Mesa modbus and pktUart

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

04 Sep 2023 15:16 #279838

by Donno

Replied by Donno on topic Mesa modbus and pktUart

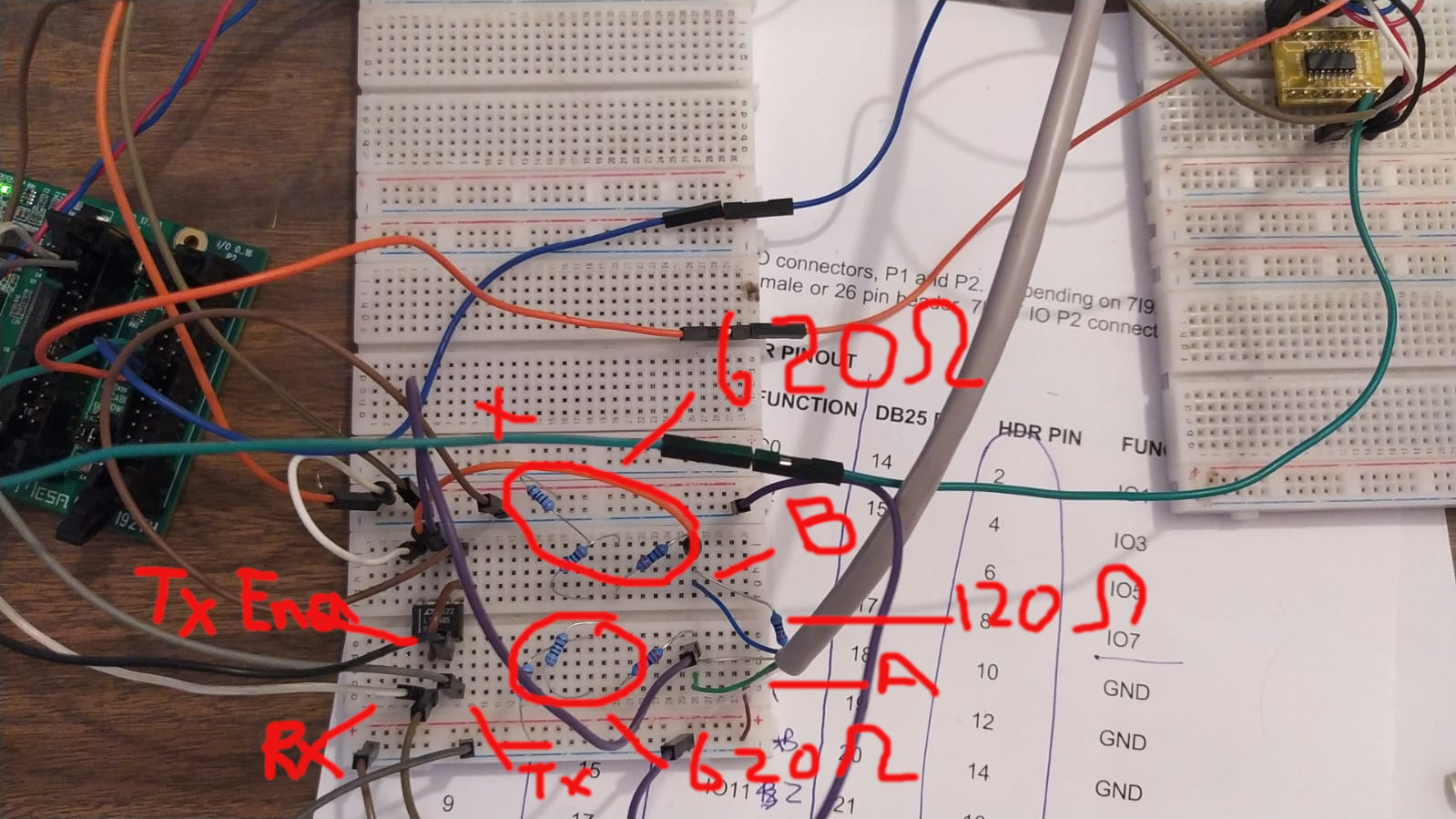

Yes I have Pos - 620ohm - 120 ohm - 620 ohm -Neg

If i wire it any other way i get fault or if i remove 120ohm then i get a fault so i am pretty sure it is connecting. What are the default data and stop bit ?

