Mesa modbus and pktUart

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

07 Sep 2023 20:23 - 07 Sep 2023 20:26 #280227

by Donno

Replied by Donno on topic Mesa modbus and pktUart

Last edit: 07 Sep 2023 20:26 by Donno.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Donno

-

- Offline

- Premium Member

-

Less

More

- Posts: 137

- Thank you received: 17

08 Sep 2023 06:40 #280247

by Donno

Replied by Donno on topic Mesa modbus and pktUart

After re-write of driver everything works as expected :

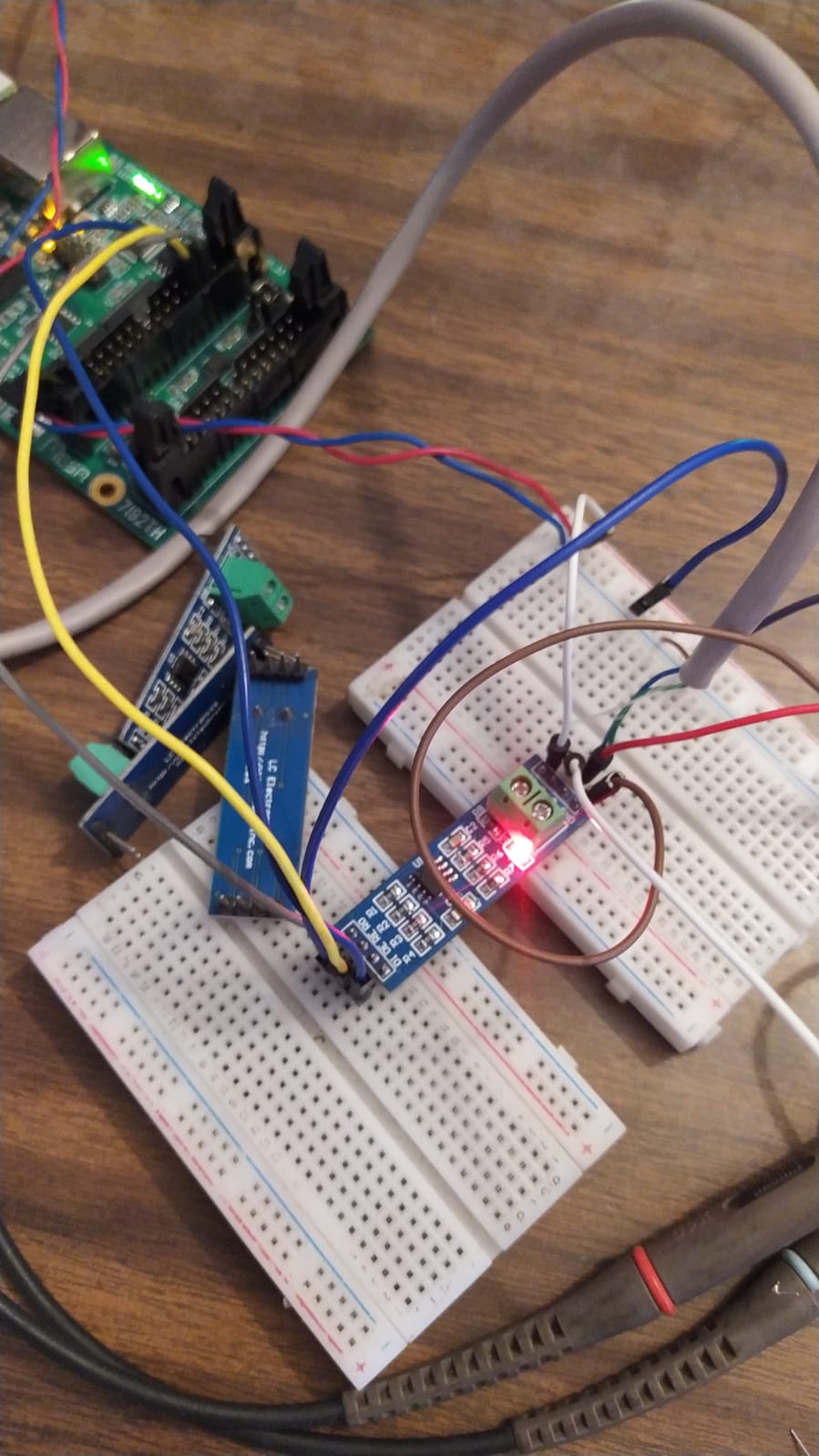

pktuart for modbus is much better than usb to modbus with mb2hal. On pktuart i get modbus checksum error but that is to be expected as i am using unshielded modbus wires and these chinese servo drives are noisy ! I manage to remove all exsta resistor from tty2modbus and everything still works, signal is alot more noisy without 620 ohm resisitors.

