Orientation position problem after run Gcode

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 131

- Thank you received: 8

21 Sep 2023 10:12 #281288

by abdulasis12

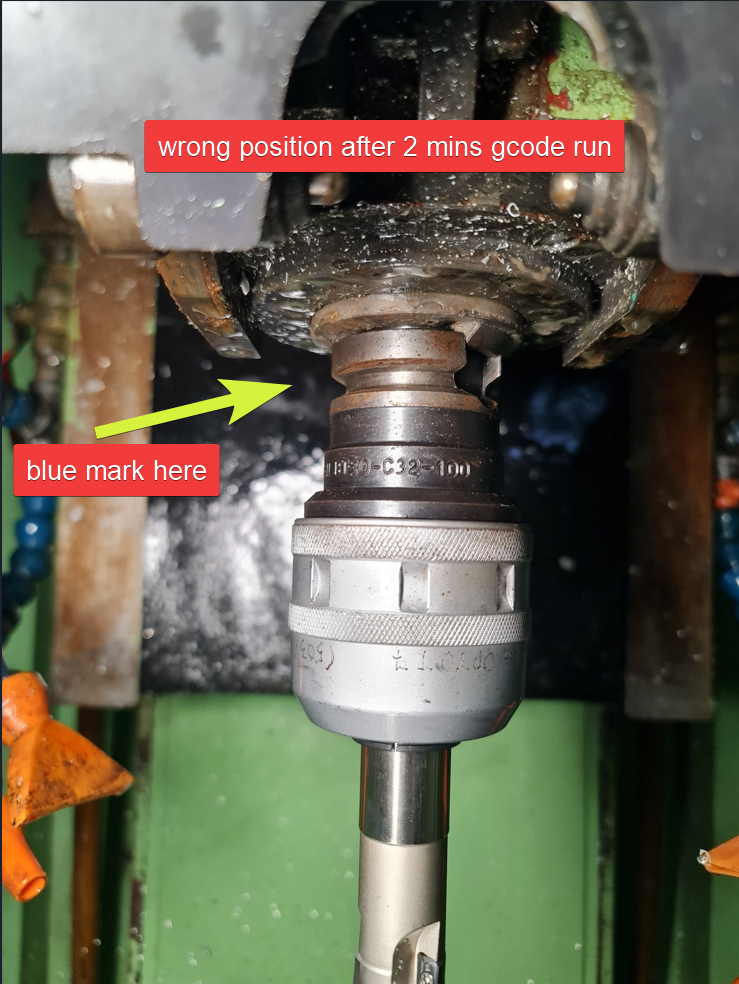

Orientation position problem after run Gcode was created by abdulasis12

Hi

My Board is 7i96s + 7i77

I use Encoder 05 from 7i77 setup to spindle Encoder

First open linuxcnc program I will m3 s200 for index spindle setup.

I try M19 r0 it's move correct position on my mark Blue color on spindle

then I run file .ngc about 2minuts after gcode run completed I type M19 r0 , it's wrong position

why it's wrong position after run Gcode 2mins ?

I think , how for reset index spindle and I will m3 s200 for get new index spindle before ATC every time ?

or any solution for fix this problem ?

My Board is 7i96s + 7i77

I use Encoder 05 from 7i77 setup to spindle Encoder

#*******************

# SPINDLE S

#*******************

setp pid.s.Pgain [SPINDLE_9]P

setp pid.s.Igain [SPINDLE_9]I

setp pid.s.Dgain [SPINDLE_9]D

setp pid.s.bias [SPINDLE_9]BIAS

setp pid.s.FF0 [SPINDLE_9]FF0

setp pid.s.FF1 [SPINDLE_9]FF1

setp pid.s.FF2 [SPINDLE_9]FF2

setp pid.s.deadband [SPINDLE_9]DEADBAND

setp pid.s.maxoutput [SPINDLE_9]MAX_OUTPUT

setp pid.s.error-previous-target true

setp orient-pid.Pgain [SPINDLE_ORIENT]P

setp orient-pid.Igain [SPINDLE_ORIENT]I

setp orient-pid.Dgain [SPINDLE_ORIENT]D

setp orient-pid.bias [SPINDLE_ORIENT]BIAS

setp orient-pid.FF0 [SPINDLE_ORIENT]FF0

setp orient-pid.FF1 [SPINDLE_ORIENT]FF1

setp orient-pid.FF2 [SPINDLE_ORIENT]FF2

setp orient-pid.deadband [SPINDLE_ORIENT]DEADBAND

setp orient-pid.maxoutput [SPINDLE_ORIENT]MAX_OUTPUT

setp orient-pid.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable <=> orient-pid.index-enable

