Orientation position problem after run Gcode

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

03 Oct 2023 02:40 #282116

by abdulasis12

10 rev move with hand and check in hallshow ,The number about 4096*10= 40,960 +- little (with hand stop position)

I try more..

50 rev with hand yes it's 4096*50 = 204,800 +- little (with hand stop position)

I pretty sure my encoder correct on 1024ppr and 4096 per 1revolution.

If not, there are two possibilities, scaling is wrong or encoder is faulty/miss wired/not counting properly/does not have quadrature outputs/voltage to low/ outputs not able to swing high enough to register/

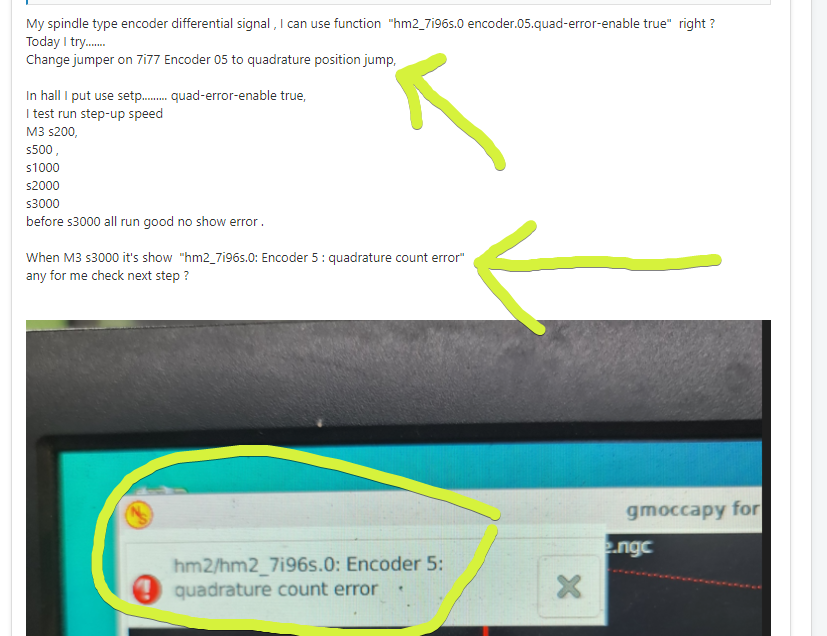

I ever try change jumper from differential to quadrature and use this solution from MR.PCW

Result is

When M3 s3000 it's show "hm2_7i96s.0: Encoder 5 : quadrature count error"

Replied by abdulasis12 on topic Orientation position problem after run Gcode

I try doneTry this:

Machine powered and enabled

Spindle off

watch the spindle encoder count in hal show

make a line on the spindle to have a 0 reference point where the encoder shows 0

turn spindle by hand 10 times

see the encoder count, it is 10 times bigger?

-

Check the spindle encoder scaling, if you have a 1024 PPR encoder, probably scale should be 4096.

In this case after 10 turns you should see 40960

If not, there are two possibilities, scaling is wrong or encoder is faulty/miss wired/not counting properly/does not have quadrature outputs/voltage to low/ outputs not able to swing high enough to register/

10 rev move with hand and check in hallshow ,The number about 4096*10= 40,960 +- little (with hand stop position)

I try more..

50 rev with hand yes it's 4096*50 = 204,800 +- little (with hand stop position)

I pretty sure my encoder correct on 1024ppr and 4096 per 1revolution.

If not, there are two possibilities, scaling is wrong or encoder is faulty/miss wired/not counting properly/does not have quadrature outputs/voltage to low/ outputs not able to swing high enough to register/

I ever try change jumper from differential to quadrature and use this solution from MR.PCW

Result is

When M3 s3000 it's show "hm2_7i96s.0: Encoder 5 : quadrature count error"

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4648

- Thank you received: 2068

03 Oct 2023 06:18 #282130

by Aciera

Replied by Aciera on topic Orientation position problem after run Gcode

Also note that spindle orientation uses an index signal that recurs once per revolution. I don't know if you are getting that from the sensor as well but if that signal looks like the A and B count signals on your scope then I don't think there is not much hope for proper spindle orientation.

Please Log in or Create an account to join the conversation.

- 0x2102

-

- Offline

- Elite Member

-

Less

More

- Posts: 213

- Thank you received: 77

03 Oct 2023 07:21 #282133

by 0x2102

Replied by 0x2102 on topic Orientation position problem after run Gcode

@abdulasis12

I noticed a similar problem with my setup. High speed spindle with encoder (36K rpm). Position would be accurate until I reach a certain rpm - 18000rpm in my case.