Test.modHAL File

This is what i am expecting on address 0 to 8

If i wire it any other way i get fault or if i remove 120ohm then i get a fault so i am pretty sure it is connecting. What are the default data and stop bit ?

Test.mod

// Test Driver

#define MAX_MSG_LEN 16 // may be increased if necessary to max 251

#define DEBUG 3

static const hm2_modbus_chan_descriptor_t channels[] = {

/* {TYPE, FUNC, ADDR, COUNT, pin_name} */

{HAL_U32, 3, 0x0000, 1, "test0"},

{HAL_U32, 3, 0x0001, 1, "test1"},

{HAL_U32, 3, 0x0002, 1, "test2"},

{HAL_U32, 3, 0x0003, 1, "test3"},

{HAL_U32, 3, 0x0004, 1, "test4"},

{HAL_U32, 3, 0x0005, 1, "test5"},

{HAL_U32, 3, 0x0006, 1, "test6"},

{HAL_U32, 3, 0x0007, 1, "test7"},

{HAL_U32, 3, 0x0008, 1, "test8"},

};# Generated by PNCconf at Mon Aug 28 20:19:10 2023

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_eth board_ip="192.168.1.121" config="num_encoders=1 num_pwmgens=0 num_stepgens=2"

loadrt test ports=hm2_7i92.0.pktuart.0

setp hm2_7i92.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.z,pid.s

loadrt abs names=abs.spindle

loadrt lowpass names=lowpass.spindle

loadrt scale names=scale.spindle

loadrt near

addf hm2_7i92.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf scale.spindle servo-thread

addf abs.spindle servo-thread

addf lowpass.spindle servo-thread

addf near.0 servo-thread

addf hm2_7i92.0.write servo-thread

addf test.00 servo-thread

setp hm2_7i92.0.dpll.01.timer-us -50

setp hm2_7i92.0.stepgen.timer-number 1

setp test.00.address 1

setp test.00.baudrate 19200

setp test.00.parity 2

setp test.00.update-hz 0.1

# external output signals

# --- DOUT-00 ---

setp hm2_7i92.0.gpio.000.is_output true

net dout-00 => hm2_7i92.0.gpio.000.out

# --- SPINDLE-ENABLE ---

setp hm2_7i92.0.gpio.005.is_output true

net spindle-enable => hm2_7i92.0.gpio.005.out

# --- SPINDLE-CW ---

setp hm2_7i92.0.gpio.006.is_output true

net spindle-cw => hm2_7i92.0.gpio.006.out

# --- SPINDLE-CCW ---

setp hm2_7i92.0.gpio.007.is_output true

net spindle-ccw => hm2_7i92.0.gpio.007.out

# --- COOLANT-MIST ---

setp hm2_7i92.0.gpio.008.is_output true

net coolant-mist => hm2_7i92.0.gpio.008.out

# --- DOUT-01 ---

setp hm2_7i92.0.gpio.013.is_output true

net dout-01 => hm2_7i92.0.gpio.013.out

# --- DOUT-02 ---

setp hm2_7i92.0.gpio.015.is_output true

net dout-02 => hm2_7i92.0.gpio.015.out

# --- DOUT-03 ---

setp hm2_7i92.0.gpio.016.is_output true

net dout-03 => hm2_7i92.0.gpio.016.out

# --- ESTOP-OUT ---

setp hm2_7i92.0.gpio.030.is_output true

net estop-out => hm2_7i92.0.gpio.030.out

# --- MACHINE-IS-ENABLED ---

setp hm2_7i92.0.gpio.032.is_output true

net machine-is-enabled => hm2_7i92.0.gpio.032.out

# --- SPINDLE-ENABLE ---

setp hm2_7i92.0.gpio.033.is_output true

net spindle-enable => hm2_7i92.0.gpio.033.out

# external input signals

# --- HOME-X ---

net home-x <= hm2_7i92.0.gpio.012.in

# --- HOME-Z ---

net home-z <= hm2_7i92.0.gpio.014.in

# --- DIN-00 ---

net din-00 <= hm2_7i92.0.gpio.019.in

# --- DIN-01 ---

net din-01 <= hm2_7i92.0.gpio.020.in

# --- DIN-02 ---

net din-02 <= hm2_7i92.0.gpio.021.in

# --- DIN-03 ---

net din-03 <= hm2_7i92.0.gpio.022.in

# --- ESTOP-EXT ---

net estop-ext <= hm2_7i92.0.gpio.023.in

# --- PROBE-IN ---

net probe-in <= hm2_7i92.0.gpio.024.in

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i92.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i92.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i92.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i92.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i92.0.stepgen.00.step_type 0