net spindle-motion-enable spindle.0.on => pid.s.enable => spindle-enable-or.in0

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-vel-output pid.s.output orient-mux.in0

net spindle-output <= orient-mux.out

# ---PWM Generator signals/setup---

setp hm2_7i96s.0.7i77.0.1.analogout5-scalemax [SPINDLE_9]OUTPUT_SCALE

setp hm2_7i96s.0.7i77.0.1.analogout5-minlim [SPINDLE_9]OUTPUT_MIN_LIMIT

setp hm2_7i96s.0.7i77.0.1.analogout5-maxlim [SPINDLE_9]OUTPUT_MAX_LIMIT

net spindle-output => hm2_7i96s.0.7i77.0.1.analogout5

net spindle-enable => hm2_7i96s.0.7i77.0.1.spinena

# ---Encoder feedback signals/setup---

setp hm2_7i96s.0.encoder.05.counter-mode 0

setp hm2_7i96s.0.encoder.05.filter 1

setp hm2_7i96s.0.encoder.05.index-invert 0

setp hm2_7i96s.0.encoder.05.index-mask 0

setp hm2_7i96s.0.encoder.05.index-mask-invert 0

setp hm2_7i96s.0.encoder.05.scale [SPINDLE_9]ENCODER_SCALE

net spindle-revs <= hm2_7i96s.0.encoder.05.position

net spindle-vel-fb-rps <= hm2_7i96s.0.encoder.05.velocity

net spindle-index-enable <=> hm2_7i96s.0.encoder.05.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable-or-out spindle-enable-or.in1 spindle-enable-xor.out

net spindle-enable <= spindle-enable-or.out

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

net spindle-is-oriented => spindle.0.is-oriented

net spindle-orient-fault => spindle.0.orient-fault

net spindle-locked <= spindle.0.locked

net spindle-locked => spindle-enable-xor.in0 => orient-mux-or.in1

net orient-angle spindle.0.orient-angle orient.angle

net orient-mode spindle.0.orient-mode orient.mode

net orient-enable spindle.0.orient => orient.enable orient-mux-or.in0 spindle-enable-xor.in1

net orient-mux-sel orient-mux-or.out orient-mux.sel orient-pid.enable

net spindle-revs => orient.position orient-pid.feedback near-spindle.in2

net orient-command orient.command orient-pid.command near-spindle.in1

setp near-spindle.difference 0.01

#setp near-spindle.difference 0.5

#setp near-spindle.difference 1.5

#mux for switching between velocity and position pid output for the spindle#

net spindle-pos-output orient-pid.output orient-mux.in1

net spindle-near near-spindle.out => debounce.0.0.in

setp debounce.0.delay 20

#setp debounce.0.delay 50

net spindle-is-oriented-and0 <= debounce.0.0.out

net spindle-is-oriented-and0 => spindle-is-oriented-and.in0

net orient-enable => spindle-is-oriented-and.in1

net spindle-is-oriented-edge <= spindle-is-oriented-and.out

net spindle-is-oriented-edge => edge.0.in

net spindle-is-oriented <= edge.0.out

# rising edge

#setp edge.0.in-edge false

setp edge.0.in-edge true

# only rising edge

#setp edge.0.both false

setp edge.0.both true

#output pulse length

setp edge.0.out-width-ns 10000000

#home the spindle during first revolution

sets spindle-index-enable true

#fault on unhomed spindle

#net spindle-orient-fault <= spindle.0.index-enablenet spindle-orient-fault <= spindle.0.index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed trueFirst open linuxcnc program I will m3 s200 for index spindle setup.

