Lathe G2/G3 arc move path inaccuracy

- agdeutschman

- Offline

- New Member

-

Less

More

- Posts: 10

- Thank you received: 0

28 Feb 2023 21:04 #265615

by agdeutschman

Replied by agdeutschman on topic Lathe G2/G3 arc move path inaccuracy

andypugh, thanks for sketching out and verifying!

I will attempt solutions 1 and 2 tonight and measure tomorrow morning.

Thanks!

I will attempt solutions 1 and 2 tonight and measure tomorrow morning.

Thanks!

Please Log in or Create an account to join the conversation.

- agdeutschman

- Offline

- New Member

-

Less

More

- Posts: 10

- Thank you received: 0

01 Mar 2023 14:53 #265656

by agdeutschman

Replied by agdeutschman on topic Lathe G2/G3 arc move path inaccuracy

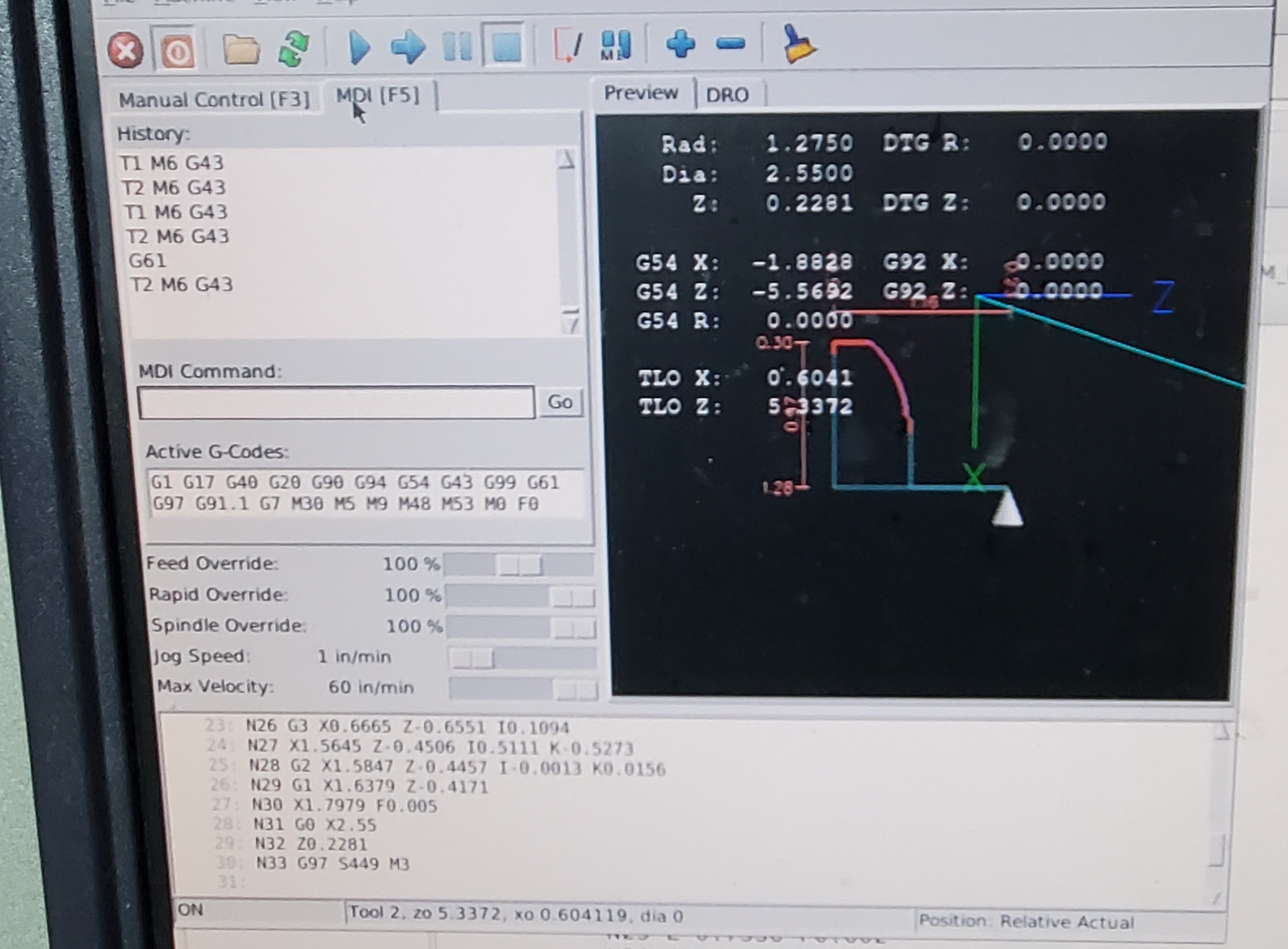

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19798

- Thank you received: 4608

01 Mar 2023 17:09 #265661

by andypugh

Replied by andypugh on topic Lathe G2/G3 arc move path inaccuracy

I am running out of ideas.

Maybe you could log the XZ position with HALscope, then plot the points to see what the actual path is? Or have you done something equivalent to this?

Maybe you could log the XZ position with HALscope, then plot the points to see what the actual path is? Or have you done something equivalent to this?

Please Log in or Create an account to join the conversation.

- agdeutschman

- Offline

- New Member

-

Less

More

- Posts: 10

- Thank you received: 0

01 Mar 2023 17:42 - 01 Mar 2023 18:01 #265664

by agdeutschman

Replied by agdeutschman on topic Lathe G2/G3 arc move path inaccuracy

I took a slow motion video of the X,Z coordinates on the preview tab while running the program. I made a X,Z point cloud from the video and applied a best fit arc in CAD. The arc radius measured .734". This with a .016" insert radius should yield .750". I zipped and attached point cloud data with both G64 and G61 evoked.

Are the coordinates displayed in linuxcnc a real time representation of the TCP?

Thanks!

Are the coordinates displayed in linuxcnc a real time representation of the TCP?

