QTPlasmaC with six axis

- mariusl

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Is it possible to run QTPlasmaC with six axis? XYZ as linear and ABC as rotary. Each rotary axis is rotating around its parent linear axis?

If not, what kind of effort will it take to achieve this?

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

If you want I could make a test branch in the next day or so that you could build and try out.

Please Log in or Create an account to join the conversation.

- mariusl

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11624

- Thank you received: 3913

I have an abandoned project that reports among other things the arc radius and the tangential heading in real time

github.com/LinuxCNC/linuxcnc/pull/900

Once 2.9 is released I had hoped to find the time to revisit it.

Assuming the following 5 axis design below, The A axis will determine the bevel angle

There will be a XY plane at the pivot point that is a constant Z height regardless of the direction of the bevel.

The distance from the torch tip to the pivot point in X & Y then can easilly be calculated from the A axis Angle

So given we have a tangential heading, we know the direction of the pivot point will be normal to the heading.

So now we just need a component that calculates the required X,Y position for a bevel cut in real time.

This component could then use external offsets to position the torch in the X,Y plane. Phils is the expert there

So this methodology would allow bevel cutting to be applied to a standard 2D DXF file cut without the need for any 5 axis kinematics.

Let me know your thoughts.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

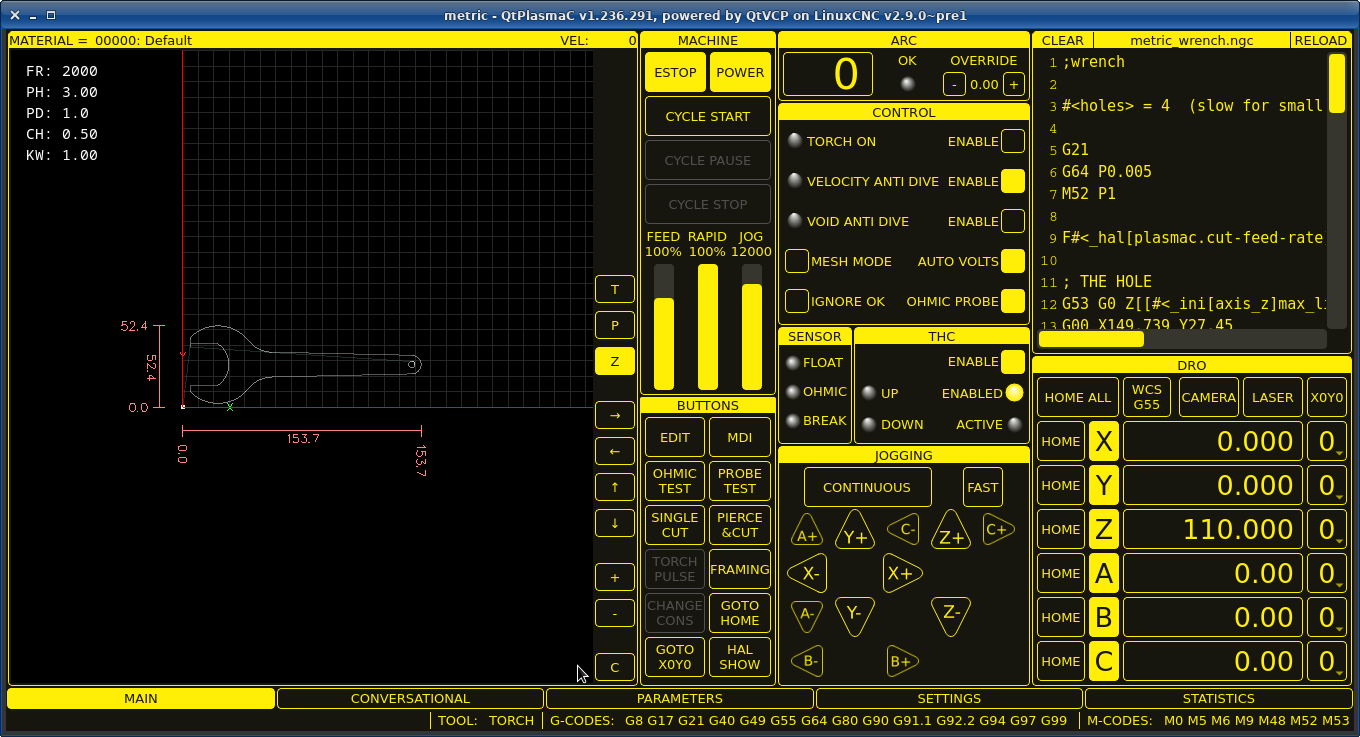

github.com/LinuxCNC/linuxcnc/tree/phillc54/qtplasmac_6_axes

The GUI's need a little bit of polish but should be fine for your testing.

It did make me notice a couple of issues with the fifth axis...

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

- Posts: 21164

- Thank you received: 7228

Still on 1366X768 resolution?

-

To all others, well whoever might do something about it, please do something so Phill can get at least a Full HD monitor!!!

-

I would gladly donate an Eizo 27" QHD monitor to you, but the shipping will costs about 5-10 times the monitor price, and that aint no cheap monitor.

And, no i do not have any other means of paying besides a bit of crypto i have left. I do have paypal but no card that works with it so it is useless (and paypal has the worst website on planet earth), i do have several credit cards, i had to call the bank every time i wanted to buy something online, so i stopped using those.

Yeah, i know, i live in a s#itty country, but still better than most of the world... does not include Eastern Europe and Japan. No i did not forget USA, it is better for a lot of things, but it is worse for probably the same amount of things!

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

It is all good Tom. I just use that as a worst case.@Phill,

Still on 1366X768 resolution?

-