I try M19 r0 it's move correct position on my mark Blue color on spindle

then I run file .ngc about 2minuts after gcode run completed I type M19 r0 , it's wrong position

why it's wrong position after run Gcode 2mins ?

I think , how for reset index spindle and I will m3 s200 for get new index spindle before ATC every time ?

or any solution for fix this problem ?

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4628

- Thank you received: 2049

21 Sep 2023 12:02 #281297

by Aciera

Replied by Aciera on topic Orientation position problem after run Gcode

Sounds like your spindle orientation is maybe not setup correctly.

For example you have 'orient-mux-or' component in your hal but I don't see the 'orient-mux-or.sel' used in the section you posted. Doesn't necessarily mean it's a problem but might be.

For example you have 'orient-mux-or' component in your hal but I don't see the 'orient-mux-or.sel' used in the section you posted. Doesn't necessarily mean it's a problem but might be.

The following user(s) said Thank You: abdulasis12

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 131

- Thank you received: 8

21 Sep 2023 13:10 #281303

by abdulasis12

This tight ?

Replied by abdulasis12 on topic Orientation position problem after run Gcode

Sounds like your spindle orientation is maybe not setup correctly.

For example you have 'orient-mux-or' component in your hal but I don't see the 'orient-mux-or.sel' used in the section you posted. Doesn't necessarily mean it's a problem but might be.

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS num_dio=34

loadrt hostmot2

loadusr io

loadrt hm2_eth board_ip="10.10.10.10" config=" num_encoders=6 num_pwmgens=0 num_stepgens=5 sserial_port_0=000000"

setp hm2_7i96s.0.watchdog.timeout_ns 10000000

loadrt pid names=pid.x,pid.y,pid.z,pid.a,pid.s,orient-pid

loadrt orient names=orient

loadrt mux2 names=orient-mux,z-limit-mux

loadrt or2 names=orient-mux-or,spindle-enable-or,atc-out-or,cam-out-or

loadrt xor2 names=spindle-enable-xor

loadrt near names=near-spindle

loadrt debounce cfg=1

loadrt edge count=1

loadrt and2 names=spindle-is-oriented-and,probe-and

loadrt bitwise names=probe-comp

loadrt conv_s32_u32 names=conv1

This tight ?

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 131

- Thank you received: 8

21 Sep 2023 13:13 #281304

by abdulasis12

Replied by abdulasis12 on topic Orientation position problem after run Gcode

my hall file :

# Generated by PNCconf at Tue Feb 18 06:20:29 2020

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS num_dio=34

loadrt hostmot2

loadusr io

loadrt hm2_eth board_ip="10.10.10.10" config=" num_encoders=6 num_pwmgens=0 num_stepgens=5 sserial_port_0=000000"

setp hm2_7i96s.0.watchdog.timeout_ns 10000000

loadrt pid names=pid.x,pid.y,pid.z,pid.a,pid.s,orient-pid

loadrt orient names=orient

loadrt mux2 names=orient-mux,z-limit-mux

loadrt or2 names=orient-mux-or,spindle-enable-or,atc-out-or,cam-out-or

loadrt xor2 names=spindle-enable-xor

loadrt near names=near-spindle

loadrt debounce cfg=1

loadrt edge count=1

loadrt and2 names=spindle-is-oriented-and,probe-and

loadrt bitwise names=probe-comp

loadrt conv_s32_u32 names=conv1

addf hm2_7i96s.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf z-limit-mux servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.a.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf orient-pid.do-pid-calcs servo-thread

