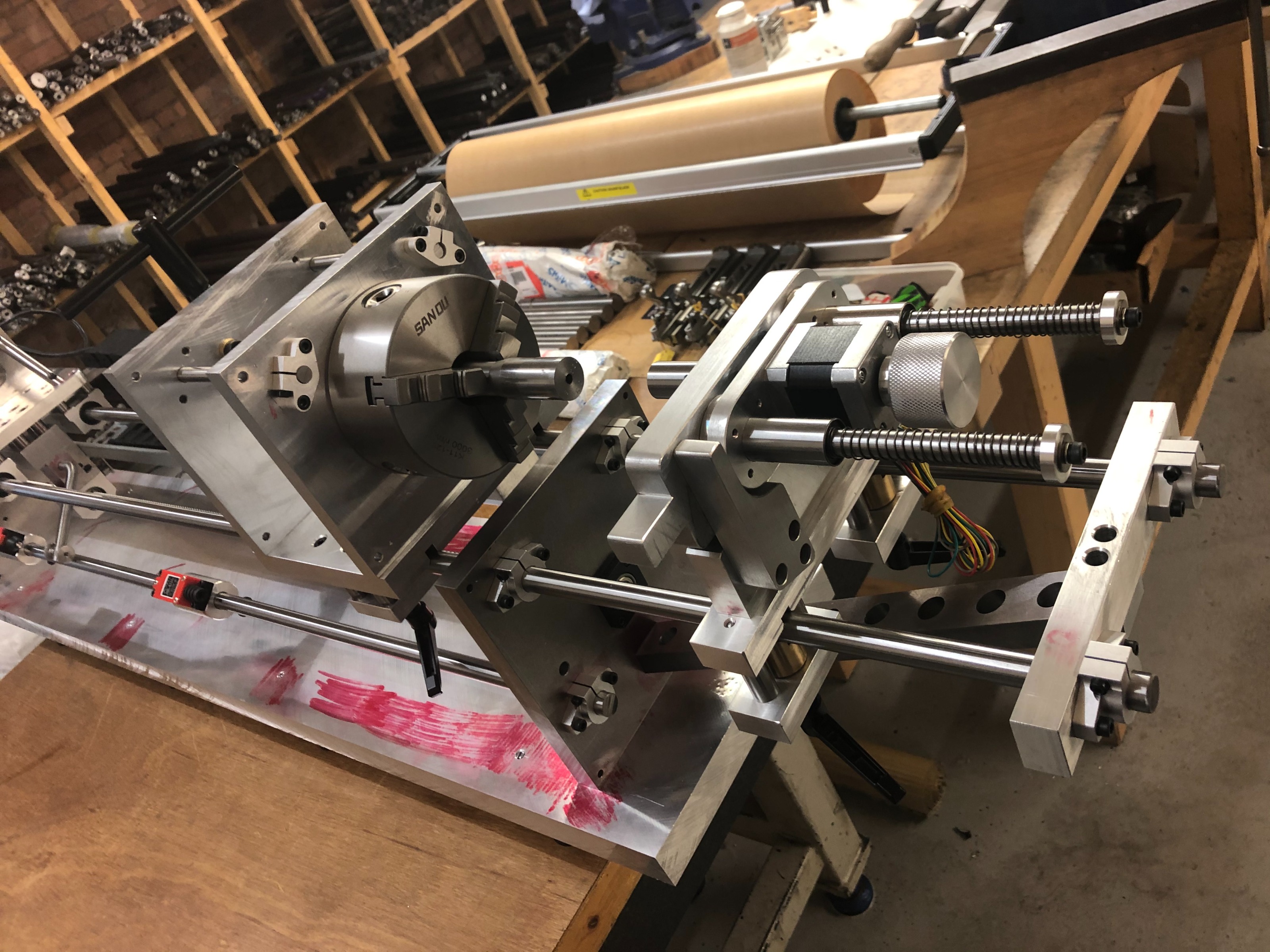

Cut Rifling Machine Help

- SPC89

- Offline

- New Member

-

- Posts: 11

- Thank you received: 4

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19755

- Thank you received: 4587

For your application it is probably worth noting the info hidden in section7.6Taking very small steps tbh. I cant stress enough how new I am to this again. Just started learning how to make buttons in Glade and connecting them up through Hal Config.

This can be used to pass values to a G-code subroutine.

As a concrete example, I have a GUI which has an "action button" which contains the command:

O<turning> call [${turn.x-f}] [${turn.sf-f}] [${turn.cut-f}] [${turn.feed-f}] [${turn.z-f}] [${turn.rad-f}] [${turn.angle-f}] [${turn.tool-s}]This calls a G-code programme, passing the values of various Glade "HAL_Spinbutton" controls to the G-code as paramenters #1, #3 etc.

O<turning> sub

; #1 finish diameter

; #2 speed

; #3 depth of cut

; #4 feed/rpm

; #5 finish length

; #6 radius

; #7 angle

; #8 tool numberI think that this is how I would configure your rifling machine, with a G-code subroutine that cuts rifling according to the parameters passed in (such as length, lead, number of grooves etc)

Please Log in or Create an account to join the conversation.

