tool radius compensation

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 495

- Thank you received: 209

28 Feb 2023 15:50 - 28 Feb 2023 15:56 #265574

by MaHa

Replied by MaHa on topic tool radius compensation

This way you can use tooltable and compensate wear, without G41/G42

#5410 is diameter of loaded tool.

Just remembered G64. If there is not something like 'G64 P.005' , it may give unwanted results

#5410 is diameter of loaded tool.

Just remembered G64. If there is not something like 'G64 P.005' , it may give unwanted results

G17 G21 G40 G90 G94

T1 M6

G54 S5000 M3 F800

G0 Z30

X0 Y0

Z10

G1 Z0

G1 X[10 - [#5410 / 2]]

G2 X[10 - [#5410 / 2]] Y0 I-[10 - [#5410 / 2]] J0 Z-5 P5

G3 X[10 - [#5410 / 2]] Y0 I-[10 - [#5410 / 2]] J0

G1 X0 Y0

G0Z30

M30

Last edit: 28 Feb 2023 15:56 by MaHa.

Please Log in or Create an account to join the conversation.

- Routercnc

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

28 Feb 2023 18:30 #265587

by Routercnc

Replied by Routercnc on topic tool radius compensation

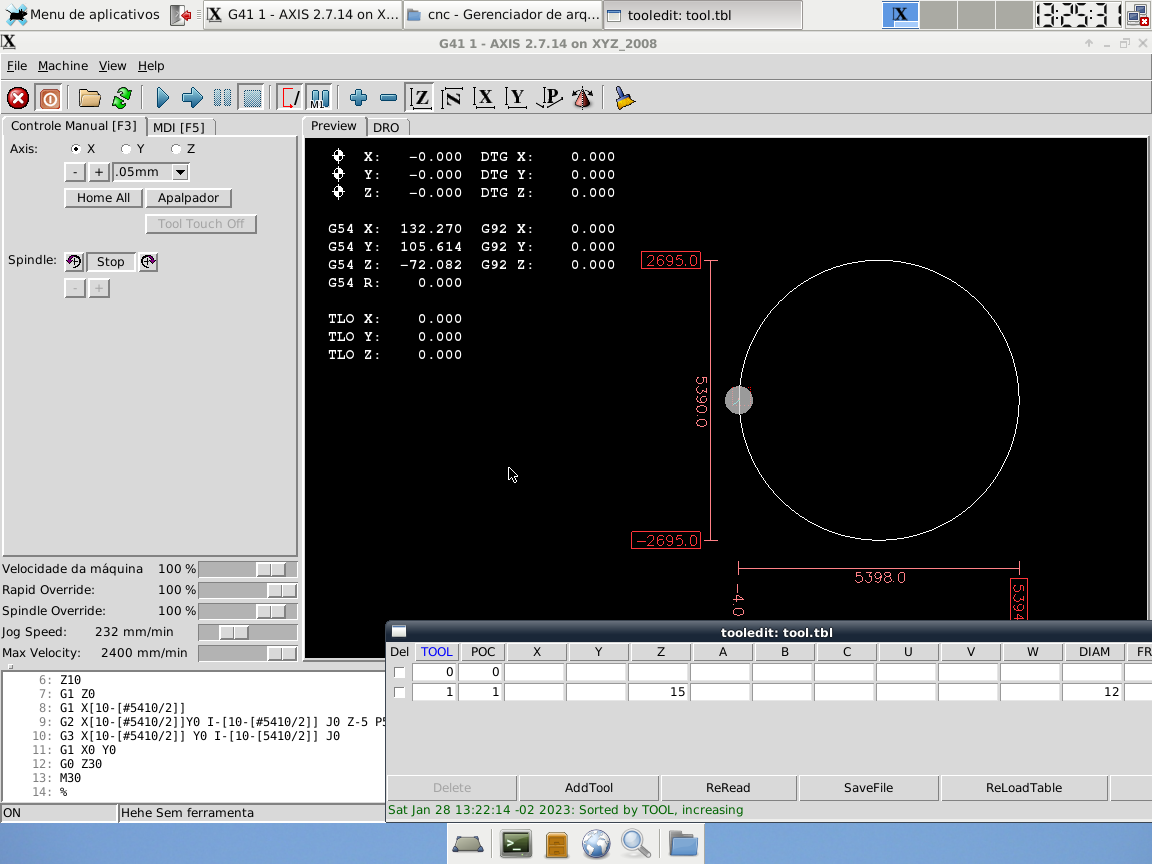

I tested this program, but the diameter was huge..

I changed the cutter from 12mm to 10mm, the tool diameter compensation worked..

I changed the cutter from 12mm to 10mm, the tool diameter compensation worked..

Please Log in or Create an account to join the conversation.

- Routercnc

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

28 Feb 2023 18:32 #265589

by Routercnc

Replied by Routercnc on topic tool radius compensation

Attachments:

Please Log in or Create an account to join the conversation.

- Routercnc

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

28 Feb 2023 18:37 #265592

by Routercnc

Replied by Routercnc on topic tool radius compensation

I have another question... does linuxcnc interpret a Macro program?

I use this program on the Fanuc command.