In modcompile if u use it like ./modcompile to compile mod file i get error that it can't find makefile so i had to include dir on line 45

to

if someone can commit it ?

// Lichuan A5 AC Servo Drive Driver

#define MAX_MSG_LEN 16 // may be increased if necessary to max 251

#define DEBUG 3

static const hm2_modbus_chan_descriptor_t channels[] = {

/* {TYPE, FUNC, ADDR, COUNT, pin_name} */

{HAL_FLOAT, 3, 0x9C8, 1, "speed-actual"},

{HAL_FLOAT, 3, 0x9C9, 1, "speed-instruction"},

{HAL_FLOAT, 3, 0x9CA, 1, "torque-instruction"},

{HAL_FLOAT, 3, 0x9D4, 1, "avg-load-rate"},

{HAL_FLOAT, 3, 0x9E0, 1, "phase-current"},

{HAL_FLOAT, 3, 0x9E2, 1, "bus-voltage"},

{HAL_FLOAT, 3, 0x9E3, 1, "tempreture"},

{HAL_S32, 6, 0x4CB, 1, "set-speed"}

};pktuart for modbus is much better than usb to modbus with mb2hal. On pktuart i get modbus checksum error but that is to be expected as i am using unshielded modbus wires and these chinese servo drives are noisy ! I manage to remove all exsta resistor from tty2modbus and everything still works, signal is alot more noisy without 620 ohm resisitors.

In modcompile if u use it like ./modcompile to compile mod file i get error that it can't find makefile so i had to include dir on line 45

for e in ['src', 'etc/linuxcnc', '/etc/linuxcnc', 'share/linuxcnc']:to

for e in ['../src','src', 'etc/linuxcnc', '/etc/linuxcnc', 'share/linuxcnc']:if someone can commit it ?

Attachments:

The following user(s) said Thank You: tommylight, COFHAL

Please Log in or Create an account to join the conversation.

