QTPlasmaC with six axis

- rodw

-

- Away

- Platinum Member

-

- Posts: 11668

- Thank you received: 3932

My vision was that 5 axis kinematics would not be not required and the bevel cutting would use the normal postprocessor with just the bevel angle set. So it might not even need changing the normal sheetcam postprocessor.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21230

- Thank you received: 7249

That is done to avoid using 4 or 5 axis CAM software, as Rod mentioned, complicates things a lot and costs a fortune for software that usually does not work for what you need, or makes you jumps through hoops to get there.

Still, the question no one asked (or i missed it, glasses foggy) , why 6 axis?

Almost all are 4 axis, except Kjellberg Finsterwalde that have full 5 axis ones. Just do not ask for their price!!!

I have seen one with "nutating" head, the 45 degree spinning thingy, looked very interesting...

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21230

- Thank you received: 7249

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11668

- Thank you received: 3932

Another nice one here but not the same geometry as I had in mind

I am sure this can be done (well in my head anyway

I like the way this one starts the pierce on an angle to let the slag escape.

Also QTP I don't think yet does wiggle pierce or ramp pierce. A user mentioned off forum that they cut 37mm plate but his QTP machine could not piearce past 32mm. I think ramp pierce would have let it do it..

Please Log in or Create an account to join the conversation.

- mariusl

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

The six axis is required for doing complex tube cutting.Still, the question no one asked (or i missed it, glasses foggy) , why 6 axis?

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4649

- Thank you received: 2070

I think you'd be able to do this using the 'drag knife' feature (which I think Sheetcam offers) together with the 5axis XYZAC or XYZBC kinematic (TCP) in linuxcnc.My vision was that 5 axis kinematics would not be not required and the bevel cutting would use the normal postprocessor with just the bevel angle set.

Please Log in or Create an account to join the conversation.

- mariusl

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Not what is required here.

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

- mariusl

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

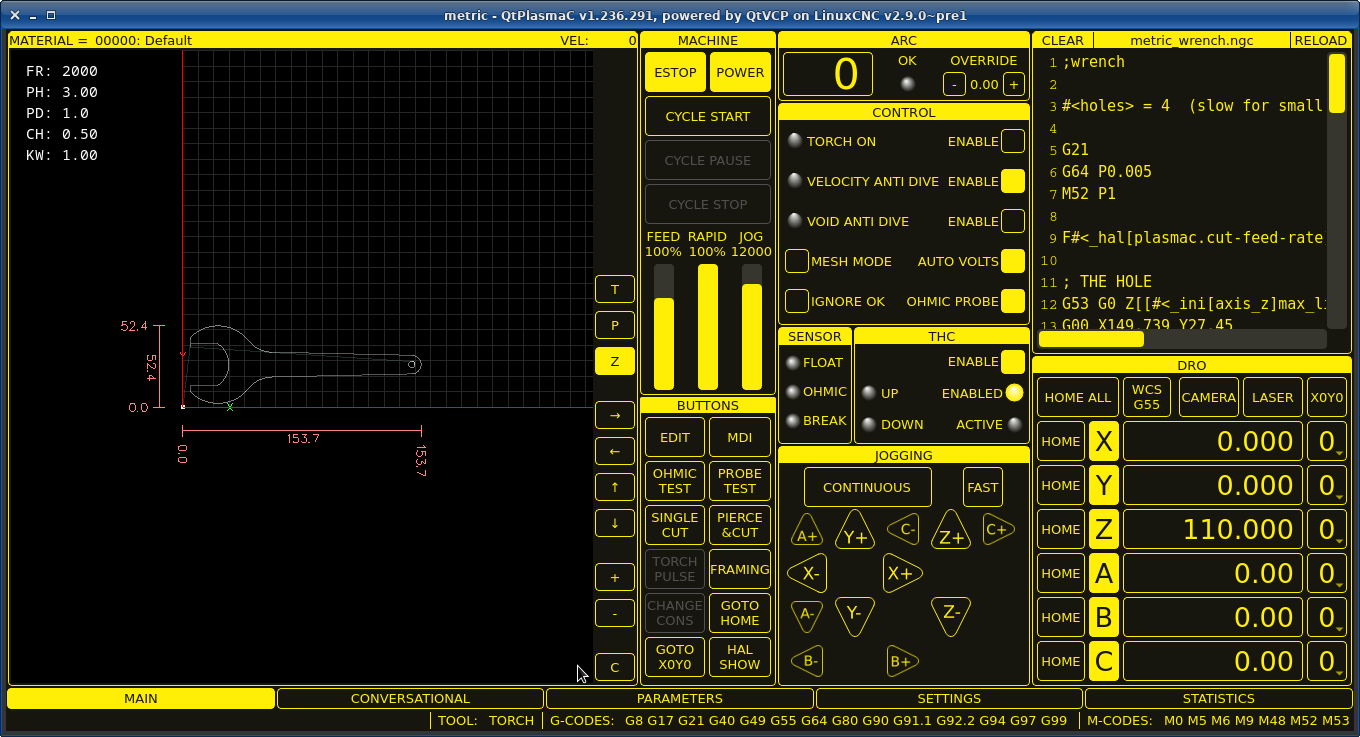

I know I have grown more stupid with the years but not like this. I cannot get to clone your branch or the master. I made a fork on github but only got master branch in that fork. I was under the impression that I will have access to all branches.I have pushed a new branch named phillc54/qtplasmac_6_axes which is based on master branch.

github.com/LinuxCNC/linuxcnc/tree/phillc54/qtplasmac_6_axes

The GUI's need a little bit of polish but should be fine for your testing.

It did make me notice a couple of issues with the fifth axis...

I can clone my own github fork of linuxcnc.

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4649

- Thank you received: 2070

Well it may not work for your case, so apologies if I'm not being totally on topic but you have not really given much information about what you are actually trying to do other than '6axis complex pipe cutting' which could mean a lot of things.Not what is required here.

@ Rodw

Since 'Drag knife' gcode orients the c axis (ie the torch in this case) to the tool path it may work for sheets and probably also for pipe. You could define the bevel angle using the A/B axis and then the C axis would be used to keep the torch oriented to the tool path.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

git checkout phillc54/qtplasmac_6_axesPlease Log in or Create an account to join the conversation.