addf hm2_7i96s.0.write servo-thread

setp hm2_7i96s.0.dpll.01.timer-us -50

setp hm2_7i96s.0.stepgen.timer-number 1

addf orient servo-thread

addf orient-mux servo-thread

addf orient-mux-or servo-thread

addf spindle-enable-or servo-thread

addf spindle-enable-xor servo-thread

addf near-spindle servo-thread

addf debounce.0 servo-thread

addf edge.0 servo-thread

addf spindle-is-oriented-and servo-thread

addf probe-and servo-thread

addf conv1 servo-thread

addf atc-out-or servo-thread

addf cam-out-or servo-thread

# motion controller IO:

net tool-change-confirmed motion.digital-out-00 => iocontrol.0.tool-changed

# switch atc ranges from toolchange subroutine

net z-limit-select motion.digital-out-01 => z-limit-mux.sel

# spindle index pulse wired to motion controller

net spindle-index-enable => motion.digital-in-01

# atc-home

net atc-home motion.digital-in-16 <= hm2_7i96s.0.7i77.0.0.input-07

net atc-home => hm2_7i96s.0.7i77.0.0.output-02

# atc-range

net atc-range <= hm2_7i96s.0.7i77.0.0.input-06

# atc-direction

net atc-direction motion.digital-out-04 => hm2_7i96s.0.7i77.0.0.output-03

# atc-run

net atc-run motion.digital-out-03 => hm2_7i96s.0.7i77.0.0.output-04

#net atc-run motion.digital-out-03 => atc-out-or.in0

#net atc-out-or atc-out-or.out => hm2_7i96s.0.7i77.0.0.output-04

# atc-dec

#net atc-dec atc-out-or.in1 <= hm2_7i96s.0.7i77.0.0.input-16

# encoder atc

net atc-enc-1 motion.digital-in-11 <= hm2_7i96s.0.7i77.0.0.input-11

net atc-enc-2 motion.digital-in-12 <= hm2_7i96s.0.7i77.0.0.input-12

net atc-enc-3 motion.digital-in-13 <= hm2_7i96s.0.7i77.0.0.input-13

net atc-enc-4 motion.digital-in-14 <= hm2_7i96s.0.7i77.0.0.input-14

net atc-enc-5 motion.digital-in-10 <= hm2_7i96s.0.7i77.0.0.input-15

# optical probe interface wired to motion controller for atc probe activation

#net probe-touch-reset motion.digital-out-02 <= hm2_7i96s.0.7i77.0.0.output-01

#net probe-touch-in motion.digital-in-18

#net probe-touch-error motion.digital-in-19

# --- ESTOP-OUT ---

#net estop-out => hm2_7i96s.0.7i77.0.0.output-00

# --- ESTOP-EXT ---

net estop-ext <= hm2_7i96s.0.7i77.0.0.input-31

# --- ESTOP-EXT ---

#net estop-ext <= hm2_7i96s.0.7i77.0.0.input-01

# --- SPINDLE-ENABLE ---

#net spindle-enable => hm2_7i96s.0.ssr.00.out-00

# --- MACHINE-IS-ENABLED ---Spindle_On

net machine-is-enabled => hm2_7i96s.0.7i77.0.0.output-00

# --- MACHINE-IS-ENABLED ---Servo_OUT

#net machine-is-enabled => hm2_7i96s.0.7i77.0.0.output-09

# --- MACHINE-IS-ENABLED ---Servo A_OUT

#net machine-is-enabled => hm2_7i96s.0.7i77.0.0.output-15

# --- MACHINE-IS-ENABLED ---Z brake

#net machine-is-enabled => hm2_7i96s.0.7i77.0.0.output-01

# --- COOLANT-MIST ---

#net coolant-mist => hm2_7i96s.0.7i77.0.0.output-06

#net coolant-mist => hm2_7i96s.0.7i77.0.0.output-00

# --- COOLANT-FLOOD ---

net coolant-flood => hm2_7i96s.0.7i77.0.0.output-05

# --- MAX-X ---

net max-x <= hm2_7i96s.0.7i77.0.0.input-01-not

# --- MIN-X ---

net min-x <= hm2_7i96s.0.7i77.0.0.input-00-not

# --- MAX-Y ---

net max-y <= hm2_7i96s.0.7i77.0.0.input-03-not

# --- MIN-Y ---

net min-y <= hm2_7i96s.0.7i77.0.0.input-02-not

# --- MAX-Z ---

net max-z <= hm2_7i96s.0.7i77.0.0.input-05-not

# --- MIN-Z ---

net min-z <= hm2_7i96s.0.7i77.0.0.input-04-not

# --- HOME-X ---

net home-x <= hm2_7i96s.0.7i77.0.0.input-08

# --- HOME-Y ---

net home-y <= hm2_7i96s.0.7i77.0.0.input-09

# --- HOME-Z ---

#net home-z <= hm2_7i96s.0.7i77.0.0.input-10

# --- HOME-A ---

#net a-home-sw <= hm2_7i96s.0.7i77.0.0.input-31-not