- COFHAL

- Offline

- Platinum Member

-

Less

More

- Posts: 424

- Thank you received: 57

14 May 2024 02:04 - 14 May 2024 02:05 #300546

by COFHAL

Replied by COFHAL on topic Mesa modbus and pktUart

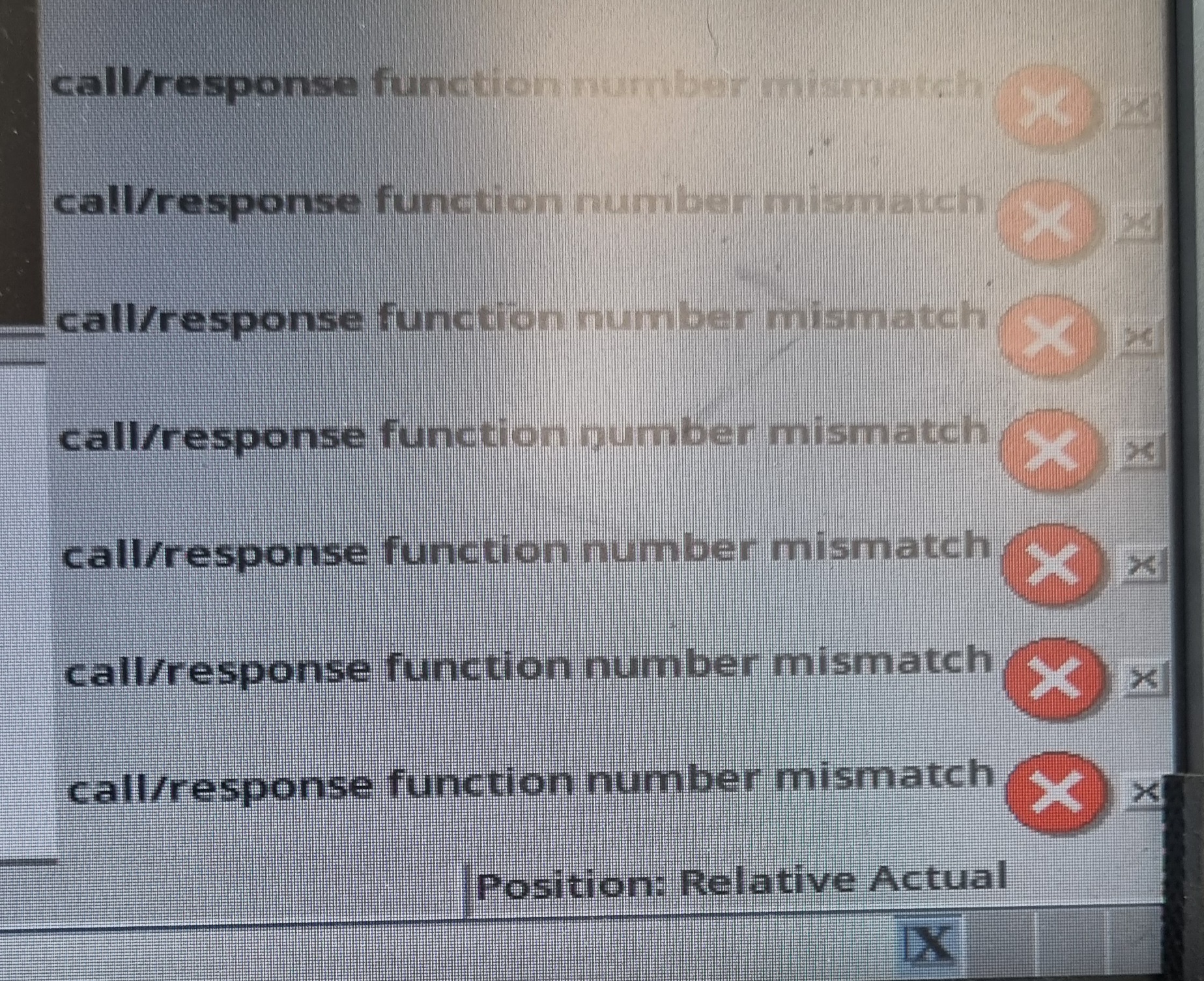

I already have MESA MODBUS working, with one I control a VDF and with another an I/O card with 4 inputs and 4 outputs. The only problem is that from time to time this error appears, and fault error 11, both when I control the VFD and the I/O card. I have tried to change the modname.update-hz parameter to 0.1 but when doing so it appears that neither the VFD nor the I/O card receive the commands. According to the documentation for this component, this parameter can help when la, fault 11 appears,

Attachments:

Last edit: 14 May 2024 02:05 by COFHAL.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

14 May 2024 02:36 #300548

by PCW

Replied by PCW on topic Mesa modbus and pktUart

That error (and others I have seen) seem to be a bug in the mesa-modbus code

The problem is that it does not reset the RX UART before using it, so if it has left over

RX data from the previous run. garbage from power cycles etc etc

Here's my list of know bugs, missing features:

Current Mesa Modbus issues:

BUGS:

At startup there can be "call/response function number missmatch"

error popups or sig11 (segv)s due to the fact that the PKTUART is

not cleared at startup, so random numbers of garbage characters

may be present in the RX FIFOs, leftover from the last LinuxCNC run.

A temporary workaround is to run this before launching linuxcnc:

mesaflash --device cardname --addr ipaddr --wpo 0x6800=0x00010000

(writing 0x10000 to 0x6800=pktuartr_mode_reg clears the RX FIFOs)

If you ever set the update rate to 0 (maximum), changing to a

non-zero rate will not work (communication stops)

There is a check for TX overflow in the PKTUART code that's

in the wrong location (TX section) so will print bogus error

messages with particular outgoing messages.

FEATURES:

Channel setting should not be global but in the .mod file

to support more than one device.

It would be good to have the error timeout/recovery

time programmable.

For multiple reads/writes it would be good to have the

possibility of mixed types,

This means for modbus devices that support table reads,

all I/O for a device could be done in a single read and a single

write.

The problem is that it does not reset the RX UART before using it, so if it has left over

RX data from the previous run. garbage from power cycles etc etc

Here's my list of know bugs, missing features:

Current Mesa Modbus issues:

BUGS:

At startup there can be "call/response function number missmatch"

error popups or sig11 (segv)s due to the fact that the PKTUART is

not cleared at startup, so random numbers of garbage characters

may be present in the RX FIFOs, leftover from the last LinuxCNC run.

A temporary workaround is to run this before launching linuxcnc:

mesaflash --device cardname --addr ipaddr --wpo 0x6800=0x00010000

(writing 0x10000 to 0x6800=pktuartr_mode_reg clears the RX FIFOs)

If you ever set the update rate to 0 (maximum), changing to a

non-zero rate will not work (communication stops)

There is a check for TX overflow in the PKTUART code that's

in the wrong location (TX section) so will print bogus error

messages with particular outgoing messages.

FEATURES:

Channel setting should not be global but in the .mod file

to support more than one device.

It would be good to have the error timeout/recovery

time programmable.

For multiple reads/writes it would be good to have the

possibility of mixed types,

This means for modbus devices that support table reads,

all I/O for a device could be done in a single read and a single

write.

The following user(s) said Thank You: tommylight, COFHAL, nwallace

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

09 Jan 2025 16:42 #318551

by vre

Replied by vre on topic Mesa modbus and pktUart

How can i use PKTUART with 7i80hd?