N50T1(RIGHT SIDE RUNNER MILLER DAY 50MM)

N55M6

N60G54S763F450M3

N65T1(NEXT TOOL)

N70G0X109.771Y108.998M8

N75G43G0Z10.D1H1

N80#1=0(INITIAL Z)

N85#2=-119.(FINAL Z)

N90#3=3.4(DEPTH CUT)

N95#4=[#1-#3]

N100G1Z#4

N105WHILE[#4LE#2]DO1

N110G1X98.999Y71.468

N115G2X98.999Y-71.468R122.1

N120G1X110.519Y-97.078

N125G3X110.519Y97.078R147.1F1000

N130G1X109.771Y108.998F450

N135G1X103.088Y104.935

N140G1X82.029Y58.119

N145G1X76.40Y59.3

N150G3X76.4Y31.3R14.

N155G1X62.816Y39.620

N160G1X64.1Y0

N165G1X62.816Y-39.620

N170G1X76.40Y-31.3

N175G3X76.40Y-59.3R14.

N180G1X82.029Y-58.119

N185G1X95.434Y-87.898

N190G1X103.088Y104.935

N195G1X109,771Y108,998

N200#4=#4-#3

N205END1

N210G0Z10.

N220G53G0Z0H0M5

I use this program on the Fanuc command.

N50T1(RIGHT SIDE RUNNER MILLER DAY 50MM)

N55M6

N60G54S763F450M3

N65T1(NEXT TOOL)

N70G0X109.771Y108.998M8

N75G43G0Z10.D1H1

N80#1=0(INITIAL Z)

N85#2=-119.(FINAL Z)

N90#3=3.4(DEPTH CUT)

N95#4=[#1-#3]

N100G1Z#4

N105WHILE[#4LE#2]DO1

N110G1X98.999Y71.468

N115G2X98.999Y-71.468R122.1

N120G1X110.519Y-97.078

N125G3X110.519Y97.078R147.1F1000

N130G1X109.771Y108.998F450

N135G1X103.088Y104.935

N140G1X82.029Y58.119

N145G1X76.40Y59.3

N150G3X76.4Y31.3R14.

N155G1X62.816Y39.620

N160G1X64.1Y0

N165G1X62.816Y-39.620

N170G1X76.40Y-31.3

N175G3X76.40Y-59.3R14.

N180G1X82.029Y-58.119

N185G1X95.434Y-87.898

N190G1X103.088Y104.935

N195G1X109,771Y108,998

N200#4=#4-#3

N205END1

N210G0Z10.

N220G53G0Z0H0M5

Please Log in or Create an account to join the conversation.

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 495

- Thank you received: 209

28 Feb 2023 19:41 #265604

by MaHa

Replied by MaHa on topic tool radius compensation

If you try this with 'sem ferramenta' , but #5410 is only usable with loaded tool. I have a few parametric routines built this way and it works.

*

I would change following in the Macro and try:

*

I would change following in the Macro and try:

- G94 is missing (feed per minute)

- N105WHILE[#4LE#2]DO1 to o105 WHILE[#4 LE #2]

- N205END1 to o105 ENDWHILE

- N220G53G0Z0H0M5 to N220 G53 G0 Z0 G49 M5

- Normally #1 to #30 are used and overwritten in subroutines, as they are global. I would name numbered parameters outside this range.

Please Log in or Create an account to join the conversation.

- cakeslob

- Offline

- Platinum Member

-

Less

More

- Posts: 922

- Thank you received: 275

01 Mar 2023 00:35 #265626

by cakeslob

Replied by cakeslob on topic tool radius compensation

Hey, someone in another thread had the same issue the other day

forum.linuxcnc.org/38-general-linuxcnc-q...thout-gouging#264366

question, do you use diameter control with your fanuc controller? generally I use wear compensation with 10% of diameter with lead in arc/length, and never have issues. Im wondering how full diameter control works with the same parameters on fanuc, or if it will give the same issue as linuxcnc

I get the sense that using diameter compensation has fallen out of favor compared to wear compensation, or at least it seems uncommon compared to wear

forum.linuxcnc.org/38-general-linuxcnc-q...thout-gouging#264366

question, do you use diameter control with your fanuc controller? generally I use wear compensation with 10% of diameter with lead in arc/length, and never have issues. Im wondering how full diameter control works with the same parameters on fanuc, or if it will give the same issue as linuxcnc

I get the sense that using diameter compensation has fallen out of favor compared to wear compensation, or at least it seems uncommon compared to wear

Please Log in or Create an account to join the conversation.

- Routercnc

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

01 Mar 2023 16:15 #265657

by Routercnc

Replied by Routercnc on topic tool radius compensation

The machine I work with is a CNC Romi Fanuc command ... I only use tool radius compensation

Please Log in or Create an account to join the conversation.

- Routercnc

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

01 Mar 2023 16:18 #265658

by Routercnc

Replied by Routercnc on topic tool radius compensation

I'm going to study these macros to use in Linuxcnc...

thank you for your attention

thanks

thank you for your attention

thanks

Please Log in or Create an account to join the conversation.

Time to create page: 0.090 seconds