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp hm2_7i96s.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i96s.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i96s.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i96s.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i96s.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i96s.0.stepgen.00.step_type 0

setp hm2_7i96s.0.stepgen.00.control-type 1

setp hm2_7i96s.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_7i96s.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => hm2_7i96s.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i96s.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_7i96s.0.stepgen.00.enable

# ---setup home / limit switch signals---

net home-x => joint.0.home-sw-in

net min-x => joint.0.neg-lim-sw-in

net max-x => joint.0.pos-lim-sw-in

# ---Encoder feedback signals/setup---

setp hm2_7i96s.0.encoder.00.counter-mode 0

setp hm2_7i96s.0.encoder.00.filter 1

setp hm2_7i96s.0.encoder.00.index-invert 0

setp hm2_7i96s.0.encoder.00.index-mask 0

setp hm2_7i96s.0.encoder.00.index-mask-invert 0

setp hm2_7i96s.0.encoder.00.scale [JOINT_0]ENCODER_SCALE

#net x-pos-fb <= hm2_7i96s.0.encoder.00.position

net x-vel-fb <= hm2_7i96s.0.encoder.00.velocity

net x-pos-fb => joint.0.motor-pos-fb

net x-index-enable joint.0.index-enable <=> hm2_7i96s.0.encoder.00.index-enable

net x-pos-rawcounts <= hm2_7i96s.0.encoder.00.rawcounts

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y.maxerror 0.012700

net y-index-enable => pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-vel-cmd => pid.y.command-deriv

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# Step Gen signals/setup

setp hm2_7i96s.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_7i96s.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_7i96s.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_7i96s.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_7i96s.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_7i96s.0.stepgen.01.step_type 0

setp hm2_7i96s.0.stepgen.01.control-type 1

setp hm2_7i96s.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_7i96s.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output => hm2_7i96s.0.stepgen.01.velocity-cmd

net y-pos-fb <= hm2_7i96s.0.stepgen.01.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => hm2_7i96s.0.stepgen.01.enable

net y-pos-rawcounts <= hm2_7i96s.0.encoder.01.rawcounts

# ---setup home / limit switch signals---

net home-y => joint.1.home-sw-in

net min-y => joint.1.neg-lim-sw-in

net max-y => joint.1.pos-lim-sw-in

# ---Encoder feedback signals/setup---

setp hm2_7i96s.0.encoder.01.counter-mode 0

setp hm2_7i96s.0.encoder.01.filter 1

setp hm2_7i96s.0.encoder.01.index-invert 0

setp hm2_7i96s.0.encoder.01.index-mask 0

setp hm2_7i96s.0.encoder.01.index-mask-invert 0

setp hm2_7i96s.0.encoder.01.scale [JOINT_1]ENCODER_SCALE

#net y-pos-fb <= hm2_7i96s.0.encoder.01.position

net y-vel-fb <= hm2_7i96s.0.encoder.01.velocity

net y-pos-fb => joint.1.motor-pos-fb

net y-index-enable joint.1.index-enable <=> hm2_7i96s.0.encoder.01.index-enable

net y-pos-rawcounts <= hm2_7i96s.0.encoder.01.rawcounts

#*******************

# AXIS Z JOINT 2

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

#net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp hm2_7i96s.0.stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp hm2_7i96s.0.stepgen.02.dirhold [JOINT_2]DIRHOLD

setp hm2_7i96s.0.stepgen.02.steplen [JOINT_2]STEPLEN

setp hm2_7i96s.0.stepgen.02.stepspace [JOINT_2]STEPSPACE

setp hm2_7i96s.0.stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp hm2_7i96s.0.stepgen.02.step_type 0