setp hm2_7i92.0.stepgen.00.control-type 1

setp hm2_7i92.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => hm2_7i92.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i92.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_7i92.0.stepgen.00.enable

# ---setup home / limit switch signals---

net home-x => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Z JOINT 1

#*******************

setp pid.z.Pgain [JOINT_1]P

setp pid.z.Igain [JOINT_1]I

setp pid.z.Dgain [JOINT_1]D

setp pid.z.bias [JOINT_1]BIAS

setp pid.z.FF0 [JOINT_1]FF0

setp pid.z.FF1 [JOINT_1]FF1

setp pid.z.FF2 [JOINT_1]FF2

setp pid.z.deadband [JOINT_1]DEADBAND

setp pid.z.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp hm2_7i92.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_7i92.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_7i92.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_7i92.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_7i92.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_7i92.0.stepgen.01.step_type 0

setp hm2_7i92.0.stepgen.01.control-type 1

setp hm2_7i92.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_7i92.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.1.motor-pos-cmd

net z-vel-cmd <= joint.1.vel-cmd

net z-output => hm2_7i92.0.stepgen.01.velocity-cmd

net z-pos-fb <= hm2_7i92.0.stepgen.01.position-fb

net z-pos-fb => joint.1.motor-pos-fb

net z-enable <= joint.1.amp-enable-out

net z-enable => hm2_7i92.0.stepgen.01.enable

# ---setup home / limit switch signals---

net home-z => joint.1.home-sw-in

net z-neg-limit => joint.1.neg-lim-sw-in

net z-pos-limit => joint.1.pos-lim-sw-in

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-output <= pid.s.output

# ---Encoder feedback signals/setup---

setp hm2_7i92.0.encoder.00.counter-mode 0

setp hm2_7i92.0.encoder.00.filter 1

setp hm2_7i92.0.encoder.00.index-invert 0

setp hm2_7i92.0.encoder.00.index-mask 0

setp hm2_7i92.0.encoder.00.index-mask-invert 0

setp hm2_7i92.0.encoder.00.scale [SPINDLE_0]ENCODER_SCALE

net spindle-revs <= hm2_7i92.0.encoder.00.position

net spindle-vel-fb-rps <= hm2_7i92.0.encoder.00.velocity

net spindle-vel-fb-rpm <= hm2_7i92.0.encoder.00.velocity-rpm

net spindle-index-enable <=> hm2_7i92.0.encoder.00.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

net spindle-vel-cmd-rps => near.0.in1

net spindle-vel-fb-rps => near.0.in2

net spindle-at-speed <= near.0.out

setp near.0.scale 1.000000

setp near.0.difference 0.166667

# Use ACTUAL spindle velocity from spindle encoder

# spindle-velocity bounces around so we filter it with lowpass

# spindle-velocity is signed so we use absolute component to remove sign

# ACTUAL velocity is in RPS not RPM so we scale it.

setp scale.spindle.gain 60

setp lowpass.spindle.gain 1.000000

net spindle-vel-fb-rps => scale.spindle.in

net spindle-fb-rpm scale.spindle.out => abs.spindle.in

net spindle-fb-rpm-abs abs.spindle.out => lowpass.spindle.in

net spindle-fb-rpm-abs-filtered lowpass.spindle.out

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.1.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

net dout-00 <= motion.digital-out-00

net dout-01 <= motion.digital-out-01

net dout-02 <= motion.digital-out-02

net dout-03 <= motion.digital-out-03

net din-00 => motion.digital-in-00

net din-01 => motion.digital-in-01

net din-02 => motion.digital-in-02

net din-03 => motion.digital-in-03

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---Use external manual tool change dialog---