In your situation, you might be able to fix it (EMI?). In my case I wrote a simple COMP to reset the spindle Index = 1 or high after I issue an M3 command.

The COMP is waiting for an M3 (the spindle to reach an RPM range where the encoder signal is stable but above your tapping speed.

Hope this makes sense and it might be food for thought.

sets spindle-sync 1

net spindle-sync enable-spindle-index.out => spindle.0.index-enable => hm2_7i95.0.encoder.04.index-enable

net spindle-brake-on spindle.0.brake => enable-spindle-index.brake-on

I noticed a similar problem with my setup. High speed spindle with encoder (36K rpm). Position would be accurate until I reach a certain rpm - 18000rpm in my case.

In your situation, you might be able to fix it (EMI?). In my case I wrote a simple COMP to reset the spindle Index = 1 or high after I issue an M3 command.

The COMP is waiting for an M3 (the spindle to reach an RPM range where the encoder signal is stable but above your tapping speed.

Hope this makes sense and it might be food for thought.

sets spindle-sync 1

net spindle-sync enable-spindle-index.out => spindle.0.index-enable => hm2_7i95.0.encoder.04.index-enable

net spindle-brake-on spindle.0.brake => enable-spindle-index.brake-on

The following user(s) said Thank You: Aciera, abdulasis12

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

04 Oct 2023 01:32 - 04 Oct 2023 01:38 #282230

by abdulasis12

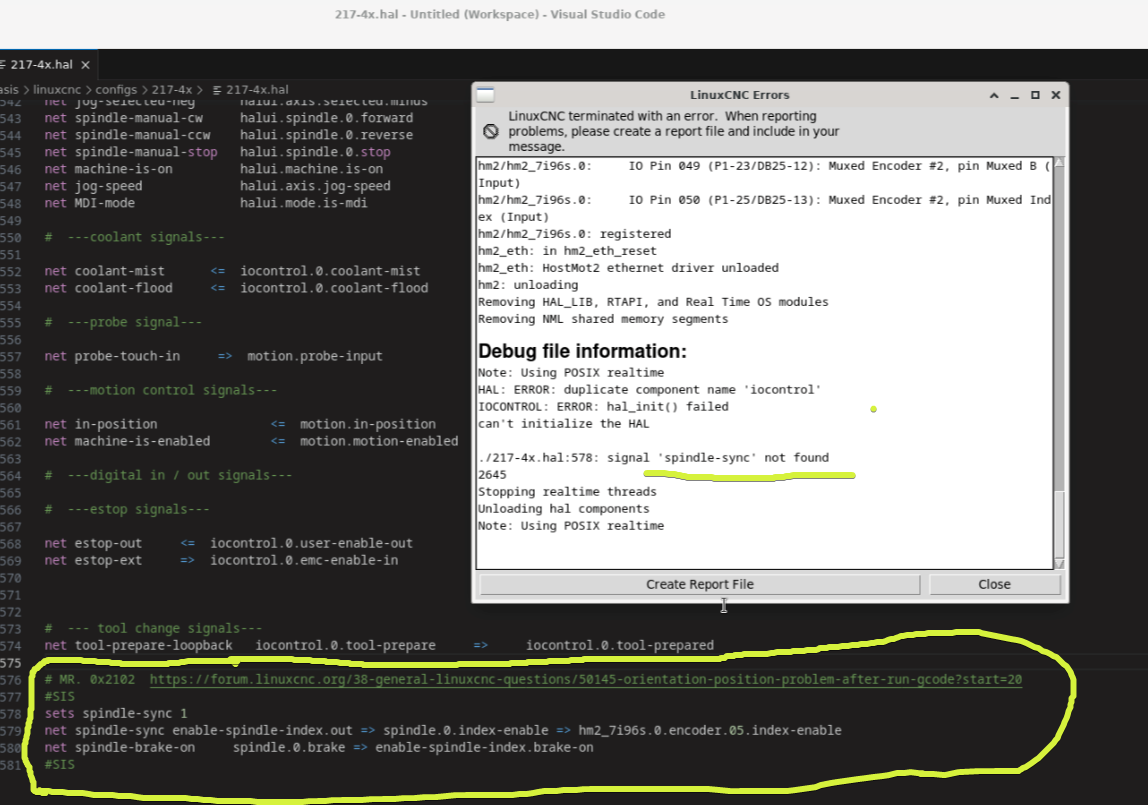

Hi MR. 0x2102

I think I will try your solution, Now I have a problem .