setp hm2_7i96s.0.stepgen.02.control-type 1

setp hm2_7i96s.0.stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp hm2_7i96s.0.stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.2.motor-pos-cmd

net z-vel-cmd <= joint.2.vel-cmd

net z-output => hm2_7i96s.0.stepgen.02.velocity-cmd

net z-pos-fb <= hm2_7i96s.0.stepgen.02.position-fb

net z-pos-fb => joint.2.motor-pos-fb

net z-enable <= joint.2.amp-enable-out

net z-enable => hm2_7i96s.0.stepgen.02.enable

# ---setup home / limit switch signals---

net atc-range => joint.2.home-sw-in

#net home-z => joint.2.home-sw-in

net min-z => joint.2.neg-lim-sw-in

net max-z => joint.2.pos-lim-sw-in

# switch z-axis soft limits

setp z-limit-mux.in0 [JOINT_2]MAX_LIMIT

setp z-limit-mux.in1 [JOINT_2]MAX_LIMIT_ATC

net z-limit-out <= z-limit-mux.out

# ini.2.max_limit is connectedd in custom_postgui.hal

# ---setup home / limit switch signals---

net a-home-sw => joint.3.home-sw-in

net a-neg-limit => joint.3.neg-lim-sw-in

net a-pos-limit => joint.3.pos-lim-sw-in

#MPG ENC

#setp hm2_7i96s.0.encoder.04.counter-mode 0

#setp hm2_7i96s.0.encoder.04.scale [JOINT_4]ENCODER_SCALE

# ---Encoder feedback signals/setup---

net y-pos-rawcounts <= hm2_7i96s.0.encoder.01.rawcounts

setp hm2_7i96s.0.encoder.02.counter-mode 0

setp hm2_7i96s.0.encoder.02.filter 1

setp hm2_7i96s.0.encoder.02.index-invert 0

setp hm2_7i96s.0.encoder.02.index-mask 0

setp hm2_7i96s.0.encoder.02.index-mask-invert 0

setp hm2_7i96s.0.encoder.02.scale [JOINT_2]ENCODER_SCALE

#net z-pos-fb <= hm2_7i96s.0.encoder.02.position

net z-vel-fb <= hm2_7i96s.0.encoder.02.velocity

net z-pos-fb => joint.2.motor-pos-fb

net z-index-enable joint.2.index-enable <=> hm2_7i96s.0.encoder.02.index-enable

net y-pos-rawcounts <= hm2_7i96s.0.encoder.01.rawcounts

#*******************

# SPINDLE S

#*******************

setp pid.s.Pgain [SPINDLE_9]P

setp pid.s.Igain [SPINDLE_9]I

setp pid.s.Dgain [SPINDLE_9]D

setp pid.s.bias [SPINDLE_9]BIAS

setp pid.s.FF0 [SPINDLE_9]FF0

setp pid.s.FF1 [SPINDLE_9]FF1

setp pid.s.FF2 [SPINDLE_9]FF2

setp pid.s.deadband [SPINDLE_9]DEADBAND

setp pid.s.maxoutput [SPINDLE_9]MAX_OUTPUT

setp pid.s.error-previous-target true

setp orient-pid.Pgain [SPINDLE_ORIENT]P

setp orient-pid.Igain [SPINDLE_ORIENT]I

setp orient-pid.Dgain [SPINDLE_ORIENT]D

setp orient-pid.bias [SPINDLE_ORIENT]BIAS

setp orient-pid.FF0 [SPINDLE_ORIENT]FF0

setp orient-pid.FF1 [SPINDLE_ORIENT]FF1

setp orient-pid.FF2 [SPINDLE_ORIENT]FF2

setp orient-pid.deadband [SPINDLE_ORIENT]DEADBAND

setp orient-pid.maxoutput [SPINDLE_ORIENT]MAX_OUTPUT

setp orient-pid.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable <=> orient-pid.index-enable

net spindle-motion-enable spindle.0.on => pid.s.enable => spindle-enable-or.in0

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-vel-output pid.s.output orient-mux.in0