loadusr -W hal_manualtoolchange

net tool-change-request => hal_manualtoolchange.change

net tool-change-confirmed <= hal_manualtoolchange.changed

net tool-number => hal_manualtoolchange.number

# ---ignore tool prepare requests---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

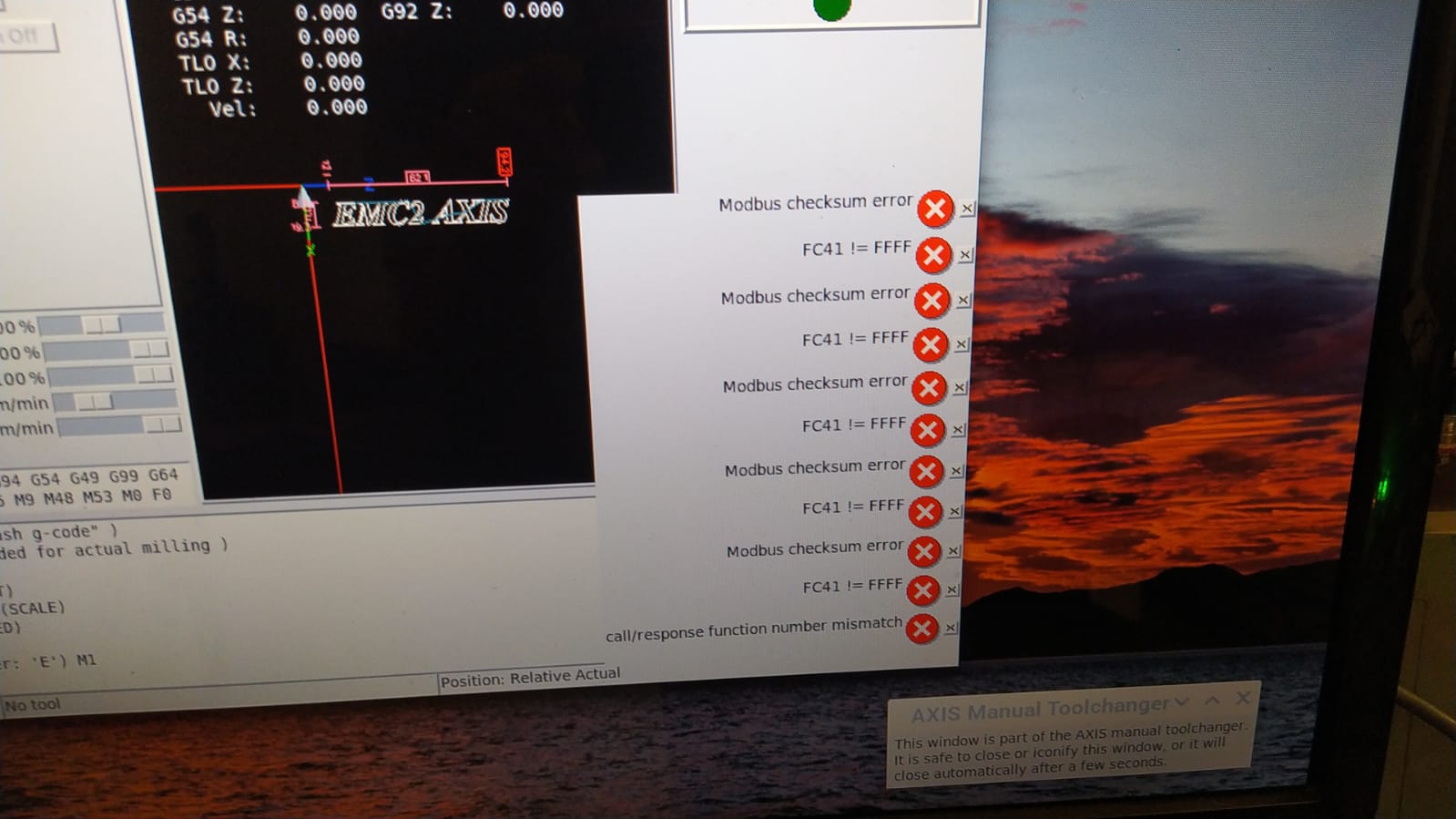

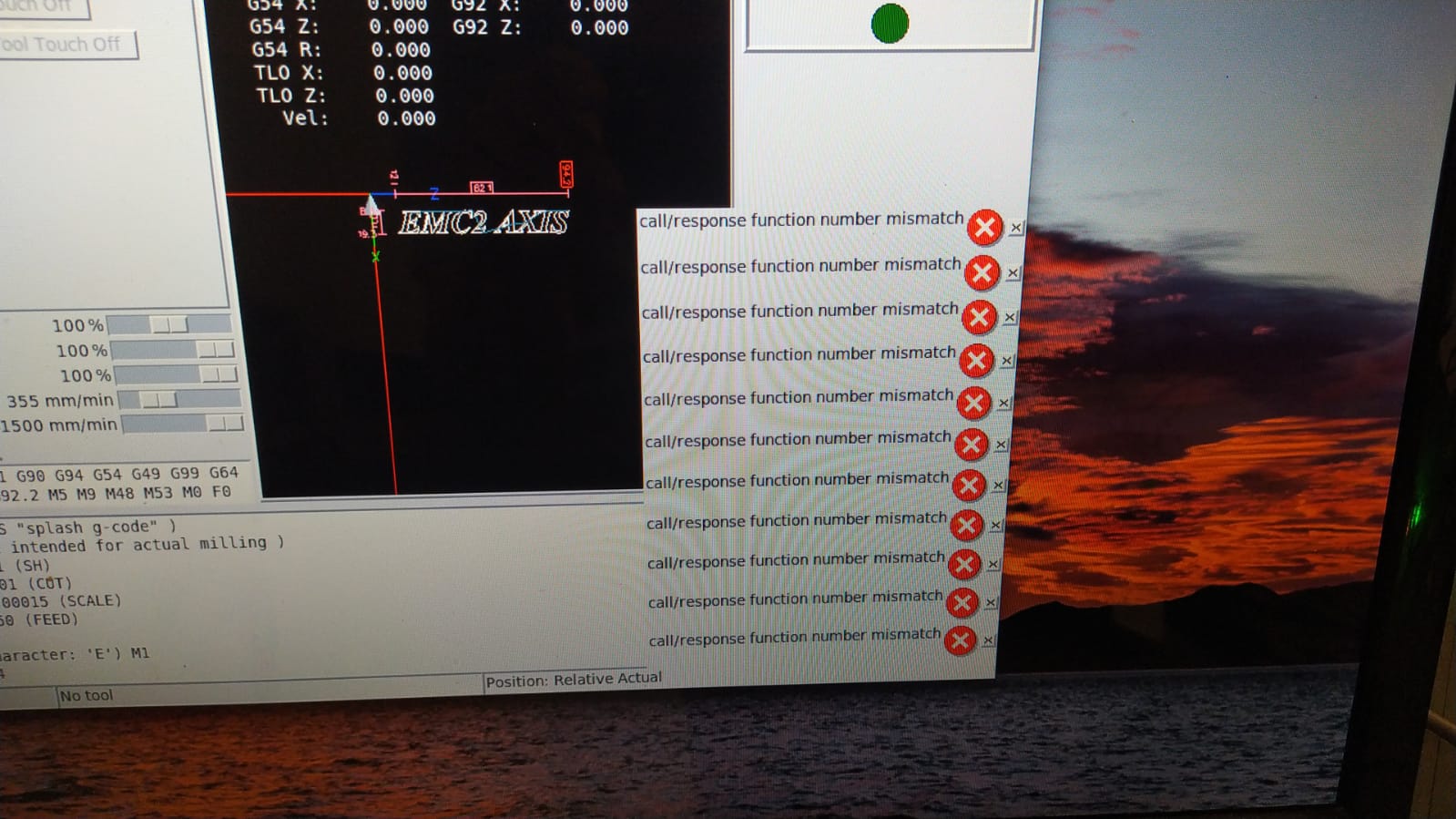

This is what i am expecting on address 0 to 8

[color=#ff5454]A5 Servo Driver | 16:59:43 [/color][color=#000000] [/color]

[color=#e74c3c]0 : 14130 | 1 : 0 | 2 : 0 | 3 : 0 | 4 : 0 | 5 : 0 | 6 : 0 | 7 : 0 | 8 : 14100 |[/color][color=#5454ff] [/color]Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

04 Sep 2023 16:02 #279843

by PCW

Replied by PCW on topic Mesa modbus and pktUart

If removing the 120 ohm termination cause a fault, that indicate a polarity or

perhaps drive enable issue

What interface chip are you using and how is it wired to the 7I92?