I put your hall and change to my hm2

sets spindle-sync 1

net spindle-sync enable-spindle-index.out => spindle.0.index-enable => hm2_7i96s.0.encoder.05.index-enable

net spindle-brake-on spindle.0.brake => enable-spindle-index.brake-on

Save and run linuxcnc, Show error signal 'spindle-syn not found '

Please give me some advice.

Replied by abdulasis12 on topic Orientation position problem after run Gcode

@abdulasis12

I noticed a similar problem with my setup. High speed spindle with encoder (36K rpm). Position would be accurate until I reach a certain rpm - 18000rpm in my case.

In your situation, you might be able to fix it (EMI?). In my case I wrote a simple COMP to reset the spindle Index = 1 or high after I issue an M3 command.

The COMP is waiting for an M3 (the spindle to reach an RPM range where the encoder signal is stable but above your tapping speed.

Hope this makes sense and it might be food for thought.

sets spindle-sync 1

net spindle-sync enable-spindle-index.out => spindle.0.index-enable => hm2_7i95.0.encoder.04.index-enable

net spindle-brake-on spindle.0.brake => enable-spindle-index.brake-on

Hi MR. 0x2102

I think I will try your solution, Now I have a problem .

I put your hall and change to my hm2

sets spindle-sync 1

net spindle-sync enable-spindle-index.out => spindle.0.index-enable => hm2_7i96s.0.encoder.05.index-enable

net spindle-brake-on spindle.0.brake => enable-spindle-index.brake-on

Save and run linuxcnc, Show error signal 'spindle-syn not found '

Please give me some advice.

Attachments:

Last edit: 04 Oct 2023 01:38 by abdulasis12.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4648

