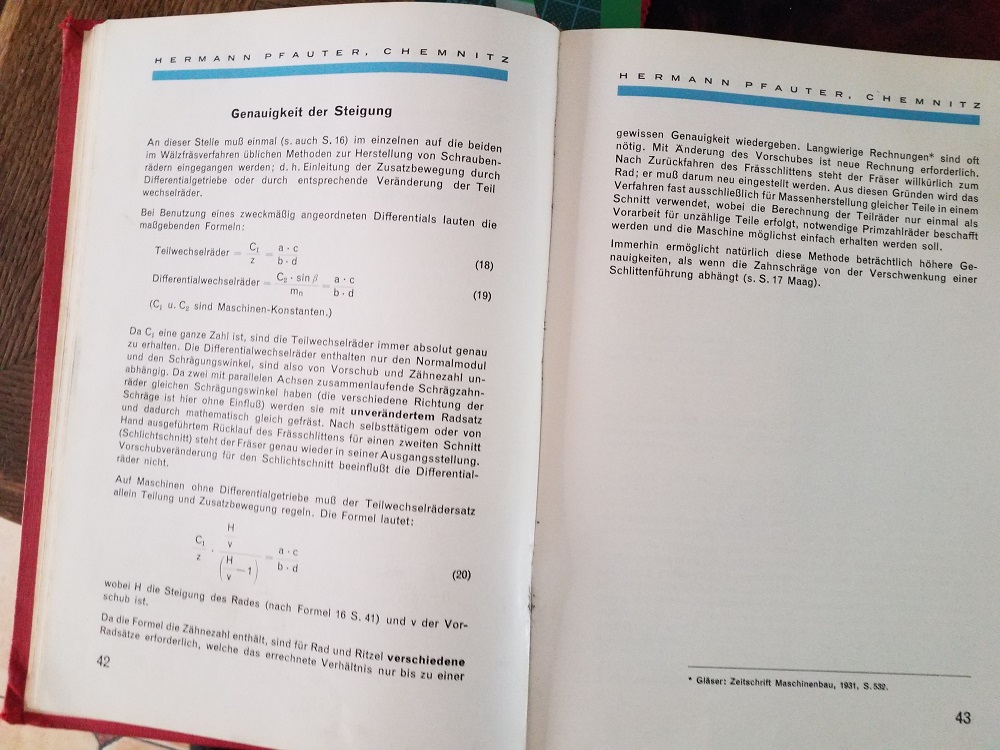

sorry it's in german

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4621

- Thank you received: 2045

04 Sep 2020 09:32 - 04 Sep 2020 09:36 #180635

by Aciera

Replied by Aciera on topic hobbing helical gear

Do you already have an encoder on your hob spindle and a stepper/servo motor on your gear mounting shaft?

I'm sure your machine is or was able to cut helical gears. Do you know how that was done on your machine originally or is that part of your question?

I'm sure your machine is or was able to cut helical gears. Do you know how that was done on your machine originally or is that part of your question?

Last edit: 04 Sep 2020 09:36 by Aciera.

Please Log in or Create an account to join the conversation.

- jefsaro

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 104

- Thank you received: 4

04 Sep 2020 14:22 #180685

by jefsaro

Replied by jefsaro on topic hobbing helical gear

yes, the machine can do it originally, but when I bought it, the parts were missing to make the helical

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4621

- Thank you received: 2045

04 Sep 2020 15:29 - 04 Sep 2020 15:45 #180688

by Aciera

Replied by Aciera on topic hobbing helical gear

You said the mechanical differential that linked the hobbing spindle to the gear blank is missing and you would like to replace that with an "electronic gear" using LinuxCNC. This can be done as Andy has demonstrated by linking the hobbing spindle by means of an encoder to a stepper motor on the blank gear mounting shaft.

Is anything else missing besides the mechanical differential to cut helical gears?

Can you read german?

And again: Do you already have an encoder on your hob spindle and a stepper/servo motor on your gear mounting shaft?

And again: Do you know how cutting helical gears was done on your machine originally?

Is anything else missing besides the mechanical differential to cut helical gears?

Can you read german?

And again: Do you already have an encoder on your hob spindle and a stepper/servo motor on your gear mounting shaft?

And again: Do you know how cutting helical gears was done on your machine originally?

Last edit: 04 Sep 2020 15:45 by Aciera. Reason: Clarification

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4621

- Thank you received: 2045

04 Sep 2020 16:44 - 04 Sep 2020 17:14 #180707

by Aciera

Replied by Aciera on topic hobbing helical gear

Attachments:

Last edit: 04 Sep 2020 17:14 by Aciera.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4621

- Thank you received: 2045

04 Sep 2020 17:27 - 04 Sep 2020 17:37 #180718

by Aciera

Replied by Aciera on topic hobbing helical gear

Phew! Now, I'm not too bad at math but after a couple hours of research on hobbing helical gears my head is spinning.

