Threading Index Varies With Speed

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17612

- Thank you received: 5149

03 Jan 2025 15:37 - 03 Jan 2025 18:15 #317937

by PCW

Replied by PCW on topic Threading Index Varies With Speed

As far as I understand it, ideally there should be no offset.

The offset is there because the algorithm only matches velocity

and does not do the calculations needed to match velocity

_and_ correct position.

The offset is there because the algorithm only matches velocity

and does not do the calculations needed to match velocity

_and_ correct position.

Last edit: 03 Jan 2025 18:15 by PCW.

The following user(s) said Thank You: spumco

Please Log in or Create an account to join the conversation.

- spumco

- Away

- Platinum Member

-

Less

More

- Posts: 1973

- Thank you received: 806

25 Jan 2025 02:48 - 25 Jan 2025 02:51 #319800

by spumco

Replied by spumco on topic Threading Index Varies With Speed

After pulling my hair out trying to figure out why G33.1 wasn't working on my lathe while attempting to test the problem raised in this thread, @cmorely pointed out I'm having the same issue.

forum.linuxcnc.org/38-general-linuxcnc-q...pping-problem#319786

So I can confirm spindle synchronization start points vary with spindle speed in G33.1 as well as G76 - and it's way worse on my lathe than the OP reported on his.

In my case a difference of 140rpm (60 vs 200) resulted in appx 0.750" difference between the Z-start point when synchronization kicked in on a 1/20 pitch (0.050").

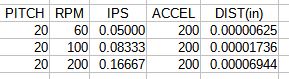

According the the formula Andy posted earlier, my Z-axis requires the following distance to get up to speed

I don't understand why there is such a significant difference between what I'm seeing and what the OP's lathe is doing.

Unless somone has other thoughts, I think this is a bug.

forum.linuxcnc.org/38-general-linuxcnc-q...pping-problem#319786

So I can confirm spindle synchronization start points vary with spindle speed in G33.1 as well as G76 - and it's way worse on my lathe than the OP reported on his.

In my case a difference of 140rpm (60 vs 200) resulted in appx 0.750" difference between the Z-start point when synchronization kicked in on a 1/20 pitch (0.050").

According the the formula Andy posted earlier, my Z-axis requires the following distance to get up to speed

I don't understand why there is such a significant difference between what I'm seeing and what the OP's lathe is doing.

Unless somone has other thoughts, I think this is a bug.

Attachments:

Last edit: 25 Jan 2025 02:51 by spumco. Reason: Forum editor blues

Please Log in or Create an account to join the conversation.

- spumco

- Away

- Platinum Member

-

Less

More

- Posts: 1973

- Thank you received: 806

26 Jan 2025 03:02 #319866

by spumco

Replied by spumco on topic Threading Index Varies With Speed

Update here:

forum.linuxcnc.org/38-general-linuxcnc-q...blem?start=10#319865

So my lathe's behavior is closer to the OP's when running a program vs. MDI.

But as I mentioned in the other thread, I don't think this behavior is correct even with the reduced 'dive' towards the synch point.

forum.linuxcnc.org/38-general-linuxcnc-q...blem?start=10#319865

So my lathe's behavior is closer to the OP's when running a program vs. MDI.

But as I mentioned in the other thread, I don't think this behavior is correct even with the reduced 'dive' towards the synch point.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17612