net spindle-output <= orient-mux.out

# ---PWM Generator signals/setup---

setp hm2_7i96s.0.7i77.0.1.analogout5-scalemax [SPINDLE_9]OUTPUT_SCALE

setp hm2_7i96s.0.7i77.0.1.analogout5-minlim [SPINDLE_9]OUTPUT_MIN_LIMIT

setp hm2_7i96s.0.7i77.0.1.analogout5-maxlim [SPINDLE_9]OUTPUT_MAX_LIMIT

net spindle-output => hm2_7i96s.0.7i77.0.1.analogout5

net spindle-enable => hm2_7i96s.0.7i77.0.1.spinena

# ---Encoder feedback signals/setup---

setp hm2_7i96s.0.encoder.05.counter-mode 0

setp hm2_7i96s.0.encoder.05.filter 1

setp hm2_7i96s.0.encoder.05.index-invert 0

setp hm2_7i96s.0.encoder.05.index-mask 0

setp hm2_7i96s.0.encoder.05.index-mask-invert 0

setp hm2_7i96s.0.encoder.05.scale [SPINDLE_9]ENCODER_SCALE

net spindle-revs <= hm2_7i96s.0.encoder.05.position

net spindle-vel-fb-rps <= hm2_7i96s.0.encoder.05.velocity

net spindle-index-enable <=> hm2_7i96s.0.encoder.05.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable-or-out spindle-enable-or.in1 spindle-enable-xor.out

net spindle-enable <= spindle-enable-or.out

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

net spindle-is-oriented => spindle.0.is-oriented

net spindle-orient-fault => spindle.0.orient-fault

net spindle-locked <= spindle.0.locked

net spindle-locked => spindle-enable-xor.in0 => orient-mux-or.in1

net orient-angle spindle.0.orient-angle orient.angle

net orient-mode spindle.0.orient-mode orient.mode

net orient-enable spindle.0.orient => orient.enable orient-mux-or.in0 spindle-enable-xor.in1

net orient-mux-sel orient-mux-or.out orient-mux.sel orient-pid.enable

net spindle-revs => orient.position orient-pid.feedback near-spindle.in2

net orient-command orient.command orient-pid.command near-spindle.in1

setp near-spindle.difference 0.01

#setp near-spindle.difference 0.5

#setp near-spindle.difference 1.5

#mux for switching between velocity and position pid output for the spindle#

net spindle-pos-output orient-pid.output orient-mux.in1

net spindle-near near-spindle.out => debounce.0.0.in

setp debounce.0.delay 20

#setp debounce.0.delay 50

net spindle-is-oriented-and0 <= debounce.0.0.out

net spindle-is-oriented-and0 => spindle-is-oriented-and.in0

net orient-enable => spindle-is-oriented-and.in1

net spindle-is-oriented-edge <= spindle-is-oriented-and.out

net spindle-is-oriented-edge => edge.0.in

net spindle-is-oriented <= edge.0.out

# rising edge

#setp edge.0.in-edge false

setp edge.0.in-edge true

# only rising edge

#setp edge.0.both false

setp edge.0.both true

#output pulse length

setp edge.0.out-width-ns 10000000

#home the spindle during first revolution

sets spindle-index-enable true

#fault on unhomed spindle

#net spindle-orient-fault <= spindle.0.index-enablenet spindle-orient-fault <= spindle.0.index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-y halui.axis.y.select

net jog-y-pos halui.axis.y.plus

net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

net y-is-homed halui.joint.1.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.2.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-touch-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# --- tool change signals---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4628

- Thank you received: 2049

21 Sep 2023 13:46 #281310

by Aciera

Replied by Aciera on topic Orientation position problem after run Gcode

Would be much better if you could attach the file rather than put the contents in the post.

The following user(s) said Thank You: abdulasis12

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 131

- Thank you received: 8

21 Sep 2023 14:58 #281318

by abdulasis12

Replied by abdulasis12 on topic Orientation position problem after run Gcode

Okay,Would be much better if you could attach the file rather than put the contents in the post.