What configuration are you using on the 7I92 and especially, what TXEN polarity are you using?

perhaps drive enable issue

What interface chip are you using and how is it wired to the 7I92?

What configuration are you using on the 7I92 and especially, what TXEN polarity are you using?

Please Log in or Create an account to join the conversation.

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

04 Sep 2023 16:57 #279849

by Donno

Replied by Donno on topic Mesa modbus and pktUart

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

04 Sep 2023 18:26 - 04 Sep 2023 18:38 #279857

by PCW

Replied by PCW on topic Mesa modbus and pktUart

OK, that's not right

7I92 MAX/LTC485

TX --> MAX485 pin 4 ( DI )

RX --> MAX485 pin 2 ( RO )

TXEN --> MAX485 pin 3 ( DE )

GND --> MAX485 pin 1 ( /RE )

620 pullup to 5V --> MAX485 pin 6 ( A )

620 pulldown to GND --> MAX485 pin 7 ( B )

Also the default TXEN polarity is wrong for direct

connection to active high enables like the MAX485 uses,

so it either must be inverted in hal or the firmware

must be compiled with a pinout the uses the ntxen pin descriptor

7I92 MAX/LTC485

TX --> MAX485 pin 4 ( DI )

RX --> MAX485 pin 2 ( RO )

TXEN --> MAX485 pin 3 ( DE )

GND --> MAX485 pin 1 ( /RE )

620 pullup to 5V --> MAX485 pin 6 ( A )

620 pulldown to GND --> MAX485 pin 7 ( B )

Also the default TXEN polarity is wrong for direct

connection to active high enables like the MAX485 uses,

so it either must be inverted in hal or the firmware

must be compiled with a pinout the uses the ntxen pin descriptor

Last edit: 04 Sep 2023 18:38 by PCW.

Please Log in or Create an account to join the conversation.

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

05 Sep 2023 08:20 #279933

by Donno

Replied by Donno on topic Mesa modbus and pktUart

Can you give me an example please of ntxen in my use case ?

OPortTag & x"00" & PktUARTTTag & PktUTDrvEnPin,

OPortTag & x"00" & PktUARTTTag & PktUTDrvEnPin,

Please Log in or Create an account to join the conversation.

