Is there a way to Flip X or Y

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

12 May 2018 20:59 - 13 May 2018 04:47 #110619

by BrendaEM

Is there a way to Flip X or Y was created by BrendaEM

Hi,

I want to run my CNC with the gantry parked in back, instead of the front edge.

I would like to place a part, like you could read it, from right to left, going down a page.

Is it possible to flip the co-ordinate system like this, without it mirroring/inverting/ruining parts?

I can flip the x-axis, but that's not the same.

I've looked into the coordinate system page, but that looks like it's for offsets.

linuxcnc.org/docs/2.5/html/gcode/coordinates.html

Metaphorically, I want to have my monitor stand at the foot of the bed, and the part at the headboard : )

Come to think of it, most CNC machine pictures have their gantries toward the headboard.

This would be a great GUI setting.

Thanks,

Brenda

I want to run my CNC with the gantry parked in back, instead of the front edge.

I would like to place a part, like you could read it, from right to left, going down a page.

Is it possible to flip the co-ordinate system like this, without it mirroring/inverting/ruining parts?

I can flip the x-axis, but that's not the same.

I've looked into the coordinate system page, but that looks like it's for offsets.

linuxcnc.org/docs/2.5/html/gcode/coordinates.html

Metaphorically, I want to have my monitor stand at the foot of the bed, and the part at the headboard : )

Come to think of it, most CNC machine pictures have their gantries toward the headboard.

This would be a great GUI setting.

Thanks,

Brenda

Last edit: 13 May 2018 04:47 by BrendaEM.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

13 May 2018 04:52 #110645

by rodw

Replied by rodw on topic Is there a way to Flip X or Y

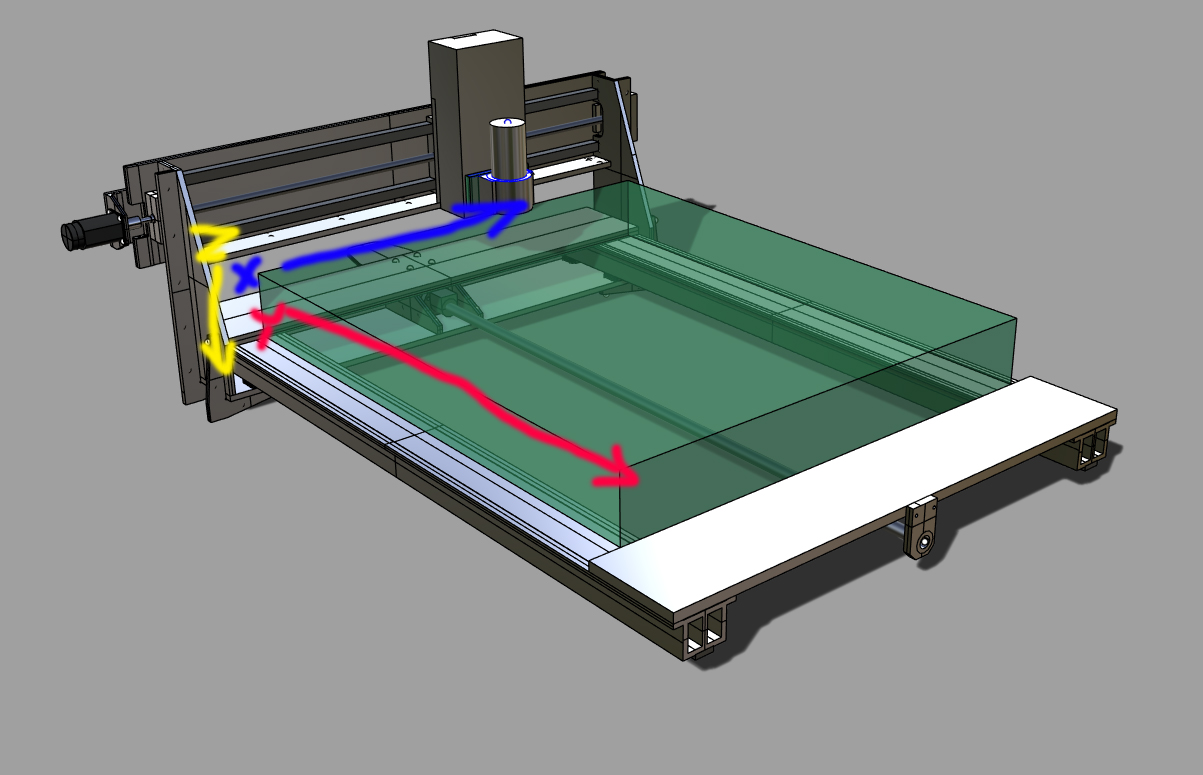

Yes you can do that but I'm not sure how well the display will show what you want becasue what you propose is not in accordance with cartesian geometry. eg. If you stand facing the table on the front side at the origin (0,0), the X axis increases to your right and the Y axis increases to your front. You have them the opposite way around. At one stage, I had my origin at the diagonally opposite corner to yours and swapped the axes around so the origin was at the bottom right of your diagram becasue it was too confusing to work with the machine. This meant the front of the machine is now the opposite end to where your gantry is.

If you are using master branch, swapping the axes and directions around is trivial by changing the ini file settings. I recently posted an example in the Hal examples section of a working 7i76e config using master branch that allows this.

If you are using master branch, swapping the axes and directions around is trivial by changing the ini file settings. I recently posted an example in the Hal examples section of a working 7i76e config using master branch that allows this.