My hat is OFF to the people who invented that.

I think I'll let Andy figure that out overnight and wait for him to present his solution (including a GUI).

My hat is OFF to the people who invented that.

I think I'll let Andy figure that out overnight and wait for him to present his solution (including a GUI).

Last edit: 04 Sep 2020 17:37 by Aciera.

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

04 Sep 2020 19:07 #180734

by Henk

Replied by Henk on topic hobbing helical gear

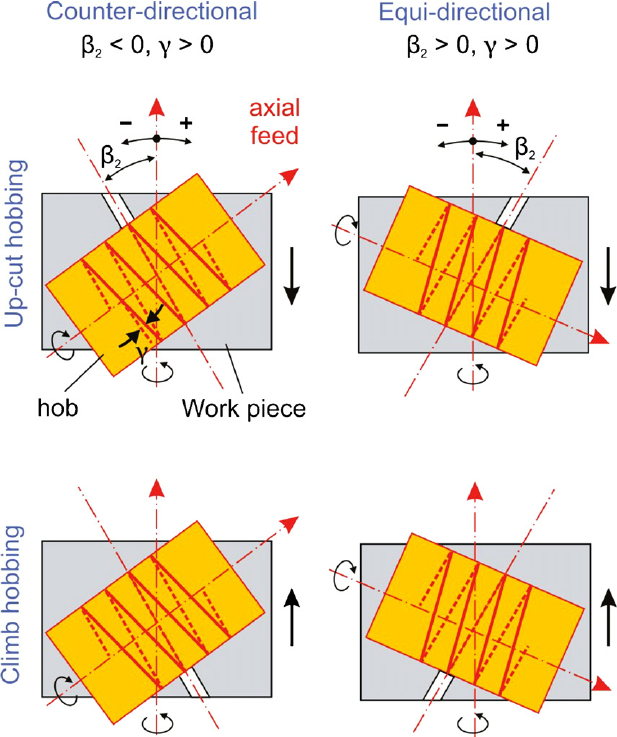

A standard conventional pfauter hobbing machine has two sets of change gears. One to set the number of teeth and one to set the lead of the helical gears. For axial feed there is another set of gears.

When hobbing helical gears, you require additional rotation of the gear blank that is linked to the axial axis movement in order to produce the helix. On my pfauter, it is the z axis. On Andy's machine it is the X axis.

So basically, there needs to be a set ratio between the gear being cut and the hob + another ratio between z axis movement and the gear being cut. The latter is controlled by the lead of the gear being cut.

Axial feed is not necessary for cutting a helical gear on a small scale. At my workplace, we hob large gears sometimes over 10 tons. Sometimes the hob will get blunt before the cut can be completed. In this case it is convenient to shift the hob axially in order to spread the action over the entire length of the hob. This can be done without stopping the cutting process, but generally we don't do that.

Henk

When hobbing helical gears, you require additional rotation of the gear blank that is linked to the axial axis movement in order to produce the helix. On my pfauter, it is the z axis. On Andy's machine it is the X axis.

So basically, there needs to be a set ratio between the gear being cut and the hob + another ratio between z axis movement and the gear being cut. The latter is controlled by the lead of the gear being cut.

Axial feed is not necessary for cutting a helical gear on a small scale. At my workplace, we hob large gears sometimes over 10 tons. Sometimes the hob will get blunt before the cut can be completed. In this case it is convenient to shift the hob axially in order to spread the action over the entire length of the hob. This can be done without stopping the cutting process, but generally we don't do that.

Henk

The following user(s) said Thank You: CORBETT, Aciera

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4621

- Thank you received: 2045

04 Sep 2020 19:20 - 04 Sep 2020 19:22 #180739

by Aciera

Replied by Aciera on topic hobbing helical gear

@Henk

So would it be possible to judge if axial feed is required for these gears?

[edit]

I wonder if larger angles also require axial feed

the gears have 24 teeth at 30 ° and 48 teeth at 60 ° module 2.

So would it be possible to judge if axial feed is required for these gears?

[edit]

I wonder if larger angles also require axial feed

Last edit: 04 Sep 2020 19:22 by Aciera.

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

04 Sep 2020 19:25 #180740

by Henk

Replied by Henk on topic hobbing helical gear

If the hob is long enough to complete the generating of the involute profile it will work. I can't see how axial feed will help at all unless the face width is small.

60 Deg seems unusual. Are these crossed helical gears? I don't have experience with those...

60 Deg seems unusual. Are these crossed helical gears? I don't have experience with those...

The following user(s) said Thank You: Aciera

Please Log in or Create an account to join the conversation.

Time to create page: 0.327 seconds