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4628

- Thank you received: 2049

21 Sep 2023 15:52 #281321

by Aciera

Replied by Aciera on topic Orientation position problem after run Gcode

Ah ok, it's actually an or2 component not a mux2 so that is fine then. I haven't gone over your hal in great detail and debugging spindle orientation can be a difficult task. Doing it remotely is very difficult indeed.

So the first thing I would suggest is to thoroughly test the spindle orient functionality by running the spindle and then do an M19 R0 then run the spindle again and do another M19 R0. You want this to work at least a hundred times using different spindle speeds and directions before moving on to other things.

So the first thing I would suggest is to thoroughly test the spindle orient functionality by running the spindle and then do an M19 R0 then run the spindle again and do another M19 R0. You want this to work at least a hundred times using different spindle speeds and directions before moving on to other things.

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 131

- Thank you received: 8

21 Sep 2023 16:26 #281322

by abdulasis12

Today I try to find this problem what or where to error

I try

m3 s1000 5minuts

recheck m19 r0 it's ok

m3 s2000 5 minuts

m3 s3000 3-4 mins

m3 s4000 4mins

m3 s5000 5 mins

m3 s6000 5mins

m3 s7000 5mins

before go next m3 i will M19 r0 for check , result = good

then I try run gcode about 1:30 - 2 mins

when gcode completed I try M19 r0 it's wrong position Orient.

Maybe I think when gcode run servo motor XYZ and motor water pump start too, Maybe noise in to Encoder05 on 7i77 for made it's error tracking ?

Asis,

Replied by abdulasis12 on topic Orientation position problem after run Gcode

Hi MR.AcieraAh ok, it's actually an or2 component not a mux2 so that is fine then. I haven't gone over your hal in great detail and debugging spindle orientation can be a difficult task. Doing it remotely is very difficult indeed.

So the first thing I would suggest is to thoroughly test the spindle orient functionality by running the spindle and then do an M19 R0 then run the spindle again and do another M19 R0. You want this to work at least a hundred times using different spindle speeds and directions before moving on to other things.Today

Today I try to find this problem what or where to error

I try

m3 s1000 5minuts

recheck m19 r0 it's ok

m3 s2000 5 minuts

m3 s3000 3-4 mins

m3 s4000 4mins

m3 s5000 5 mins

m3 s6000 5mins

m3 s7000 5mins

before go next m3 i will M19 r0 for check , result = good

then I try run gcode about 1:30 - 2 mins

when gcode completed I try M19 r0 it's wrong position Orient.

Maybe I think when gcode run servo motor XYZ and motor water pump start too, Maybe noise in to Encoder05 on 7i77 for made it's error tracking ?

Asis,

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17579

- Thank you received: 5141

21 Sep 2023 18:30 #281326

by PCW

Replied by PCW on topic Orientation position problem after run Gcode

I would set the hm2_7i96s.0 encoder.05.quad-error-enable bit,

do your gcode test and see if hm2_7i96s.encoder.05.quad-error gets set true

Is the spindle encoder differential?

If so, is the 7I77 set for differential inputs?

do your gcode test and see if hm2_7i96s.encoder.05.quad-error gets set true

Is the spindle encoder differential?

If so, is the 7I77 set for differential inputs?

The following user(s) said Thank You: abdulasis12

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 131

- Thank you received: 8

22 Sep 2023 02:04 #281342

by abdulasis12

Yes, My spindle Encoder is Differential.

---- If so, is the 7I77 set for differential inputs?

Hmmm, I not sure , How to recheck ?

Replied by abdulasis12 on topic Orientation position problem after run Gcode

Hi MR.PCWI would set the hm2_7i96s.0 encoder.05.quad-error-enable bit,

do your gcode test and see if hm2_7i96s.encoder.05.quad-error gets set true

Is the spindle encoder differential?

If so, is the 7I77 set for differential inputs?

Yes, My spindle Encoder is Differential.

---- If so, is the 7I77 set for differential inputs?

Hmmm, I not sure , How to recheck ?

Please Log in or Create an account to join the conversation.

Time to create page: 0.449 seconds