- SPC89

- Offline

- New Member

-

- Posts: 11

- Thank you received: 4

G21 G90 G40

#201=482.0 (BARREL LENTH)

#202=203.2 (TWIST RATE)

#203=25.0 (ADDITIONAL LENTH)

#204=1.0 (RAISE HEIGHT)

#205=2 (NUMBER OF CYCLES)

#105=[360/#202] (DEG PER MM)

#106=[#201+#203+#203] (FINAL LENGTH)

#107=[#106*#105] (FINAL TWIST)

O100 DO

G0 Z-25.0 X0 (FIRST POSITION)

G1 Z#106 X#107 F600.00 (FIRST CUT)

G1 Z-25.0 X0.0 (FIRST RETURN)

G0 X90.0 (ROTATE 90 FOR SECOND CUT)

G1 Z#106 X[#107+90] F6000. (SECOND CUT)

G1 Z-25.0 X90 (SECOND RETURN RETURN)

G0 x180.0 (ROTATE 90 FOR THIRD CUT)

G1 Z#106 X[#107+180] F6000. (THIRD CUT)

G1 Z-25.0 X180 (THIRD RETURN)

G0 x270.0 (ROTATE 90 FOR FORTH CUT)

G1 Z#106 X[#107+270.0] F6000. (FORTH CUT)

G1 Z-25.0 X270.0 (FORTH RETURN)

G0 x0 (ROTATE 90 FOR FIRST CUT)

G91

G1 Y#204

G90

#205=[#205-1]

O100 WHILE[#205 GT 0]

M30We have tried this and technically it will rifle something but I'm not too sure how consistent the rotation axis of the tool is locked in with the carriage travel along the barrel. Plus setting the tool zero on the barrel points is not easy as such.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19755

- Thank you received: 4587

Personally I would have configured the axes as X and A or maybe Z and C, but that has no bearing on basic functions. Though in either case there is some question about feed-rate calculations. It is probably better to use inverse-time feed rate and calculate a cycle time based purely on barrel length. But that is a detail for later.

For maintainability it might be good to switch internally to named parameters:

#<B_LENGTH>If calling the routine from an action button in the GUI the numbers come in on #1, #2 etc. It's probably best to load the internal parameters from those immediately. Though there is the option for the routine to "pull" the values rather than have them "pushed"

#<B_LENGTH> = #<_hal[rifling-gui.barrel-length-f]>Please Log in or Create an account to join the conversation.

- SPC89

- Offline

- New Member

-

- Posts: 11

- Thank you received: 4

Agree as well, deff start to name the parameters for what they represent and guessing like you said, be simpler to connect them up to the GUI. Still got loads to learn there.

Plan of attack is to get the program running well and fairly refined to the finished article and then try and connect the parameters to a GUI.

Also got to try and put a pause button in the program to stop the machine at a very specific point to use a dia-test gauge to measure the depth of rifling and then a resume button to continue on from where it is.

On a separate note i have wrote down a flo chart, as such, for my self to understand how i want the machine to operate and be a sort of instructions guide for new users. Ill post it on here when i have a chance.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19755

- Thank you received: 4587

i've been talking to some senior programmers here and they recon we can minimize the program even further with a few "if" "GOTO" and "while statements, if Linux CNC can run them ?

Yes: linuxcnc.org/docs/2.8/html/gcode/o-code.html

Also got to try and put a pause button in the program to stop the machine at a very specific point to use a dia-test gauge to measure the depth of rifling and then a resume button to continue on from where it is.

That sounds like a job for the M0 code: linuxcnc.org/docs/2.8/html/gcode/m-code.html#mcode:m0-m1

Please Log in or Create an account to join the conversation.

- fc60

- Offline

- Premium Member

-

- Posts: 124

- Thank you received: 9

Back to the machining process...

Is this a "cut" rifling process? Not a button rifling?

If cut, does it have multiple teeth to cut the depth in one pass?

Does it cut all the grooves in one pass; or, one at a time?

If single groove cut, how is the cutter returned to the beginning of the part?

This project is most interesting to me and I have been following it closely.

Cheers,

Dave

Please Log in or Create an account to join the conversation.

- SPC89

- Offline

- New Member

-

- Posts: 11

- Thank you received: 4

Yes it is a cutting process. The tool is removing about 0.0001 every pass it makes. Once it has done a cycle of grooves say 4 it then gets raised by a mechanism that rotates a screw in the tool that pushes on a wedge that raises the cutter up.

A rifling button doesn't cut it swages the metal to the right shape. Puts alot of stress in the metal so we heat treat it afterwards.

below is a cut rifling tool we use on our machines. A piece of carbide is used to do the cutting work and ground up with correct angles for any given twist as such.

Attachments:

Please Log in or Create an account to join the conversation.

- SPC89

- Offline

- New Member

-

- Posts: 11

- Thank you received: 4

They make excellent barrels blanks!!!!!!

Bartlein Barrels Rifling Machine - YouTube

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19755

- Thank you received: 4587

The video seems to indicate that the tool is engaged with a separate mechanism that tweaks the screw to add feed.Yes it is a cutting process. The tool is removing about 0.0001 every pass it makes. Once it has done a cycle of grooves say 4 it then gets raised by a mechanism that rotates a screw in the tool that pushes on a wedge that raises the cutter up.

It would also be possible to have a motor coaxial with the indexing / rotating motor permanently engaged with the adjusting scew. The secret to making that work would be CNC, you would rotate both motors the same amount to index and twist, and then only move one to feed.

But simply engaging with a fixed "tweaker" isn't a bad solution.

Please Log in or Create an account to join the conversation.