The following user(s) said Thank You: BrendaEM

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

13 May 2018 05:29 - 13 May 2018 05:30 #110648

by BrendaEM

Replied by BrendaEM on topic Is there a way to Flip X or Y

The thing I don't understand is: all the signs I see on CNC gantry machines are cut rotated.

So this was homed toward the camera?

cdn.instructables.com/F66/P8Y2/HP5L78PV/...?auto=webp&width=933

So this was homed toward the camera?

cdn.instructables.com/F66/P8Y2/HP5L78PV/...?auto=webp&width=933

Last edit: 13 May 2018 05:30 by BrendaEM.

Please Log in or Create an account to join the conversation.

- ozzyrob

-

- Visitor

-

13 May 2018 08:07 #110660

by ozzyrob

Replied by ozzyrob on topic Is there a way to Flip X or Y

As Rod alluded to, keep with Cartesian geometry otherwise confusion will come your way.

As I understand it, origin would be fixed at the top LH looking at the machine in the picture (if we consider the spindle being placed at the "front" of the gantry. Home is just a convenient place to park your machine. Please beat me with a mallet if I got this one wrong.

As I understand it, origin would be fixed at the top LH looking at the machine in the picture (if we consider the spindle being placed at the "front" of the gantry. Home is just a convenient place to park your machine. Please beat me with a mallet if I got this one wrong.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

13 May 2018 09:41 #110661

by rodw

Replied by rodw on topic Is there a way to Flip X or Y

I would say the origin (0,0) is at the bottom left. It is on my machine anyway.

I Made a Gmoccappy macro button called park which puts the machine at to right corner.

I Made a Gmoccappy macro button called park which puts the machine at to right corner.

The following user(s) said Thank You: BrendaEM

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

13 May 2018 12:44 - 13 May 2018 12:47 #110668

by BrendaEM

Replied by BrendaEM on topic Is there a way to Flip X or Y

Thanks for the help.

I shouldn't be so hard on myself. At least I figured out that I needed the homing offset to move the axis away from the switches, so they wouldn't error out.

For the next month, I had planned to really focus on configuring and testing the machine learning software, and coming up with a toolchain before dropping thecash credit for a spindle motor, but now that I have all the axis moving around, I am getting a little impatient motivated.

www.facebook.com/brenda.make/videos/1710303622380662/

(I have Rhino 3D, am likely going use Pycam for toolpaths. I love Rhino3D, but the CAM plugins are spendy for it. There's a CAM plugin for FreeCad now called "Path Workbench," as well.)

I shouldn't be so hard on myself. At least I figured out that I needed the homing offset to move the axis away from the switches, so they wouldn't error out.

For the next month, I had planned to really focus on configuring and testing the machine learning software, and coming up with a toolchain before dropping the

www.facebook.com/brenda.make/videos/1710303622380662/

(I have Rhino 3D, am likely going use Pycam for toolpaths. I love Rhino3D, but the CAM plugins are spendy for it. There's a CAM plugin for FreeCad now called "Path Workbench," as well.)

Last edit: 13 May 2018 12:47 by BrendaEM.

Please Log in or Create an account to join the conversation.

- ozzyrob

-

- Visitor

-

13 May 2018 13:28 - 13 May 2018 13:31 #110672

by ozzyrob

Replied by ozzyrob on topic Is there a way to Flip X or Y

Yep I put my hoof in it..again

Last edit: 13 May 2018 13:31 by ozzyrob.

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

13 May 2018 18:51 #110695

by BrendaEM

Replied by BrendaEM on topic Is there a way to Flip X or Y

Ozzyrob, you didn't do anything wrong. I just feel bad that I've needed so much help getting this going. I'm usually the person that helps everyone get their stuff going. It's all about the shoe fitting awkwardly on the other...hand.

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

13 May 2018 23:04 - 13 May 2018 23:08 #110704

by BrendaEM

Replied by BrendaEM on topic Is there a way to Flip X or Y

I've taken your advise and worked toward the standard solution, but....

I have a big problem. When I can get the X-Axis in LinuxCNC to move in the positive direction, it will home toward the high side of the axis. X-positive is supposed to be heading toward the right in the picture above, right?

I am using a step forward / step backward 1,1,1 option in the HAL.

Could it be bugged?

I've tried combinations in both the .hal and ini, as far as swapping it homes to the positive.

Isn't it supposed home back toward 0 looking for the switch?

I am going to try a negative homing speed.

forum.linuxcnc.org/38-general-linuxcnc-q...ction-of-home-search

I have a big problem. When I can get the X-Axis in LinuxCNC to move in the positive direction, it will home toward the high side of the axis. X-positive is supposed to be heading toward the right in the picture above, right?

I am using a step forward / step backward 1,1,1 option in the HAL.

Could it be bugged?

I've tried combinations in both the .hal and ini, as far as swapping it homes to the positive.

Isn't it supposed home back toward 0 looking for the switch?

I am going to try a negative homing speed.

forum.linuxcnc.org/38-general-linuxcnc-q...ction-of-home-search

Last edit: 13 May 2018 23:08 by BrendaEM.

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

13 May 2018 23:34 #110706

by BrendaEM

Replied by BrendaEM on topic Is there a way to Flip X or Y

That did it.

I also had to put a negative value in for my homing offset to untrip the switch.

I ran the LinuxCNC logo test, well out in mid-air, without a spindle motor, yet.

I also had to put a negative value in for my homing offset to untrip the switch.

I ran the LinuxCNC logo test, well out in mid-air, without a spindle motor, yet.

Please Log in or Create an account to join the conversation.

Time to create page: 0.089 seconds