To all others, well whoever might do something about it, please do something so Phill can get at least a Full HD monitor!!!

Thank you for the kind thought.I would gladly donate an Eizo 27" QHD monitor to you, but the shipping will costs about 5-10 times the monitor price, and that aint no cheap monitor.

Please Log in or Create an account to join the conversation.

- mariusl

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Wow you are a champion man. I will install and test on Monday and I will give you some feedback. It will not be precise testing as we are still working on the kinematics for the 6 axis solution. One of these will be a tube so it's a bit more of a challenge. The bevel cutting on flat plate should already be possible with a kinematics model I just completed for a 17m x 4.5m x 1.8m 5 axis router.I have pushed a new branch named phillc54/qtplasmac_6_axes which is based on master branch.

github.com/LinuxCNC/linuxcnc/tree/phillc54/qtplasmac_6_axes

The GUI's need a little bit of polish but should be fine for your testing.

It did make me notice a couple of issues with the fifth axis...

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

- mariusl

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Rod that should be possible without any extra modules.We already have 5 Axis kinematics that can be slightly modified ( or could work as is ) to make bevel cutting possible.Marius, I had this idea a few days ago for bevel cutting.

I have an abandoned project that reports among other things the arc radius and the tangential heading in real time

github.com/LinuxCNC/linuxcnc/pull/900

Once 2.9 is released I had hoped to find the time to revisit it.

Assuming the following 5 axis design below, The A axis will determine the bevel angle

There will be a XY plane at the pivot point that is a constant Z height regardless of the direction of the bevel.

The distance from the torch tip to the pivot point in X & Y then can easilly be calculated from the A axis Angle

So given we have a tangential heading, we know the direction of the pivot point will be normal to the heading.

So now we just need a component that calculates the required X,Y position for a bevel cut in real time.

This component could then use external offsets to position the torch in the X,Y plane. Phils is the expert there

So this methodology would allow bevel cutting to be applied to a standard 2D DXF file cut without the need for any 5 axis kinematics.

Let me know your thoughts.

The bigger challenge will be the post processor to generate the Gcode. At this point in time our only avenue is Fusion or maybe Freecad although I don't know if Freecad has a working 5 Axis solution yet. Because QTPlamac takes care of the probing, it makes the CAM solution a bit easier. It's a one pass cut on the bevelled edge of your part to generate the Gcode. The trick is that the CAM must produce TCP paths.

I hope to simulate some simple cutting process in the week. I will most likely hand code the Gcode to see how QTPlasmac handles it.

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.