- Thank you received: 2068

04 Oct 2023 01:57 #282234

by Aciera

Replied by Aciera on topic Orientation position problem after run Gcode

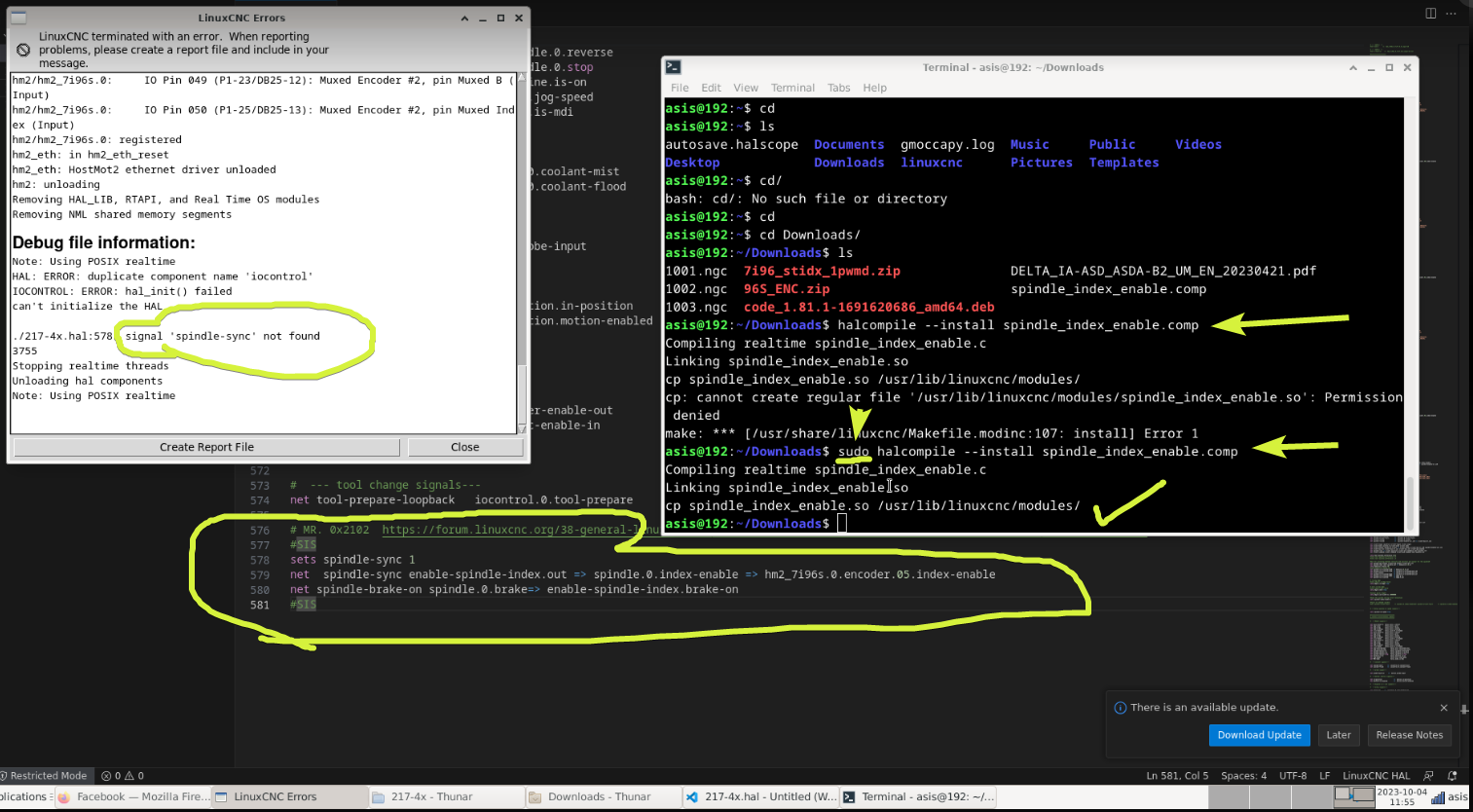

1. Have you installed the component?

$ sudo halcompile --install spindle_index_enable.comp

(don't use 'sudo' if you are on a rip installation ie if you have compiled linuxcnc on your computer)

2. There also is another error 'duplicate component name iocontrol' not sure where that comes from.

$ sudo halcompile --install spindle_index_enable.comp

(don't use 'sudo' if you are on a rip installation ie if you have compiled linuxcnc on your computer)

2. There also is another error 'duplicate component name iocontrol' not sure where that comes from.

The following user(s) said Thank You: abdulasis12

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

04 Oct 2023 05:00 #282246

by abdulasis12

Now I install sudo halcompile --install spindle_index_enable.comp Done (must sudo can work).

Now wait MR. 0x2102 for advice about signal 'spindle-syn not found '

Replied by abdulasis12 on topic Orientation position problem after run Gcode

Thank you MR.Aciera1. Have you installed the component?

$ sudo halcompile --install spindle_index_enable.comp

(don't use 'sudo' if you are on a rip installation ie if you have compiled linuxcnc on your computer)

2. There also is another error 'duplicate component name iocontrol' not sure where that comes from.

Now I install sudo halcompile --install spindle_index_enable.comp Done (must sudo can work).

Now wait MR. 0x2102 for advice about signal 'spindle-syn not found '

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4648

- Thank you received: 2068

04 Oct 2023 08:52 - 04 Oct 2023 08:53 #282256

by Aciera

Replied by Aciera on topic Orientation position problem after run Gcode

Also, don't forget to 'loadrt ... ' and 'addf ...' the new component in your hal file.

Last edit: 04 Oct 2023 08:53 by Aciera.

The following user(s) said Thank You: abdulasis12

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

04 Oct 2023 15:47 #282297

by abdulasis12

loadrt spindle_index_enable

addf spindle_index_enable servo-thread

Right ?

Asis,

Replied by abdulasis12 on topic Orientation position problem after run Gcode

Ahh I don't know this step , Thank you ^^" .Also, don't forget to 'loadrt ... ' and 'addf ...' the new component in your hal file.

loadrt spindle_index_enable

addf spindle_index_enable servo-thread

Right ?

Asis,

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4648

- Thank you received: 2068

04 Oct 2023 16:28 #282299

by Aciera

Replied by Aciera on topic Orientation position problem after run Gcode

I think you would need (note the '.0' in the addf line):

loadrt spindle_index_enable

addf spindle_index_enable.0 servo-thread

loadrt spindle_index_enable

addf spindle_index_enable.0 servo-thread

The following user(s) said Thank You: abdulasis12

Please Log in or Create an account to join the conversation.

- abdulasis12

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 8

04 Oct 2023 17:49 #282304

by abdulasis12

Replied by abdulasis12 on topic Orientation position problem after run Gcode

Thank you MR.

Aciera

, Will try tomorow

Please Log in or Create an account to join the conversation.

Time to create page: 0.245 seconds