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

05 Sep 2023 13:10 #279967

by Donno

Replied by Donno on topic Mesa modbus and pktUart

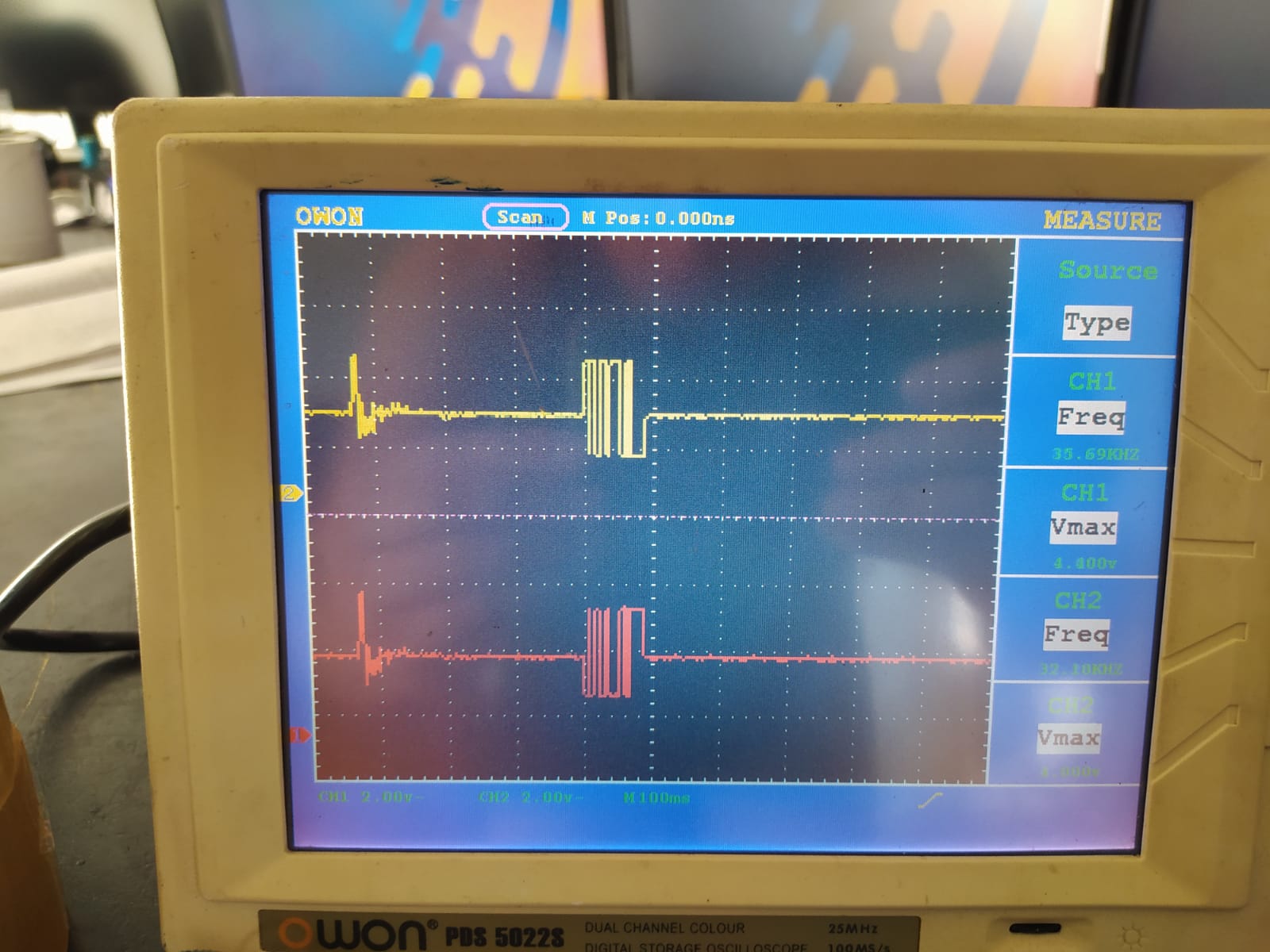

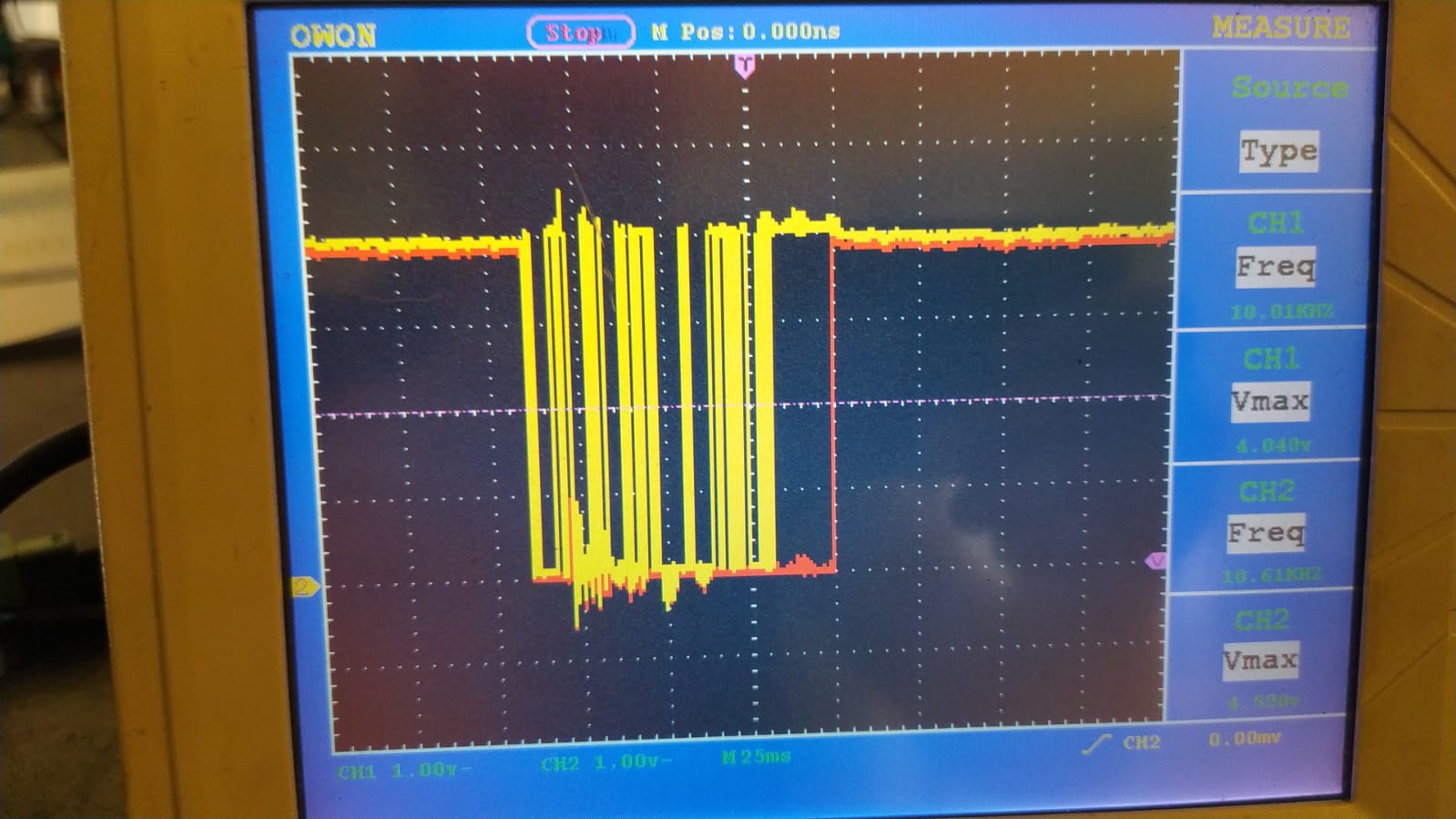

I mixed up my TX/GND Pin in Photo ! I have added a 74HC04 to TXena pin and still nothing I found a tty to RS458 converter and tried that as well.

I re-installed LinuxCNC 2.9pre and setup everything again. I also set my pktuart on different pins just in case i might have damage one pin still no joy.

If i disconnect servo drive and probe A/B i can see signals on the probe:

I re-installed LinuxCNC 2.9pre and setup everything again. I also set my pktuart on different pins just in case i might have damage one pin still no joy.

If i disconnect servo drive and probe A/B i can see signals on the probe:

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

05 Sep 2023 13:52 #279973

by PCW

Replied by PCW on topic Mesa modbus and pktUart

The signals on A/B do not look right.

When undriven, A _must_ be higher than B

(or the VFD will receive garbage)

Can you scope TXEN and TXdata at the adapter pins?

When undriven, A _must_ be higher than B

(or the VFD will receive garbage)

Can you scope TXEN and TXdata at the adapter pins?

Please Log in or Create an account to join the conversation.

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

05 Sep 2023 14:56 #279984

by Donno

Replied by Donno on topic Mesa modbus and pktUart

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

05 Sep 2023 15:13 #279989

by PCW

Replied by PCW on topic Mesa modbus and pktUart

IOPortTag & x"00" & PktUARTTTag & PktUTNDrvEnPin,Can you give me an example please of ntxen in my use case ?

OPortTag & x"00" & PktUARTTTag & PktUTDrvEnPin,

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

05 Sep 2023 15:50 #279998

by PCW

Replied by PCW on topic Mesa modbus and pktUart

Is that TXEN at the adapter or direct from the 7I92

(the adapter needs active high TXEN)

(the adapter needs active high TXEN)

Please Log in or Create an account to join the conversation.

Time to create page: 0.283 seconds