Thanks!

Last edit: 01 Mar 2023 18:01 by agdeutschman. Reason: grammar

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19798

- Thank you received: 4608

01 Mar 2023 21:19 #265673

by andypugh

Maybe try repeating the procedure with actual / feedback position displayed?

Are you 100% sure that your Z scaling is correct? (I imagine that if it wasn't you would have noticed before now) but I have been caught out once by a 5tpi screw that I thought was 5mm pitch.

(Though I just tried dividing the Z positions by 1.016 in the sketch, and it made the radius .7226, which is even smaller than you are seeing?)

Replied by andypugh on topic Lathe G2/G3 arc move path inaccuracy

They can be, you have the choice of displaying commanded or actual position.Are the coordinates displayed in linuxcnc a real time representation of the TCP?

Maybe try repeating the procedure with actual / feedback position displayed?

Are you 100% sure that your Z scaling is correct? (I imagine that if it wasn't you would have noticed before now) but I have been caught out once by a 5tpi screw that I thought was 5mm pitch.

(Though I just tried dividing the Z positions by 1.016 in the sketch, and it made the radius .7226, which is even smaller than you are seeing?)

Please Log in or Create an account to join the conversation.

- agdeutschman

- Offline

- New Member

-

Less

More

- Posts: 10

- Thank you received: 0

01 Mar 2023 21:39 #265677

by agdeutschman

Replied by agdeutschman on topic Lathe G2/G3 arc move path inaccuracy

Thanks, I will re-attempt using feedback position.

I feel confident in the Z scaling because my Z-lengths are all well within tolerance over dozens of parts. It wouldn't hurt to put a travel dial indicator on the Z axis and test though so I will try it.

I feel confident in the Z scaling because my Z-lengths are all well within tolerance over dozens of parts. It wouldn't hurt to put a travel dial indicator on the Z axis and test though so I will try it.

Please Log in or Create an account to join the conversation.

Time to create page: 0.131 seconds