- Thank you received: 5149

24 May 2025 23:36 - 24 May 2025 23:58 #329084

by PCW

Replied by PCW on topic Threading Index Varies With Speed

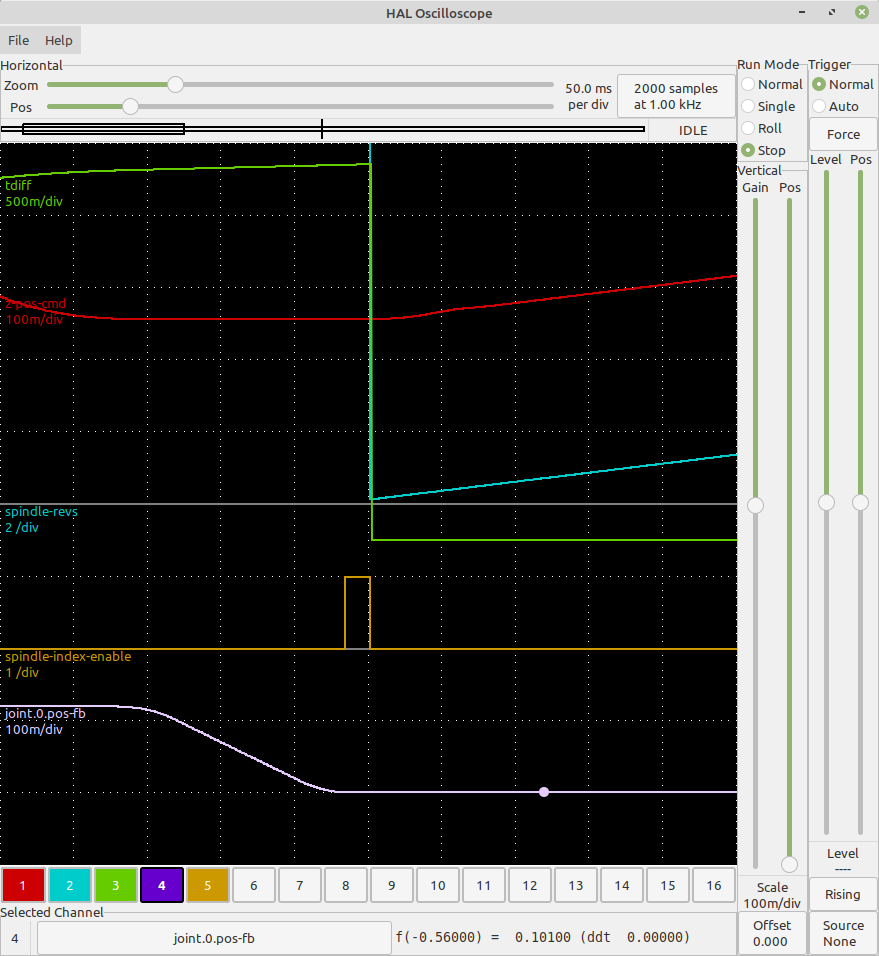

I was able to reproduce this error with a simple test setup

with no mechanics and using g76. It also causes errors even

at a constant spindle speed, as the offset changes with thread

depth over the multiple threading passes which would cause

a wider than expected cut.

To test this I setup a 7I96S with a stepgen spindle setup to

emulate a 8 count encoder with index (using the stepgen table mode)

I checked the offset by using the sum2 component to scale the spindle

rotations to the thread pitch and subtract the result. This offset

should be independent of spindle speed, X,Z motion constraints

and drive line distance to thread pass, but it is not.

Have you raised an issue on the LinuxCNC github page?

with no mechanics and using g76. It also causes errors even

at a constant spindle speed, as the offset changes with thread

depth over the multiple threading passes which would cause

a wider than expected cut.

To test this I setup a 7I96S with a stepgen spindle setup to

emulate a 8 count encoder with index (using the stepgen table mode)

I checked the offset by using the sum2 component to scale the spindle

rotations to the thread pitch and subtract the result. This offset

should be independent of spindle speed, X,Z motion constraints

and drive line distance to thread pass, but it is not.

Have you raised an issue on the LinuxCNC github page?

Last edit: 24 May 2025 23:58 by PCW.

The following user(s) said Thank You: tommylight, Clive S, spumco

Please Log in or Create an account to join the conversation.

- spumco

- Away

- Platinum Member

-

Less

More

- Posts: 1973

- Thank you received: 806

25 May 2025 14:30 - 25 May 2025 14:45 #329107

by spumco

Replied by spumco on topic Threading Index Varies With Speed

Have you raised an issue on the LinuxCNC github page?

While I've raised a couple issues in the past, I am reluctant to directly engage on GH because I don't speak 'computer' fluently. I can describe an issue in laymans terms, but as soon as any discussion moves towards code-type testing & solutions I'm lost. My typical modus operandi is to prompt enough discussion on this forum that somone clever takes up the torch over on GH.

I'll raise one now, thanks for the reminder about it.

EDIT: github.com/LinuxCNC/linuxcnc/issues/3455

While I've raised a couple issues in the past, I am reluctant to directly engage on GH because I don't speak 'computer' fluently. I can describe an issue in laymans terms, but as soon as any discussion moves towards code-type testing & solutions I'm lost. My typical modus operandi is to prompt enough discussion on this forum that somone clever takes up the torch over on GH.

I'll raise one now, thanks for the reminder about it.

EDIT: github.com/LinuxCNC/linuxcnc/issues/3455

Last edit: 25 May 2025 14:45 by spumco. Reason: GH issue link

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

25 May 2025 15:48 #329111

by andypugh

In your constant speed example, is there any possibility that what you are seeing is the "virtual compound angle" Q ?

Replied by andypugh on topic Threading Index Varies With Speed

Which LinuxCNC version? Not being able to cut threads would be a huge problem.It also causes errors even

at a constant spindle speed, as the offset changes with thread

depth over the multiple threading passes

In your constant speed example, is there any possibility that what you are seeing is the "virtual compound angle" Q ?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17612

- Thank you received: 5149

25 May 2025 16:22 #329116

by PCW

Replied by PCW on topic Threading Index Varies With Speed

Yes, you are right, there is no error on multiple constant speed

paths, I had neglected to 0 the q parameter when testing.

This is because the return path has a constant x distance from

the cutting path.

You get the error if you change the spindle speed (or motion constraints)

Basically I would think the the z motion should be strictly geared to

the spindle (+- any deliberate offsets like "q") just like a mechanical

lathe.

paths, I had neglected to 0 the q parameter when testing.

This is because the return path has a constant x distance from

the cutting path.

You get the error if you change the spindle speed (or motion constraints)

Basically I would think the the z motion should be strictly geared to

the spindle (+- any deliberate offsets like "q") just like a mechanical

lathe.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

25 May 2025 16:34 #329121

by andypugh

Replied by andypugh on topic Threading Index Varies With Speed

Are you using position-interpolated with your 8-count encoder?

Is there any quantisation of the error you see?

I haven't looked at the spindle synch code, but if it tries to "start early" before the index then possibly a low-count encoder will make that more difficult.

Is there any quantisation of the error you see?

I haven't looked at the spindle synch code, but if it tries to "start early" before the index then possibly a low-count encoder will make that more difficult.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17612

- Thank you received: 5149

25 May 2025 17:09 #329127

by PCW

Replied by PCW on topic Threading Index Varies With Speed

Yes, I am using interpolated position (which is very precise with the hardware generated "encoder' signals)

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17612

- Thank you received: 5149

26 May 2025 20:39 - 26 May 2025 20:40 #329179

by PCW

Replied by PCW on topic Threading Index Varies With Speed

Attachments:

Last edit: 26 May 2025 20:40 by PCW.

Please Log in or Create an account to join the conversation.

Time to create page: 0.191 seconds