Include smartserial funtion in bitfile and use a ttl to rs485 converter module?

Include smartserial funtion in bitfile and use a ttl to rs485 converter module?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

09 Jan 2025 17:18 #318556

by PCW

Replied by PCW on topic Mesa modbus and pktUart

You can add a PktUART to any Mesa (or other hostmot2) card

Its not the same as SmartSerial. To use Mesa Modbus you must

have a RS-485 interface (with RX,TX, and TXEN pins on the FPGA side)

Its not the same as SmartSerial. To use Mesa Modbus you must

have a RS-485 interface (with RX,TX, and TXEN pins on the FPGA side)

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

10 Jan 2025 01:21 - 10 Jan 2025 01:36 #318596

by vre

Replied by vre on topic Mesa modbus and pktUart

What module must include to PIN file PktUARTTTag ?

like this

Something else?

What is PktUARTRTag receive and PktUARTTTag transmit ?

like this

(PktUARTTTag, x"00", ClockLowTag, x"08", PktUARTTDataAddr&PadT, PktUARTTNumRegs, x"00", PktUARTTMPBitMask),

IOPortTag & x"00" & PktUARTTTag & PktUTDataPin,

IOPortTag & x"00" & PktUARTTTag & PktUTDrvEnPin,Something else?

What is PktUARTRTag receive and PktUARTTTag transmit ?

Last edit: 10 Jan 2025 01:36 by vre.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

10 Jan 2025 01:44 #318599

by PCW

Replied by PCW on topic Mesa modbus and pktUart

Here's an example working pinout file with a PktUART

You should be able to cut/paste into your actual pinout file

You need both the:

PktUARTTTag

PktUARTRTag

Note that the

PktUTDrvEnPin is active low, if you need active high, use PktUTNDrvEnPin

IOPortTag & x"00" & PktUARTRTag & PktURDataPin, -- I/O 30 RX PKTUART PIN

IOPortTag & x"00" & PktUARTTTag & PktUTDataPin, -- I/O 31 TX PKTUART PIN

IOPortTag & x"00" & PktUARTTTag & PktUTDrvEnPin, -- I/O 32 TX PKTUART PIN

You should be able to cut/paste into your actual pinout file

You need both the:

PktUARTTTag

PktUARTRTag

Note that the

PktUTDrvEnPin is active low, if you need active high, use PktUTNDrvEnPin

IOPortTag & x"00" & PktUARTRTag & PktURDataPin, -- I/O 30 RX PKTUART PIN

IOPortTag & x"00" & PktUARTTTag & PktUTDataPin, -- I/O 31 TX PKTUART PIN

IOPortTag & x"00" & PktUARTTTag & PktUTDrvEnPin, -- I/O 32 TX PKTUART PIN

Attachments:

The following user(s) said Thank You: vre

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

11 Jan 2025 00:22 #318674

by vre

Replied by vre on topic Mesa modbus and pktUart

With this config for mb2hal i have a working system

And i have this config for mesa modbus.

Is that correct ?

[TRANSACTION_00]

LINK_TYPE=serial

SERIAL_PORT=/dev/ttyS0

SERIAL_BAUD=19200

SERIAL_BITS=8

SERIAL_PARITY=none

SERIAL_STOP=1

SERIAL_DELAY_MS=5

MB_SLAVE_ID=1

#address here is in DEC base

FIRST_ELEMENT=129

PIN_NAMES=01,02,03,04,05,06,07,08,09,10,11,12,13,14,15,16

HAL_TX_NAME=in

MB_TX_CODE=fnct_03_read_holding_registers

[TRANSACTION_01]

PIN_NAMES=01,02,03,04,05,06,07,08,09,10,11,12,13,14,15,16

MB_TX_CODE=fnct_16_write_multiple_registers

#address here is in DEC base

FIRST_ELEMENT=1

HAL_TX_NAME=out

MAX_UPDATE_RATE=0.0And i have this config for mesa modbus.

Is that correct ?

#define MAX_MSG_LEN 16 // may be increased if necessary to max 251

static const hm2_modbus_chan_descriptor_t channels[] = {

/* {TYPE, FUNC, ADDR, COUNT, pin_name} */

{HAL_S32, 3, 0x0081, 0x07, "in"},

{HAL_S32, 16, 0x0001, 0x07, "out"},

};

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

11 Jan 2025 02:00 #318681

by PCW

Replied by PCW on topic Mesa modbus and pktUart

Not sure. what device are you interfacing?

Do you really have 7 input and 7 output registers with integer values?

Do you really have 7 input and 7 output registers with integer values?

Please Log in or Create an account to join the conversation.

Time to create page: 0.287 seconds